Power Storage Container Production Process: From Raw

Ever wondered how those sleek metal boxes storing solar energy for your neighborhood actually come to life? The power storage container production process is like baking a multi-layered

What does the whole process of energy storage battery

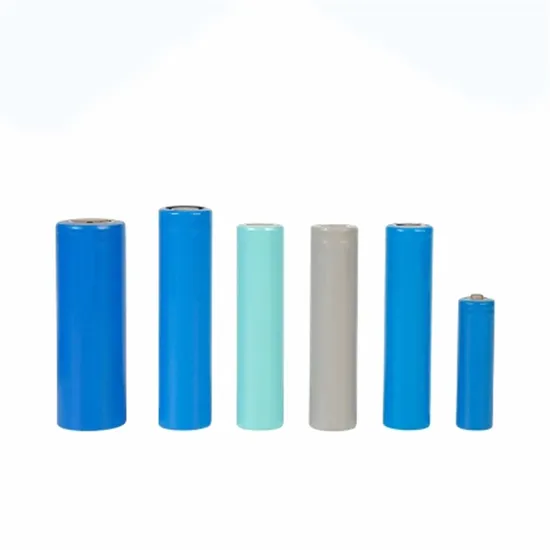

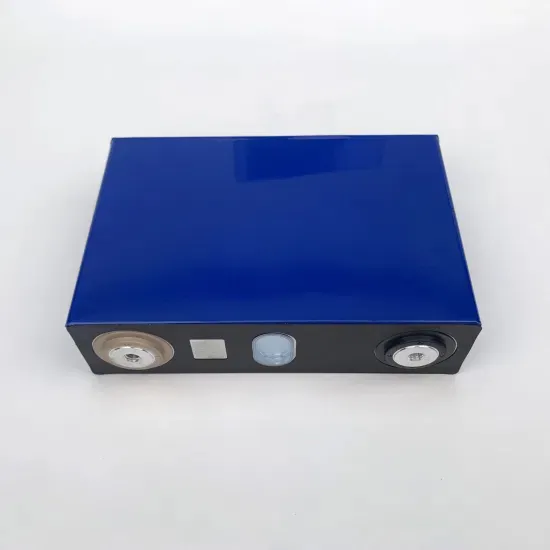

Apr 9, 2024 · The foundation of energy storage battery development lies in material selection. Various options are available, ranging from lead-acid and nickel-cadmium to more modern

Installation process of energy storage container

A battery energy storage system (BESS) captures energy from renewable and non-renewable sources and stores it in rechargeable batteries (storage devices) for later use. A battery is a

container energy storage battery

Energy Storage System Whole-life Cost Management. Thanks to features such as the high reliability, long service life and high energy efficiency of CATL''''s battery systems, "renewable

Battery Manufacturing Process: Materials,

Jul 3, 2024 · The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Understanding the Battery Cell Assembly Process

Nov 11, 2023 · The production process of a lithium-ion battery cell consists of three critical stages: electrode manufacturing, cell assembly, and cell finishing.

Production Line Guide | CHISAGE Battery Pack

Sep 14, 2023 · The energy storage battery Pack process is a key part of manufacturing, which directly affects the performance, life, safety, and other

THE INGENIOUS MANUFACTURE PROCESS OF

Jul 27, 2023 · TLS Offshore Containers'' Battery Energy Storage System containers are a testament to the relentless pursuit of innovation and

Storage battery container formation charging process

The storage battery container formation charging process shortens charging time, meanwhile saves the discharging step in the traditional process, is simple and convenient to operate,

Energy Storage Container Battery Rack Production Process

TLS Offshore Containers'''' Battery Energy Storage System containers are a testament to the relentless pursuit of innovation and excellence in the renewable energy sector. Their cutting

Optimal whole-life-cycle planning for battery energy storage

Nov 20, 2022 · The application services of the battery energy storage system (BESS) in the power system are more diverse, such as frequency regulation, peak shaving, time-shift arbitrage, etc.

Development of Containerized Energy Storage System

Dec 24, 2014 · Mitsubishi Heavy Industries, Ltd. (MHI) has been developing a large-scale energy storage system (ESS) using 50Ah-class P140 lithium-ion batteries that we developed. This

Battery Pack Manufacturing Process

Mar 15, 2025 · The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are

Battery Pack Assembly Process Series 7

Jun 6, 2025 · The manufacturing quality of energy storage containers highly relies on precise and reliable equipment support - whether it is the production consistency of battery units, the

Eve Energy''s 60GWh Super Energy Storage Plant

Dec 13, 2024 · With the commissioning of the energy storage super factory and the mass production of Mr. Big, EVE Energy''s global capacity construction

Key Points of Lithium Battery PACK

Jun 27, 2024 · Curious about how lithium batterypacks are made? Dive into the detailed process behind these essential energy storage solutions! From

Battery Storage Containers for Sustainable Energy

Jul 19, 2025 · What Are Battery Storage Containers? Battery storage containers are specialized units—often based on repurposed or custom-built shipping containers—designed to house

How are energy storage containers produced? | NenPower

Mar 6, 2024 · The production of energy storage containers is pivotal in advancing global energy strategies, supporting the transition towards sustainable energy solutions, and offering

A thermal management system for an energy storage battery container

May 1, 2023 · The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes

Characteristic Advantages of CATL Tener Energy Battery Storage

Feb 13, 2025 · CATL Tener Energy Battery Storage Container System achieve zero capacity attenuation in the first five years and zero power attenuation in the first five years.

Battery Energy Storage System in China

Professional Battery energy storage system from China. Gathering and managing power from the solar and wind efficiently. Competitve Factory Price.

Park energy storage container layout planning

What is a battery energy storage system (BESS) container design sequence? The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design

The Ultimate Guide to Battery Energy Storage

Apr 6, 2024 · Maximize your energy potential with advanced battery energy storage systems. Elevate operational efficiency, reduce expenses, and amplify

Container energy storage battery manufacturing process

A Lithium Battery Storage Container securely houses lithium-ion batteries for efficient energy storage, essential for renewable energy integration, backup power, and grid

Essentials of Container Battery Storage: Key

Dec 11, 2023 · In an era where efficient and sustainable energy solutions are paramount, Container Battery Storage emerges as a game-changer. This

Nicosia container energy storage transformation

Container energy storage is usually pre-installed with key components such as batteries, inverters, monitoring systems and the corresponding interface and connection facilities,

What Is A Battery Container?

Nov 4, 2024 · Battery containers are large-scale, flexible energy storage systems housed in shipping containers, crucial for grid stabilization, renewable energy

Lithium-ion Battery Module and Pack Production

Apr 12, 2024 · Lithium-ion Battery Module and Pack Production Line Process Flow The lithium-ion battery module and pack production line is a complex

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · The publication "Production process of a lithium-ion battery cell" provides a comprehensive process overview of the production of different battery cell formats from

Container Design for Battery Energy Storage

Aug 14, 2025 · The client is a leading Taiwanese energy storage solutions provider, specializing in the design and integration of battery storage systems

energy storage container battery cabinet production process

ABB containerized energy storage offers plug-in battery power ABB has responded to rapidly rising demand for low and zero emissions from ships by developing Containerized ESS – a

Development of Containerized Energy Storage System

Dec 24, 2014 · Our company has been developing a containerized energy storage system by installing a varyingly utilizable energy storage system in a container from 2010. The module

BESS, ESS, battery energy storage system,

Based in China, Shenzhen Sinostorage Energy Co., Ltd is a specialist manufacturer of battery energy storage systems and back-up power solutions

6 FAQs about [The whole process of energy storage battery container production]

What is the battery manufacturing process?

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process, from material selection to the final product’s assembly and testing.

What is the process chain for the production of battery modules?

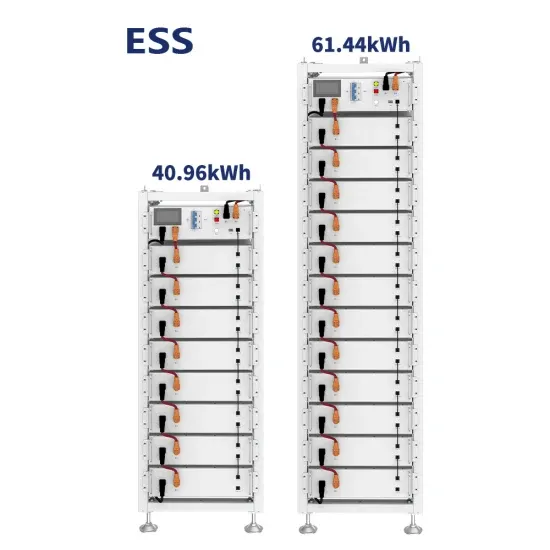

, this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain Overview of the production sequence from cell to system

What is a battery energy storage system?

Battery Energy Storage Systems (BESS) have become a cornerstone technology in the pursuit of sustainable and efficient energy solutions. This detailed guide offers an extensive exploration of BESS, beginning with the fundamentals of these systems and advancing to a thorough examination of their operational mechanisms.

What is the production process of lithium-ion battery cells?

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

Why is battery storage important?

Battery storage plays an essential role in balancing and managing the energy grid by storing surplus electricity when production exceeds demand and supplying it when demand exceeds production. This capability is vital for integrating fluctuating renewable energy sources into the grid.

What is the production process for chisage ESS battery packs?

The production process for Chisage ESS Battery Packs consists of eight main steps: cell sorting, module stacking, code pasting and scanning, laser cleaning, laser welding, pack assembly, pack testing, and packaging for storage. Now, following in the footsteps of Chisage ESS, our sales engineers are ready to take you on a virtual tour!

Industry Information

- Huawei Energy Storage New Energy

- Voltage and current of 550W photovoltaic panel

- Factory price 240 amp breaker in Ecuador

- 16 kW solar energy

- Palikir Home Energy Storage Prospects

- Communication base station supercapacitor photovoltaic power generation refrigeration repair

- Design of solar energy ecosystem in Mombasa Kenya

- Equatorial Guinea Photovoltaic Charging Pile Energy Storage Field

- Albania Residential Energy Storage Project Planning

- Royu circuit breaker in China in Uruguay

- Solar cell area and wattage

- Construction of energy management for 5G communication base stations in Zagreb

- Enterprise energy storage system customized on demand

- How much does it cost to migrate a communication base station battery energy storage system

- Laayoune What is Energy Storage Solutions Company

- Can a 300a lithium battery be used with a 5000w inverter

- Cheap high quality 3 2 kva inverter Buyer

- Chilean Technology Energy Storage Container

- Temporary mobile power box

- 21700 battery cell application

- Solar high temperature power generation hydraulic system

- Huawei Photovoltaic Inverter General Agent in New Zealand

- Photovoltaic panels that can generate electricity during the day

Commercial & Industrial Solar Storage Market Growth

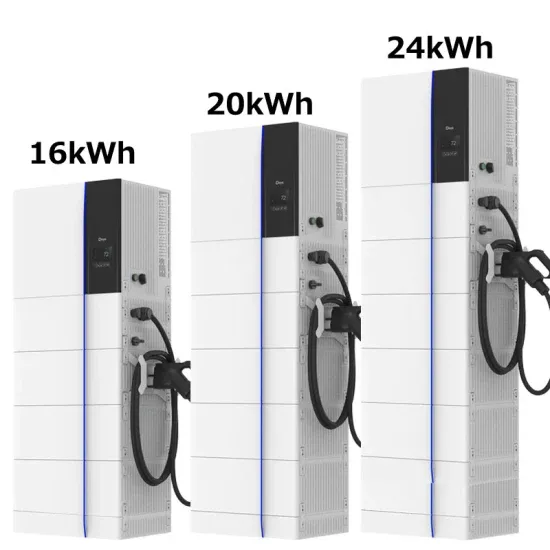

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.