A comprehensive equivalent circuit model for lithium-ion batteries

Nov 1, 2021 · The equivalent circuit model (ECM) is a battery model often used in the battery management system (BMS) to monitor and control lithium-ion batteries (

Three-Dimensional Model of a cylindrical Lithium-Ion Cell ŌĆō

Jun 21, 2023 · To find the best trade-off among fast-charging capability, lifespan and energy density, three-dimensional electrical and thermal models of lithium-ion cells are

Thermal Modeling of a Cylindrical Lithium-Ion

The battery canister (0.25 mm thick) is not included as a domain in the geometry, since the effect of the steel canister on the temperature profile are small, as

Modified Pseudo-Two-Dimensional Model for Spiral-Wound Cylindrical

This study investigates the sufficiency of P2D-lumped model for cylindrical LIBs for tabbed and tab-less design: first, via a scale analysis and then, by comparing its predictions with detailed

Cylindrical lithium battery classification and

May 17, 2023 · Cylindrical lithium batteries are divided into different systems of lithium iron phosphate,lithium cobaltate,lithium manganate,cobalt-manganese

Thermal modeling of cylindrical batteries

Nov 9, 2017 · I''ve recently created simple simulations of heat transfer within cylindrical batteries for my research. While countless papers have done

Analysis of Cylindrical Lithium Battery Advantages and Common Models

According to data presented by Tesla, the 4680 large cylindrical lithium battery increases energy density by five times compared to the 21700 cylindrical cells, enhances mileage by 16%, and

Lithium Ion Battery Models and Parameter

Nowadays, battery storage systems are very important in both stationary and mobile applications. In particular, lithium ion batteries are a good and

Analysis of cylindrical lithium battery advantages

Feb 6, 2023 · According to the data shown by Tesla, the 4680 large cylindrical lithium battery will increase the energy by 5 times on the basis of the 21700

Introduction of the Cylindrical Lithium Ion Battery

Apr 13, 2023 · Cylindrical lithium ion batteries are divided into different systems of lithium iron phosphate, lithium cobalt oxide, lithium manganate, cobalt-manganese hybrid, and ternary

Analysis of Cylindrical Lithium Battery Advantages and Common Models

1. Definition of cylindrical lithium battery Cylindrical lithium battery is a kind of lithium ion battery, its shape is cylindrical, so it is called cylindrical lithium battery. The structure of a typical

Bridging physics-based and equivalent circuit models for lithium-ion

Mar 10, 2021 · In this article, a novel implementation of a widely used pseudo-two-dimensional (P2D) model for lithium-ion battery simulation is presented with a transmission line circuit

Thermal Modeling of a Cylindrical Lithium-Ion Battery in

Nov 29, 2021 · Introduction This example simulates an air-cooled cylindrical 18,650 lithium-ion battery in 3D. A one-dimensional cell model is used to model the battery cell chemistry, and a

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · This research proposes a novel experimental methodology and a theoretical model for evaluating the mechanical performance of cylindrical lithium-ion batteries under

Cyprus cylindrical lithium battery millivolt normal

The Essential Guide to Common Cylindrical Lithium Battery Major Battery Brand, Models and Specs on the market: The first and second digits, "21," represent the diameter (21mm). The

A comprehensive review of battery modeling and state

Oct 1, 2020 · With the rapid development of new energy electric vehicles and smart grids, the demand for batteries is increasing. The battery management system (BMS) plays a crucial role

Battery Pack Design of Cylindrical Lithium-Ion Cells and

Sep 12, 2022 · Battery Pack Design of Cylindrical Lithium-Ion Cells and Modelling of Prismatic Lithium-Ion Battery Based on Characterization Tests By Ruiwen Chen, B.Eng. & Co-op.

Thermal Modeling of a Cylindrical Lithium-ion Battery in

Apr 15, 2015 · Introduction This example simulates an air-cooled cylindrical 18650 lithium-ion battery in 3D. The model follows the same approach as the Application Libraries example

Could Cylindrical Batteries Become Standard for

Mar 25, 2024 · By the time the mainstream Tesla Model S hit the market in 2012, those 18650 cells were being made by Panasonic with as many as 7,728 cells

Electrochemical and thermal modeling of lithium-ion batteries

May 1, 2024 · Yin et al. [173] investigated the aging of cylindrical lithium-ion batteries due to self-heating by developing an integrated battery model that couples a 3D electrochemical model

Analysis of cylindrical lithium battery advantages and common models

Aug 4, 2025 · This kind of cylindrical lithium battery has the characteristics of excellent capacity and high consistency, and has gradually become a trend to replace batteries. Many products

Comprehensive review of multi-scale Lithium-ion batteries

Feb 1, 2025 · This review integrates the state-of-the-art in lithium-ion battery modeling, covering various scales, from particle-level simulations to pack-level thermal management systems,

Thermal Modeling of a Cylindrical Lithium-Ion Battery in 2D

This model example simulates an air-cooled cylindrical 18650 lithium-ion battery during a charge-discharge cycle, followed by a relaxing period. A lumped (0D) cell model is used to model the

Battery Design Module Application Library

Dec 13, 2022 · Introduction This example simulates an air-cooled cylindrical 18,650 lithium-ion battery in 3D. A one-dimensional cell model is used to model the battery cell chemistry, and a

Analysis of cylindrical lithium battery advantages

Feb 6, 2023 · Cylindrical lithium battery is a kind of lithium ion battery, its shape is cylindrical, so it is called cylindrical lithium battery.

COMSOL_WhitePapers_Li-IonBattery dd

Jul 20, 2020 · The workhorse for high-fidelity modeling of lithium-ion batteries is the so-called Newman model. The model is based on the Maxwell-Stefan equations for the transport of ions

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

Cyprus battery storage system Achieves

Jun 6, 2025 · The battery energy storage system utilizes advanced lithium-ion technology, which is renowned for its high energy density and long cycle life.

գ嵤▒ÕĮóķöéń”╗ÕŁÉńöĄµ▒ĀńāŁÕ╗║µ©Ī

µ£¼µ©ĪÕ×ŗńż║õŠŗµ©Īµŗ¤ÕģģµöŠńöĄÕŠ¬ńÄ»µ£¤ķŚ┤õ╗źÕÅŖķÜÅÕÉÄĶłÆÕ╝Āµ£¤ńÜäķŻÄÕåĘգ嵤▒ 18650 ķöéń”╗ÕŁÉńöĄµ▒ĀŃĆéõĖĆń╗┤ÕŹĢńöĄµ▒Āµ©ĪÕ×ŗńö©õ║ÄÕ»╣ńöĄµ▒ĀÕŹĢÕģāÕī¢ÕŁ”µĆ¦Ķ┤©Ķ┐øĶĪīÕ╗║µ©Ī,õ║īń╗┤ĶĮ┤Õ»╣ń¦░µ©ĪÕ×ŗńö©õ║ÄÕ»╣ńöĄµ▒Ā

Complete List of Cylindrical Lithium Battery Models.

Cylindrical lithium-ion batteries are usually represented by five digits. Starting from the left, the first and second digits refer to the battery diameter, the third and fourth digits refer to the battery

Investigating thermal dynamics in cylindrical Li-ion batteries

4 days ago · Thermal dynamics in cylindrical Li-ion batteries, governed by electrochemical heat generation, are critical to performance and safety in high-power applications such as electric

Cylindrical Lithium Technologies

5 days ago · Safely harness pure lithium energy with Panasonic Cylindrical Lithium. A lightweight, high-energy-density battery optimized for stable

Thermal Modeling of a Cylindrical Lithium-Ion

Thermal Modeling of a Cylindrical Lithium-Ion Battery in 3D. This example simulates the heat profile in an air-cooled cylindrical battery in 3d. The battery

6 FAQs about [Cyprus cylindrical lithium battery model]

How to model a cylindrical lithium ion battery in 3D?

Thermal Modeling of a Cylindrical Lithium-Ion Battery in 3D This example simulates the heat profile in an air-cooled cylindrical battery in 3d. The battery is placed in a matrix in a battery pack. The thermal model is coupled to a 1d-battery model that is used to generate a heat source in the active battery material.

Does the 18650 cylindrical lithium-ion battery have a quasi-static compression test?

4. Conclusion In this paper, the 18650 cylindrical lithium-ion battery and its jellyroll quasi-static compression test, and establishes an optimization model based on the experimental results.

Are cylindrical lithium-ion batteries safe?

Abstract In engineering applications such as electric vehicles and energy storage systems, the structural safety of cylindrical lithium-ion batteries is crucial, especially under external impact or compressive loads that may induce deformation or damage, affecting overall safety performance.

How do you model a cylindrical lithium-ion battery?

For the modeling of cylindrical lithium-ion batteries, detailed structural models including cathode material, cathode material, diaphragms, and shells can more accurately react to battery deformation and faults, and determine the failure position, but usually require significant computational costs and the model is particularly complex.

Is there a homogenization model for lithium ion batteries?

At present, there have been many breakthroughs in the research of homogenization models. Xia et al. and Wang et al. respectively established a homogenization model of the cylindrical lithium-ion battery, considering the material as anisotropy and the influence of SOC and dynamic effect.

What is a 18650 lithium-ion battery made of?

Experimental methods and validation The experimental sample used in this study is the 18650 lithium-ion battery, which is composed of stainless steel shell and cylindrical jellyroll. The jellyroll consists of layers of cathode, anode, separator, and electrolyte, wound into a spiral structure in the sequence of ŌĆścathode-separator-anode-separatorŌĆÖ.

Industry Information

- Phnom Penh integrated energy storage solution design

- Energy storage efficiency of the St Petersburg Industrial Park in Russia

- Power breaker switch factory in Tunisia

- Moldova Terrace Solar Windmill

- Rooper energy storage battery

- What are the battery cabinet factories in Kampala

- General lithium battery pack

- Lithium power station factory in Angola

- Is it safe to buy an outdoor power supply

- Energy storage device industry background

- Outdoor communication power supply BESS for indoor use

- Lithium battery pack and storage battery pack are used separately

- How big is the wire that connects the UPS to the battery cabinet

- Solomon Islands EK12v outdoor power supply

- Household solar panel booster pump

- Global battery energy storage investment

- Boston Uninterruptible Power Supply Customization Factory

- Huawei Villa Energy Storage System

- Solar photovoltaic panels 30 megawatts

- How much inverter power is required for 50 Hz

- Korean special energy storage battery

- Are flexible photovoltaic panels thin films

- What kind of power supply is generally used for base stations

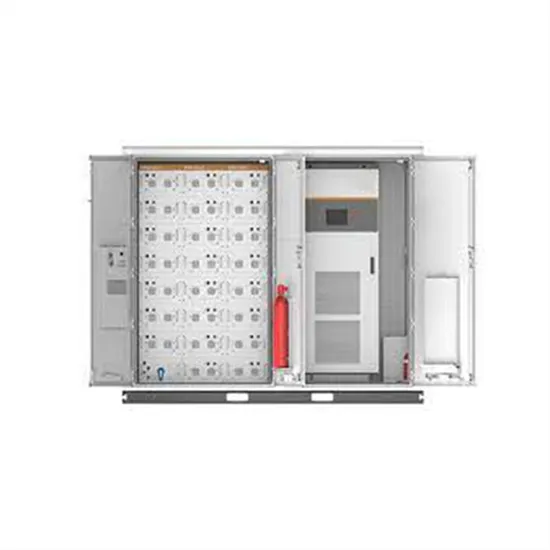

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

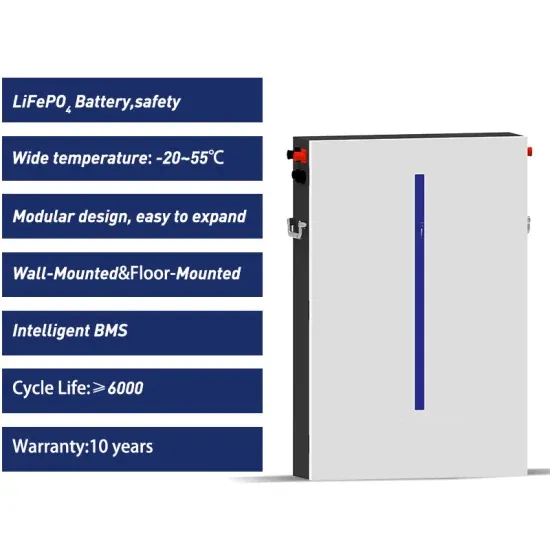

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.