Review of silicon recovery in the photovoltaic industry

Dec 1, 2023 · Figure 1 illustrates the value chain of the silicon photovoltaic industry, ranging from industrial silicon through polysilicon, monocrystalline silicon, silicon wafer cutting, solar cell

Monocrystalline Silicon Wafer Recovery Via Chemical

Jul 25, 2024 · 1 Introduction Silicon wafer recovery has a very important role in this technology world. From the silicon wafer recovery process we can reduce the total cost of the solar

Manufacturing Technologies

Large-Sized Monocrystalline Silicon Ingot Large-Sized Monocrystalline Silicon Wafer TOPCon Solar Cell Adani Solar reached a historic milestone by

Free-standing ultrathin silicon wafers and solar cells through

May 7, 2024 · Crystalline silicon solar cells with regular rigidity characteristics dominate the photovoltaic market, while lightweight and flexible thin crystalline silicon solar cells with

Advance of Sustainable Energy Materials:

Sep 12, 2024 · Modules based on c-Si cells account for more than 90% of the photovoltaic capacity installed worldwide, which is why the analysis in this

Numerical study of mono-crystalline silicon solar cells with

Jun 1, 2020 · Mono-crystalline silicon solar cells with a passivated emitter rear contact (PERC) configuration have attracted extensive attention from both industry and scientific communities.

Monocrystalline silicon solar cells applied in photovoltaic

Sep 19, 2013 · Purpose: The aim of the paper is to fabricate the monocrystalline silicon solar cells using the conventional technology by means of screen printing process and to make of them

Solar panel types and differences:

The main types of solar panels on the market today are monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. Differences between

Mechanical Properties of Monocrystalline Silicon

Jun 5, 2025 · Learn how monocrystalline silicon wafers exhibit anisotropic mechanical properties. Their Young''s modulus and fracture behavior vary by

Photovoltaics Manufacturing, Polysilicon | Solar Power

Silicon waste from the sawing process can be re-cycled into polysilicon. Polycrystalline wafer: Polycrystalline silicon consists of small grains of monocrystalline silicon. Cube-shaped ingots

Improving the light trapping ability and flexural strength of

Jul 1, 2024 · Abstract Ultrathin monocrystalline silicon (mono-Si) wafers with thicknesses less than 100 μm have gained significant attention from the PV community, not only because of the

Solar Photovoltaic Manufacturing Basics

4 days ago · Though less common, kerfless wafer production can be accomplished by pulling cooled layers off a molten bath of silicon, or by using

5 Steps For Monocrystalline Silicon Solar Cell Production

May 17, 2024 · Monocrystalline silicon solar cell production involves growing high-purity silicon ingots via Czochralski method (99.999% purity), slicing into 180-200μm wafers, texturing with

Thermo-mechanical stress modelling and fracture

Mar 1, 2025 · Thinning of crystalline silicon (c-Si) wafers will reduce material cost and improve productivity, which significantly impacts the development of solar photovoltaic (PV) industry.

Material intensity and carbon footprint of crystalline silicon

Feb 1, 2024 · The growing solar photovoltaic (PV) installations have raised concerns about the life cycle carbon impact of PV manufacturing. While silicon PV modules share a similar framed

The solar cell wafering process

May 21, 2024 · In this paper, the basic principles and challenges of the wafering process are discussed. The multi-wire sawing technique used to manufacture wafers for crystalline silicon

Crystalline Silicon Photovoltaics

Crystalline silicon solar cells are connected together and then laminated under toughened or heat strengthened, high transmittance glass to produce reliable,

Thermo-mechanical and fracture properties in single

Aug 1, 2025 · Abstract Single crystal silicon is extensively used in the semiconductor industry.Even though most of the steps during processing involve somehow thermo

Novel Method for Quantifying Optical Losses of Glass and

Jan 1, 2012 · Using this method, the optical losses (at near normal incidence) of single-cell monocrystalline silicon wafer PV modules with various glass structures (textured, planar,

Manufacturing of Silicon Solar Cells and Modules

Jun 13, 2023 · To get from cell making to module making requires proper preparation of pristine wafers to be physically and electrically connected in series to achieve the rated output of a PV

Unleashing the Power of Monocrystalline Solar

Sep 27, 2024 · Discover the unparalleled power of monocrystalline solar panels, the cutting-edge technology revolutionizing solar energy efficiency. With their

Photovoltaic (PV) Cell Types | Monocrystalline,

5 days ago · The article provides an overview of the main types of photovoltaic (PV) cells, including monocrystalline, polycrystalline, and thin-film solar

Novel Method for Quantifying Optical Losses of Glass and

Jan 1, 2012 · In this paper, a method for quantifying the optical losses associated with the cover glass and the encapsulant material of silicon wafer based PV modules is presented. The

PV spot price

6 days ago · InfoLink Consulting provides weekly updates on PV spot prices, covering module price, cell price, wafer price, and polysilicon price. Learn about photovoltaic panel price trends

Recent developments on manufacturing and characterization

Mar 1, 2023 · The dominating technology of solar cell production today is based on monocrystalline silicon, produced mostly by the Czochralski process. Recently, the solar cell

Advances in crystalline silicon solar cell technology for

Jul 22, 2010 · Various technologies for mono- and polycrystalline PV cells are compared and discussed with respect to the corresponding material technologies, such as silicon ingot and

Fabricating Different Types of Photovoltaic Cells

Jun 2, 2021 · A wafer is a thin, flat disk or rectangle of base semiconductor material. Wafers are 180μm to 350μm thick and are made from p-type silicon.

Enhancement of efficiency in monocrystalline silicon

Sep 6, 2024 · With the development of silicon materials and cut-silicon wafer technologies, monocrystalline products have become more cost-effective, accelerating the replacement of

Solar Cells on Multicrystalline Silicon Thin Films Converted

Sep 2, 2024 · Alternatively, thin-film multicrystalline (mc) silicon on glass can help to save both energy and material consumption compared to full-silicon-wafer technologies. Competitive PV

A wafer-based monocrystalline silicon photovoltaics road

Jul 1, 2013 · As an initial investigation into the current and potential economics of one of today''s most widely deployed photovoltaic technologies, we have engaged in a detailed analysis of

Silicon Solar Cells: Trends, Manufacturing

Feb 7, 2024 · Approximately 95% of the total market share of solar cells comes from crystalline silicon materials [1]. The reasons for silicon''s popularity within

PV-Manufacturing – The free online resource

Silicon photovoltaic modules comprise ~90% of the photovoltaic modules manufactured and sold worldwide. This online textbook provides an

Crystalline Silicon Photovoltaic Module Manufacturing

Feb 10, 2020 · Executive Summary Over the past decade, the crystalline-silicon (c-Si) photovoltaic (PV) industry has grown rapidly and developed a truly global supply chain, driven

Monocrystalline Perovskite Wafer/Thin Film for

May 1, 2024 · Recently, the newly emerging semiconducting materials of halide perovskites (HPs) have attracted much attention owing to their continuing success in high-efficiency solar cells.

6 FAQs about [Monocrystalline silicon wafer and photovoltaic glass]

What is a monocrystalline silicon (mono-Si) solar cell?

In recent years, monocrystalline silicon (mono-Si) solar cells have become the dominant technology in the global solar energy market, accounting for over 90 % of market share due to their superior photovoltaic conversion efficiency, high reliability, and relatively low cost . These cells utilize mono-Si wafers as substrates.

Can monocrystalline silicon solar cells reduce optical and electrical losses?

Together with five types of monocrystalline silicon solar cells, exploring ways to reduce optical and electrical losses in various cells to increase the conversion efficiency, taking into account the cost factor.

Can wire sawing produce crystalline wafers for solar cells?

Wire sawing will remain the dominant method of producing crystalline wafers for solar cells, at least for the near future. Recent research efforts have kept their focus on reducing the wafer thickness and kerf, with both approaches aiming to produce the same amount of solar cells with less silicon material usage.

Are photovoltaic cells crystalline or monocrystalline?

Photovoltaic cells have therefore become a popular research direction. Among them, photovoltaic cells made of silicon with a crystalline structure account for exceeding 90% of the photovoltaic market. Meanwhile, monocrystalline silicon has a perfect crystal structure and large abundance.

What is the performance of DWS mono-Si wafers in solar cells?

Solar cell performance Two groups of 200 pcs DWS mono-Si wafers were employed to fabricate solar cells on a standard cell production line, one group consisting of untreated wafers and the other comprising wafers subjected to a heat treatment at 550 °C for 60 min.

Which crystalline solar cells dominate the photovoltaic market?

[email protected] Abstract. As the representative of the first generation of solar cells, crystalline silicon solar cells still dominate the photovoltaic market, including monocrystalline and polycrystalline silicon cells.

Industry Information

- Recommended inverter manufacturers for Chinese and African enterprises

- China camping charger station in Karachi

- Hot sale wholesale 2000 amp switchgear distributor

- Yemen industrial-grade UPS uninterruptible power supply equipment

- How much power does a wind power inverter usually have

- Tehran off-grid inverter price

- Which brand of UPS uninterruptible power supply is good

- Honduras Iron Phosphate Telecom Photovoltaic Site

- Royu circuit breaker factory in Mozambique

- Oman energy storage power supply manufacturer

- 2V to 12V inverter

- General weight of energy storage battery

- Can small inverters be connected to the grid for household electricity

- Majuro Mobile Company Communication Base Station Wind Power

- Is the energy storage power station a distribution device

- Energy storage cabinet outdoor power supply 100w solar energy

- Solar power storage in China in Kazakhstan

- Solar Wireless On-site Energy

- Cylindrical lithium battery safety

- How much does an uninterruptible power supply cost in Belmopan

- How much does a three-phase UPS uninterruptible power supply cost in Malabo

- What are the hydrogen energy photovoltaic sites in Belarus

- Battery cabinet production line site

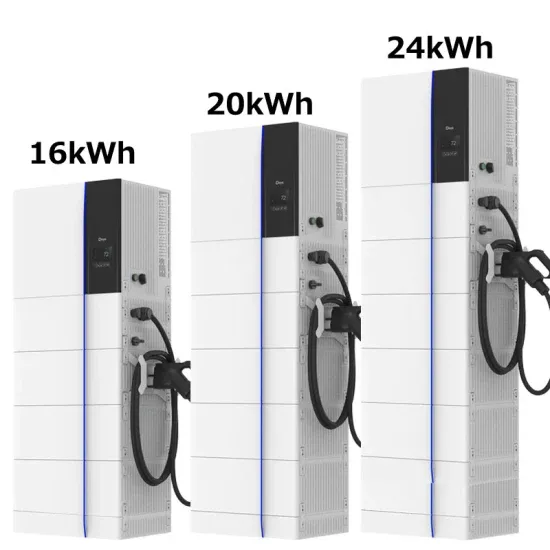

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.