Thermal management of lithium-ion batteries with simultaneous

Feb 1, 2022 · Thermal management of lithium-ion batteries with simultaneous use of hybrid nanofluid and nano-enhanced phase change material: A numerical study

Phase change materials for battery thermal management of

Sep 1, 2022 · This work consists of the discussions on battery thermal management systems using phase change materials, enhancement of Phase Change Materials'' thermal conductivity,

Investigation on battery thermal management based on phase change

May 12, 2021 · Electric vehicles are gradually replacing some of the traditional fuel vehicles because of their characteristics in low pollution, energy-saving and environmental protection.

Preparation of thermally conductive composite phase change

Aug 1, 2022 · Abstract Phase change material (PCM) cooling performs excellently in lithium-ion battery (LIB) thermal management. In order to improve the thermal conductivity of PCM, the

Multifunctional and Flexible Phase Change Composites for

Aug 4, 2025 · In this study, multifunctional, flexible, and leakage-proof phase change composites (PCCs) are developed to overcome these limitations and enable dual-mode thermal regulation

Solid-liquid phase change materials for the battery

Jun 28, 2022 · e days, BTMSs benefit from the features of phase-change materials (PCMs) to control the temperature of batteries in passive or semi-passive systems. This paper provides

Challenges in thermal management of lithium-ion batteries using phase

Oct 20, 2024 · As such, lithium-ion batteries (LIBs) are widely used in automotive energy storage systems mainly due to their long life cycle, low self-discharge rate, and high energy and

Ultra-wide-temperature-range thermal self

Jun 18, 2025 · Xianglin Li et al. develop a dual-phase-transition composite material for lithium battery thermal management, achieving rapid heating,

Dual-strategy-encapsulated phase change materials with

Oct 20, 2023 · Dual-strategy-encapsulated phase change materials with thermal immune functions for efficient energy storage and all-climate battery thermal management

Modeling and simulation of phase change material-based

Apr 30, 2025 · Modeling and simulation of phase change material-based passive and hybrid thermal management systems for lithium-ion batteries: A comprehensive review

Research progress of composite phase change materials for

This review discusses the use of composite phase change materials in battery cooling, heating, and thermal runaway protection. It also explores how the balance between heat storage

Comparison of cooling methods for lithium ion

Dec 13, 2023 · Comparison of cooling methods for lithium ion battery pack heat dissipation: air cooling vs. liquid cooling vs. phase change material cooling vs.

Recent research progress on phase change materials for thermal

Jan 1, 2022 · However, lithium-ion batteries are sensitive to the temperature, so the battery thermal management (BTM) is an indispensable component of commercialized lithium-ion

Thermal management of 500 Ah large-capacity lithium-ion battery

Jul 30, 2025 · With the growing demand for energy storage solutions, large-capacity lithium-ion batteries (LIBs) are increasingly being deployed in various systems.

Research on electric vehicle BTMS using phase change material energy

Mar 2, 2025 · The regulation of battery temperature within an optimal range and the mitigation of fluctuations during operation are essential technologies for enhancing the performance of

Thermal management of Li-ion batteries using phase change

Mar 1, 2025 · Phase change materials (PCMs) have recently emerged as a promising passive cooling technology for lithium-ion batteries, offering high latent heat capacity, constant

A fast-response preheating system coupled with

Dec 20, 2023 · A fast-response preheating system coupled with supercapacitor and electric conductive phase change materials for lithium-ion battery energy storage system at low

Thermal management of Li-ion batteries using phase change

Mar 1, 2025 · With the rising adoption of lithium-ion batteries in electric vehicles and renewable energy storage, effective thermal management has become imperative for safe and optimal

Using Phase Change Materials For Energy

Mar 3, 2021 · Much research into phase change energy storage is centered around refining solutions and using additives and other techniques to engineer

Optimization of battery thermal management system based on phase change

Aug 15, 2025 · In this paper, a novel composite battery thermal management method based on phase change materials (PCMs) and oil immersion cooling is proposed, and their cooling

A comprehensive review on lithium-ion battery thermal

May 23, 2025 · This review focuses on the role of phase change materials (PCMs) in BTM systems, highlighting their ability to absorb excess heat through phase transitions and

Phase change material-based thermal energy storage

Aug 18, 2021 · Solid-liquid phase change materials (PCMs) have been studied for decades, with application to thermal management and energy storage due to the large latent heat with a

Thermal management of lithium-ion batteries using phase change

Abstract: Good battery thermal management systems (BTMSs) are essential for Liion batteries for safe, reliability and efficiency. A BTMS needs to ensure not only the temperature of all battery

Energy Storage

Apr 21, 2025 · Cooling lithium-ion batteries using phase change material and star-shaped channel for flowing fluid is presented in this paper. The proposed design is tested on six 21700

Active and hybrid battery thermal management system

Nov 30, 2024 · Efficient battery thermal management (BTM) is key to the safety and performance of Lithium-ion batteries. This study focuses on cooling a module of 15 prismatic Lithium

Comprehensive Application of Phase Change

Mar 8, 2025 · Phase change materials (PCMs), renowned for their superior heat storage capabilities, face the challenge of inherently low thermal conductivity

Lithium-Ion Battery Thermal Management Using Phase Change

Dec 24, 2024 · Phase change material (PCM) is a viable medium for storing and releasing thermal energy. In this work, a lithium-ion battery surrounded by a PCM layer, which is placed inside a

Recent progress on battery thermal management with composite phase

Jun 1, 2024 · A good battery thermal management system (BTMS) is essential for the safe working of electric vehicles with lithium-ion batteries (LIBs) to address thermal runaway and

The role of phase change materials in lithium-ion batteries: A

Jul 1, 2023 · Phase change materials (PCMs) have been used as high-performance materials in various applications since they have great features such as low viscosity, low melting

Thermal management performance and optimization of a

Jul 15, 2025 · Battery energy storage systems become increasingly important to address the intermittency of renewable energies, but their widespread adoption is still hindered by thermal

6 FAQs about [Lithium Batteries and Phase Change Energy Storage]

Does a phase change material make a lithium-ion battery thermally efficient?

Heyhat et al. examined the thermal ability of the passive heat control system of an 18,650 lithium-ion battery using phase change materials (PCM). They concluded that the porous PCM showed more gravity efficacy than the nano-PCM and the fin-PCM ones.

Are phase change composites suitable for lithium-ion batteries?

This study develops flexible, leakage-proof phase change composites with dual-mode thermal management for lithium-ion batteries. The composites offer Joule heating, passive cooling, and temperature sensing. Simulations validate their performance and provide insights into material optimisation.

What are the challenges faced by energy storage systems like Li-ion batteries?

Energy storage systems like Li-ion batteries are facing many challenges and one of the main challenges in these systems is their cooling component. PCMs could transfer the heat during their phase change from solid to liquid and be transferred to their solid phase below their melting point.

Can Li-ion batteries be cooled with phase change materials?

Liquid cooling with phase change materials for cylindrical li-ion batteries: an experimental and numerical study Energy, 191 ( 2020), Article 116565, 10.1016/j.energy.2019.116565 Experimental and numerical investigation of the application of phase change materials in a simulative power batteries thermal management system

Why is lithium battery energy storage important?

One of the most promising technologies for the sustainable energy revolution and modern electric vehicles is lithium battery energy storage. However, because lithium batteries generate heat internally, their operating temperature has a considerable impact on their performance and lifespan.

How to analyze phase change materials (PCMs) in lithium-ion batteries?

In summary, there are several numerical methods that can be used to analyze Phase Change Materials (PCMs) in lithium-ion batteries: 1. Finite Element Analysis (FEA): FEA is a numerical technique used to solve partial differential equations.

Industry Information

- Install photovoltaic solar panels

- Profit model of New Zealand energy storage power station

- Kyiv Power Energy Storage System Solution

- 655w photovoltaic panel specifications

- Peak power of photovoltaic panels

- China s largest communication base station inverter

- Usp uninterruptible power supply 750w

- Single column photovoltaic solar panel installation

- Energy storage power supply DC charging voltage

- 220v super capacitor price

- St Johns Single Phase PV Inverter

- Uninterruptible Power Supply Solution for Banjul

- Brunei energy storage equipment manufacturer

- Photovoltaic inverter removal

- Microinverter Gateway

- Photovoltaic B-grade panel manufacturers

- Telecom distribution cabinet container base station

- Talk about photovoltaic power generation with wind and solar complementarity for communication base stations

- Rome Grid Energy Storage Company

- Commercial energy storage container system

- Bolivia rack inverter price

- Huawei North America Heavy Industry Energy Storage Cabinet

- 12V inverter 220V

Commercial & Industrial Solar Storage Market Growth

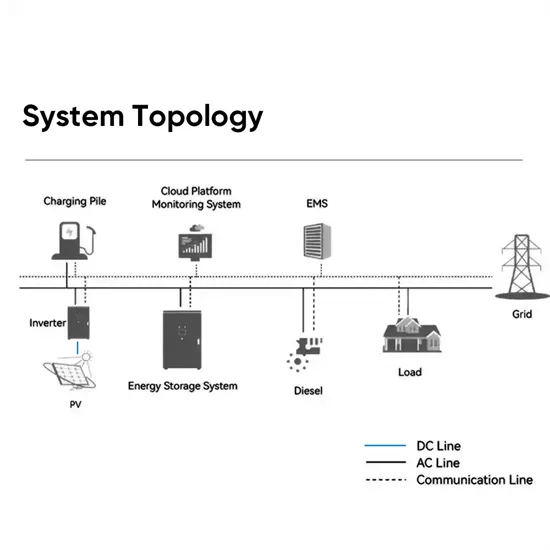

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.