DIY 18650 Battery Pack Tutorial: Quick and Easy

Feb 4, 2024 · How to build a DIY 18650 battery pack? Engaging guide details the step-by-step process, from selecting cells to wiring components for a

Amazon.ca: Lithium Batteries 36v

Amazon.ca: lithium batteries 36vCheck each product page for other buying options. Price and other details may vary based on product size and colour.

Electric Scooter Standard 36V 6Ah Lithium Battery

Jul 13, 2025 · Check MoreSmartPropel 36 volt lithium ion scooter battery has below features: 1. Light, good design, standard dimension and model can be

An Exhaustive Guide To Building 18650 Packs

Jun 12, 2019 · Fortunately [Adam Bender] is on hand with an extremely comprehensive two-part guide to designing and building lithium-ion battery

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · A combination of both can be used to achieve desired voltage and capacity targets for specific applications. Q3. Why is a Battery Management System (BMS) crucial for lithium

How to Make a 36V Lithium-Ion Battery from Scratch

4 days ago · Building your own 36V lithium-ion battery can be a rewarding project. Here''s how to get started: Begin by testing and sorting your lithium-ion cells. Ensure they have similar

Amazon : 36v Ebike Battery

36V Ebike Battery 8Ah 14Ah 20Ah Lithium Battery Pack with 30A BMS 2A Fast Charger, for 100W-800W Electric Bikes, Electric Bicycles, Scooters, ATVs, Motorcycles (36V 8Ah)

DIY Professional 18650 Battery Pack

DIY Professional 18650 Battery Pack: The world is shifting away from fossil fuels and will one day become fully electric. In the present world, Lithium-ion is the

How to assemble lithium batteries

How to build a lithium battery? Conclusion Building a lithium battery involves several key steps. First, gather the necessary materials, including lithium cells, a battery management system,

Assemble lithium battery

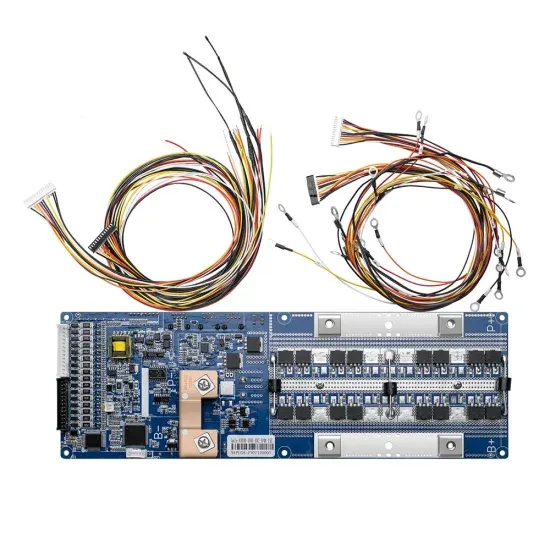

What are the parts of a lithium battery pack? c. Wire: used to connect the lithium battery cell and the protective circuit board (PCB). d. Battery clamp: used to fix the lithium battery cell and

How to Build a Lithium Ion Battery Pack? A Step

Apr 9, 2025 · Starting from selecting materials and tools needed in how to build a lithium ion battery pack, designing the battery pack, step by step in how to

Beginner-Friendly Tips for Assembling Lithium Battery Packs

May 7, 2025 · Effective planning lays the foundation for a reliable lithium battery pack. You should start by defining the application requirements, such as voltage, capacity, and size constraints.

Building Your Own 36V Lithium-Ion Battery Pack: A

Aug 11, 2025 · Step 1: Determine Battery Configuration and Capacity Requirements Before starting the assembly process, determine the desired battery configuration and capacity

Amazon : 36v Lifepo4 Battery

36 Volt Lithium Battery 50Ah for 36V Trolling Motor, Upgrade 1.2C Discharge 60A Current, 36V LiFePO4 Battery with Low Temp Protection, Up to 15000 Deep Cycle Lithium Battery Group31

Lithium Ion Battery Packaging: Soft Pack Design

Apr 8, 2025 · Soft-pack lithium-ion battery packaging faces key design challenges. Learn how manufacturers solve issues for safety and performance.

How to Assemble a LiFePO4 Lithium Battery Pack for Solar

Jul 25, 2025 · As clean energy continues to rise in popularity, lithium-ion batteries—especially LiFePO4 (Lithium Iron Phosphate)—are essential in everything from solar home kits to

How to Build Your Own DIY Battery Pack with 18650 Lithium

Feb 21, 2025 · Building a DIY battery pack with 18650 lithium cells is a rewarding project that allows you to create a custom power source for various applications, from electric bikes to

36V 11.6Ah Li-ion Battery Pack

36V 11.6Ah Li-ion Battery Pack: Building a 36V 11.6Ah 18650 lithium-ion NCA cells battery pack and a 12V electric system for headlight and other 12V electric devices. Key-switched

Beginner-Friendly Tips for Assembling Lithium Battery Packs

May 7, 2025 · Learn how to assemble a lithium battery pack with beginner-friendly tips on design, safety, and tools for optimal performance and reliability.

Battery Rebuild

Craftsman and Ryobi packs The pricing above includes most battery brands like Dewalt, Milwakee, Bosch. If you have a brand like Craftsman, Ryobi, or even Harbor Freight the cost is

How to Make Your Own 18650 Battery Pack

Nov 23, 2024 · Making your own 18650 battery pack may seem intimidating, but it''s actually a straightforward DIY project if you have the right parts, tools, and

How to assemble a battery pack

Before assembling the 48V lithium battery pack, it is necessary to calculate according to the product voltage, size and the required load capacity of the lithium battery pack, and then

Battery Pack Assembly : 5 Steps

Battery Pack Assembly: The goal of this project is to create a battery pack from purchased power cells. Is important to understand how cells can be connected

36V Lithium-Ion Batteries: Lifespan, Voltage, Compatibility

Aug 16, 2024 · In today''s world of advanced energy storage solutions, the 36V lithium-ion battery stands out for its impressive balance of power, efficiency, and compactness. As we delve into

How to Assemble Lithium Battery Cells into Battery Pack

Apr 14, 2025 · The process of assembling lithium battery cells into complete battery pack is called battery PACK. It involves integrating key components such as battery cells, protection board,

How to assemble a 48V lithium battery pack by

Mar 4, 2022 · A successfully assembled lithium battery pack can also be called a lithium battery pack, but a real lithium battery pack needs more materials in

How to Build a Lithium Battery: Step-by-Step for Beginners

Feb 22, 2024 · Building my own lithium battery pack was a challenging yet rewarding experience that allowed me to gain a deeper appreciation for this technology. In this article, I''ll share my

EZ Auction – Find your next deal! Phoenix Online

6 days ago · Whether you''re an established retailer or just starting out, bidding on full pallets is a smart way to streamline your purchasing process, lower per

How to Assemble a Lithium-Ion Battery Pack

Oct 7, 2024 · Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · In this guide, we''ll walk you through everything you need to know – from the basics of what a battery pack is, to the tools and materials required, the step-by-step assembly

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

Jun 15, 2025 · In this step-by-step guide, as a professional lithium battery pack manufacturer, I''ll walk you through the entire DIY battery pack assembly process to help you build a safe, high

How To Build a 48V Battery Pack

Mar 28, 2025 · They provide a good balance between energy storage capacity and cost-effectiveness, making them ideal for a variety of applications. So, if you''re looking to harness

How to assemble a 36V lithium battery

How to Make a 36 Volt Battery Charger To build a charger for a 36V lithium battery, you will need to follow a few steps. First, determine the charging amperage and voltage Then, assemble

Here is how to arrange the cells to make a

Most garage-builders who decide to assemble their own battery pack usually have a lot of experience. However, pack-building continues to be a frequent

How To Repair Electric Bike Batteries: The

Apr 19, 2019 · What''s an E-bike Battery and How Does it Work? Most electric bicycles use the lithium-ion battery type, which is unique from the lead acid 12

6 FAQs about [Assemble lithium battery pack 36 volt]

How to build a lithium battery?

Part 4. Conclusion Building a lithium battery involves several key steps. First, gather the necessary materials, including lithium cells, a battery management system, connectors, and protective casing. Begin by designing the battery layout, ensuring proper spacing and alignment of cells.

What is the voltage of a lithium battery?

The voltage of a lithium battery represents the potential difference between its positive and negative electrodes. The unit is volt (V). Different types of lithium batteries have different nominal voltages. Common ones are 3.6V, 3.7V, 7.2V, etc.

How do you test a lithium battery pack?

Voltage and Current Testing: Use a multimeter to ensure the pack operates within safe parameters. Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations.

How should lithium batteries be protected?

Lithium batteries should be protected from severe vibration and external impact during assembly and use to avoid damaging the battery structure and performance. In applications such as mobile equipment and electric vehicles, suitable securing and cushioning measures should be taken. 5. Pay attention to storage conditions

What is a lithium battery management system (BMS)?

The cells within a lithium battery pack are typically arranged in series or parallel configurations to achieve the desired voltage and capacity. Additionally, a Battery Management System (BMS) is often integrated to monitor and ensure the safe operation of the battery pack.

How to connect a lithium battery cell to a protective circuit board?

Use tape or other fixing methods to secure the protective circuit board to the lithium battery cell. This prevents it from loosening or shifting. Make sure there is no metal contact between the protective circuit board and the lithium battery cell to avoid short circuit or other safety issues. 5. Connect the wires

Industry Information

- Nauru battery cabinet platform system

- Outdoor wireless AP base station supply

- Hanoi UPS uninterruptible power supply 30kva

- Sri Lanka will build energy storage power station

- Palau outdoor uninterruptible power supply manufacturer

- China 1000kwh energy storage system producer

- Esg energy storage equipment site energy BESS

- Energy storage cabinet assembly

- Solar power satellite factory in Finland

- Panama High Frequency Power Inverter

- Guatemala City 215 kWh energy storage cabinet equipment

- Where is the address of the Kabul emergency communication base station for wind and solar hybrid

- Large-scale industrial energy storage

- China tandem circuit breaker in Bandung

- EK Energy Storage Prices in Addis Ababa

- Solar Energy Storage Revolution

- 60v inverter to 220v

- Nigerian lithium battery energy storage system manufacturers

- Cooling of photovoltaic power station generators

- Battery for floor communication base station

- China earth leakage breaker factory Seller

- Valletta Ningneng Group Energy Storage Power Station

- Flywheel Energy Storage Uninterruptible Power Supply

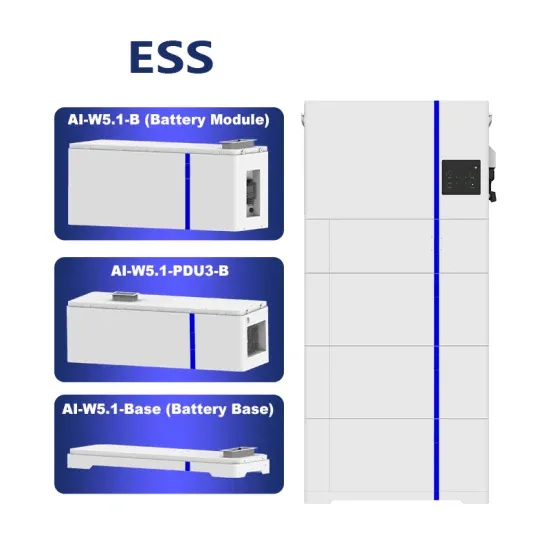

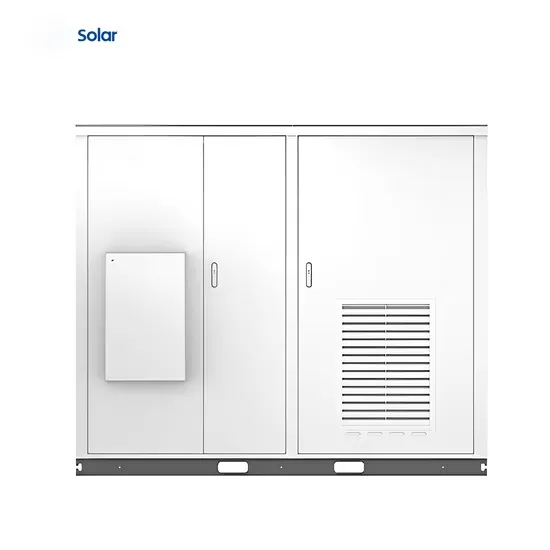

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.