Active balancing method for series battery pack based on

Mar 3, 2020 · Lithium battery has become the main power source of new energy vehicles due to its high energy density and low self-discharge rate. In the actual use of the series battery pack,

Modular balancing strategy for lithium battery pack based

Jun 30, 2024 · Battery balancing is crucial to potentiate the capacity and lifecycle of battery packs. This paper proposes a balancing scheme for lithium battery packs based on a ring layered

The Significance of Cell Balancing in Lithium Packs

Apr 25, 2024 · Part 7. Conclusion To sum it up, cell balancing is super essential for getting the most out of lithium-ion battery packs. By ensuring each cell has

Integrated Strategy for Optimized Charging and Balancing of Lithium

Oct 4, 2024 · Hence, this article proposes an optimized fast charging and balancing strategy with electrothermal regulation of LIB packs. Therefore, the power dissipation constraints of passive

Battery Equalizer 2-24S 15A Intelligent Active

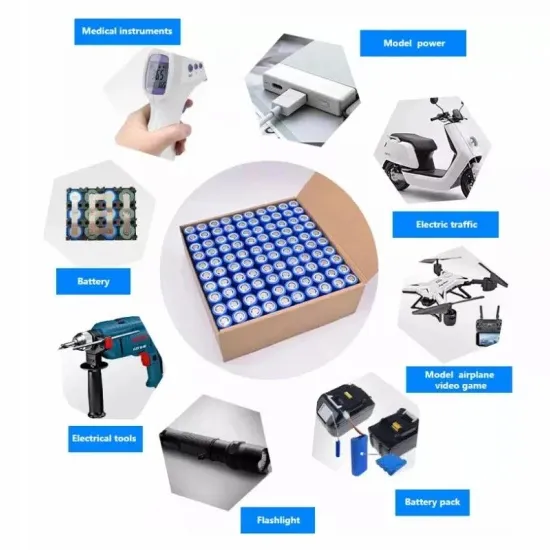

This is a tailor-made equalization management system for high-capacity series-connected battery packs. It can be used in the battery pack of small

LiFePO4 Cell Balancing & How To Balance

What is LiFePO4 cell balancing and why does it matter? We take a look at how to balance LiFePO4 cells and get teh best out of your battery.

What is Battery Balancing and the Role of

Comparison of Passive and Active Balancing The Role of BMS in Balancing Strategies The Battery Management System (BMS) is the core control unit of

Cell Balancing

Cell balancing is all about the dissipation or movement of energy between cells. The aim being to align them all with respect to state of charge. Aligning the

Active Cell Balancing in Battery Packs

Nov 23, 2016 · 2 Balancing methods There are two main methods for battery cell charge balancing: passive and active balancing. The natural method of passive balancing a string of

Performance Analysis of Optimized Active Cell Balancing

Mar 10, 2025 · Active cell balancing is essential for maintaining uniform charge distribution across cells, improving the lifespan, capacity, and safety of LIBs. The paper presents a

Adaptive Recombination-Based Control Strategy

May 29, 2025 · This paper presents a novel adaptive cell recombination strategy for balancing lithium-ion battery packs, targeting electric vehicle (EV)

A Comprehensive Guide to Battery Balancing

Understanding Battery Balancing Battery balancing involves equalizing the State of Charge (SOC) across all cells in a battery pack. This process ensures that

Active balancing method for series battery pack based on

Mar 3, 2020 · To improve the consistency of the series battery pack, a novel balancing method based on the flyback converter is proposed in this study. The flyback converter with a simple

(PDF) Cell Balancing in Electric Vehicle Battery

May 7, 2022 · Cell Balancing in Electric Vehicle Battery Pack Passive and Active cell balancing techniques May 2022 International Journal of Engineering

Equalization strategy of lithium-ion battery packs under two

Jun 15, 2025 · These factors can negatively impact both the performance and longevity of the battery pack. To enhance the service life of the battery pack, it is essential to balance the

An Active Energy balancing System for Lithium-Ion

As is well known, series connected lithium-ion cells may experience overcharge or over-discharge, which can damage or shorten the battery life. To avoid this critical situation, an

Active balancing: How it works and what are its

Jul 7, 2024 · Why active balancing is more viable With a growing demand for safer, more energy efficient, and longer lasting lithium-ion battery systems,

A novel active lithium-ion cell balancing method based on

May 6, 2025 · Compared with the voltage-based and SoC -based cell equalization algorithms, the proposed algorithm determines cell imbalance using State-of-Power (SoP) invariance among

Active balancing method for series battery pack

Nov 25, 2020 · Such inconsistencies will reduce the energy utilisation rate and service life of the battery pack, and even endanger the safety of the battery

Design and implementation of an inductor based cell balancing

Nov 20, 2024 · Article Open access Published: 20 November 2024 Design and implementation of an inductor based cell balancing circuit with reduced switches for Lithium-ion batteries R.

Analysis and Implementation of Inductor Based Active Battery

Dec 19, 2020 · Lithium ion batteries are most popular in present world. Battery cell balancing is an integral part of lithium ion battery packs for optimal use of battery capacity. The paper explains

A Novel Switched Capacitor Circuit for Battery Cell

Oct 25, 2020 · In most applications, the battery pack consists of hundreds of lithium-ion battery cells in order to meet high voltage and high power demands [2]. However, owing to

A novel charging and active balancing system based on

Nov 25, 2022 · Lithium-ion batteries are widely used in applications that require tightness, such as underwater unmanned vehicles and mine-searching robots. The traditional wired charging and

An Active Energy balancing System for Lithium-Ion

Abstract—In this paper, a cell balancing circuit for the Lithium-ion battery pack based on the Flyback topology is proposed. Balancing the lithium-ion battery pack is often employed to

Overview of cell balancing methods for Li‐ion battery

Aug 13, 2020 · Abstract Li-ion batteries are influenced by numerous features such as over-voltage, undervoltage, overcharge and discharge current, thermal runaway, and cell voltage

Active Battery Cell Balancing by Real-Time Model

Jul 10, 2023 · Electrical vehicles (EV) have been considered to be an effective way to combat global climate change. To extend the driving range of EV, this paper studies the active battery

Li-ion Battery Pack Balance – What You Need to

The meaning of battery balance is to keep the voltage of the lithium-ion battery cell or the voltage deviation of the battery pack within the expected range. So

Lithium-ion battery pack equalization: A multi-objective

Mar 10, 2025 · To address the challenges of the current lithium-ion battery pack active balancing systems, such as limited scalability, high cost, and ineffective balancing under complex

How to Achieve EV Battery Balancing?

Jun 14, 2024 · Learn how to achieve optimal EV battery balancing with our in-depth guide- the essential techniques, tools, and best practices.

Why Proper Cell Balancing is Necessary in

Contributed Commentary by Anton Beck, Battery Product Manager, Epec When a lithium battery pack is designed using multiple cells in series, it is very

Method and algorithm for efficient cell balancing in the

Dec 8, 2024 · s the development of a new combined passive balancing method for lithium-ion battery packs. The proposed algorithm integrates existing passive balancing techniques that

Battery Balancing: What, Why, and How – PowMr

Jan 15, 2025 · Battery balancing is a vital process for maintaining the efficiency, performance, and safety of battery systems, whether for solar energy storage,

Battery Balancing: Techniques, Benefits, and How It Works

Learn how battery balancing improves performance, safety, and lifespan. Explore key techniques, benefits, and the science behind balancing battery cells effectively.

6 FAQs about [Automatic balancing of lithium battery pack]

What is a combined passive balancing method for lithium-ion battery packs?

s the development of a new combined passive balancing method for lithium-ion battery packs. The proposed algorithm integrates existing passive balancing techniques that are base on measuring the current voltage and determining the cell voltage at open-circuit voltage. The aim of the work is to reduce the energy imbalance between serially

What are the balancing criteria for Li-ion battery cells?

The experimental results of four Li-ion cells: (a) SoC, (b) current, (c) Switching signals, (d) SoP, and (e) terminal Voltage. This work presents a new active cell balancing algorithm for Li-ion battery cells based on DSoP and CSoP as the balancing criteria.

Can passive and active cell balancing improve EV battery range?

Consequently, the authors review the passive and active cell balancing method based on voltage and SoC as a balancing criterion to determine which technique can be used to reduce the inconsistencies among cells in the battery pack to enhance the usable capacity thus driving range of the EVs.

How does a battery balancing system work?

The BMS compares the voltage differences between cells to a predefined threshold voltage, if the voltage difference exceeds the predetermined threshold, it initiates cell balancing, cells with lower voltage within the battery pack are charged using energy from cells with higher voltage (Diao et al., 2018).

Why is SoC balancing important in EV battery pack?

After performing cell balancing, each cell's SoC reaches 60 % (average SoC) which signifies that all cells have reached to same level or balanced. Therefore, SoC balancing is crucial in EV battery pack to increase the usable capacity. Fig. 3. Charge among five cells connected in series before and after SoC balancing.

Can a flyback transformer and switch matrix balancing a lithium-ion battery pack?

To address the challenges of the current lithium-ion battery pack active balancing systems, such as limited scalability, high cost, and ineffective balancing under complex unbalanced conditions, this study proposes a novel balancing structure based on a flyback transformer and switch matrix.

Industry Information

- 2000V Solar Photovoltaic Panel

- Circuit breaker fuse for sale in Nairobi

- Prices of photovoltaic modules on the islands of El Salvador

- Cheap himel circuit breaker factory Seller

- New Energy Power Inverter Price

- Xia 5rh communication distance without base station

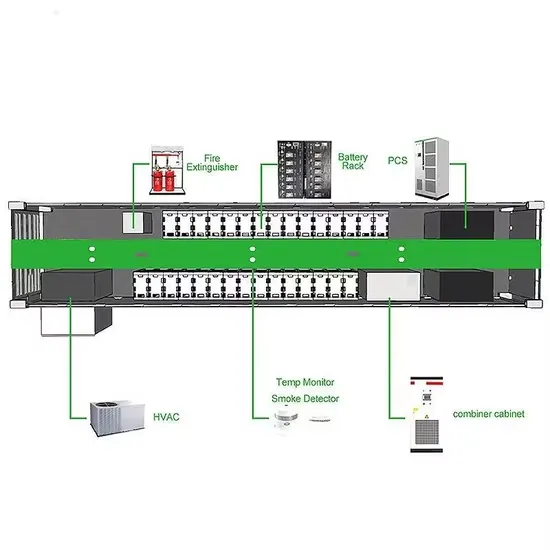

- Power energy storage battery system

- Latvian rooftop solar systems

- Solar power collection and installation photovoltaic area calculation

- Wholesale 3000 amp switchgear in Congo

- 16-series lithium iron communication base station battery pack BMS

- Singapore capacitor energy storage system

- Battery storage prices in Chile

- What is the prospect of battery cabinet production

- High quality 220 volt breaker in Italy

- Türkiye Communications 2MWH5g Base Station

- Berne Photovoltaic Energy Storage Battery Pump Manufacturer

- Power station charging pile energy storage

- Hargeisa Photovoltaic Inverter

- Outdoor power supply high power

- How big a photovoltaic panel is needed for 3000w household electricity

- Huawei Chile Energy Storage Battery

- Famous brand manufacturer of photovoltaic panels in Togo

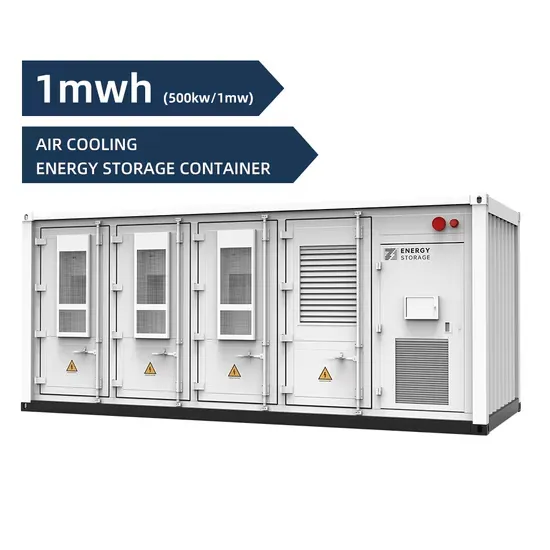

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

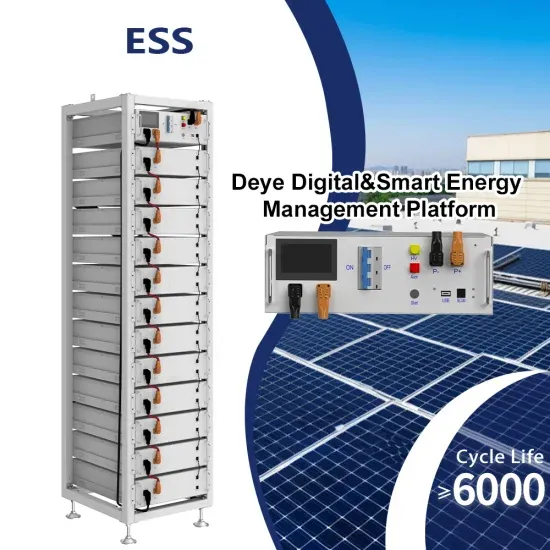

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.