Preparation of SiO2–PVA nanocomposite and monolithic

Jan 1, 2011 · We present a procedure for fabricating transparent silica glass that involves the sintering of green bodies prepared from an inorganic–organic nanocomposite. The

What''s the difference between PVA and PVB

What''s PVA? Are PVA and PVB the same? Let''s find the answer together! PVA (Polyvinyl alcohol) is a kind of white powder, whose physical properties are affected by chemical structure,

Enhancing photovoltaic efficiency in perovskite solar cells

Oct 1, 2024 · Under typical solar conditions, the built-in PSC, which has the architecture FTO/TiO 2 /Perovskite/PVA & F-127/Pt, exhibits a remarkable efficiency of 1.29 %. Interestingly, PSC

Preparation and characterization of down converting

Dec 1, 2023 · The gap between the apex of excitation and the emission spectrum (stokes shift) in PVA/PANI@CuS NC is also between 60 and 105 nm. The considerable Stokes shift values

Liquid bridges between particles and the hydrophobic or

May 20, 2022 · Furthermore, the self-cleaning abilities of these two surfaces are also discussed. The results indicate that the liquid bridges formed between a particle and a hydrophilic PV

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · 1. What is solar photovoltaic glass?Solar photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by

A study of the relationship between the electroluminescence

Aug 1, 1996 · A series of poly(p-phenylene vinylene) (PPV)-poly(vinyl alcohol) (PVA)-based polymers were prepared from the PPV precursor and PVA aqueous solution mi

Enhancing glass surface hydrophobicity: the role

Oct 19, 2024 · This study presents a novel approach to fabricate self-cleaning, superhydrophobic coatings on glass surfaces and photovoltaic cells. Using a

A Dual-Function Poly (vinyl alcohol) Hydrogel for

Mar 6, 2025 · In this study, we develop PVA-based dual-function hydrogels that combine good photothermal properties with excellent thermoelectric

Optical Properties and Conductivity of PVA–H3PO4

The relationship between radiation dose and absorbance of each λ (310, 350, and 550 nm) for H 3 PO 4 75 v% concentration. For peak III, the first two absorbance data were considered as

Performance exploration of polyvinyl alcohol/modified glass

Dec 15, 2023 · The results showed that PVA molecular chains, crystals and modified glass fibers arranged in a directional and orderly manner inside the composites. The strength and

Solarvolt Photovoltaic Glass System | Vitro

Solarvolt ™ Building Integrated Photovoltaic (BIPV) Glass System Seamlessly integrated into the building structure, the Solarvolt ™ BIPV glass system

Photovoltaic thermal management with highly transparent

The hydrogel-cooled PV system is depicted in Fig. 1. In a general PV panel, the PV cell is shielded by highly transparent glass and encapsulated within an aluminum plate featuring

Optical properties of polyvinyl alcohol-glass waste powder

Oct 17, 2024 · The effect of glass powder on the UV-Vis spectroscopy of polyvinyl alcohol (PVA) has been studied. The glass powder was obtained from fluorescent tubes waste. The solution

Window-Integrated PV Glass: The Future of Solar

Feb 19, 2025 · Photovoltaic (PV) glass stands at the forefront of sustainable building technology, revolutionizing how we harness solar energy in modern

Difference Between Polyvinyl Butyral (PVB) Resin And

Mar 9, 2023 · Polyvinyl Butyral (PVB) resin and Polyvinyl Alcohol (PVA) are two synthetic polymers that are widely used in various applications. Although they are similar in some

The effect of the degree of hydrolysis of the PVA and the

Jul 1, 2008 · But, although the mechanical properties of the blended films depended on the type of PVA used, there was no direct relationship between these properties and the degree of

Development of Versatile, thermally stable, flexible, UV

Jun 30, 2024 · This research paper reports an enhancement of thermal, optical, mechanical and antibacterial activities of the Polyvinyl alcohol–Nanodiamonds (PVA-NDs) composite required

Water governs the mechanical properties of poly(vinyl alcohol)

Jan 20, 2021 · The presence of water molecules can significantly determine the macroscopic mechanical property and microscopic chain dynamics of poly (vinyl alcohol) (PVA). However,

High efficiency of transparent silicon solar cell using

Mar 13, 2025 · A transparent multilayer thin-film silicon solar cell was proposed using Polyvinyl Alcohol (PVA)—A water-soluble synthetic polymer (PVA) 10% NaI as the substrate and

Characterization and Physical Properties of Low

Dec 4, 2023 · In this study, we report a series of low molecular weight PV Acs and PV As having a 2-hydroxyethylthio group at one end, and examine the degree of polymerization of these

Relationship between polymers compatibility and casting

Sep 1, 2017 · In addition, owing to the poor thermodynamic compatibility between PVDF and PVA, the decreased dynamic miscibility between blend polymers with the increase of PVA dosage

Water vapor permeability of polymeric packaging

Jul 8, 2024 · In this paper, we focus on the moisture barrier prop-erties of different polymeric materials for use in glass-free PV modules, including fiber-reinforced skins as well as

Physical Properties of Glass and the Requirements for

Feb 16, 2011 · Weathering of float glass can be categorized into two stages: "Stage I": Ion-exchange (leaching) of mobile alkali and alkaline-earth cations with H+/H3O+, formation of

Optical and structural properties of drop-cast PVA/PEG

Jan 1, 2021 · In the present study, the drop cast films of polyvinyl alcohol (PVA), polyethylene glycol (PEG) and optimized PVA:PEG (50:50) polyblend were studied. The pure polymer and

Polyvinyl Butyral

Polyvinyl butyral (PVB) is defined as a polymer formed from the reaction of an aldehyde and alcohol, typically comprising a blend of PVB, polyvinyl alcohol (PVOH), and polyvinyl acetate

Solar Photovoltaic Glass: Classification and

Jun 26, 2024 · Demand for solar photovoltaic glass has surged with the growing interest in green energy. This article explores ultra-thin, surface-coated, and

Novel glass materials-based (PVA/PVP/Al

Mar 22, 2022 · PVA and PVP backbone are belonging to hydroxyl (–OH) and carbonyl (C=O) functional groups, respectively, which exhibit electrostatic interactions between the

PVI3-04 dd

May 21, 2024 · Glass used in the PV industry is referred to as sheet glass, which may be produced using two different processes. For the so-called float glass process, red-hot and

Efficient Passive Cooling for Photovoltaic Cells via

Jun 6, 2025 · In this study, a self‐hygroscopic polyvinyl alcohol/graphene (SPG) cooling film, comprising a graphene layer and a polyvinyl alcohol (PVA) hydrogel layer with lithium bromide

6 FAQs about [The relationship between PVA and photovoltaic glass]

How does PvP/PVA interact with perovskite?

PSC with 1.5 wt%PVP/0.5 wt%PVA kept 82.2% of its initial PCE after 30 days in air. Interaction between PVP/PVA and perovskite improves film quality and stability. Synergistic effect between PVP/PVA and perovskite improves cell performance.

Why is PVA a good choice for solar panels?

PVA is a flexible, transparent, non-toxic, non-hazardous, and biocompatible substrate. The new PV depends on a selective light-absorption layer to reach high power conversion energy. These kinds of solar cells have sufficient efficiency. At the same time, selective material is very important to simulate development and market requirements.

Can PVA improve the life of solar cells?

As researchers continue to investigate new materials and techniques for solar cell fabrication [14, 15, 16, 17, 18, 19], PVA can help increase the stability and lifetime of dye- sensitized solar cells. An efficient field-effect passivation was designed through multiple layers, the first being the protective PVA layer.

Can PvP/PVA improve the stability of perovskite?

Such synergistic effect of complexation and hydrogen bonds after adding PVP/PVA can not only passivate the defects of perovskite, but also enhance the stability of perovskite crystal structure, thus improving the efficiency and stability of solar cells. Fig. 11.

Do modified glass fibers increase the crystallinity of PVA?

Meanwhile, the peak of PVA/modified glass fiber composites in the 2θ range of 17–20° increased with the different modified glass fibers added. These observations could be found because of the different hydrogen bonding interactions formed between PVA and the modified glass fibers, and showed an increased difference in the crystallinity of PVA .

How tensile process induced the crystallization of PVA compared to pure PVA?

Furthermore, compared with pure PVA, the crystallinity and grain size of the composites increased, indicating that the tensile process and the orderly arrangement of glass fibers synergistically induced the further growth of PVA grains. And the introduction of glass fibers further promoted the crystallization process of PVA. Fig. 7.

Industry Information

- Discover the technology of outdoor energy storage power supply

- San Marino Communication Energy Storage Battery

- Photovoltaic energy storage for sale

- Oceania Energy Storage Container Northwest

- Battery BMS custom development

- Grid-side energy storage facilities

- Energy storage device in Ethiopia office building

- Can solar lights be installed indoors or outdoors

- Dewalt tool battery

- Niger household energy storage system installation

- Industrial switchgear factory in Sweden

- Hit battery and inverter

- Is the Skopje new energy battery cabinet under warranty

- EMS Survey of China s Communication Base Stations

- Control principle of liquid flow battery in communication base station

- PV inverter output price

- Average availability of photovoltaic inverters

- Solar Wireless On-site Energy Small

- How many batteries are needed for the energy storage system

- Nauru Solar Base Station Price Inquiry

- Energy storage system grid connection solution

- Photovoltaic panel installation on rural roof in Kyiv

- Eatonups uninterruptible power supply

Commercial & Industrial Solar Storage Market Growth

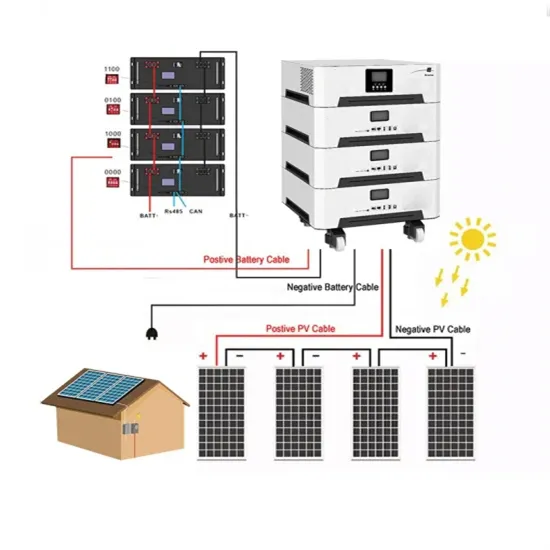

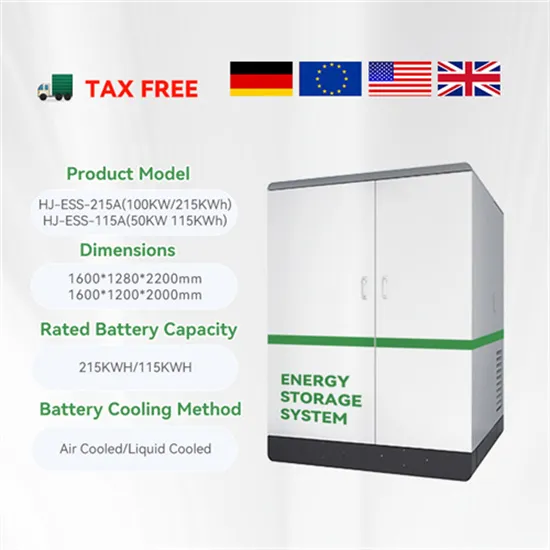

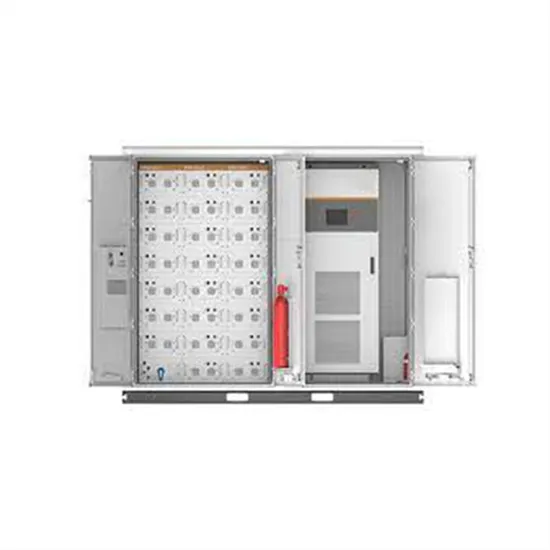

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

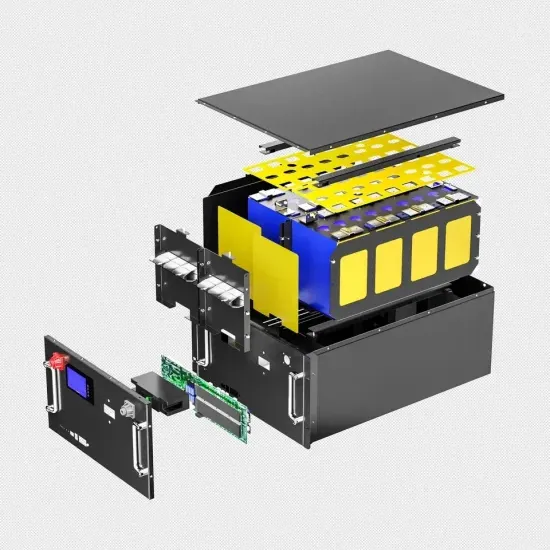

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.