THERMAL MANAGEMENT FOR ENERGY

Apr 2, 2023 · Compared to air cooling, liquid cooling is generally more effective at dissipating high amounts of heat, and can provide more precise temperature

Liquid Cooling System Design, Calculation, and

Aug 19, 2025 · The lithium battery energy storage system consists of a battery chamber and an electrical chamber. The battery chamber includes the battery

How Is The Design Of The Energy Storage Liquid

Mar 17, 2025 · Conclusion The project designed a 20 foot liquid cooled container energy storage system, including system theoretical design, thermal

Review on operation control of cold thermal energy storage in cooling

Jun 1, 2025 · Most importantly, the operation control which is necessary to performance optimization is presented, including operational control strategies, cold load predictions, and

What is Container Energy Storage? Applications & Advantages

Mar 7, 2025 · The liquid cooling system is more suitable for large-scale, high-energy density energy storage projects, especially in situations where the battery pack has high energy

DESIGNING AN HVAC SYSTEM FOR A BESS CONTAINER:

Jun 8, 2023 · Explore the intricate design and operational strategy of HVAC systems in Battery Energy Storage Systems (BESS) containers. This comprehensive guide discusses the crucial

125KW/233KWh Liquid-Cooling Energy Storage

Dec 30, 2024 · In order to ensure the safety of energy storage power stations, the selection and design of energy storage system equipment should follow the principles of "prevention first,

Integrated cooling system with multiple operating modes for temperature

Mar 1, 2025 · In winter, low condensing temperature heat pump technology is used to replace traditional PTC electric heating, which has good energy saving benefits. The proposed

Liquid-cooling becomes preferred BESS

Jan 21, 2025 · For every new 5-MWh lithium-iron phosphate (LFP) energy storage container on the market, one thing is certain: a liquid cooling system will be

Liquid Cooling in Energy Storage: Innovative Power Solutions

Jul 29, 2024 · The Need for Advanced Power Solutions As the world transitions to renewable energy sources, the need for advanced power solutions becomes critical. Traditional energy

EMW series liquid cooling unit for energy

Battcool-C series air cooled chiller for energy storage container is mainly developed for container battery cooling in the energy storage industry. It is

CATL EnerC+ 306 4MWH Battery Energy Storage

Aug 12, 2025 · The EnerC+ container is a battery energy storage system (BESS) that has four main components: batteries, battery management systems

2.5MW/5MWh Liquid-cooling Energy Storage System

Oct 29, 2024 · The temperature control system consists of a liquid cooling unit and liquid cooling pipes. Batteries are sensitive to temperature varying, with the suitable operating temperature

Modeling and analysis of liquid-cooling thermal

Sep 1, 2023 · Modeling and analysis of liquid-cooling thermal management of an in-house developed 100 kW/500 kWh energy storage container consisting of lithium-ion batteries retired

Liquid-cooled Energy Storage Cabinet

Commercial & Industrial ESSExcellent Life Cycle Cost • Cells with up to 12,000 cycles. • Lifespan of over 5 years; payback within 3 years. • Intelligent Liquid Cooling, maintaining a temperature

Integrated cooling system with multiple operating modes for temperature

Apr 15, 2025 · In winter, low condensing temperature heat pump technology is used to replace traditional PTC electric heating, which has good energy saving benefits. The proposed

Integrated cooling system with multiple operating modes for temperature

Mar 1, 2025 · The proposed energy storage container temperature control system provides new insights into energy saving and emission reduction in the field of energy storage.

Liquid Cooled Battery Energy Storage Systems

Jan 28, 2024 · In the ever-evolving landscape of battery energy storage systems, the quest for efficiency, reliability, and longevity has led to the development of more innovative

Integrated cooling system with multiple operating modes for temperature

Apr 15, 2025 · Meanwhile, in view of the insufficient energy-saving potential of the existing liquid cooled air conditioning system for energy storage, this paper introduces the vapor pump heat

Thermal Management of Liquid-Cooled Energy

Dec 13, 2024 · Compared to traditional air-cooling systems, liquid-cooling systems have stronger safety performance, which is one of the reasons why

集装箱式储能电站两相冷板液冷系统的温控效果研究

Jan 9, 2024 · Study on the temperature control effect of a two-phase cold plate liquid cooling system in a container energy storage power station Yaxin

Liquid Cooling Energy Storage System

Jan 16, 2025 · Featuring an all-in-one design, the liquid cooling energy storage system integrates high- performance PCS, BMS, high-capacity battery modules, smart EMS, and advanced

liquid cooling energy storage system

The core of liquid cooling energy storage lies in effectively managing the temperature of energy storage devices through liquid cooling systems.

液冷散热技术在电化学储能系统中的研究进展

Apr 1, 2024 · Liquid cooling technology requires ongoing optimization in several areas, including key system parameter design, control strategy development,

BATTCOOL ENERGY STORAGE ONE-STOP LIQUID COOLING

BattCool Energy Storage Full-chain Liquid Cooling Solution Full-chain solution to ensure safety and create value throughout the whole chain Full-chain solution featuring independent

集装箱式储能电站两相冷板液冷系统的温控效果研究

Jan 9, 2024 · 研究结果表明,两相冷板液冷系统在整个充、放电过程中能够有效降低电池的温升,并将全舱电池的最大温差从传统液冷系统的4.17 ℃降低至3 ℃以内,提高了电池温度的一致

CONTAINERIZED LIQUID COOLING ENERGY

Jun 14, 2023 · Paragraph 3: Application Prospects The containerized liquid cooling energy storage system holds promising application prospects in

All-in-One Liquid Cooling Energy Storage

GSL ENERGY''s All-in-One Liquid-Cooled Energy Storage Systems offer advanced thermal management and compact integration for commercial and

Jiangsu Seemor Temperature Control System Co. LTD._Horizontal liquid

Seemor Temperature Control devotes itself to the present while envisioning the future, driving forward with technological innovation to steadfastly provide liquid cooling temperature control

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS

Apr 8, 2024 · Battery Energy Storage System (BESS) containers are a cost-effective and modular solution for storing and managing energy generated from renewable sources. With their ability

6 FAQs about [Temperature control strategy for container energy storage liquid cooling unit]

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

How does a battery temperature control system work?

The temperature control system consists of a liquid cooling unit and liquid cooling pipes. Batteries are sensitive to temperature varying, with the suitable operating temperature range for lithium iron phosphate batteries typically between 10–35°C.

Can liquid cooling system reduce peak temperature and temperature inconsistency?

The simulation results show that the liquid cooling system can significantly reduce the peak temperature and temperature inconsistency in the ESS; the ambient temperature and coolant flow rate of the liquid cooling system are found to have important influence on the ESS thermal behavior.

What is a liquid cooling unit?

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

What is the maximum temperature rise of a liquid cooling system?

With the liquid-cooling system on, from the initial temperature, the maximum temperature rise of the LIBs is 2 K at the end of the charging process and 2.2 K at the end of the discharging process compared with the initial temperature.

Industry Information

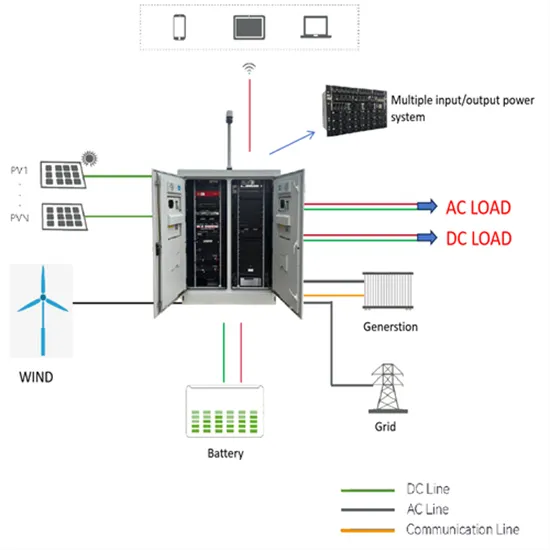

- Power generation system with energy storage equipment

- Sierra Leone Industrial and Commercial Energy Storage Cabinet Wholesale

- Ecuador 400MW energy storage project

- Factory price circuit breaker in Brisbane

- Where can I buy battery cabinets in Colombia

- North American Energy Storage Batteries

- Uninterruptible power supply unit in basement

- Best 2 5 kw solar inverter factory Price

- Somalia Customized Cylindrical Lithium Battery

- Georgian container photovoltaic energy storage

- Battery energy storage system prices in Turkmenistan

- Solar power storage batteries in Nairobi

- How many strings of 48v lithium battery packs

- How many watts are the suspended solar panels

- Gabon Monocrystalline Photovoltaic Panel Purchase Guide

- Wholesale 220 circuit breaker in Oman

- How many watts does cadmium telluride photovoltaic glass have

- Ottawa small solar lights for home use

- Photovoltaic panel assembly export

- Motor circuit breaker factory in Calcutta

- Wind turbines wind and solar energy storage

- Antananarivo Small Solar Air Conditioner

- Uzbekistan Heavy Industry Energy Storage Cabinet Quote

Commercial & Industrial Solar Storage Market Growth

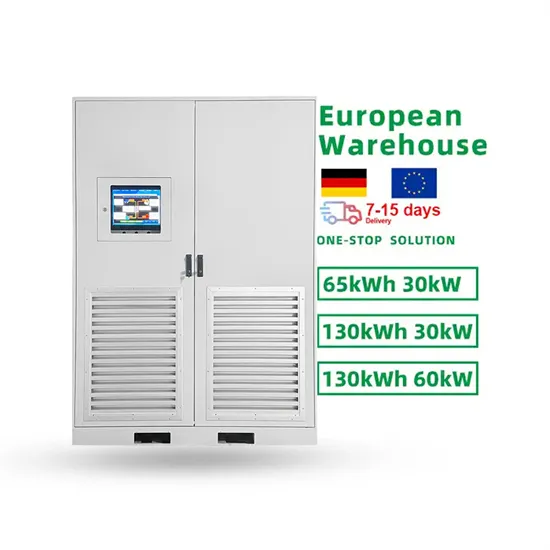

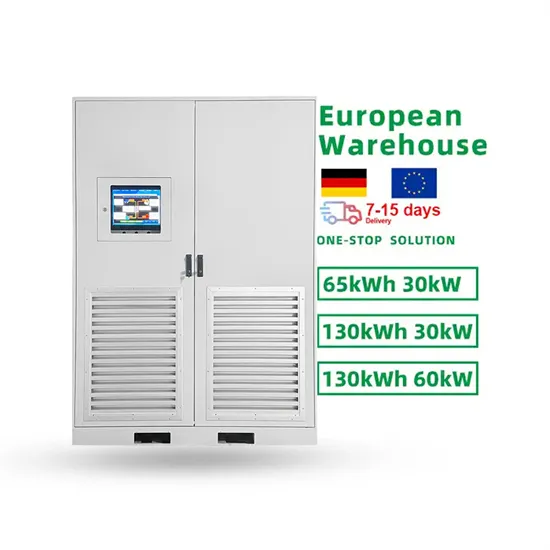

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.