Battery safety: Machine learning-based prognostics

May 1, 2024 · Over the past decade, scholars and industry experts are intensively exploring methods to monitor battery safety, spanning from materials to cell, pack and system levels and

Lithium Battery Pack: Types, Design, Safety, and

Jun 25, 2024 · Designing a lithium battery pack involves several critical considerations to optimize performance and safety: Cell Arrangement: The

Battery Pack Design: Efficient & Safe Energy

Mar 15, 2025 · Learn how to design a high-performance battery pack with the right cell configuration, cooling system, and safety features.

RETRACTED: Enhancing battery pack safety against cone

Nov 1, 2024 · Enhancing battery pack safety against cone impact using machine learning techniques and Gaussian noise Qian Zhang a, Shaoyong Han b,*, Azher M. Abed c,d,**, Ali

Battery Safety Standards Testing | Tech

Jan 22, 2025 · In recent years, the use of lithium-ion batteries has grown exponentially with the widespread adoption of electric vehicles (EVs), energy

EV Lithium Battery PACK Design Process from

Mar 18, 2025 · EV Lithium Battery PACK Design Process: A Comprehensive Guide The design of Electric Vehicle (EV) lithium battery packs ⇱ is a complex

The Fundamentals of Battery/Module Pack Test

Oct 17, 2023 · Module and pack tests typically evaluate the overall battery performance, safety, battery management systems (BMS), cooling systems, and internal heating characteristics.

Automotive Battery Pack Standards and Design

Apr 7, 2025 · Also, advances in energy density (up to 300 Wh/kg) and battery capacities make advancements in enhancing the electric vehicle''s range beyond 1000 km per charge. Key

Anti-vibration safety performance research of battery pack

Jul 28, 2017 · The battery pack anti-vibration safety was analysed by structural intensity Finite Element Analytical Method and the battery pack intensity, stiffness and anti-vibration FEA

Innovations in Traction Battery Pack Design for Enhanced Safety

Nov 26, 2024 · The dual demands of safety and performance drive continuous innovation, ensuring that battery packs meet the rigorous standards required for modern EVs. Additionally,

Automotive Battery Pack Standards and Design

Mar 18, 2025 · BMS play a critical role in ensuring the optimal performance, safety, and longevity of EV battery packs. Among the primary tasks of the BMS are the SOC estimation, which

Evaluation of the safety standards system of power batteries

Nov 1, 2023 · Generally speaking, Chinese vehicle battery safety standards divide the test objects into battery cells, battery modules, battery packs, and battery systems. GB 38031–2020

Safety Performance and Failure Criteria of

Sep 1, 2023 · It compares the advantages and disadvantages of using homogeneous and detailed models in the modeling process, summarizes ISC

Battery Pack Design: Safety, Cost, and Performance

Mar 10, 2024 · The battery pack design must consider potential abuse situations like short circuits, overcharge, and penetration, ensuring safety and preventing thermal runaway in lithium-ion

Improving the Safety Performance of Lithium Battery Packs

Dec 27, 2024 · Lithium battery packs are at the heart of numerous modern technologies, powering everything from electric vehicles and consumer electronics to industrial energy storage

Safety risk assessment for automotive battery pack based on

Aug 10, 2024 · Safety risk assessment is essential for evaluating the health status and averting sudden battery failures in electric vehicles. This study introduces a novel safety risk

Battery Pack EOL Test: Ensure Safety

Jan 21, 2025 · Explore the importance of the Battery Pack EOL Test in verifying battery safety, performance, and compliance during the final stage of lithium

Battery Packs: Are They Safe? Risks, Best Practices, And

Mar 28, 2025 · To ensure safety, follow usage guidelines, avoid excessive heat, and regularly inspect battery packs. Practicing these recommended measures increases consumer

Advancing structural efficacy and resonance

Aug 20, 2024 · The paramount concern in this context is the overall efficiency of the power source and the holistic safety of the battery pack which is important

Battery Pack Design Considerations for Performance and Safety

1 day ago · At the conclusion of our webinar, Custom Battery Pack Design Considerations for Performance and Safety, we had several questions submitted to our presenter, Battery

Lithium Battery Pack: Types, Design, Safety, and

Jun 25, 2024 · Lithium battery packs have revolutionized the landscape of portable electronics and electric vehicles, offering advanced technology that

How Battery Pack Design for Electric Vehicle Impacts Performance

Jun 16, 2025 · Safety: Proper thermal control and cell monitoring reduce fire and failure risks. Lifecycle: A durable design ensures thousands of charge cycles with minimal degradation. A

A review on electrical and mechanical performance

Dec 10, 2022 · It leaves aside a holistic and comprehensive study to evaluate performance in lithium-ion battery packs. This review paper presents more than ten performance parameters

Battery Pack Requirements for EV Safety & Performance

Battery packs are the heart of electric vehicles, but what goes into making a safe and reliable one? This article explores the various requirements that battery packs need to meet. Charging:

Automotive Battery Pack Standards and Design

Mar 18, 2025 · Proper temperature regulation is essential for ensuring the performance, longevity, and safety of battery packs. There are various technologies used within BTMS to control the

A Comprehensive Review of Thermal

Feb 9, 2025 · The scientific aim of the study is to propose a comprehensive review of thermal management systems (TMSs) used in electric vehicle (EV)

A Comprehensive Approach to Battery Module and Pack

A comprehensive approach to battery module and pack testing is critical for ensuring the safety, performance, and durability of battery systems. With the growing reliance on batteries in

A Detailed Guide on Safety and Security of

Mar 20, 2024 · In this blog post, we will discuss the potential hazards that can be detrimental to the battery''s life cycle and BMS''s role in the safety and security

An experimental study on lithium-ion electric vehicles battery packs

Nov 1, 2024 · The need for efficient and dependable lithium-ion battery packs has significantly increased as a result of the progressively rising sales of electric vehicles (EVs). Thermal

What does SAE J3277 mean for EV Batteries'' packs performance and safety?

Jul 1, 2025 · By adopting SAE J3277 and its associated practices, we can elevate the standard of EV battery pack safety and performance, mitigating incidents like those experienced during

The Fundamentals of Battery Pack and Module

Apr 19, 2024 · Battery Module and Pack tests typically evaluate the battery performance, safety mechanisms, cooling systems, and internal heating

Effect of composite cooling strategy including phase change

May 15, 2024 · In this work, a composite cooling system including composite phase change material (CPCM) and liquid cooling is designed for battery pack, and the effects of coolant flow

Performance analysis of safety barriers against cascading

Dec 1, 2022 · However, some critical issues in a battery pack still exist, such as thermal failures on initial cells that impact the temperatures of the surrounding cells. Such cascading failures

The Battery Pack Housing|Home Energy Storage

The battery pack housing is an indispensable key component in the battery pack. It not only provides protection and support for the battery unit, but also plays

Exploring Battery Testing Standards: A

Apr 8, 2024 · Battery Testing Standards play a pivotal role in ensuring the safety, reliability, and performance of batteries in electric and hybrid vehicles.

A Comprehensive Review of Thermal Management Methods

Feb 9, 2025 · The scientific aim of the study is to propose a comprehensive review of thermal management systems (TMSs) used in electric vehicle (EV) battery packs on matters pertaining

Battery vent valve technology White paper Ensuring EV

Sep 15, 2024 · As battery packs become progressively more powerful and create more heat, the vent valve plays a crucial role in maintaining the safety of the battery pack. In case of

A coupled electrochemical-mechanical performance evaluation for safety

Jun 10, 2019 · The battery pack safety relies on its mechanical performance, such as the capabilities of anti-deformation and bearing the vibratory impulse generated due to vehicle

6 FAQs about [Battery PACK Safety Performance]

How do we evaluate the safety risk of a battery pack?

To comprehensively identify the potential risks in the battery pack, we proposed a novel approach to hierarchically evaluate the safety risk of batteries in this study. Based on this method, we can give a grading evaluation of battery inconsistency and provide appropriate battery safety warnings from pack and cell levels.

How can a battery management system ensure safety and security?

The most viable way to enforce the safety and security of battery packs is via integration with the battery management system. BMS can safeguard the battery pack from a wide range of potential threats such as overcurrent, instantaneous ignition, temperature, and voltage fluctuations.

What are the requirements of automotive battery packs?

Safety is one of the most important requirements of automotive battery packs, as discussed in Section V. The battery pack should be electrically and mechanically safe, and different criteria should be fulfilled as required by the standards. Functional safety is also the main tool for realizing the requirements mentioned.

Why is BMS important for EV battery packs?

The idea was to complement the materials provided in the previous sections. BMS play a critical role in ensuring the optimal performance, safety, and longevity of EV battery packs.

Can a battery pack operate in a harsh automotive environment?

The final battery pack should be able to operate in a harsh automotive environment, which is mainly governed by ISO 16750 ISO16750-1 ; ISO16750-2 ; ISO16750-3 ; ISO16750-4 ; ISO16750-5 . The battery pack was subjected to extensive environmental testing, such as temperature, vibration, and humidity. This is discussed in Section IV.

How does temperature affect the performance of a battery pack?

Uneven temperature distribution leads to different charge and discharge behaviours causing electrical unbalance in the modules which reduces the performance of the battery pack. When a battery pack is integrated with the vehicle, it becomes a more complex system confronting many safety problems (Garg et al., 2016).

Industry Information

- Energy Storage Container Enterprise Ranking

- Tehran grid-side energy storage policy

- The voltage that each mosfet in the inverter can withstand

- China drawout circuit breaker in Uk

- Liberia Solar Island Power System

- High quality outdoor breaker in Moscow

- 600W Photovoltaic Power Inverter

- Outdoor power supply 60v

- Centralized photovoltaic energy storage peak-shaving electricity price

- Aren t lithium batteries considered energy storage batteries

- Main circuit breaker factory in Oman

- Solar Power Station Watt Inverter

- Communication base station flywheel energy storage city power generation

- Huawei Microgrid Energy Storage

- Solar Storage Battery Cabinet China

- What products are included in the foreign trade energy storage battery cabinet

- Ultra-high voltage inverter

- Can battery energy storage power stations make money

- Solar powered portable outlet in Tajikistan

- Seychelles Industrial Energy Storage Battery

- Somalia energy storage container installation factory operation

- Hybrid inverter mppt in China in Malta

- Poland Krakow single glass photovoltaic module price

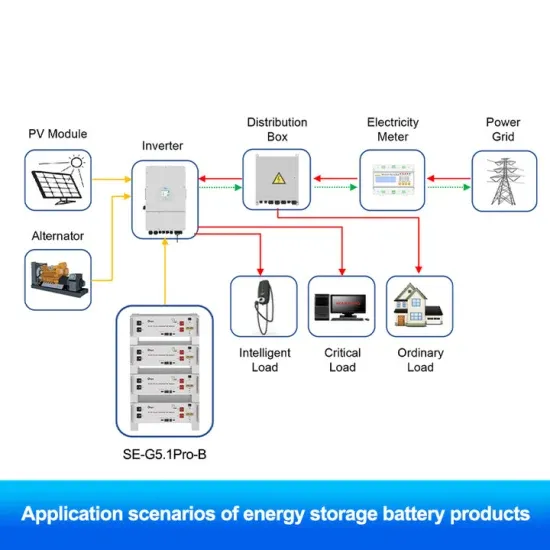

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.