Types of photovoltaic solar panels and their

Nov 6, 2017 · Learn the differences between monocrystalline, polycrystalline and thin-film solar panels. Find out which one is best suited for your solar energy

What are polycrystalline silicon solar cells?

Sep 22, 2024 · Polycrystalline silicon solar cells represent one of the most common forms of solar technology utilized for converting sunlight into

The Basics of Polycrystalline Solar Panel

May 9, 2023 · The world is rapidly transitioning towards renewable sources of energy, and solar power is at the forefront of this change. Solar panels are

Monocrystalline vs. Polycrystalline Solar Panels: Key

Apr 3, 2025 · The solar cells have rounded corners (due to the crystal ingot cutting process). Crystal Structure: Highly ordered silicon atomic arrangement, with high purity (typically

Polycrystalline Solar Panel Specifications

Nov 17, 2023 · The surface of these solar cells resembles a mosaic which comes under polycrystalline solar panel specifications. These solar panels are square

Monocrystalline vs. Polycrystalline Solar Panels

May 5, 2023 · A solar panel is a composition of solar photovoltaic (PV) cells that absorb light from the sun and convert it into electricity. Typically, solar cells are made of silicon. There are two

Microsoft PowerPoint

Feb 24, 2011 · Crystalline and Polycrystalline Silicon PV Technology Crystalline silicon PV cells are used in the largest quantity of all types of panels on the market, representing about 90% of

Polycrystalline Solar Panel: Features, Working

Jun 15, 2024 · Polycrystalline solar panel working principle These solar panels are made of multiple photovoltaic cells. Each cell contains silicon crystals

Polycrystalline Solar Panels – What Are They?

Mar 19, 2025 · Polycrystalline solar panels use the photovoltaic effect to generate electricity by converting sunlight into usable energy. Each panel comprises

Advantages and Disadvantages of Polycrystalline

Aug 26, 2023 · Overview and Understanding of Polycrystalline Solar Panels Polycrystalline solar panels have several advantages, such as being cheaper

Polycrystalline Solar Panel: Definition, How it

Aug 12, 2024 · In polycrystalline solar cells, silicon crystals are melted and fused together, resulting in a less uniform structure than monocrystalline solar cells.

How Do Solar Cells Work? Photovoltaic Cells

Jul 25, 2024 · You''ve probably seen solar panels on rooftops all around your neighborhood, but do you know how they work to generate electricity? In this

Monocrystalline vs Polycrystalline Solar Panels:

Sep 30, 2024 · Compare the differences in their manufacturing processes to understand how monocrystalline solar cells are made from a single, high

Monocrystalline silicon: efficiency and

Sep 3, 2018 · For this reason, lower quality silicon is used. Despite this, the monocrystalline silicon solar PV industry has improved considerably.

What is the difference between mono-crystalline

Jun 22, 2018 · As a first time buyer of solar lights, we might get confused over which solar panels to go for. There are mainly 2 variations which you can

The Basics of Polycrystalline Solar Panels and

Aug 18, 2025 · Polycrystalline solar panels are made up of multiple silicon crystals fused together to form a single panel. These panels are known for

Polycrystalline Solar Panel Function,

Feb 7, 2025 · Key Takeaways Polycrystalline solar panels are made from multiple silicon crystals, which makes them less expensive to produce compared to

Monocrystalline vs. Polycrystalline Solar Cells

Dec 17, 2024 · Solar panels are composed of multiple solar cells, typically made from silicon or other semiconductors, which convert energy from sunlight into

Polycrystalline Solar Panels: What You Need To

Apr 17, 2024 · These polycrystalline solar panels hold a mosaic looking surface made up of numerous polycrystalline silicon. This is what makes these solar

Types of Solar Panels Explained: Monocrystalline vs. Polycrystalline

Jun 7, 2025 · Solar panels are the heart of any photovoltaic (PV) system, and their type can significantly influence efficiency, aesthetics, cost, and installation options. The three primary

Polycrystalline solar panels: the expert guide [2025]

Jul 14, 2025 · In this guide, we''ll explain what polycrystalline solar panels are, how they''re made, and why they''ve fallen so far from their position as the most widely used domestic solar

Polycrystalline Solar Panels – What Are They?

Mar 19, 2025 · How Do They Work? Polycrystalline solar panels use the photovoltaic effect to generate electricity by converting sunlight into usable

Monocrystalline Silicon Solar Panels: Efficient

Feb 3, 2025 · As the demand for solar panel business continues to grow, choosing the right solar panels is crucial for maximizing energy efficiency.

What are polycrystalline solar panels?

May 17, 2025 · Monocrystalline vs polycrystalline panels Monocrystalline solar panels are the higher-end alternative to polycrystalline panels. These panels are made from a single piece of

A Complete Guide to Polycrystalline Solar Panels

Jul 31, 2025 · Multiple Silicon Crystals, when melted together, form solar cells, a unique type of photovoltaic (PV) solar panel known as a Polycrystalline Solar Panel. These Solar Panels are

Polycrystalline silicon solar cells

Jan 1, 2021 · The silicon demand for photovoltaic applications will be increased. The relations among the manufacturers of polycrystalline silicon with demand in the market from 2003 to

Polycrystalline solar panels: the expert guide [2025]

Jul 14, 2025 · Here''s what polycrystalline solar panels are, how they''re made, and why they''ve fallen out of favour.

Monocrystalline vs Polycrystalline Solar Cells and How to

Mar 12, 2025 · Monocrystalline and polycrystalline silicon solar panels With the rapid development of solar photovoltaic energy storage, its solar panel technology update iteration is also very

Polycrystalline Solar Panels Explained

Aug 13, 2025 · Find out everything about polycrystalline solar panels, including their definition, efficiency, pros and cons, and pricing details with Soly''s expert guide.

Demystifying Polycrystalline Solar Panels: How They Operate

Oct 11, 2024 · Asked Questions Polycrystalline solar panels are primarily made of semiconductor materials, with silicon being the most common material used in their construction.

What are the latest technologies in polycrystalline silicon PV panels

Jul 9, 2025 · The latest technologies in polycrystalline silicon PV panels are making solar energy more efficient, reliable, and cost-effective than ever before. From advanced cell design and

Which is Better, Polycrystalline or

Aug 7, 2023 · The advantage of using monocrystalline photovoltaic panels is the greater efficiency, even in low light conditions, such as cloudier days.

Polycrystalline Solar Panels: Specialties Unveiled

Nov 17, 2023 · Polycrystalline solar panels, also known as multi-crystalline panels, are a common type of solar panel used in residential and commercial

Polycrystalline Solar Panel Function,

Feb 7, 2025 · Polycrystalline solar panels convert sunlight into electricity through a series of well-coordinated steps. Initially, sunlight hits the surface of the solar

6 FAQs about [Polycrystalline silicon photovoltaic panels solar lights]

How do polycrystalline solar panels work?

As there are multiple silicon crystals in each cell, polycrystalline panels allow little movement of electrons inside the cells. These solar panels absorb energy from the sun and convert it into electricity. These solar panels are made of multiple photovoltaic cells.

How are polycrystalline solar panels made?

Several fragments of silicon are melted together to form the wafers of polycrystalline solar panels. In the case of polycrystalline solar cells, the vat of molten silicon used to produce the cells is allowed to cool on the panel itself. These solar panels have a surface that looks like a mosaic.

What is a polycrystalline solar cell?

In polycrystalline solar cells, silicon crystals are melted and fused together, resulting in a less uniform structure than monocrystalline solar cells. When light interacts with polycrystalline cells, it reflects off the non-uniform silicon crystal structure, giving the panels a characteristic bluish hue and speckled appearance.

What does a polycrystalline solar panel look like?

In the case of polycrystalline solar cells, the vat of molten silicon used to produce the cells is allowed to cool on the panel itself. These solar panels have a surface that looks like a mosaic. They have a square shape and a shining blue hue as they are made up of several polycrystalline silicon.

Can I buy a new polycrystalline solar system?

Polycrystalline solar panels now make up 0% of global production, so you almost certainly won’t find an installer offering to install a new polycrystalline system for any price. You can pay for used solar panels, but this is usually a bad idea.

Are polycrystalline solar panels eco-friendly?

Polycrystalline solar panels are more eco-friendly than monocrystalline solar panels as they do not require individual shaping and placement of each crystal and most of the silicon is utilized during production. So, very less waste is produced.

Industry Information

- Working principle of battery cabinet in energy storage power station

- 220v battery cabinet price

- Rabat exports energy storage power

- Independent energy storage grid

- Six 6-watt solar panels connected in parallel

- Future development trend of supercapacitors for communication base stations

- Customized container energy storage configuration

- High voltage lithium battery pack charging

- Construction of wind solar and energy storage projects in North Africa

- Ecuadorian high-performance energy storage battery company

- Hot sale high quality thermal breaker Wholesaler

- Bandar Seri Begawan Distributed Wind Power Generation System

- Praia Container Generator Communication Power Supply Department

- Inverter recommended high frequency and industrial frequency

- Guinea-Bissau photovoltaic off-grid energy storage manufacturer

- Where to buy photovoltaic communication battery cabinets in Brunei

- High Voltage PES Inverter

- Ulaanbaatar Solar Desert

- How much does an EK outdoor power supply cost

- Kitjia 80kw lithium battery energy storage system inverter

- Ghana Photovoltaic Panel Power Generation Company

- Dublin Off-Grid Inverter Installation

- Abuja imports energy storage batteries

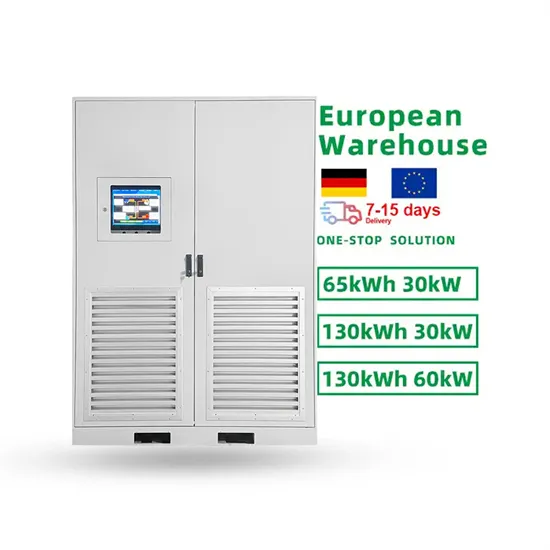

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

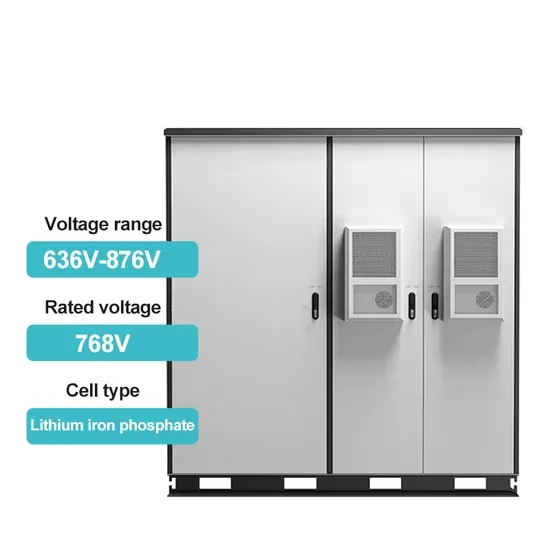

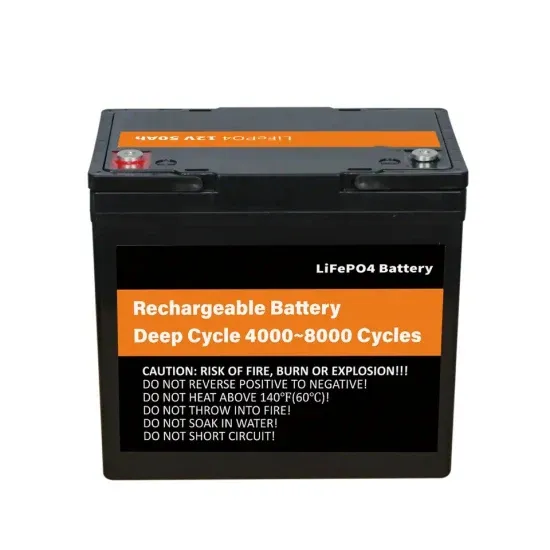

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.