The highest frequency and basic frequency of

May 14, 2024 · The maximum frequency is the maximum frequency that the inverter allows to output, expressed by fmax. Its specific meaning varies

Key Differences Between Frequency Inverters and Inverters

When should I choose a low-frequency inverter over a high-frequency inverter? You should choose a low-frequency inverter when your application requires handling heavy loads or high

What are the Types of Frequency Inverter?

Oct 22, 2023 · These frequency converters are typically used in low-power applications and high-frequency applications. Frequency inverters are

Top Industrial Frequency Inverters Compared for 2025

Compare top frequency inverter models for 2025, including Hitachi SJ-P1, Mitsubishi FR-A800, and more. Discover their performance, efficiency, and ROI insights.

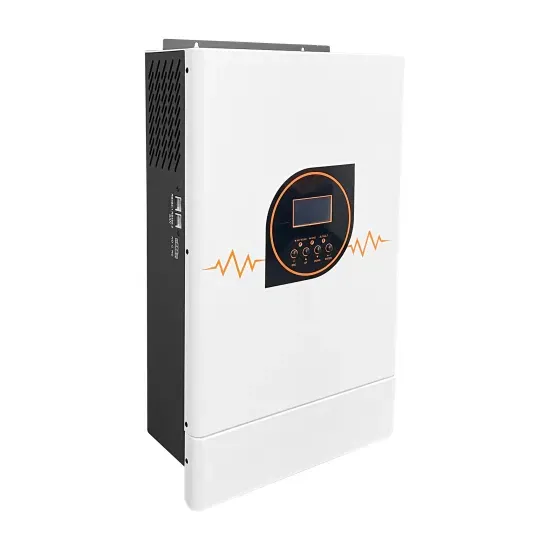

How to Distinguish High Frequency Inverter and Low Frequency Inverter

Apr 11, 2024 · The high frequency inverter can deliver the same power at higher frequency with a much smaller and lighter transformer, as a result, the HF inverter is often called transformer

High frequency inverter vs low frequency

Nov 2, 2023 · This article compares high frequency inverter vs low frequency inverter from the aspects of working frequency, components, efficiency, size

Technical comparison between Low Frequency

Aug 19, 2025 · What internal frequency the inverter circuits operate at – low frequency or high frequency (not to be confused with AC power output

Medium frequency and high frequency DC inverter

Apr 2, 2025 · Due to their different frequency characteristics, medium-frequency DC inverter transformers and high-frequency DC inverter transformers are suitable for industrial heating,

Low-Frequency vs. High-Frequency Inverters: Technical

Jul 17, 2025 · This analysis evaluates the performance characteristics of low-frequency (LF) and high-frequency (HF) inverters based on current industry data and technical literature. Key

Using Variable Frequency Drives and Instrumentation

Nov 16, 2020 · The high-speed switching of the inverter stage can emit significant radio frequency energy. Without mitigation, this energy can interfere with other nearby electrical equipment.

Industrial Frequency Converter

ABB Frequency Converter ABB Inverter occupies an important position in the frequency converter market with its stable performance, rich combination

Demystifying High Frequency vs Low Frequency

Jul 2, 2023 · The main difference between High-frequency and Transformer-based Low-Frequency Inverters/UPS is the frequency at which they operate.

High Frequency Inverter vs Low Frequency

Aug 18, 2025 · Discover the disparities between high frequency inverter vs low frequency inverter in this concise article, aiding your decision-making process.

High Frequency Inverter vs low Frequency Inverter

Conclusion In conclusion, the choice between high-frequency and low-frequency inverters depends largely on the specific needs of the application. High-frequency inverters offer the

Surge vs. Efficiency: Choosing Between Low and High-Frequency Inverters

Jul 25, 2025 · Line-Frequency vs. High-Frequency Inverters: A Technical Deep Dive for Engineers In the world of power electronics, the inverter is a cornerstone technology, responsible for the

Frequency Inverter Basic: Introduction, Functions

Dec 11, 2023 · Function of Frequency Inverter Speed Regulation Function: Frequency inverters can change the speed of the motor by adjusting the

Understanding Frequency Inverters: A Comprehensive Guide

Feb 23, 2025 · A frequency inverter, also known as a variable frequency drive (VFD), is an essential device used to control the speed and torque of electric motors by adjusting the input

High-frequency versus low-frequency inverters which is right

Jun 13, 2025 · Key Takeaways High-frequency inverters are small, efficient, and cost-effective, making them ideal for light loads and limited spaces like homes and offices. Low-frequency

Inversion Methods Explained: High Frequency vs Low Frequency

4 days ago · The large majority of inverters available in the retail market are high frequency. They are typically less expensive, have smaller footprints, and have a lower tolerance for industrial

Low frequency inverter vs high frequency

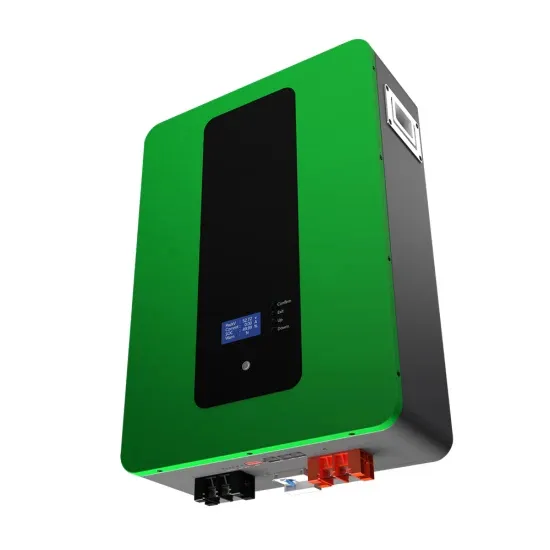

Mar 12, 2025 · When choosing an inverter for your solar system, one of the key decisions is whether to use a low-frequency inverter or a high-frequency

High Vs Low Frequency Inverters/UPS

Jul 1, 2023 · Let us compare High Vs Low-Frequency Inverters/UPS Comparison. Two kinds of commonly used Inverters/UPS; High Frequency and Low

Power Frequency Inverter vs. High Frequency

May 15, 2024 · High frequency inverter: High frequency inverters use high-frequency switching technology to chop DC power at high frequency through

Comparing High-Frequency vs. Low-Frequency

5 days ago · Inverters are essential components of many electrical systems, converting direct current (DC) into alternating current (AC) to power various

High-Frequency Bonding for Inverter-Driven Motors and

Jan 15, 2025 · To facilitate the flow of high-frequency currents and optimize the performance of inverter-driven motor systems, major motor and drive manufacturers recommend bonding all

The differences and similarities between high-frequency inverters

Industrial frequency inverters are usually used for higher power applications, such as home power systems, industrial power, etc. High frequency inverters are often used in applications that

The differences and similarities between high-frequency inverters

The frequency range of the inverter is affected by the application needs and specific requirements. Industrial frequency inverters are usually used for higher power applications, such as home

Ultimate Guide to Choosing the Best Frequency Inverter for

Jun 14, 2025 · This ultimate guide will explore the industry standards associated with frequency inverters, highlight common problems encountered during selection, and offer insights into

High Gain DC–AC High-Frequency Link Inverter With Improved

Feb 25, 2021 · This article presents a high gain pure sine- wave inverter based on the full-bridge dc–ac high-frequency link cycloconverter topology for telecom or general-purpose applications.

Surge vs. Efficiency: Choosing Between Low and High-Frequency Inverters

Jul 25, 2025 · High-frequency inverters represent a more modern approach, engineered to overcome the size and weight limitations of their line-frequency counterparts. The topology is

Mastering Inverter Switching Frequencies: A

Apr 25, 2024 · This frequency is critical in the conversion process from DC (direct current) to AC (alternating current) to efficiently drive electric motors. High

The difference between industrial frequency inverter and high frequency

Jan 6, 2021 · The high-frequency inverter first uses high-frequency DC/DC conversion technology to invert low-voltage direct current into high-frequency and low-voltage alternating current;

High-Frequency vs. Low-Frequency Inverters

Inverters are crucial components in solar power systems, uninterruptible power supplies (UPS), and other electrical systems. Their job is to convert DC (direct current) power into AC

A Complete Guide to Inverters/Variable

Jan 1, 2025 · There are a number of different types of inverters but we will be discussing the type that is used to control electric motors in electrical

Industrial frequency inverter, Industrial

Find your industrial frequency inverter easily amongst the 68 products from the leading brands (Bonfiglioli, NORD, INVT,) on DirectIndustry, the industry

The difference between high frequency inverter

May 15, 2024 · Low frequency inverters, on the other hand, may be more suitable for applications with inductive loads or where a higher level of harmonic

Power Frequency Inverter vs High-Frequency Inverter

Nov 14, 2024 · Power Frequency Inverter vs High-Frequency Inverter- Which One Should I Prefer? To conclude, power-frequency inverters and high-frequency inverters each have pros

The difference between industrial frequency inverter and high frequency

Jan 6, 2021 · Consumers are always entangled between industrial frequency inverters and high frequency inverters when purchasing inverters. What is the difference between the two? Which

Inversion Methods Explained: High Frequency vs Low Frequency

4 days ago · There are two distinct types of industrial grade power inverters distinguished by the size of their transformers, and the switching speed of their transistors. The ability of an inverter

High-Frequency Inverter: How They Work and

3 days ago · A high-frequency inverter is an electrical device that converts direct current (DC) into alternating current (AC) at a high switching frequency,

6 FAQs about [Inverter recommended high frequency and industrial frequency]

What is the output frequency of a high-frequency inverter?

The output frequency of the high-frequency inverter is much higher than the power frequency, usually between a few kilohertz and tens of kilohertz.

Are high-frequency inverters a good choice?

Due to the use of high-frequency switching technology, high-frequency inverters have the advantages of small size, lightweight, and high efficiency, but they also have the problem of relatively poor output waveform quality.

What are the advantages of high frequency inverters?

Volume and weight: Since high frequency inverters use high-frequency switching technology and compact circuit design, their size and weight are usually much smaller than power frequency inverters. This gives high frequency inverters significant advantages in mobile power supplies, aerospace, electric vehicles, and other fields.

Are power frequency inverters good?

In contrast, power frequency inverters can maintain high efficiency and stability under heavy load or overload. Output waveform quality: The output waveform quality of power frequency inverters is usually better than that of high frequency inverters.

Why are frequency drive inverters more efficient?

Efficiency and energy consumption: Because frequency drive inverters use high-frequency switching technology, their switching losses and iron losses are relatively small, so their efficiency is usually higher than that of power frequency inverters.

What is a power frequency inverter?

Inverter.com will conduct a detailed comparison and analysis of these two inverters from multiple perspectives to help you better understand their advantages and disadvantages and make a more informed choice. Power frequency inverter: Power frequency inverter usually refers to an inverter with an output frequency of 50Hz or 60Hz.

Industry Information

- Which is the best off-grid inverter in Montenegro

- Black Mountain Solar Photovoltaic Pump Factory

- Uninterruptible Power Supply Portable

- Container Energy Storage System Introduction Base Station

- Price of photovoltaic curtain wall

- Outdoor integrated battery cabinet

- Wholesale 10a circuit breaker in Afghanistan

- Sophia lithium battery pack factory

- What battery should I use with a 6v 45 watt solar panel

- Dili supports communication green base station

- Amman uninterruptible power supply solution design

- Congo downgrades PV module exports

- How much does a 300 watt solar panel cost

- Southern Europe rooftop photovoltaic panel manufacturer

- Factory price d curve breaker in Brisbane

- Two days camping outdoor power supply

- Armenia RV Outdoor Power Supply

- 2000w solar inverter in China in Burundi

- Roman lithium energy storage power customization company

- How many phases of power are used for mobile base station equipment

- Accra portable solar photovoltaic foldable container liquid cooling

- Huawei South Africa Outdoor Power Supply BESS

- Tokyo BESS sells brand new uninterruptible power supply recommendation

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.