What are the main environmental challenges associated with battery

Feb 13, 2025 · Pollution from Production: Battery production releases pollution and carbon emissions, contributing to ecological degradation beyond just carbon footprint. 3. End-of-Life

Battery Pollution: The Hidden Crisis Demanding Attention

Jun 29, 2025 · By highlighting the environmental impact of battery production, use, and disposal, we can encourage the development and adoption of sustainable alternatives, responsible

Reducing Electric Car Battery Pollution: Practical Solutions

May 16, 2024 · Discover effective strategies to reduce pollution from electric car batteries. Learn about battery recycling, repurposing for energy storage, design practices for easier recycling,

The Dark Side Of Batteries: Environmental Pollution

Jun 7, 2025 · The Dark Side of Batteries: Environmental Pollution — Uncovering the toxic truth behind battery production and disposal, and its devastating impact on the environment.

Battery Cars: Environmental Impact And Pollution Mystery

Jun 7, 2025 · In conclusion, while the production of EV batteries may initially cause pollution, the long-term benefits of reduced emissions and environmental impact associated with oil-based

How to reduce the greenhouse gas emissions and air pollution caused

The reduction of greenhouse gas emissions is one of the greatest global challenges through 2050. Besides greenhouse gas emissions, air pollution, such as nitrogen oxide and particulate

Lithium Batteries: Pollution Or Power Solution? | ShunWaste

Mar 22, 2025 · The rising demand for lithium-ion batteries has brought to light the pollution caused by their production, use, and disposal. Lithium extraction from ores is a complex process that

Assessing the environmental impacts associated with China''s battery

Jan 1, 2025 · Battery mineral production causes impacts on the environment and human health, which may increase the probability of supply restrictions imposed by exporting countries. As

Electric Car Batteries: Pollution Paradox? | ShunWaste

Mar 22, 2025 · Are electric car batteries environmentally friendly? Uncover the pollution paradox surrounding their production, use, and disposal.

5 Environmental Impacts of Battery Manufacturing

Modern technology relies heavily on batteries, which power everything from laptops and cellphones to electric cars (EVs) and renewable energy storage devices. It is impossible to

Main pollution caused by battery production

pollution caused by battery largely depends on the manufacturing technology and production requirements of the manufacturer. The pollution potential of batteries varies greatly. Therefore,

Electric Vehicle Batteries Surprising New Source

Jul 9, 2024 · Scientists have uncovered a new source of hazardous "forever chemical" pollution: the rechargeable lithium-ion batteries found in most

The Carbon Footprint of Battery Production and How to

Discover the carbon footprint of battery production and explore strategies to reduce it. Learn about sustainable practices in mining, manufacturing, and recycling for a greener future.

The Hidden Costs: Unearthing the Environmental

Aug 17, 2023 · One way to reduce the environmental impacts of battery production is to adopt cleaner production processes. This can include using

What are the Standards for Emission or Discharge of

May 2, 2025 · The battery manufacturing industry, which includes the production of lead-acid and dry cell batteries as well as lead recycling, releases harmful pollutants such as lead, mercury,

Management status of waste lithium-ion batteries in China

Jul 1, 2021 · As the biggest producer of batteries in the world, China has also taken necessary measures to deal with this situation. This paper presents the latest regulations of waste LIBs in

How to Deal With Battery Production

Aug 6, 2021 · If the lithium battery production wastewater that has not been thoroughly treated is directly discharged into the water environment, it will

Tesla Battery Environmental Impact: Pros and Cons

Jan 10, 2025 · Tesla batteries eliminate tailpipe emissions but their production involves lithium and cobalt mining, which can harm ecosystems and use large

Environmental Problems That Batteries Cause

Mar 13, 2018 · The increasing global demand for batteries is largely due to the rapid increase in portable power-consuming products such as cellular phones

The Impact of New Energy Vehicle Batteries on the Natural

Jun 28, 2023 · At present, new energy vehicles mainly use lithium cobalt acid batteries, Li-iron phosphate batteries, nickel-metal hydride batteries, and ternary batteries as power reserves.

The Environmental Impact of Lithium-Ion Battery

Mar 11, 2025 · Lithium-ion batteries are central to the modern energy landscape, powering everything from portable electronics to electric vehicles. However,

Understanding Lithium Battery Pollution and Its

Mar 7, 2025 · Lithium batteries have become an essential part of our modern lives, powering everything from smartphones to electric vehicles. However, as

What is the environmental impact of a battery?

Nov 22, 2023 · What''s the carbon footprint of electric batteries? From cars to phones, find out if electric power truly reduces emissions, or shifts the impact

Battery Production''s Pollution Problem | ShunWaste

Jun 28, 2025 · The environmental impact of battery production is a highly debated topic, with the world seeking cleaner alternatives to combat climate change. The manufacturing process of

Battery Disposal: An Overlooked Environmental Hazard

Jun 14, 2025 · Landfill pollution: batteries end up in landfills, releasing toxic chemicals Batteries that are not recycled often end up in landfills, which can cause serious environmental damage.

The Dark Side Of Batteries: Pollution Generated | ShunWaste

Jun 22, 2025 · The production of batteries, especially lithium-ion batteries, has been associated with pollution and environmental degradation. Lithium mining contributes to this issue, as it

Five Key Insights into Lithium Ion Battery Pollution and Its

Mar 2, 2025 · The production phase of lithium-ion batteries generates considerable pollution. During this phase, various chemicals and heavy metals are released into the environment,

Lithium Batteries'' Dirty Secret: Manufacturing

Oct 16, 2018 · Once in operation, electric cars certainly reduce your carbon footprint, but making the lithium-ion batteries could emit 74% more CO2 than

Environmental impact of emerging contaminants from battery waste

Jun 1, 2021 · The full impact of novel battery compounds on the environment is still uncertain and could cause further hindrances in recycling and containment efforts. Currently, only a handful

How Much Pollution Creates Batteries

Feb 14, 2025 · Battery production in clean technologies like electric cars and solar power produces significant pollution, with lithium-ion batteries emitting around 15 tonnes of CO2

Soil, air, and water pollution from mining and industrial

Sep 1, 2024 · Mining activities, as essential components of industrial development, play a crucial role in the economy. However, they often entail significant environmental consequences,

The Environmental Impact of Battery Production

Jan 11, 2023 · There are two primary environmental costs relating to an electric car – the manufacturing of batteries and the energy source to power these

How much CO2 is emitted by manufacturing

Aug 8, 2025 · It depends exactly where and how the battery is made—but when it comes to clean technologies like electric cars and solar power, even the

The Dark Side Of Batteries: Pollution And Environmental

Mar 27, 2025 · The pollution caused by mining and manufacturing batteries is not limited to the production stage but extends to the disposal and recycling of batteries. While lead-acid

Burning the Rubber: The Environmental Impact

Dec 17, 2023 · Additionally, the production of electric car batteries requires significant amounts of energy that produce greenhouse gas emissions and

Lithium ion battery energy storage systems (BESS) hazards

Feb 1, 2023 · There has been an increase in the development and deployment of battery energy storage systems (BESS) in recent years. In particular, BESS using lithium-ion batteries have

What is the environmental impact of a cabinet

Jun 12, 2025 · Lead is a highly toxic heavy metal, and the production and disposal of lead - acid batteries can cause serious environmental pollution. In contrast,

Battery-Powered Vehicles: Cleaning Up Our

Dec 17, 2023 · However, there are some concerns about the pollution associated with the production and disposal of electric car batteries. While it is true that

6 FAQs about [How to deal with pollution caused by battery cabinet production]

What is the policy on pollution prevention techniques of waste batteries?

The Policy on Pollution Prevention Techniques of Waste Batteries was released by the Ministry of Ecological and Environment (MEE) on 26 December 2016, which mainly includes the pollution prevention and control technologies on waste LIBs collection, transportation, storage, utilization, and disposal.

Are new battery compounds affecting the environment?

The full impact of novel battery compounds on the environment is still uncertain and could cause further hindrances in recycling and containment efforts. Currently, only a handful of countries are able to recycle mass-produced lithium batteries, accounting for only 5% of the total waste of the total more than 345,000 tons in 2018.

How does battery manufacturing affect the environment?

The manufacturing process begins with building the chassis using a combination of aluminium and steel; emissions from smelting these remain the same in both ICE and EV. However, the environmental impact of battery production begins to change when we consider the manufacturing process of the battery in the latter type.

Are batteries harmful to the environment?

For batteries, a number of pollutive agents has been already identified on consolidated manufacturing trends, including lead, cadmium, lithium, and other heavy metals. Moreover, the emerging materials used in battery assembly may pose new concerns on environmental safety as the reports on their toxic effects remain ambiguous.

Is battery leakage a pollution hazard?

Nevertheless, the leakage of emerging materials used in battery manufacture is still not thoroughly studied, and the elucidation of pollutive effects in environmental elements such as soil, groundwater, and atmosphere are an ongoing topic of interest for research.

Does China have a good waste lithium-ion battery management?

After so many years of continuous development, China has also made great progress in waste LIB management. However, there are still some problems in the details of waste lithium-ion battery management, which led to the unsatisfactory recovery effect of waste LIBs. To this end, some management suggestions are put forward:

Industry Information

- Angola Photovoltaic Power Station Energy Storage Solution

- Kenya container energy storage system prices

- Guinea Photovoltaic New Energy Storage Field

- Building solar photovoltaic panels in rural areas

- 48 inverter can connect to 12V

- Moscow outdoor inverter manufacturer

- Factory price 110 amp breaker in Puerto-Rico

- High frequency inverter rotation

- Energy storage inverter brand

- Communication base station inverter related products

- What equipment do solar water pumps need

- What is the size of the photovoltaic 620 panel

- Energy storage battery charging equipment

- Cost of large energy storage cabinet in Skopje

- Current independent energy storage power stations

- Dubai Communications Green Base Station 372KWh

- How to view the battery of wind power in communication base stations

- Oslo photovoltaic curtain wall price

- North Korea s energy storage battery assembly

- INR21700E5500 battery

- Spanish folding container wholesale

- High quality solar battery storage factory supplier

- Botswana UPS uninterruptible power supply manufacturer

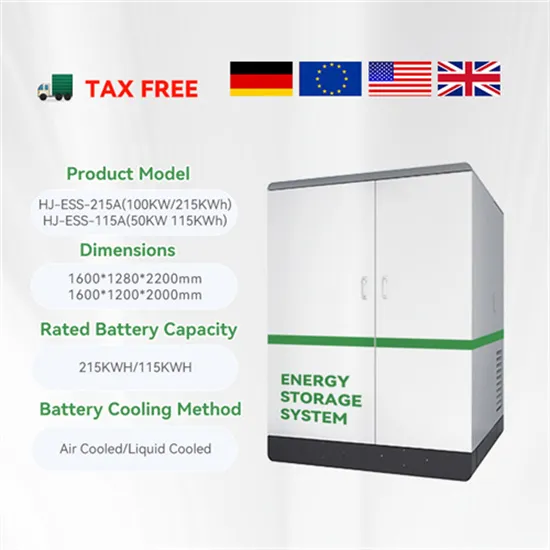

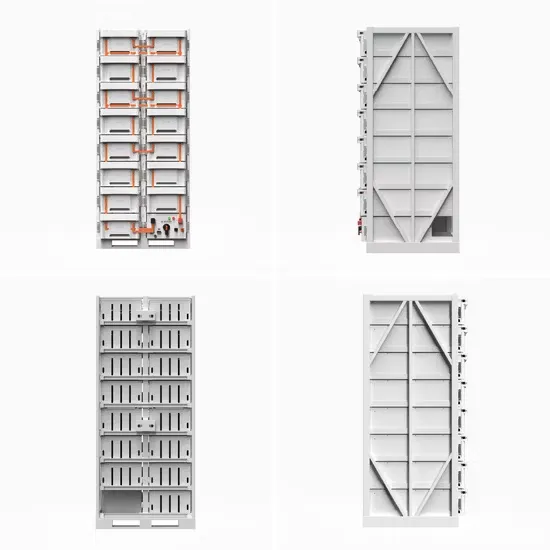

Commercial & Industrial Solar Storage Market Growth

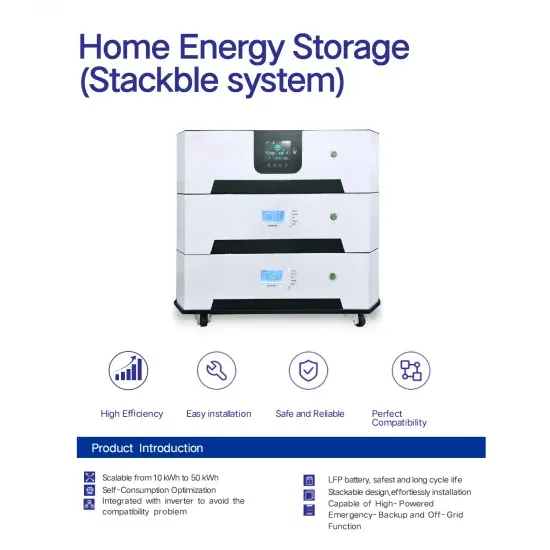

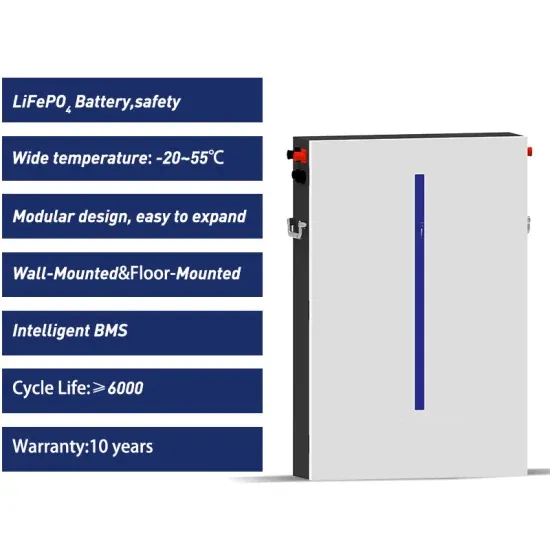

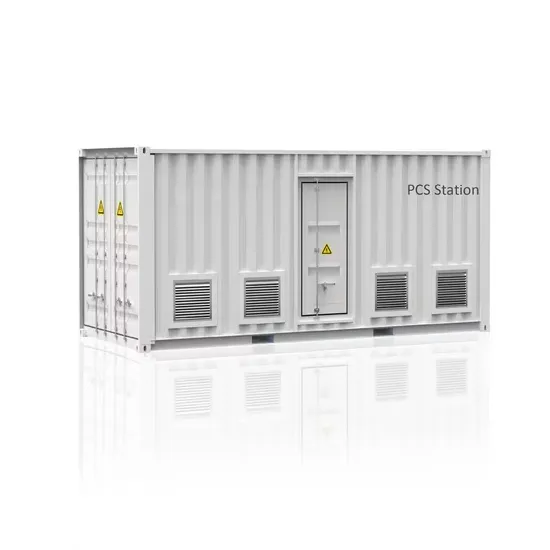

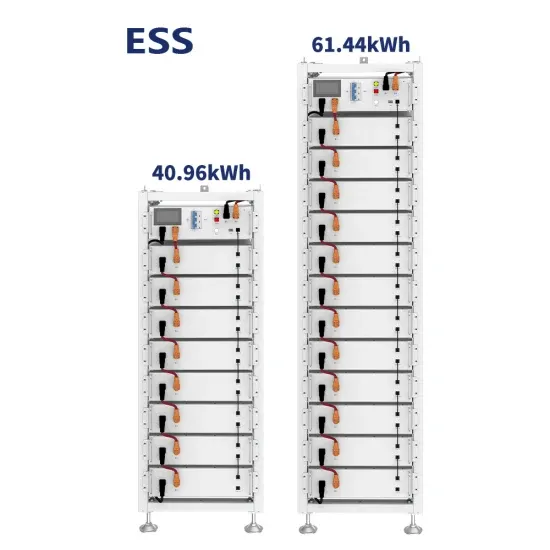

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

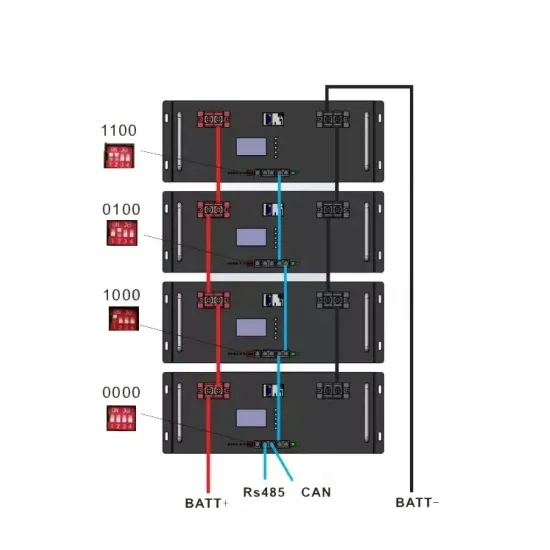

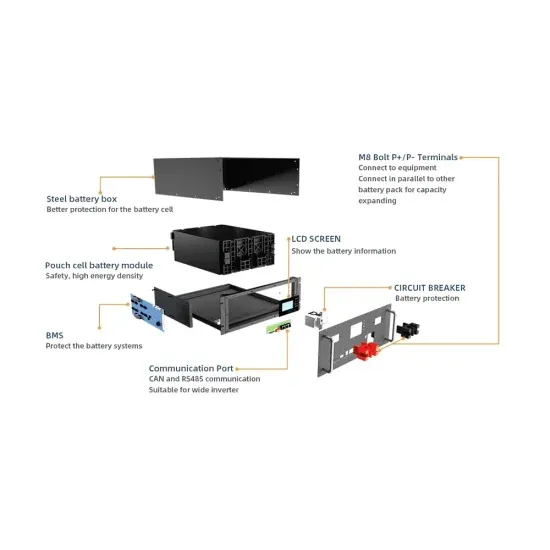

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.