From Inverter Testing to Power Electronics based Test

Dec 4, 2019 · Energy, stored in the fuel tank is transferred into rotating kinetic energy by the combustion engine which acts as the "powerprocessor". The gear box matches the rotation

Understanding High-Frequency Inverters

6 days ago · In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to

Power Frequency Inverter vs. High Frequency

May 15, 2024 · In the field of power electronics and energy conversion, inverters, as key equipment for power conversion, play a vital role. Inverters are capable

Frequency Inverters for Your Drives | SEW‑EURODRIVE

SEW‑EURODRIVE produces high-quality frequency inverters for controlling the speed of AC motors in your applications and production processes.

Mastering These 16 Frequency Inverter

Jan 23, 2025 · The typical maximum frequency for inverters is up to 60Hz, with some reaching 400Hz. High frequencies allow motors to operate at high

The 3 Most Common Faults on Inverters and

At IDS we have a wealth of inverter experience. We have been an ABB Partner for over 20 years and are used to supporting clients with a variety of inverter

What is a High-Frequency Power Inverter?

1 day ago · Introduction A power inverter converts DC power into AC power for operating AC loads and equipment. High-frequency power inverters utilize

Understanding High-Frequency Inverters

6 days ago · Benefits of High-Frequency Inverters: Uncover the advantages offered by high-frequency operation, such as reduced size, improved efficiency, and noise suppression.

Frequency Inverter in Numerical Control Machine

Sep 5, 2018 · V. Characteristics of the Frequency inverter This magnetic flux vector control frequency inverter adopt up-to-date technology in automation control industries, integrated

Low Frequency VS High Frequency Inverter

May 2, 2023 · Discover the differences between low-frequency and high-frequency off-grid inverters, their efficiency, weight, and ideal applications for

A High Performance High Frequency Inverter Architecture

Oct 14, 2021 · In this work, a high frequency inverter system that can work in a wide range of inductive or capacitive load is proposed, which includes Class D inverter, novel

Frequency Inverters for Your Drives

SEW‑EURODRIVE produces high-quality frequency inverters for controlling the speed of AC motors in your applications and production processes.

High-Frequency Bonding for Inverter-Driven Motors and

Jan 15, 2025 · To facilitate the flow of high-frequency currents and optimize the performance of inverter-driven motor systems, major motor and drive manufacturers recommend bonding all

800VA Pure Sine Wave Inverter''s Reference Design

Apr 1, 2023 · The pure Sine Wave inverter has various applications because of its key advantages such as operation with very low harmonic distortion and clean power like utility-supplied

High Gain DC–AC High-Frequency Link Inverter With Improved

Feb 25, 2021 · This article presents a high gain pure sine- wave inverter based on the full-bridge dc–ac high-frequency link cycloconverter topology for telecom or general-purpose

An Intelligent Frequency Control Scheme for Inverting Station in High

Jan 22, 2025 · However, our current research aims on improving frequency control at Inverter station in HVDC transmission system by implementing advanced algorithms like ANN, ANFIS,

What is Frequency Converter? How it works?

But, it will always be there in high quality, general purpose frequency converters (those manufactured by dedicated frequency converter manufacturers).

Solid-State Transformer (SST)-Based High-Frequency MV

Jan 30, 2025 · The solid-state transformer (SST) technology offers attractive features for high-frequency marine propulsion drives. Existing solutions based on Si-IGBTs face limitations due

Impact of high-frequency harmonics (0–9 kHz) generated by

Nov 1, 2020 · Pulse Width Modulated (PWM) voltage generated by power converters can generate significant high-frequency harmonics at its switching frequency. The switching

Frequency inverters | Explanation, function

Frequency inverters: Definition, function, design, advantages + areas of application of frequency converters. Click here to find out more!

CSM_Inverter_Selection_TG_E_2_1

Oct 23, 2012 · Forward rotation direction is forward for the speed, and the torque in the forward rotation direction is forward for the torque. Calculate a braking torque using the above "Motor

Understanding inverter frequency – effects and adjustments

Oct 1, 2024 · In most regions, the standard inverter frequency for AC power systems is 50 or 60 Hz, representing the number of complete cycles per second. This inverter frequency is

Inverters-FREQROL | Products | MITSUBISHI

Jan 31, 2025 · Inverters are variable frequency power supply units which can change the rotation speed of the three-phase induction motors easily and

How does an inverter work?

3 days ago · We''ll start the introduction by explaining the inverter device''s mechanism in detail. The inverter device''s role is to control the voltage and

AKX00057-1

Jul 26, 2018 · While the output voltage of a two-level PWM inverter takes either the zero or High level, three-level and multilevel PWM inverters provide the output voltage at multiple levels by

Which is Better Low Frequency or High

3 days ago · Introduction Inverters convert DC power into AC power to operate AC equipment and devices. They utilize power electronic switching at different

High frequency vs low frequency pure sine wave

Aug 16, 2016 · By definition, Low frequency power inverters got the name of "low frequency" because they use high speed power transistors to invert the DC

MIT Open Access Articles A High Frequency Inverter for

Oct 1, 2022 · zero voltage switching needed for high efficiency operation at high frequency. While an inverter can be inductively preloaded to provide the needed inductive load current for zero

Mastering These 16 Frequency Inverter

Jan 23, 2025 · High frequencies allow motors to operate at high speeds, which can strain the bearings and rotors of standard motors beyond their rated

Induction motors fed by PWM frequency inverters

Mar 30, 2021 · The analysis of the formula above shows that the mechanical speed of an induction motor is a function of three parameters. Thus the change of any of those parameters

Nine-level high-frequency inverter

Aug 7, 2024 · At present, to generate HFAC output, existing inverters mainly use a DC/AC inverter to produce high-frequency square wave or high-frequency quasi-square wave output,

6 FAQs about [High frequency inverter rotation]

What are the topologies of high-frequency inverters?

Topologies of High-Frequency Inverters: Examine the different topologies used in high-frequency inverters, including half-bridge, full-bridge, and multilevel. Modulation Techniques: Discover various modulation techniques employed in high-frequency inverters to control the output AC waveform.

What are the advantages and disadvantages of high frequency inverters?

Benefits of High-Frequency Inverters: Uncover the advantages offered by high-frequency operation, such as reduced size, improved efficiency, and noise suppression. Topologies of High-Frequency Inverters: Examine the different topologies used in high-frequency inverters, including half-bridge, full-bridge, and multilevel.

What is a high-frequency inverter?

In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to transform direct current (DC) into alternating current (AC) at remarkably high frequencies, unlocking a world of boundless possibilities.

What is a modulation technique in a high-frequency inverter?

Modulation Techniques: Discover various modulation techniques employed in high-frequency inverters to control the output AC waveform. Applications of High-Frequency Inverters: Explore the vast range of applications for high-frequency inverters, including motor drives, renewable energy systems, and power grid integration.

What is a high frequency variable load inverter?

ut Pmax VINmax13:56MHz21:31kW375VIV. CONTROL SCHEMEA. Control ChallengesIn Section II the high frequency variable load inverter was modeled with each constituent inverter as an ideal voltage source that could drive any resistiv / inductive load, only sub-ject to maximum output voltage and current limits. However, real inverters h

What is a standard inverter frequency?

In most regions, the standard inverter frequency for AC power systems is 50 or 60 Hz, representing the number of complete cycles per second. This inverter frequency is essential for the proper functioning of electrical devices and systems, as it dictates the speed at which motors rotate, lights flicker, and electronic components operate. 2.

Industry Information

- Hot sale new circuit breaker for sale Factory

- How to connect the energy storage cabinet to the load

- Kathmandu Solar Energy Storage Inverter

- Bridgetown restricts PV inverters

- Energy storage container power station outdoor site

- What is the price of inverter in Milan Italy

- 98KW inverter

- Skopje DC uninterruptible power supply manufacturer

- Mobile lithium battery station cabinet

- Use energy storage cabinet batteries to charge energy storage

- Circuit breaker fuse in China in Moscow

- Myanmar Energy Storage Power Station 2025

- Bahamas New Energy Container Energy Storage

- Djibouti home photovoltaic inverter price

- Kyiv photovoltaic energy storage project construction

- Honiara PV grid-connected inverter

- Algiers energy storage low temperature lithium battery

- Outdoor energy storage vehicle franchise fee

- Libya 2025 Energy Storage Project

- Southern European air energy storage battery companies

- Communication green base station and other batteries

- What to do with mobile power photovoltaic battery cabinet

- Factory energy storage power station solves virtual electricity

Commercial & Industrial Solar Storage Market Growth

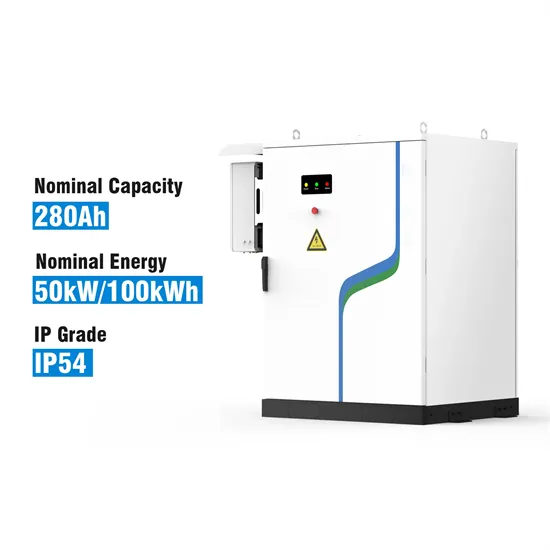

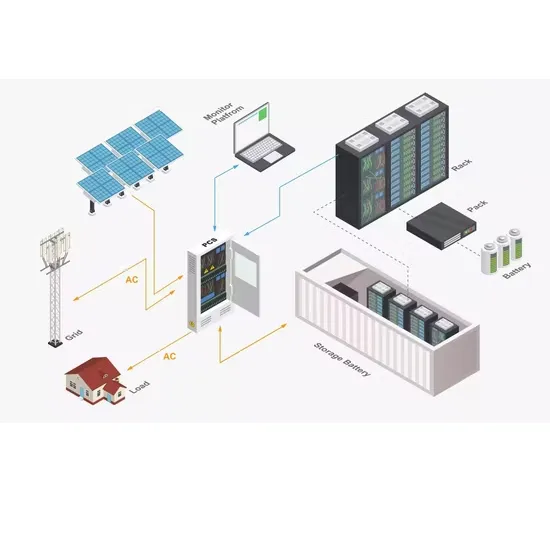

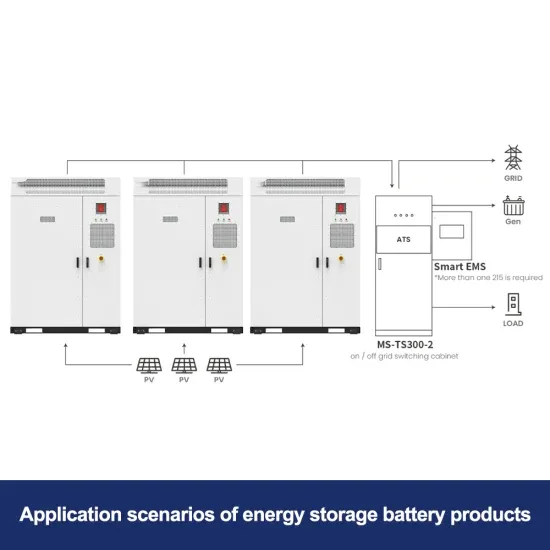

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

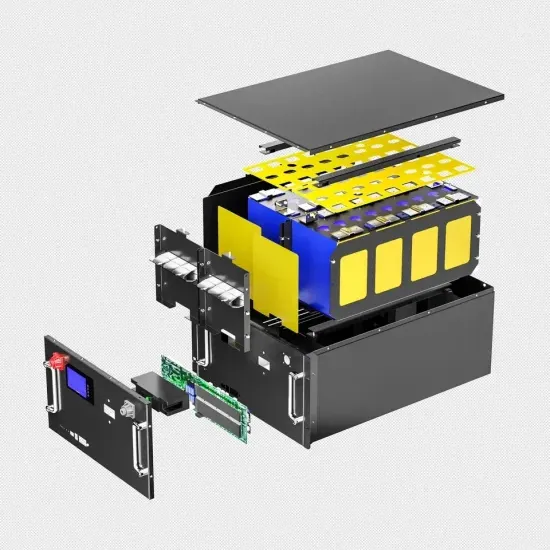

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.