A Novel Lithium-ion Battery Pack Modeling Framework

Jul 3, 2020 · In this paper, a novel physics-based modeling framework is developed for lithium ion battery packs. To address a gap in the literature for pack-level simulation

Polarium® Battery Smarter, Stronger and Safer Lithium Batteries

This requires batteries that can do more than just store energy. Polarium Battery is our series of intelligent, connected, and robust batteries built on lithium-ion battery technology, with a

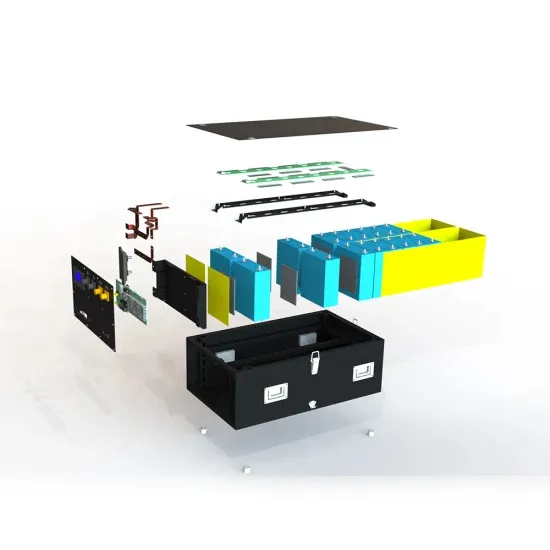

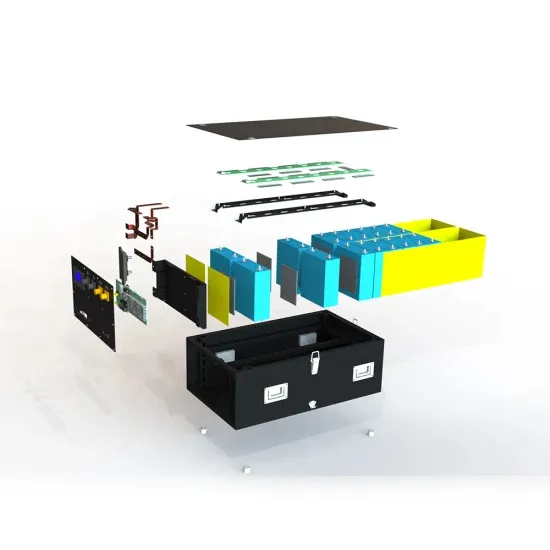

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · From precise cell welding to smart BMS integration—uncover how lithium-ion battery packs are engineered for safety and power.

18650 Battery Pack

18650 Battery Pack Our 18650 battery packs are designed to deliver reliable, high-density power for applications such as portable electronics, electric tools,

Paul C. Buff, Inc. | Portable Power

All Vagabond™ products containing a lithium battery (the VM120 Vagabond Mini™ Lithium system or the VMBA8.6A spare battery) are subject to a $22.50 Air Regulation Fee if the

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

BQSTUDIO-STABLE Application software & framework | TI

May 7, 2020 · BQSTUDIO-STABLE Battery Management Studio (bqStudio) Software – stable version downloads for bq series of TI battery fuel gauges

How To Create Active Material In Battery Design Studio

Dec 27, 2024 · Simcenter™ Battery Design Studio™ software is a tool that helps engineers digitally validate lithium-ion (Li-ion) cell design through detailed geometrical cell specifications

Comparison of Different Packaging Methods for Lithium-ion Batteries

Lithium-ion batteries are divided into two categories, hard casesoft pack, according to the different s of the cells. The materials of the hard are mainly steel aluminum s, while the soft pack uses

BatteryStutio

Mar 16, 2024 · This document provides an operation manual for the Battery Studio BMS HMI software. It describes how to install the software, quickly start

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Among various energy storage technologies, lithium-ion battery packs have emerged as the preferred choice due to their high energy density, long cycle life, and

Wio Terminal Chassis

The Wio Terminal Battery Chassis is a must-have extension board for Wio-Terminal Dev Board as it provides an external power source for Wio Terminal

Power Packs | Studio Lighting | Park Cameras

Power Packs Power packs are used for studio lighting to regulate the power supply between the mains and the studio flash head. Using a power pack prevents surges into flash heads which

Battery Modeling

Battery Modeling APPLICATION HIGHLIGHTS Predict electric vehicle range and performance using simplified lumped electrical-equivalent battery models

Applications of Commercial Software for Lithium-Ion Battery

Mar 15, 2023 · The advent of lithium-ion battery electric vehicles (BEVs) created a significant market for software to design and simulate batteries primarily because of the importance of

Custom battery pack design with lithium ion

Many companies can arrange lithium-ion cells in a cradle and create a battery pack, but few can develop a pack from analytical models. There is great

Simcenter Battery Design Studio

Apr 30, 2024 · Using SimcenterTM Battery Design StudioTM software supports you in digitally validating lithium-ion (Li-ion) cell design thanks to detailed geometrical cell specifications and

Computational fluid dynamic and thermal analysis of Lithium-ion battery

Sep 1, 2016 · In this work, computational fluid dynamic analysis is performed to investigate the air cooling system for a 38,120 cell battery pack. The battery pack contained 24 pieces of 38,120

How to Build a Custom Lithium Battery Pack:

Mar 20, 2025 · Custom lithium batteries power everything from EV conversions to solar storage systems and DIY robotics. Compared to off-the-shelf options,

Battery Pack Modeling

These MATLAB objects allow you to define your own battery design specifications, visualize your battery in a 3-D space, customize the modeling

A Leading Expert in Lithium-based Renewable

Xupai, founded in 1995, is a leading producer of lead acid batteries in China. Motivated by a passion for green energy, Xupai established Superpack, a joint

Battery Pack Modeling

Build battery models using MATLAB and SimscapeSimscape™ Battery™ includes MATLAB ® objects and methods to automate the creation of

Modelling Software

NREL has developed software tools to help battery designers, developers, and manufacturers create affordable, high-performance lithium-ion (Li-ion) batteries for next-generation electric

A user-friendly lithium battery simulator based on open

Dec 1, 2022 · The growing use of lithium-ion batteries (LIBs) for automotive and stationary storage applications has put increasingly stringent requirements on battery thermal management and

Battery Design and Simulation Software

5 days ago · Altair battery design and simulation software reduces prototyping and development costs while optimizing battery safety, performance, range,

(2-Pack) 3.7V 2600mAh Li-ion Replacement

Apr 25, 2021 · About this item HIGH-CAPACITY DESIGN: 2600mAh Li-ion battery provides extended music playback time for your Onyx Studio wireless

Battery Production Flyer: Lithion Ion Cell Production

Feb 7, 2024 · The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode

Battery Design Studio

Battery Design Studio® is a unique tool that allows engineers to design battery cells, simulate performance, and analyse data from both simulation and test

Battery Modeling and Simulation Software | Ansys

Aug 17, 2025 · Ansys battery modeling and simulation solutions use multiphysics to help you maximize battery performance and safety while reducing cost and testing time.

Build your own Lithium battery pack

Jun 20, 2019 · Check out the two tutorials embedded below to learn how to design your very own lithium battery and build your very own lithium battery

bq27750 1-Series Li-Ion Battery Pack Manager

Jun 7, 2017 · The circuit module includes one bq27750 integrated circuit (IC) and all other onboard components necessary to monitor and predict capacity, monitor critical parameters,

Re-think Lithium-ion battery cell design now

Sep 11, 2024 · Simcenter STAR-CCM+ 2310 offers a new unique capability for lithium-ion battery cell design in 3D with high geometric and physical fidelity.

锂电池pack基础知识

Apr 17, 2020 · 锂电池 电芯组装成组的过程称为 PACK,可以是单只电池,也可以是串并联的电池模组等。当下新国标大背景下,锂电池需求量越来越大,很多

Lithium Ion (Li-Ion) Battery Packs

Mar 5, 2024 · Lithium-ion cells whose equivalent lithium content exceeds 1.5 grams or 8 grams per battery pack must be shipped as "Class 9 miscellaneous hazardous material." Cell

6 FAQs about [Pack lithium battery studio]

What is a lithium-ion battery pack?

Among various energy storage technologies, lithium-ion battery packs have emerged as the preferred choice due to their high energy density, long cycle life, and lightweight properties. In this blog post, we will delve into the key steps and considerations involved in designing a lithium-ion battery pack.

What is Simcenter battery design studio?

Simcenter Battery Design Studio helps engineers digitally validate Li-ion cell design through geometrical cell specifications and cell performance simulation.

How safe is a lithium-ion battery pack?

Safety is paramount in lithium-ion battery pack design. Here are some key safety considerations: Overcharge Protection: Implement safeguards to prevent overcharging, which can lead to thermal runaway and fire. Over-Discharge Protection: Prevent cells from discharging below their safe voltage limit to avoid permanent damage.

Does Simcenter battery design studio support Li-ion cell types?

Templates are available for a wide range of cell types and a comprehensive material database makes it easy to set up accurate cell models. Furthermore, the tool supports you by automatically setting up performance analysis. Simcenter Battery Design Studio supports a wide range of Li-Ion cell types.

Why should you use Simcenter battery design studio?

Why Simcenter Battery Design Studio? Simcenter Battery Design Studio supports engineers in digitally validate Li-ion cell design thanks to details geometrical cell specifications and cell performance simulation. Extensive components of a battery cell are available, as well as a material database to support your model development.

What is a battery pack model?

The generated battery pack model contains two types of battery modules, each with different battery cell components inside. Use this example to analyze the performance effects of combining different battery cells within a single battery system, such as power capability versus range.

Industry Information

- Tehran Energy Storage Battery Cabinet Photovoltaic Technology

- Solar lights can provide 5000mah lighting for several hours

- What to do if the wind and solar power complement each other in communication base stations overlap

- Photovoltaic inverter stm32dsp

- Zimbabwe energy storage battery

- Oman outdoor inverter factory direct sales

- Photovoltaic curtain wall utilization rate

- Diversification of energy storage batteries

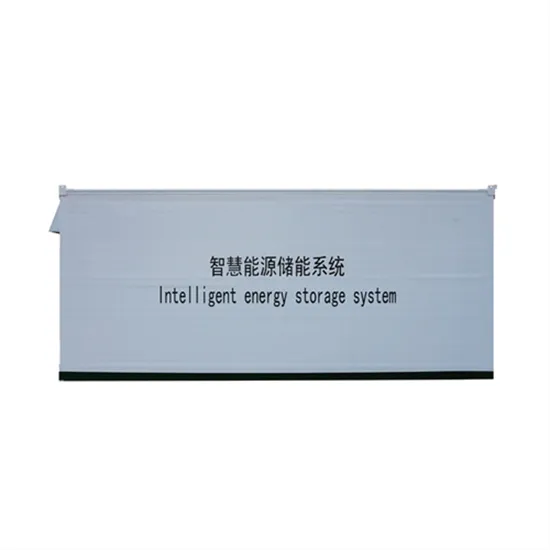

- AC side modular energy storage system

- Kingston s first mobile energy storage station opens

- How to open Huawei energy storage battery cabinet

- North America Outdoor Communication Battery Cabinet Charging and Discharging System

- Container modified dual fuel generator

- Quality requirements of lithium batteries for battery packs

- Wholesale main breaker switch in Germany

- Austrian power grid energy storage companies

- How big should a solar water pump be

- Amount of lithium batteries used in Huawei 5G base stations

- New energy storage quotation in Gothenburg Sweden

- Huawei power storage vehicle customization

- Lithium battery for Windhoek energy storage system

- Huawei s energy storage system in Mexico

- Photovoltaic panels and batteries can be connected in series

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.