BIS Registration for Lithium-Ion Batteries: Complete Guide

May 6, 2025 · Get the complete 2024 guide to BIS registration for lithium-ion batteries in India. Learn about IS 16046 standards, application steps, documentation, penalties & how Induce

How to Select the Best Lithium Battery for Unmanned Survey

11 hours ago · Select the best lithium battery for unmanned survey vessels by focusing on capacity, safety, chemistry, and certified supplier quality.

Quality Control and Management Systems for Lithium-Ion Battery

Apr 23, 2025 · In response to increasing environmental concerns and the transition toward electromobility, lithium-ion batteries (LIBs) have become the dominant energy source for

Ինչպես ընտրել լավագույն լիթիումային մարտկոցը

Selecting a lithium battery for unmanned survey vessels requires you to focus on energy capacity, durability, safety, and supplier quality. You must evaluate lithium battery for unmanned survey

Quality Assurance for Lithium

Jan 18, 2024 · s - speed, accuracy, robustness and operational costs. Combined with the power of intelligent algorithms, machine-learning and digital twin modelling, the impedance data of

Understanding Global Lithium Battery Standards and

Feb 11, 2025 · SAE provides important guidelines for lithium batteries in transportation industries. This includes safety requirements for EV battery systems (SAE J2929), abuse testing

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · The paper analyzes the design practices for Li-ion battery packs employed in applications such as battery vehicles and similar energy storage systems. Twenty years ago,

Quality Management for Battery Production: A

Dec 31, 2016 · In order to reduce costs and improve the quality of lithium-ion batteries, a comprehensive quality management concept is proposed in this

Battery Certification 2025: Types, Costs and

Aug 14, 2024 · Why is Battery Certification Important? Safety Assurance: Certification helps to ensure that batteries do not pose safety risks, such as

Understanding Certifications for Custom Battery

Understanding Certifications for Custom Battery Packs Custom battery packs are designed to meet specific application requirements, making them highly

UL Certifications for Lithium Batteries: Cell vs. Pack Level –

Nov 4, 2024 · Verifying its pack-level UL certifications is important to ensure your battery meets the highest safety standards. Here''s how: Check the UL Mark: Look for the UL label on the

A Complete Guide to Lithium Battery

Mar 17, 2025 · Understand lithium battery certifications, their mandatory vs optional types, and their role in safety, compliance, and marketability for global

Battery Pack Certifications – Costs, Timelines and Key

The result: a faster path to market, reduced costs, and total confidence in your product''s compliance. Lithium battery safety is at the top of the list for anyone who manufactures custom

Lithium-Ion Battery Solutions

Microvast is a leader in the innovation and technology of lithium-ion (Li-ion) batteries. We design, develop, and manufacture premier battery cells,

Battery Regulations and Compliance

Learn how to meet battery regulations and compliance requirements. This guide offers tips for safety, labeling, and legal compliance.

Lithium-Ion Battery Standards | Artech books | IEEE Xplore

Feb 4, 2025 · The book explains the differences between Lithium-ion batteries and other battery systems, highlighting the critical importance of system integration and design. It offers insights

Battery brochure_11-4-12

Jul 5, 2022 · Global standards and customer requirements define the performance, reliability and endurance of Lithium batteries. Ranging from small cells to heavy vehicle battery systems, the

What Quality Control Standards Govern Lithium-Ion Rack Battery

May 10, 2025 · How Do UL 1973 and IEC 62619 Ensure Battery Safety? UL 1973 and IEC 62619 are critical standards for lithium-ion rack batteries. UL 1973 focuses on stationary storage

Battery Pack EOL Test: Ensure Safety

Jan 21, 2025 · In the fast-evolving world of lithium-ion batteries, ensuring the performance and safety of battery packs is crucial. One key procedure to

Latest Standardization, Certification and Regulatory

May 2, 2024 · What are applicable standards for micromobility, portable & wearable use batteries? IEC and UN UN 38.3 - UN Manual of Tests and Criteria, Lithium Metal and Lithium

Understanding Lithium Battery Testing

Sep 19, 2024 · Learn how lithium battery testing standards ensure safety, reliability, and compliance. Discover key tests like capacity, thermal, and cycle

Challenges and opportunities for high-quality battery

Jan 12, 2025 · Here we highlight both the challenges and opportunities to enable battery quality at scale. We first describe the interplay between various battery failure modes and their

Export Notice: Implementation of Mandatory CCC

Mar 14, 2024 · The main standard for CCC certification of lithium batteries is the national mandatory standard GB31241 "Safety Technical Specifications for Lithium-ion Batteries and

CHINA QUALITY CERTIFICATION CENTRE CO.,LTD.-Notice

Aug 7, 2025 · Accordingly, China Quality Certification Centre (CQC) has formulated CQC-C0902-2025 "Implementation Specifications for Mandatory Product Certification of Power Banks,

Lithium Battery Regulations and Standards in the

Oct 31, 2024 · Summary of Lithium Battery Regulations in the United States As an expert in the area, I have actually seen the development of lithium battery

BIS Certification and Standards for Batteries: A

Jan 4, 2025 · For products like batteries, this certification ensures that they are safe to use, efficient, and environmentally friendly. When it comes to batteries,

Quality Assurance: Risk Mitigation for Lithium

5 days ago · Quality and your safety are the main requirements of Li-ion battery packs. For the development and manufacture of Li-ion battery packs, many

Custom Battery Packs, Lithium Battery Packs

We also have professional engineers and technicians with rich experience in providing innovative and high-quality battery packs. Whatever your project

Best Practice Nondestructive Testing for EV Battery Packs,

Jun 27, 2025 · Industry Standards Help Battery Manufacturers Improve Quality Until recently, leak testing of lithium-ion battery packs for EVs was left to the discretion of the battery

Battery Module and Pack Testing for

5 days ago · Our battery module and pack testing expertise We offer testing of battery products for use in a variety of motive or transportation-related

How Battery Pack Design Influences Portable Oxygen

11 hours ago · The energy density of lithium-ion battery packs used in portable oxygen concentrator battery pack design typically ranges from 180 to 300 Wh/kg, depending on the

How To Ensure Quality in Lithium-Ion Battery Production

Nov 27, 2024 · The demand for high-performance lithium-ion batteries continues to surge, driven by the global shift toward clean energy and electric vehicles. However, inconsistencies in

The Ultimate Guide to Battery Certifications 2025

Jul 25, 2025 · Battery certifications are critical for ensuring the safe transportation, quality, meet industry standards and environmental impact of lithium-ion batteries. Whether you are

Understanding ISO Standards for Lithium-Ion Batteries in

Apr 18, 2025 · For lithium-ion batteries, these standards provide essential guidelines to meet safety requirements, improve performance, and maintain reliability. They address critical

EV Lithium Battery PACK Design Process from

Mar 18, 2025 · EV Lithium Battery PACK Design Process: A Comprehensive Guide The design of Electric Vehicle (EV) lithium battery packs ⇱ is a complex

6 FAQs about [Quality requirements of lithium batteries for battery packs]

What are the requirements for portable lithium ion storage batteries (mobile batteries)?

From February 1st, 2019, portable lithium ion storage batteries (mobile battery) with a density of 400Wh/L or above, must have a round PSE mark on the product, and meet the other table. Nine or other standard requirements of J62133 (H28) (JISC8712 (2015) or IEC62133 (2012) integration) Official website announcement

Is there a standard size for a lithium battery pack?

First, we need to note that there is no standard size for lithium battery pack, nor is there likely to be any in the near future, for a simple reason: different manufacturers build and integrate electric vehicles differently. The power lithium battery pack needs to adapt to the vehicle structure, so it is difficult to have a uniform size standard.

What are the important considerations in lithium-ion battery pack design?

Another important consideration in lithium-ion battery pack design is ease of follow-up maintenance. In lithium-ion battery pack designs, some producers use mechanical components, bolts or nuts to link the cell. This kind of design allows the user to replace the cell and use the pack throughout the life of battery.

What are the UL standards for lithium ion batteries?

They have specific standards that ensure the safety of lithium-ion cells in consumer electronics (UL 1642), apply to battery pack durability (UL 2054), apply to EV battery safety (UL 2580), and apply to portable lithium batteries (UL 62133-2). 2. IEC (International Electrotechnical Commission) Standards

Will lithium batteries be standardized?

As a result, standardization of lithium battery pack or batteries is unlikely, at least in the near term.

What are the ISO standards for EV batteries?

ISO sets international quality and safety standards. They ensure quality management in production (ISO 9001), environmental management in battery manufacturing and disposal (ISO 14001), and functional safety for EV batteries (ISO 26262). 4. SAE (Society of Automotive Engineers) Standards

Industry Information

- Huawei Energy Storage Container Investment

- 100f super farad capacitor

- Photovoltaic power generation outdoor unit base station

- Madagascar DTE cylindrical lithium battery

- Tunisia Household Solar Photovoltaic System

- Solar power supply system or assembly

- 1000w pure sine wave inverter

- Kathmandu Energy Storage Container Fire Fighting System

- Bhutan energy storage container production plant address

- Charging speed of lithium battery pack

- Main facilities of energy storage power station

- How much charging current can a 48v inverter provide

- User-side energy storage power station access

- 220v circuit breaker in China in Netherlands

- Wholesale main power breaker in Johannesburg

- Changji 60v to 220v inverter

- Palikir Uninterruptible Power Supply UPS

- Uruguay Smart Photovoltaic Modules Solar Panels

- Mongolia solar air conditioning is a bureau

- Ecuador courtyard photovoltaic glass

- Kabul mobile energy storage vehicle equipment

- Battery pack pressure resistance

- Nuc power bank portable

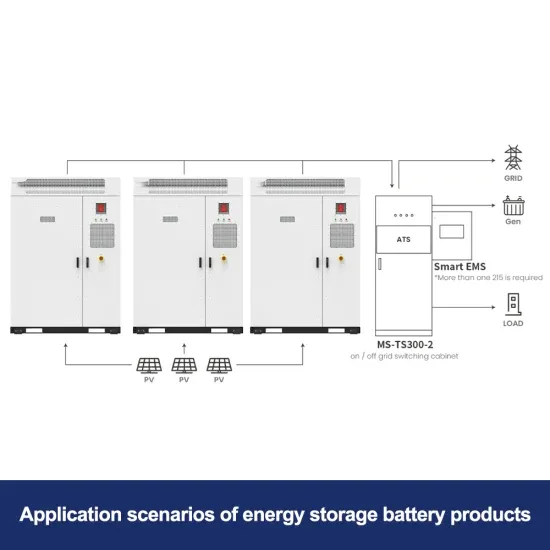

Commercial & Industrial Solar Storage Market Growth

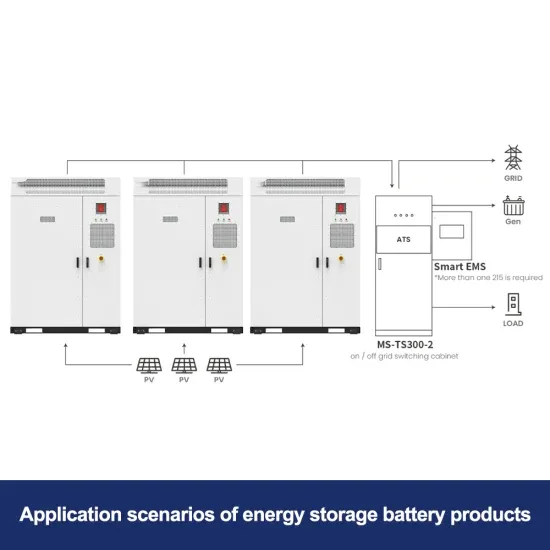

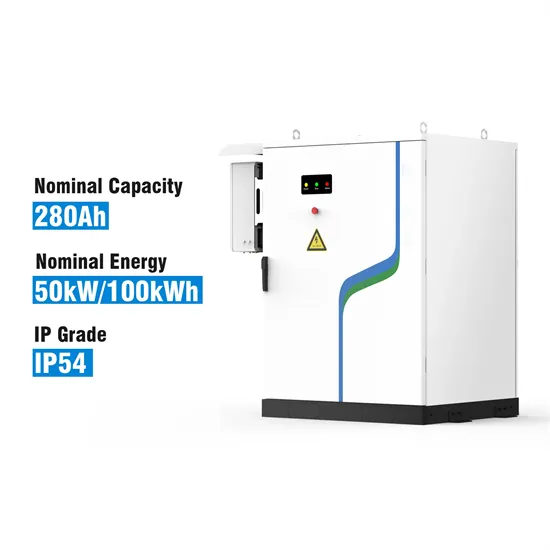

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.