Vanadium Redox Flow Battery Stack Balancing to

Sep 13, 2023 · Vanadium redox flow batteries are gaining great popularity in the world due to their long service life, simple (from a technological point of view)

Flow batteries

Jan 1, 2025 · Reasonable designs of the stack structure, especially optimization of the flow field structure, can greatly improve the performance of the RFB stack. The structure of the stack

Flow field structure design for redox flow battery:

Aug 1, 2024 · In this review, the flow and distribution characteristics of traditional flow fields are presented. The effects of traditional flow fields on distribution uniformities in single battery and

An alternative low-loss stack topology for vanadium redox flow battery

Feb 1, 2017 · Two vanadium redox flow battery topologies have been compared. In the conventional series stack, bipolar plates connect cells electrically in series and hydraulically in

Analysis and optimization for multi-stack vanadium flow battery

Dec 15, 2021 · The large-scale all-vanadium flow battery module is commonly formed by a number of hydraulically parallel connected stacks. The existence of permeabil

Perspectives on zinc-based flow batteries

Jun 17, 2024 · To bridge the gap between laboratory-scale development of battery components and industrial-scale zinc-based flow battery stack operation, tremendous research work on cell

What Are Liquid Flow Batteries And Their

Dec 25, 2024 · Figure 1 is a schematic diagram of the liquid flow battery and a schematic diagram of the battery stack structure. The positive and negative

Redox Flow Battery

The basic structure of a flow battery with two tanks, pumps, and a stack with a large number of half cells had already described at that time and continues to exist basically unchanged.

Is the Structure of the Flow Battery Stack Complex A

Summary: Flow batteries are gaining traction for large-scale energy storage, but how complex is their core component—the stack? This article explores the structure of flow battery stacks,

Novel Flow Frame Design for Redox Flow Battery

As a result, modelling the stack and system is a more cost-effective approach for battery designs suitable for manufacturing real commercial-size battery stacks. This thesis aims to develop

Bringing Flow to the Battery World

Mar 20, 2024 · What is a flow battery? A redox flow battery (RFB) consists of three main spatially separate components: a cell stack, a positive electrolyte

Mechanical Design of Flow Batteries

Jan 13, 2022 · The cost model and mechanical designs presented will help researchers (i) identify how to modify existing materials, (ii) find new desirable materials, and (iii) use those materials

Redox flow batteries and their stack-scale flow

Nov 1, 2023 · Among various emerging energy storage technologies, redox flow batteries are particularly promising due to their good safety, scalability, and

Flow field design and visualization for flow

Mar 27, 2024 · We design a flow field for flow-through type aqueous organic redox flow batteries (AORFBs) by placing multistep distributive flow channels

How do flow batteries work?

Aug 17, 2020 · Flow batteries operate on different electrochemical processes and are more scalable than conventional regenerative fuel cells.

Redox flow batteries and their stack-scale flow

Nov 1, 2023 · One of the key components that impact the battery per formance is the flow field, which is to distribute elec- trolytes onto electrodes. The design

Material design and engineering of next-generation flow-battery

Nov 8, 2016 · Flow-battery technologies open a new age of large-scale electrical energy-storage systems. This Review highlights the latest innovative materials and their technical feasibility for

Cost structure analysis and efficiency improvement and cost

Jun 19, 2025 · Cost structure analysis and efficiency improvement and cost reduction route of all vanadium flow batteries-Shenzhen ZH Energy Storage - Zhonghe VRFB - Vanadium Flow

Requirements for future redox flow battery stacks

Jul 5, 2023 · Ref-1 and Ref-2 are state-of-the-art membranes, F-reduced and F-free membranes are promising novel R&D membranes. Tensile strength analysis of "dog bone" shaped

Stack Design Considerations for Vanadium Redox Flow Battery

Jun 25, 2018 · In this paper we deal with strategic considerations in designing the stack of a vanadium redox flow battery. The design of the stacks is complicated by the presence of a

SECTION 5: FLOW BATTERIES

Jun 14, 2022 · Flow batteries are electrochemical cells, in which the reacting substances are stored in electrolyte solutions

Rechargeable redox flow batteries: flow fields,

Oct 9, 2018 · In this review, we focus on the less-discussed practical aspects of devices, such as flow fields, stack and design considerations for developing

Vanadium Redox Flow Batteries: Electrochemical

Apr 3, 2019 · The importance of reliable energy storage system in large scale is increasing to replace fossil fuel power and nuclear power with renewable

S-Stack

The design of the S-stack is a result of almost 10 years of know-how in the field of flow battery test cells and maybe the only research stack product on the

Flow Batteries: What You Need to Know

Oct 18, 2024 · Flow batteries offer scalable, durable energy storage with modular design, supporting renewable integration and industrial applications.

The Stack Structure Of Vanadium Flow Battery

Aug 27, 2024 · The Stack Structure Of Vanadium Flow Battery The vanadium liquid flow battery energy storage system is mainly composed of a battery stack, an electrolyte storage and

Fact Sheet: Vanadium Redox Flow Batteries (October 2012)

Dec 6, 2012 · Pacific Northwest National Laboratory Redox flow batteries (RFBs) store energy in two tanks that are separated from the cell stack (which converts chemical energy to electrical

Flow Battery

Flow batteries are defined as a type of battery that combines features of conventional batteries and fuel cells, utilizing separate tanks to store the chemical reactants and products, which are

Bringing Flow to the Battery World

Mar 20, 2024 · What is a flow battery? A redox flow battery (RFB) consists of three main spatially separate components: a cell stack, a positive electrolyte (shortened: posolyte) reservoir and a

Flow batteries

Jan 1, 2025 · In this chapter, the principle, structure, and classification of flow batteries are briefly introduced. The key materials of single cells and their optimized methods are reviewed from

ELECTRODE STRUCTURE OF FLOW BATTERY, FLOW BATTERY STACK

An electrode structure of a flow battery, a flow battery stack, and a sealing structure of the flow battery stack, wherein the density of the vertical tow in the electrode fiber is larger than the

6 FAQs about [Flow battery stack structure]

What are the practical aspects of flow batteries?

Recent contributions on flow batteries have addressed various aspects, including electrolyte, electrode, membrane, cell design, etc. In this review, we focus on the less-discussed practical aspects of devices, such as flow fields, stack and design considerations for developing high performance large-scale flow batteries.

How do flow fields affect distribution in single battery and stack?

However, the effects of flow fields on distribution in single battery and in stack are different. The distribution uniformity is decreased in the order of IFF > SSFF>No-FF for single battery while the distribution uniformity along cell number is decreased in the order of No-FF > SSFF>IFF for stack.

How do flow fields affect battery performance?

One of the key components that impact the battery performance is the flow field, which is to distribute electrolytes onto electrodes. The design principle of flow fields is to maximize the distribution uniformity of electrolytes at a minimum pumping work.

What is flow field design for redox flow battery (RFB)?

Prospects of flow field design for RFB have been exhibited. Flow field is an important component for redox flow battery (RFB), which plays a great role in electrolyte flow and species distribution in porous electrode to enhance the mass transport. Besides, flow field structure also has a great influence in pressure drop of the battery.

Does flow field structure affect pressure drop of battery?

Besides, flow field structure also has a great influence in pressure drop of the battery. Better flow field not only can improve the mass transport in electrode but also is able to decrease the pressure drop of RFB.

Can redox flow batteries be used in large-scale energy storage applications?

Finally, we provide suggestions for further studies on developing advanced flow batteries and large-scale flow battery stacks. Rechargeable redox flow batteries are being developed for medium and large-scale stationary energy storage applications.

Industry Information

- Portable photovoltaic energy storage

- High-end large-capacity outdoor power supply

- Omega solar inverter in China in Belarus

- Power battery pack front and back

- Irish Home Energy Storage

- China transfer switch breaker in Vietnam

- Myanmar 24-hour energy storage system

- EK s first zero-carbon energy storage battery factory in Kuala Lumpur

- Independent photovoltaic power generation system off-grid

- Factory price 3000w inverters in Chile

- New energy battery cabinet assembly method

- Pakistan Karachi Power Photovoltaic Module Prices

- Dakar single glass photovoltaic curtain wall advantages

- The latest energy storage power station project in Montenegro

- Do communication base stations have electromagnetic batteries

- Household energy storage power supply price

- Does the BESS battery have a BMS

- 72v inverter 2000 watts

- What are the container battery factories in Valletta

- Senegal 5G communication base station wind power construction

- Base station power cabinet replacement

- Best new circuit breaker in China distributor

- Energy storage cells in new energy

Commercial & Industrial Solar Storage Market Growth

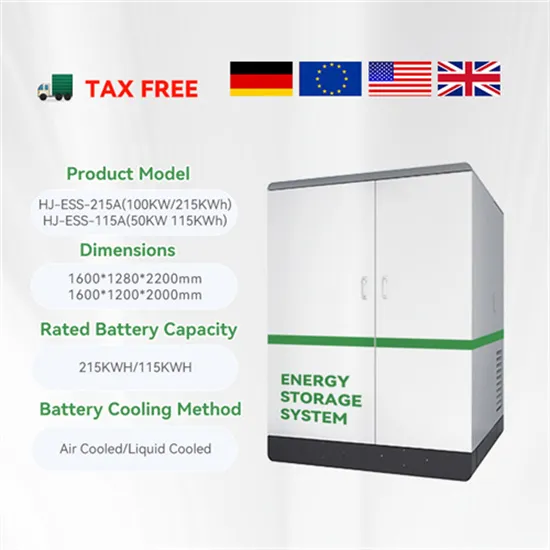

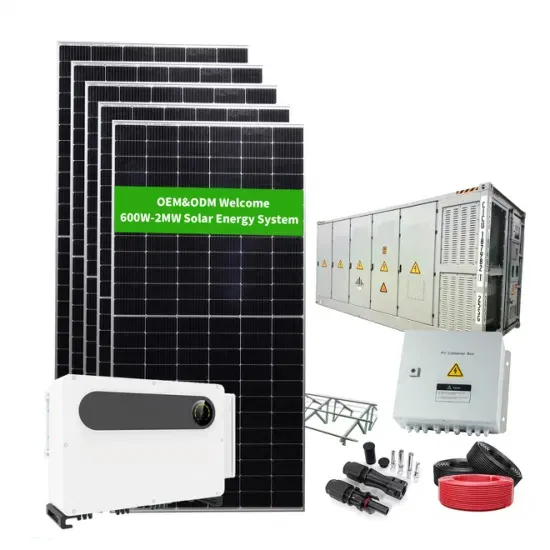

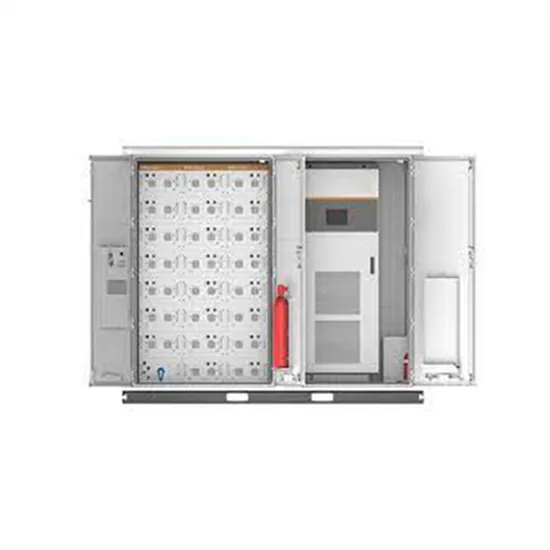

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.