Battery Cabinets vs. Battery Racks

Aug 27, 2018 · Battery cabinets must enclose the batteries behind locked doors accessible only to authorized personnel. As long as the cabinets are kept

Understanding NFPA 855: A Homeowner''s Guide

Discover essential tips on NFPA 855 2020 battery installation code for single-family homes. Learn about installation and safety protocols.

What are the standard requirements for battery energy storage cabinets

Jun 2, 2024 · Battery energy storage cabinets must comply with several critical criteria: 1. Material durability, ensuring resilience against environmental factors, 2. Adequate thermal

Batteries and Fire (Part 3 – Placement of Energy Storage

Feb 12, 2025 · The battery system should be installed in a non-combustible container or a building designed specifically for battery storage with fire resistance class EI 60. The container or

Best Practices and Considerations for Siting Battery

Aug 23, 2024 · Manufacturer performance warranties require that batteries operate in low temperatures and have access to adequate cooling and ventilation to avoid overheating, if

What are the standard requirements for battery energy storage cabinets

Jun 2, 2024 · Thermal management systems in battery energy storage cabinets are vital for regulating the internal temperature of the batteries. As batteries discharge and charge, they

Comprehensive Guide to Lithium Battery Cabinet Safety and

Learn how a lithium battery cabinet ensures fire-safe energy storage in industrial and commercial settings. This guide covers cabinet types, compliance standards, and safety strategies.

What Are The Solar Battery Installation

Oct 10, 2024 · Green rooms are non-habitable rooms and can be used to install a solar battery provided the room abides by the above regulations. Red marks

Battery Room Ventilation and Safety

Mar 15, 2023 · BATTERY ROOM VENTILATION AND SAFETY It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms

What Are the Ventilation Requirements for High-Density Battery

Mar 22, 2025 · Proper ventilation for high-density battery racks prevents thermal runaway, ensures compliance with NFPA 855 and IEC 62485-2 standards, and maintains safe operating

2018 Title Contents

Dec 20, 2022 · In layman''s terms, a standard provides minimum requirements and/or instructions in agreement within the industry for common reference. Common standards in the battery

Battery Energy Storage Systems: Main Considerations for

5 days ago · This webpage includes information from first responder and industry guidance as well as background information on battery energy storage systems (challenges & fires), BESS

Specifications and requirements for battery cabinets in

o Battery rack/cabinet (if battery modules or Pre-assembled battery system requires external battery racks/cabinets for mechanical mounting/protection). o Balance of system components

Requirements for placing battery packs in the equipment room

Battery packs. Battery packs are connected together by an outer casing, for example, shrink-wrapped plastic. Battery packs can be either portable or industrial.

Essential Requirements for Placing Energy Storage Batteries:

Apr 14, 2025 · Why Proper Placement of Energy Storage Batteries Matters More Than You Think Ever wondered why some energy storage systems outlive their warranties while others

Understanding Lithium Ion Battery Storage Cabinets: Safety,

Jun 20, 2025 · These cabinets are designed to safely store and charge lithium-ion batteries while minimizing fire and chemical hazards. A well-built cabinet provides thermal isolation, fire

Safe Clearances for Electrical Equipment:

Terms You Should Know: Working space: The front clearance, side clearance, and height clearance requirements for electrical equipment that provide a safe

Requirements for battery enclosures – Design considerations and

May 25, 2019 · Requirements for battery enclosures – Design considerations and practical examples Conference paper First Online: 25 May 2019 pp 1352–1367 Cite this conference paper

What are the material requirements for battery cabinets

FAQS – Battery Storage Cabinets The specific type of cabinet you need may vary depending on the battery type, as some batteries have unique storage requirements. 4. Are battery storage

Storage battery requirements

Jan 27, 2017 · The International Fire Code (IFC) and NFPA 1: Fire Code need to be considered when specifying stationary storage battery systems to ensure

NFPA 70E Battery and Battery Room Requirements | NFPA

May 24, 2021 · Safety requirements for batteries and battery rooms can be found within Article 320 of NFPA 70E

Maintaining Compliance in the VRLA Battery Room

Dec 20, 2022 · Introduction Battery room compliance can be interpreted differently depending on your battery type, amount of cells or multi-cell units in a common area, volume of electrolyte

Why you shouldn''t charge lithium-ion batteries

May 22, 2025 · Where can you safely charge your lithium-ion (bike) batteries? And why is a safety cabinet – also known as a flammable storage cabinet –

NFPA 70 and NFPA 70E Battery-Related Codes Update

Jan 10, 2023 · Abstract Two code documents have a dramatic impact on the acceptance or rejection of a battery installation by an inspector. These are the National Electrical Code (NEC

Comprehensive Guide to Lithium Battery Cabinet Safety and

Meeting safety regulations is essential when deploying lithium-ion battery cabinet systems. Standards such as EN 14470-1 and SS-EN-1363-1 demand 90 to 120 minutes of fire

Codes and Standards Governing Battery Safety

Aug 19, 2025 · Discover the key codes and standards governing battery safety and compliance in building and fire regulations. Learn about the various

How to Protect Battery Energy Storage (BESS)?

Aug 16, 2023 · What is the recommended practice to protect Battery Energy Storage Systems (BESS)? NFPA 855 states that if the BESS is not a walk-in unit, then fire suppression is not

New battery installation rules

Mar 2, 2020 · If you''re planning a battery or you already have one, the new rules on where batteries can be located and who can work on them may affect you.

Essential Requirements for Placing Energy Storage Batteries:

Apr 14, 2025 · The secret often lies in how and where you place those battery units. Whether you''re setting up a home solar system or managing a commercial energy park, understanding

The Ultimate Guide to Battery Charging

Feb 14, 2025 · Lithium-ion batteries power many of our everyday devices, from industrial machinery to personal electronics. However, they also pose

Residential Energy Storage System Regulations | NFPA

Oct 1, 2021 · The most popular type of ESS is a battery system and the most common battery system is lithium-ion battery. These systems can pack a lot of energy in a small envelope, that

Practical Guide to Electrical Enclosures for Industrial

Aug 9, 2025 · Electrical Enclosures Overview An electrical enclosure is a purpose-built cabinet designed to house electrical and electronic devices, providing the required protection to keep

What Are Battery Rack Cabinets and Why Are They Essential?

Jun 15, 2025 · Battery rack cabinets are modular enclosures designed to securely house and organize multiple batteries in industrial, telecom, or renewable energy systems. They optimize

IFC Mounting Requirements for IQ Battery Systems

Oct 21, 2021 · The Enphase IQ Battery 3, 3T, 10, and 10T meet the requirements to be exempted from the IFC mounting restrictions and the manufacturer''s recommended mounting

Battery Energy Storage System Installation requirements

Mar 16, 2021 · This standard places restrictions on where a battery energy storage system (BESS) can be located and places restrictions on other equipment located in close proximity to

6 FAQs about [What are the requirements for placing a battery cabinet ]

What standards are used in a battery room?

Common standards in the battery room include those from American Society of Testing Materials (ASTM) and Institute of Electrical and Electronic Engineers (IEEE). Model codes are standards developed by committees with the intent to be adopted by states and local jurisdictions.

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

Do you need documentation before entering a battery room?

It is a requirement to have all the documentation in place prior to authorized personnel entering a battery room to perform a specific work task on a battery system under normal operating conditions. However, it is likely the employee will need to enter the battery room to deal with a battery system that is not operating normally.

What is a standard in battery testing?

In layman's terms, a standard provides minimum requirements and/or instructions in agreement within the industry for common reference. Common standards in the battery room include those from American Society of Testing Materials (ASTM) and Institute of Electrical and Electronic Engineers (IEEE).

Are battery storage systems dangerous?

There has been a fair amount of news about battery storage systems being involved in fire and explosion incidents around the world. Do not forget that these are not the only safety issues when dealing with batteries. Battery systems pose unique electrical safety hazards.

Does a battery rack need to be NEBS certified?

Even if a company installs a NEBS-certified battery rack in a site, the building inspector can still require the rack to be certified to IBC or any other building code that city or state has adopted. Which seismic code or standard is the best fit?

Industry Information

- Does a 5G base station need a UPS power supply

- Solar Panel On-site Energy Assembly

- High quality wholesale c32 circuit breaker Buyer

- Battery energy storage system manufacturers in the United Arab Emirates

- How much is the price of lithium battery for energy storage in Aarhus Denmark

- New photovoltaic panels for sale in Greece

- Circuit breaker fuse for sale in Johannesburg

- UPS uninterruptible power supply output becomes 280V DC

- Solar energy application system integration in New York USA

- Ecuador power battery bms wholesale

- High quality wholesale 1500 watt inverters for sale

- Palau photovoltaic energy storage manufacturer

- Tallinn 5G base station battery is not yet home appliance news

- Indonesia photovoltaic tile direct sales

- Mobile power supply or outdoor power supply

- Does the photovoltaic glass factory cause pollution

- Substation Direct-mounted Energy Storage

- Inverter 48W

- Type level of flywheel energy storage in communication base stations

- Wind and solar energy storage projects

- Seoul communication base station battery manufacturer

- High voltage breaker for sale in Canberra

- Ghana Large Mobile Energy Storage Vehicle

Commercial & Industrial Solar Storage Market Growth

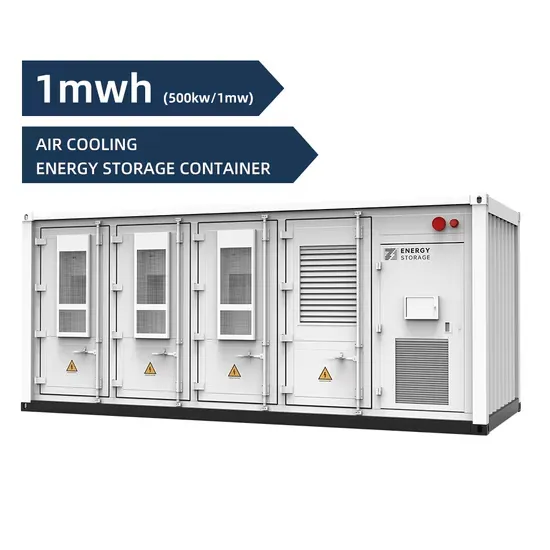

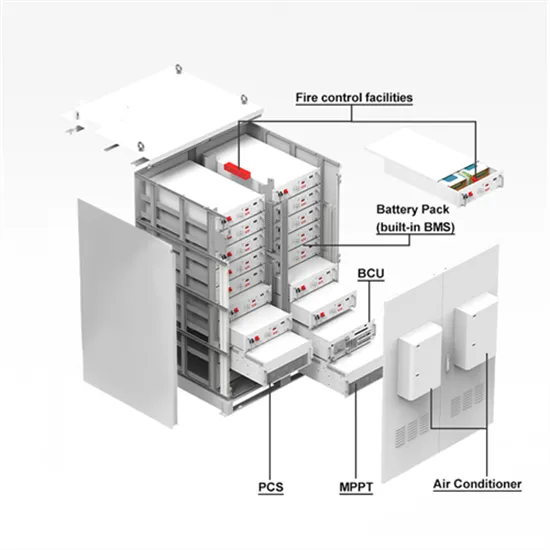

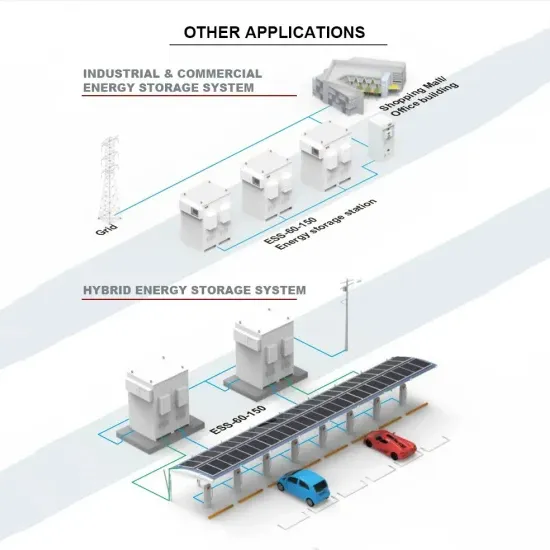

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

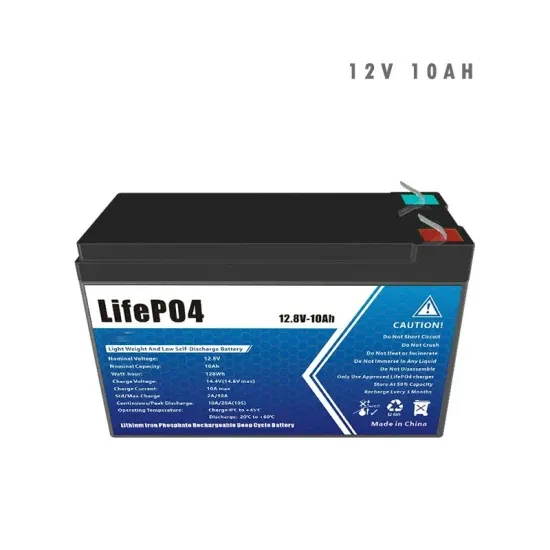

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.