Solar Panel

Jul 21, 2022 · be aimed independently of where the tank is going. Solar panel refers either to a photovoltaic module, a solar thermal energy panel, or to a set of solar

This company has invented automated robots

May 13, 2023 · Berkeley, California-based Terabase Energy ''s Terafab system features solar panel installation robots that can operate "24/7" on an

How are solar panels installed? | 11 steps

Dec 12, 2023 · Here''s how a solar panel installation works from start to finish, and what you should do before and after the installation.

How Are Solar Panels Manufactured Step-by-Step? A Clear

Discover the step-by-step journey of solar panel manufacturing, from high-purity silicon wafers to final assembly and quality testing. Explore key components like PV cells, tempered glass, and

ECOPROGETTI Srl

Jul 28, 2025 · Ecoprogetti Srl is the European market leader for Solar Panel Manufacturing Equipment. Each machine is 100% produced in Italy since 1998.

Solar Panel Manufacturing Process: Step-by-Step Guide

Apr 12, 2025 · Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Processes for the assembly and production of

Processes for the assembly and production of solar panels By Brian 2023年 7月 26日 Solar panels convert light into power, converting energy everywhere.

Solar panel assembly process-Shenzhen Desun Energy

Oct 13, 2017 · Solar panel assembly process As shown in Figure 1, the battery test: Due to the random nature of the production conditions of solar cells, the performance of solar panels

Home

Our Team Members Management Team We are a reference for excellence in Solar Energy sector in Nigeria and also help provide quality locally assembled

Micro-CPV Solar Panels Boost Efficiency and Cut Costs

Aug 6, 2025 · Discover how micro-CPV solar panels achieve 36% efficiency using low-cost materials, promising a greener future with reduced energy consumption.

Executive summary – Solar PV Global Supply

Aug 13, 2025 · Today, electricity-intensive solar PV manufacturing is mostly powered by fossil fuels, but solar panels only need to operate for 4-8 months

Cell Manufacturing and module assemblies

Solar panels: how are they madeYou already know how silicon plates are manufactured. Now, let''s turn to the next step: how are these silicon plates

Solar Panel Components (List and Functions)

May 8, 2022 · Solar panels are becoming our solution to the energy crisis that we face, but what parts make up a solar panel and system – that''s what we''ll find

How to manufacture a photovoltaic module

5 days ago · Learn how to assemble and produce high-quality solar modules. By understanding the photovoltaic module production process and to learn which

Success Story—Putting Solar Energy Installation

May 30, 2023 · It uses robotic arms to lift heavy solar panels and connect them to solar trackers, saving time, energy, and ultimately, money. The United States

How to manufacture a photovoltaic module

5 days ago · Learn how to assemble and produce high-quality solar modules. By understanding the photovoltaic module production process and to learn which machines are involved in the

Solar panel assembly process-Shenzhen Desun Energy

Oct 13, 2017 · As shown in FIG. 7, the frame is similar to the one provided with a glass frame; the aluminum frame is mounted on the glass component to increase the strength of the module

Solar Assembly Lines

Apr 26, 2025 · Solar Assembly Lines The unprecedented demand on solar panels, either to build Solar Farms or for Home/Business installations, created a huge parallel supply shortage of

PV Solar Cell Manufacturing Process

The rise of sustainable energy solutions has thrust solar power into the limelight as a pivotal force in the global energy transition. Central to this solar revolution

What are the solar energy assembly workshops? | NenPower

Jul 21, 2024 · 1. Introduction to Solar Energy Assembly Workshops: Solar energy assembly workshops are specialized facilities where the various components of solar energy systems,

1.2-GW solar panel assembly facility to open in

Nov 13, 2024 · A contract solar panel assembly facility will soon open in Aguadilla, Puerto Rico, that will supply the utility-scale market on the island

How to Assemble Solar Photovoltaic Panels | NenPower

Jul 6, 2024 · In an era where climate change poses an imminent threat, investing in solar energy not only reduces reliance on fossil fuels but also empowers individuals and communities to

Processes for the assembly and production of solar panels

Solar panels convert light into power, converting energy everywhere. However making solar panels requires complex material structures and production processes, read this article to

Solar Installation Automation Platform Sees First

Nov 17, 2023 · Terabase Energy, a provider of digital and automation solutions for solar power plants, announced the successful completion of its first

Solar Photovoltaic Panel Production Line Assembly

Solar Photovoltaic Panel Production Line is a high-tech manufacturing process that converts sunlight into electricity using photovoltaic cells, involving cutting,

️ Phases of building a photovoltaic solar farm

Solar energy is increasingly used as a renewable and sustainable source to meet our energy needs. One of the ways to take advantage of it is through the

PV module assembly line: an investment for the

Oct 28, 2016 · The formula "pv module assembly line" means the series of machines required for manufacturing modules able to convert solar energy

Solar panel manufacturing process: from cell to

During lay-up, solar cells are stringed and placed between sheets of EVA. The next step in the solar panel manufacturing process is lamination.

7 Steps How to Install Solar Panel: Step-by-Step Guide

Jul 30, 2024 · Step – 1: Solar Panel Installation Made Easy Which direction should be the solar panel face? The mounting structure provides the base for the entire solar system so make sure it is sturdy and properly fastened to the rooftops of your house or commercial establishment. A typical

Solar Panel Manufacturing

Mar 13, 2024 · Solar panels are a vital component of renewable energy systems, converting sunlight into electricity. Understanding the manufacturing

Automation in Solar Panel Production:

Explore how automation is revolutionizing solar panel production, enhancing efficiency, reducing costs, and ensuring scalability in renewable energy

How to assemble a solar panel? –

Mar 26, 2023 · Conclusion Assembling a solar panel may seem like a daunting task, but with the right tools and instructions, it can be a straightforward

Solar Panel Construction

Feb 2, 2022 · Solar panel technology is advancing rapidly with greater efficiency and lower prices, resulting in a huge increase in demand. However, despite

6 FAQs about [Solar Panel On-site Energy Assembly]

How are solar panels assembled?

Solar Panel Assembly Once the individual solar cells have been tested, they are interconnected using metal contacts to form a solar panel. The cells are arranged in rows and columns and are soldered together. 8. Lamination

How do solar panels work?

Understanding the manufacturing process of solar panels can help you understand how this technology works. Solar energy can be captured using two primary methods: Photovoltaic (PV) System: This technology converts sunlight directly into electricity using solar panels made of semiconductor materials like silicon.

How a photovoltaic module is assembled?

The assembly of photovoltaic modules consists of a series of consecutive operations that can be performed by automatic machines dedicated to optimizing the single production phases that transform the various raw material in a finished product.

How to make a solar panel?

The process revolves around ten major steps, which divide into several sub-steps, to produce a complete solar panel. Step 1: Half Cutting Using a laser cutter to divide the cells in two and switching to small area cells in series is a good solution for reducing current losses and increasing module power.

How to install a photovoltaic module?

The process is done by attaching the box with a suitable silicone or glue on the back sheet of the module and by making the electrical connection between the bus ribbon prepared before the lamination and the cables of the junction box. At the inside of the box, you can find by-pass diodes that protect the photovoltaic module when operating.

Can solar panels be used to power American homes?

Their task: to install rows upon rows of solar panels, which will soon generate clean energy to power American homes, businesses, and communities

Industry Information

- Honduras light-transmitting series photovoltaic power generation glass wholesale

- Paris Super Farad Capacitor

- El Salvador regular inverter manufacturer

- Tunisia Bidirectional Portable Energy Storage Project

- Factory price 7 5 kw inverter in Panama

- Advantages of independent energy storage power stations

- Hot sale quad circuit breaker factory Seller

- Distributed energy storage power stations are feasible

- Dual circuit breaker in China in Uae

- Communication base station inverter grid-connected special tower

- Appearance design outdoor energy storage power supply

- Tbilisi Signal Base Station Solar Panels

- Malawi Energy Storage Container Fire Fighting System

- Lesotho 60v to 220v inverter

- Nanya Industrial and Commercial Energy Storage Cabinet

- Energy storage equipment energy storage cabinet

- Skopje Communication Base Station Inverter 215KWh

- 220v small water pump modified into solar water pumping

- Does Cote d Ivoire have a 5G base station with power signal

- 4 2 kw solar inverter factory in Nairobi

- Energy storage liquid cooling unit 50kw

- Wind and solar energy air conditioning

- Wholesale 2000 amp switchgear in Bhutan

Commercial & Industrial Solar Storage Market Growth

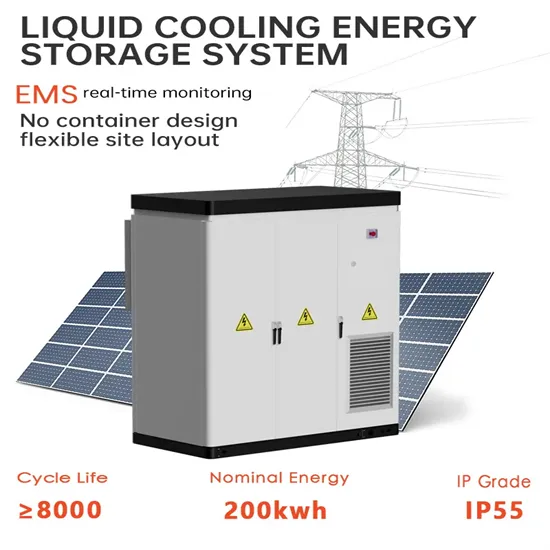

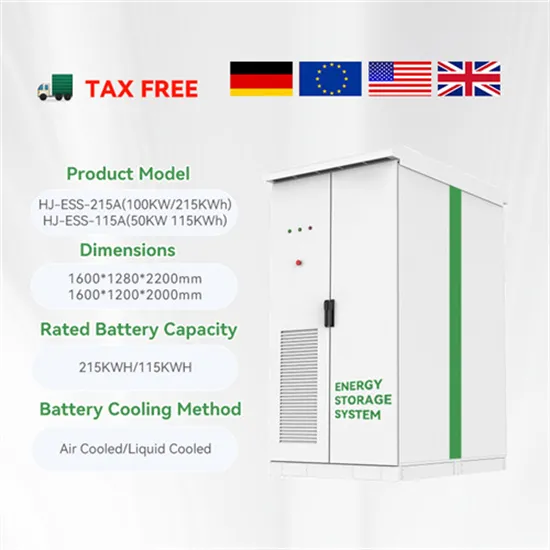

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.