TOPCon vs PERC Solar Cells: Efficiency

Feb 13, 2025 · Solar modules serve as the backbone of photovoltaic systems, and the competition between TOPCon and PERC is intensifying . While PERC

Solar cells: Technical differences between

Aug 25, 2024 · Solar cells are central components of solar panels and can therefore be found at every solar site. Therefore, in this article we want to

What is the difference between Monocrystalline Perc and N

4 days ago · Monocrystalline PERC panels are simpler and less expensive to manufacture, while N-Type panels are made from a more complex composition but offer slightly higher efficiency

N-type vs. P-type: Insight from PVEL solar

Jun 12, 2023 · N-type vs. P-type As the industry transitions to N-type technologies, extended testing can help pinpoint crucial performance and

What is the difference between Monocrystalline

4 days ago · What is the difference between Monocrystalline Perc and N Type Solar Panels Monocrystalline PERC (Passivated Emitter and Rear Cell) and N

The rise of next-generation n-type solar PV cells

Sep 6, 2022 · A version of this article originally appeared in the 2022 edition of RETC''s PV Module Index Report. By Daniel Chang, VP of Business

Solar Panel Technology Advancements: PERC, HIT, and N-type

Feb 27, 2025 · Solar Panel Technology Advancements: PERC, HIT, and N-type Explained Introduction Solar panel technology has undergone significant advancements since its

JA Solar N-Type vs P-Type Solar Panels:

Apr 3, 2023 · In the full-year test period, the energy yield performance of JA Solar n-type modules and the PERC modules are shown in Figure. The average

TOPCon vs PERC

Jan 20, 2022 · TOPCon solar cells are on their way to fully compete with PERC solar products, according to recent research from Germany''s Fraunhofer ISE.

What Is The Difference Between TOPCon, HPBC,

Nov 16, 2023 · The differences between TOPCON, HPBC, HJT, and PERC PV Module mainly lie in Solar cell technology, conversion efficiency, process

p-type and n-type explained

The contrast between p-type and n-type take different methods along the value chain to compete on efficiency, cost and differentiating value propositions. While p-type mono and multi PERC

N-Type vs P-Type Solar Cells: Key

Apr 9, 2024 · In the ever-evolving landscape of renewable energy technology, the comparison between N-Type and P-Type

A Complete Guide to PERC Solar Panels (vs.

Mar 6, 2022 · PERC solar panels are more efficient than traditional c-Si panels with reduced heating absorption. How do they compare to other cell techs?

PERC solar cell technology guide: Benefits and drawbacks

Jun 2, 2025 · Who manufactures PERC solar cells? Top PERC solar cell manufacturers like LONGi, JA Solar, and JinkoSolar offer high-efficiency PV modules for residential and utility

Solar Cell Efficiency: Comparing PERC and TOPCon

Oct 24, 2024 · This article explores the differences between PERC and TOPCon solar cells, two leading technologies in the solar energy field. By comparing their efficiency, cost, and practical

What is the difference between PERC and

Nov 23, 2023 · The article contrasts PERC and TOPcon solar cells in photovoltaics, highlighting their technical, structural, manufacturing, and

Difference between Mono PERC, TOPCon, and

Jul 7, 2025 · Understand the difference between Mono PERC, TOPCon, and HJT solar panels in terms of their design, performance, and cost.

What is Difference Between Mono PERC and Bifacial Solar

Apr 27, 2025 · As solar technology continues to evolve, new panel types offer better efficiency and performance. Two popular options in today''s market are mono PERC and bifacial solar

N-type Technology

Due to the technical production and properties of N-type silicon cells, the bifaciality of HJT Solar Panels is the highest on market at 80-95%. PERC

Choose Smart: Differences Between PERC and N-Type – Corey Solar

Jan 17, 2025 · In the world of solar energy, choosing the right technology can mean the difference between an efficient system and one that doesn''t maximize its potential. When evaluating

Choose Smart: Differences Between PERC and N-Type – Corey Solar

Jan 17, 2025 · When evaluating solar panels, it''s essential to understand the differences between two key technologies: PERC (Passivated Emitter and Rear Cell) and N-Type . Both offer

Different Types Of Solar Panels In India: Cost,

Jul 22, 2025 · Explore 10 different types of solar panels in India, ranging from first-generation monocrystalline panels to the advanced types of solar panels for

What Are TOPCon Solar Cells? P-type PERC vs N

Dec 13, 2023 · P-type PERC vs N-type TopCon. Manufacturers of photovoltaic (PV) modules are always trying to find new, more advanced alternatives to

Difference between Mono PERC, HJT & TOPCon

Apr 12, 2023 · The solar industry has evolved significantly with the introduction Mono PERC, HJT, and TOPCon solar panels technology having improved

Topcon solar cells vs Perc solar cells: a complete

Oct 14, 2023 · Comparison Between PERC Solar Cells and TOPCon Solar Cells Technology When comparing PERC and TOPCon solar cell technologies, it''s

Best 2 Difference Between TOPCon vs PERC

Durability and Longevity When evaluating the durability and longevity of TOPCon vs PERC solar cells technology, various studies present different findings. A

Solar Panel Technology Shift: From

Apr 12, 2024 · The solar industry is experiencing a rapid technological shift, with innovations continually reshaping the landscape. The pace of change is

PERC Technology and N-Type Solar Panels: The

Dec 12, 2023 · Both PERC technology and N-type cells offer significant improvements over conventional P-type cells. However, there are some key

Intuitive Comparison: PERC, TOPCon, HJT, BC,

This article discusses the significance and characteristics of five key photovoltaic cell technologies: PERC, TOPCon, HJT/HIT, BC, and perovskite cells,

Differences Between P-Type and N-Type Solar Panels

The fundamental difference between P-type and N-type solar panels begins with the type of silicon wafer they rely on. P-type modules use P-type wafers, which incorporate trivalent boron

P-type vs. N-type solar panels

May 18, 2025 · The efficiency difference between P-type and N-type solar panels is driven by their semiconductor properties. N-type panels generally achieve higher conversion efficiency

What Is the Difference between PERC and

Explore the differences between PERC and TOPCon solar cells. Understand their efficiency, cost, and applications to make informed solar energy investments.

N-type VS. P-type Solar Cells: Which One is Better?

When you start researching solar energy systems, you''ll notice that solar cells come in two types: N-type and P-type. This article discusses the

N-Type vs. P-Type Solar Panels: An In-Depth to Both

Dec 13, 2023 · In a nutshell, P-type cells are doped with boron, while N-type cells are doped with phosphorus. Comparatively, phosphorus degrades less than

PERC technology and solar panels

Jun 9, 2021 · The biggest difference between N-type and P-Type is that ordinary P cells have the problematic element boron added to silicon, while N cells

Solar Module Technology Comparison: N-type vs PERC vs

Feb 26, 2025 · Understanding the differences between N-type, PERC, and Thin-film solar panels helps consumers, installers, and investors make informed decisions. Snippet paragraph: N

Cost Comparison: N-type vs PERC vs Thin-film

Feb 26, 2025 · Cost Comparison: N-type vs PERC vs Thin-film Solar Modules Introduction Solar technology is advancing rapidly, offering buyers multiple

JA Solar N-Type vs P-Type Solar Panels:

Apr 3, 2023 · To understand the differences between P-type and N-type solar panels, it''s important to first understand how solar panels work. Solar panels

Understanding the Distinctions: Monocrystalline

Apr 9, 2024 · In the ever-evolving landscape of renewable energy, solar power stands at the forefront, heralding a future of sustainable and clean energy.

6 FAQs about [Differences between PV modules perc and n-type modules]

What is the difference between PERC and n-type solar panels?

When evaluating solar panels, it's essential to understand the differences between two key technologies: PERC (Passivated Emitter and Rear Cell) and N-Type . Both offer unique advantages but vary in aspects such as efficiency, durability, and adaptability to extreme conditions.

What are monocrystalline PERC & n-type solar panels?

Monocrystalline PERC (Passivated Emitter and Rear Cell) and N-Type (N-type Metal-Oxide-Semiconductor) solar panels are two advanced types of photovoltaic (PV) panels that are known for their high efficiency and performance.

What is the difference between n-type and P-type solar cells?

The difference between N-type and P-Type solar cells lies in the impurities added to silicon. N-type cells receive phosphorus, while P-type cells have boron added. Ordinarily, impurities in silicon are problematic. However, for solar cells to function, they must be "contaminated" with these impurities.

Are PERC panels better than n-type panels?

Monocrystalline PERC panels are simpler and less expensive to manufacture, while N-Type panels are made from a more complex composition but offer slightly higher efficiency and better performance in challenging conditions.

What are the advantages of PERC solar panels?

PERC (Passive Emitter and Rear Contact) solar panels, such as those produced by Jinergy, achieve efficiency levels of 19.5-20.5 %%. One advantage of PERC panels is their high efficiency, which makes them suitable for large investments in photovoltaic farms and solar power plants.

What is the efficiency of AKCOME's P-Type modules?

AKCOME's latest series PERC GA bifacial, double glass (with gallium) P-Type modules have an efficiency of between 22% and 22.5%. Half-CUT P-Type modules from AKCOME achieve an efficiency of between 19.5% and 20.5%. Please note that these are Double Glass modules.

Industry Information

- Moldova forklift lithium battery pack

- Is the inverter useful for outdoor use

- Buy portable power bank

- Energy storage cabinet outdoor solar power generation

- Chad photovoltaic energy storage system production

- What voltage is good for the inverter

- Colombia Grid-connected Photovoltaic Panel Manufacturer

- High frequency inverter increases output power

- Athens Home Energy Storage System

- Container mounted generator

- Group solar power generation system

- Algiers New Energy Storage Power Station Project

- Liechtenstein centralized energy storage power station environment

- Nairobi Energy Storage Grid

- Containerized solar inverter prices

- Power generation equipment container in Sao Paulo Brazil

- How many communication base station inverters are there in Madagascar

- High temperature resistant outdoor power supply recommendation

- China 300wh power station for sale Seller

- Solar energy billboard photovoltaic panel voltage

- Production frequency inverter input voltage

- Comprehensive application of wind solar and energy storage

- What is the initial price of the energy storage cabinet battery

Commercial & Industrial Solar Storage Market Growth

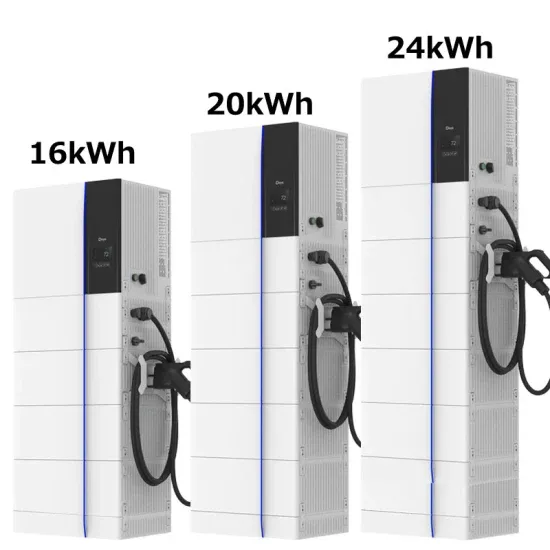

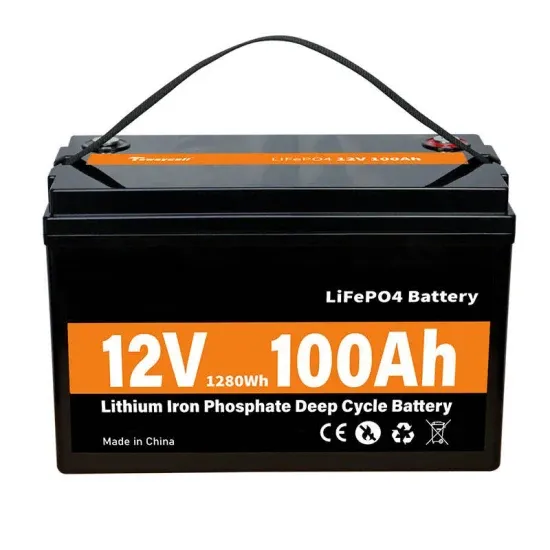

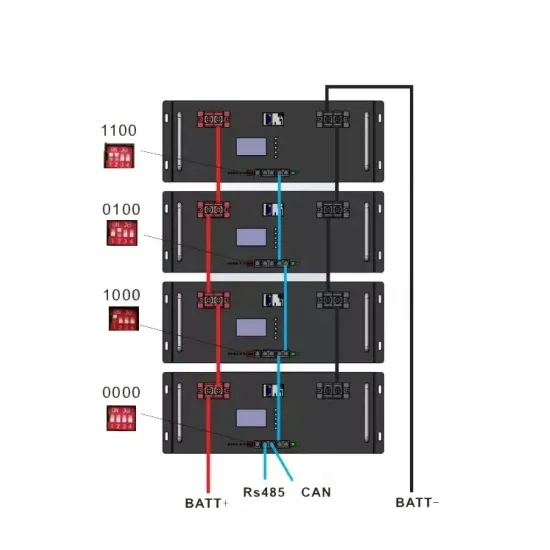

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.