Electric bus fast charging station resource planning considering

Mar 6, 2019 · As the progress of electrification for the public transportation sector is accelerated, it becomes more and more important to integrated planning charging infrastructure for public

BATTERY ENERGY STORAGE SYSTEMS FOR CHARGING

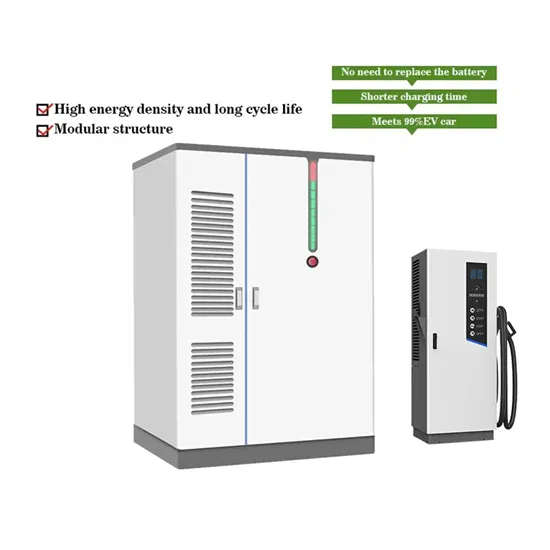

BATTERY ENERGY STORAGE SYSTEMS FOR CHARGING STATIONS Enabling EV charging and preventing grid overloads from high power requirements.

Energy Storage Charging Pile

Jun 27, 2025 · We mainly offer two directions: manufacture DC charger and offer one-stop solutions for DC Charger. We support OEM and ODM, as well as customized DC pile APP and

Shenzhen Best Bull Energy Technology Co., Ltd.

Shenzhen Best Bull Energy Technology Co., Ltd.ABOUT BESULEGY --Reliable Energy for a Moving World. BEST We are committed to delivering the highest

DC Charging Pile: Understanding Fast Charging Technology

Jan 17, 2024 · From understanding how DC charging piles work to their impact on sustainability and convenience, we''ll uncover all you need to know about these revolutionary energy

A multi-objective optimization model for fast electric vehicle charging

Mar 15, 2021 · The construction of fast electric vehicle (EV) charging stations is critical for the development of EV industry. The integration of renewable energy into the EV charging stations

What charging pile is suitable for energy storage | NenPower

Jan 10, 2024 · 1. TYPES OF CHARGING PILES Charging piles primarily come in three distinct categories: slow, fast, and ultra-fast charging stations. Each type has its specific application

Configuration of fast/slow charging piles for

Nov 23, 2024 · Through the analysis of various EV types, charging station configurations, and optimization strategies, it explores the economic and

photovoltaic energy storage charging pile application

A DC Charging Pile for New Energy Electric Vehicles This DC charging pile and its control technology provide some technical guarantee for the application of new energy electric

Charging Pile Manufacturer, Charging Station, Storage Battery

Charging Pile Supplier, Charging Station, Storage Battery Manufacturers/ Suppliers - GAC Energy Technology Co., Ltd.

Photovoltaic-energy storage-integrated charging station

Jul 1, 2024 · The results provide a reference for policymakers and charging facility operators. In this study, an evaluation framework for retrofitting traditional electric vehicle charging stations

What Do You Know About Charging Piles

Aug 16, 2025 · By balancing the electrical grid load, utilizing cost-effective electricity for storage, and supporting renewable energy integration, energy

Dynamic Energy Management Strategy of a

Jan 31, 2024 · The result shows that the incorporation of dynamic EMS with solar-and-energy storage-integrated charging stations effectively reduces electricity

Optimized operation strategy for energy storage charging piles

May 30, 2024 · The proposed method reduces the peak-to-valley ratio of typical loads by 52.8 % compared to the original algorithm, effectively allocates charging piles to store electric power

Benefit allocation model of distributed photovoltaic power

Aug 1, 2020 · Abstract In this study, to develop a benefit-allocation model, in-depth analysis of a distributed photovoltaic-power-generation carport and energy-storage charging-pile project

Charging Piles and Energy Storage: Powering the Future of

Mar 14, 2025 · Ever wondered why your smartphone battery dies faster than your enthusiasm for gym memberships? Now imagine scaling that power anxiety to electric vehicles (EVs). This is

DC Fast Charging Pile

Expand your business capabilities with our top-tier energy solutions. Boost efficiency with our energy storage and intelligent power inverters, ensuring up

Schedulable capacity assessment method for PV

May 15, 2023 · An accurate estimation of schedulable capacity (SC) is especially crucial given the rapid growth of electric vehicles, their new energy charging

New Energy Vehicle Charging Pile Solution

Sep 10, 2022 · I. Construction background Developing new energy vehicles is the only road China must take to become an advanced automobile maker from a

Design And Application Of A Smart Interactive

May 14, 2023 · With the construction of the new power system, a large number of new elements such as distributed photovoltaic, energy storage, and charging piles are continuously

VREMT 800A Ultra-fast Liquid-cooled Charging

May 27, 2024 · 800A ultra-fast liquid-cooled charging pile easily achieves "15-minute charging for a thousand kilometers" At the exhibition, VREMT

(PDF) Research on energy storage charging piles based on

Feb 1, 2024 · Abstract and Figures Aiming at the charging demand of electric vehicles, an improved genetic algorithm is proposed to optimize the energy storage charging piles

What charging pile is suitable for energy storage | NenPower

Jan 10, 2024 · Charging piles primarily come in three distinct categories: slow, fast, and ultra-fast charging stations. Each type has its specific application depending on the energy requirements

Presentation title on multiple lines

Dec 14, 2020 · SiC based AC/DC Solution for Charging Station and Energy Storage Applications JIANG Tianyang Industrial Power & Energy Competence Center Region, STMicroelectronics

Analysis of the future development trend of

Sep 30, 2022 · About the situation and development of the charging pile industry. The country''s strategic appeal for the new energy vehicle industry is very

Optimal Allocation Scheme of Energy Storage Capacity of Charging Pile

Sep 9, 2019 · With the gradual popularization of electric vehicles, users have a higher demand for fast charging. Taking Tongzhou District of Beijing and several cities in Ji

The Design of Electric Vehicle Charging Pile Energy

Apr 27, 2017 · The structure diagram and control principle of the sys-tem are given. The electric vehicle charging pile can realize the fast charging of electric vehicles, and the battery of the

Trends in charging infrastructure – Global EV

Aug 15, 2025 · The deployment of fast charging compensates for the lack of access to home chargers in densely populated cities and supports China''s

Schedulable capacity assessment method for PV and

May 15, 2023 · Fast charging technology for EVs may quickly charge the battery with a high charging current, which can significantly reduce the "mileage anxiety" issue that EV owners

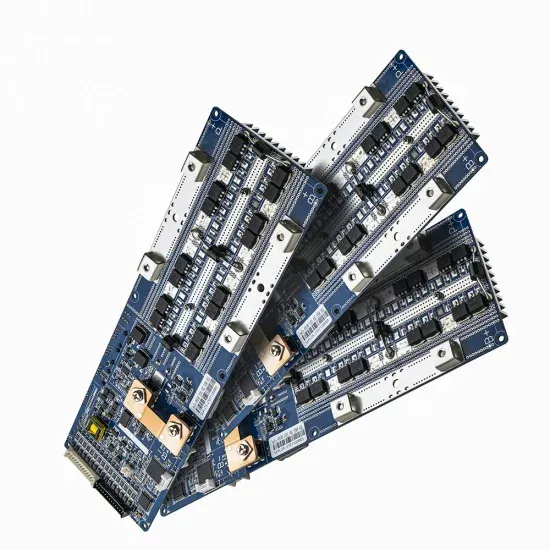

Energy storage charging pile fast charging

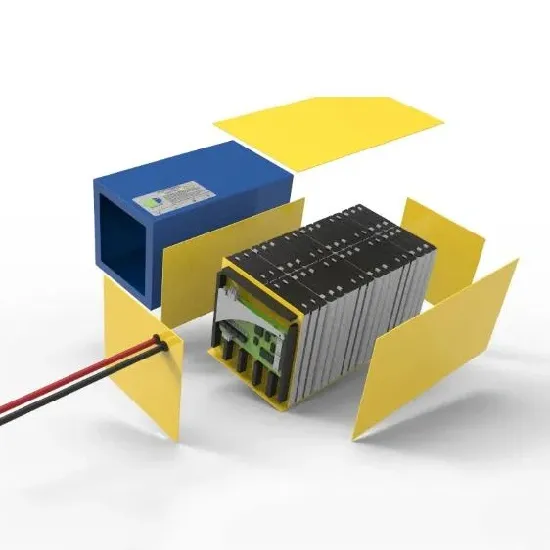

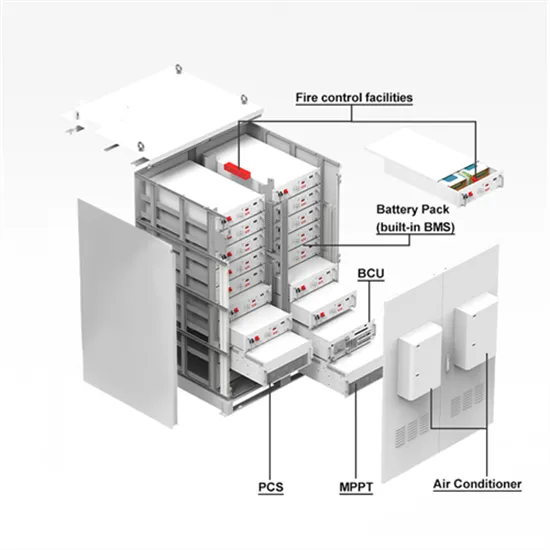

What is the energy storage charging pile system for EV? The new energy storage charging pile system for EV is mainly composed of two parts: a power regulation systemand a charge and

6 FAQs about [Fast energy storage charging pile]

How effective is the energy storage charging pile?

The energy storage charging pile achieved energy storage benefits through charging during off-peak periods and discharging during peak periods, with benefits ranging from 699.94 to 2284.23 yuan (see Table 6), which verifies the effectiveness of the method described in this paper. Table 6.

Can fast charging piles improve the energy consumption of EVs?

According to the taxi trajectory and the photovoltaic output characteristics in the power grid, Reference Shan et al. (2019) realized the matching of charging load and photovoltaic power output by planning fast charging piles, which promoted the consumption of new energy while satisfying the charging demand of EVs.

How does the energy storage charging pile's scheduling strategy affect cost optimization?

By using the energy storage charging pile's scheduling strategy, most of the user's charging demand during peak periods is shifted to periods with flat and valley electricity prices. At an average demand of 30 % battery capacity, with 50–200 electric vehicles, the cost optimization decreased by 18.7%–26.3 % before and after optimization.

Do energy storage charging pile optimization strategies reduce peak-to-Valley ratios?

The simulation results demonstrate that our proposed optimization scheduling strategy for energy storage Charging piles significantly reduces the peak-to-valley ratio of typical daily loads, substantially lowers user charging costs, and maximizes Charging pile revenue.

How to reduce charging cost for users and charging piles?

Based Eq. , to reduce the charging cost for users and charging piles, an effective charging and discharging load scheduling strategy is implemented by setting the charging and discharging power range for energy storage charging piles during different time periods based on peak and off-peak electricity prices in a certain region.

How to plan the capacity of charging piles?

The capacity planning of charging piles is restricted by many factors. It not only needs to consider the construction investment cost, but also takes into account the charging demand, vehicle flow, charging price and the impact on the safe operation of the power grid (Bai & Feng, 2022; Campaa et al., 2021).

Industry Information

- Container volume for solar power collection

- Energy Storage Container Solar Buildings for Sale China

- Jakarta container communication base station replaced with photovoltaic site

- 12 kWh inverter

- Kampala small power inverter

- China factory price bryant breakers exporter

- Kilowatts of solar power

- What other products does the energy storage cabinet battery produce

- Hot sale high quality lfp powerstation Buyer

- How much is the outdoor power supply in San Jose

- Solar power station in China in Jakarta

- Is Armenia s new energy storage an industry

- Solar 60W Battery

- Mine cave wind and solar energy storage power generation project

- Energy storage grid approval

- Factory price socket breaker in Suriname

- Outdoor power supply charging overload

- Sukhumi Communication Green Base Station Verification

- South Africa inverter 12v to 220v

- Photovoltaic panels installed on rooftops in Chad Township

- Cote d Ivoire All-Vanadium Liquid Flow Energy Storage Power Station

- Slovakia Solar Photovoltaic Water Pump

- Water pump can be used both solar and electric

Commercial & Industrial Solar Storage Market Growth

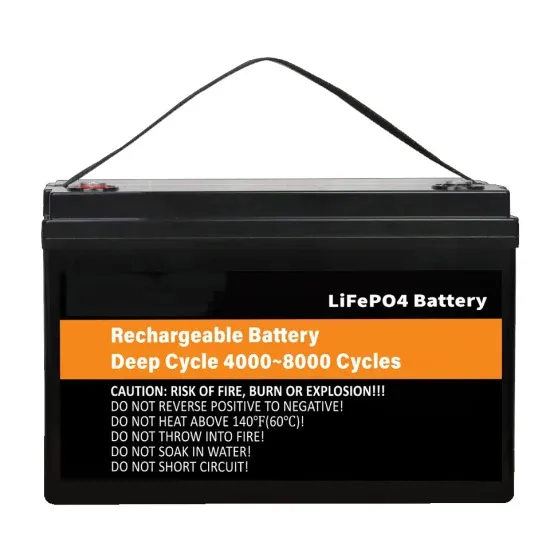

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.