Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

Cameroon Power Storage Battery: The Key to Unlocking

Aug 23, 2019 · Cameroon''s energy paradox is striking: The government isn''t just talking – they''re installing. Take the 10-phase storage initiative launching in 2025 [1]: Fun fact: These batteries

Assembly of lithium battery packs in Douala Cameroon

The production of lithium battery modules, also known as Battery Packs, involves a meticulous and multi-step manufacturing process. This article outlines the key points of the lithium battery

cameroon energy storage lithium battery pack

Here''s some videos on about cameroon energy storage lithium battery pack Lithium Battery Pack With Growatt SPH3000 6000 Today GSL has established a solid foundation of

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · PDF | Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly

Energy Storage Battery Factories in Douala Cameroon

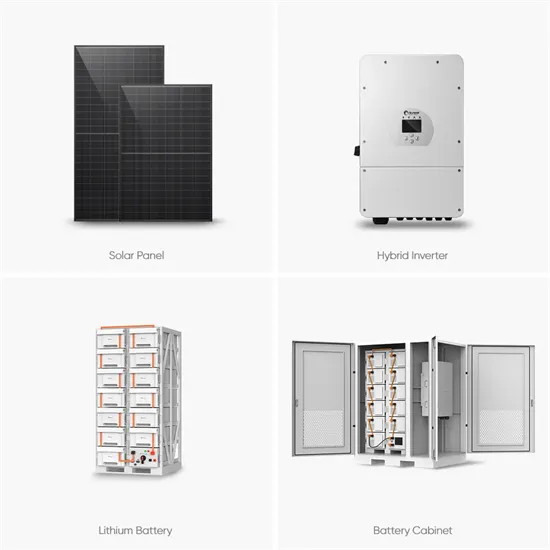

Local manufacturers primarily focus on lithium-ion and lead-acid battery solutions, with some adopting modular battery systems for flexible deployment. A recent innovation includes hybrid

Cameroon Douala Photovoltaic Energy Storage Lithium Battery

Summary: Discover how lithium battery systems are transforming solar energy storage in Cameroon''s economic hub, Douala. This guide explores maintenance strategies, cost-saving

Batteries solaires

Découvrez nos batteries solaires de haute qualité pour stocker efficacement l''énergie de vos panneaux photovoltaïques. Idéales pour une autonomie énergétique accrue, réduisez vos

Lithium battery for energy storage system in Douala Cameroon

Grimaldi Group completes installation of Corvus About Corvus Energy Corvus Energy provides high power energy storage in the form of modular lithium ion battery systems. Its purpose-built,

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Diferent shapes of the lithium-ion cell Nomenclature of lithium-ion cell/battery Overview of Li-ion battery packs Assembling Process Detailed flowchart for Li-ion battery pack

Innovating battery assembly

Aug 13, 2025 · EV batteries have become an integral part of the vehicle structure, making lithium-ion cell assembly and their integrity a safety-critical issue. One major diferentiating feature of

How Are Lithium Battery Packs Assembled?

Aug 18, 2025 · By following the key steps involved in lithium battery pack assembly, including cell selection and testing, cell arrangement and connection, BMS integration, and final assembly

How Are Lithium Battery Packs Assembled?

Aug 18, 2025 · How Are Lithium Battery Packs Assembled? Lithium battery packs are essential components in various applications, from electric vehicles to renewable energy storage

Lithium Battery Pack Assembly: A

May 6, 2024 · As the world transitions towards sustainable energy solutions, the demand for high-performance lithium battery packs continues to soar. At the

Cameroon Forklift Energy Storage Battery Price: What You

Why Forklift Batteries Are the Backbone of Cameroon''s Logistics a bustling port in Douala where forklifts work like disciplined ants, moving goods 24/7. What keeps these mechanical

Custom Lithium Battery Pack Manufacturing

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves

Automated assembly of Li-ion vehicle batteries: A feasibility study

Jan 1, 2020 · Electric Vehicles (EVs) with rechargeable Lithium-Ion batteries (Li-ion) are at the forefront of the global trend for lower-emission transportation and decarbonisation. Capable

Cameroon''s Lithium Battery Energy Storage: Powering

This isn''t magic; it''s cold, hard electrochemistry. Lithium Batteries 101: Not Your Grandpa''s Power Bank Think of lithium batteries as the Beyonc? of energy storage--versatile, high-performance,

Lithium Battery Energy Storage Price in Douala Cameroon

Douala, Cameroon''s economic hub, faces growing energy demands driven by rapid urbanization and industrial expansion. Lithium battery storage systems have emerged as a cost-effective

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Cameroon Douala lithium battery cylindrical battery

Lithium-ion Battery Manufacturing. As a professional Lithium Iron Battery manufacturer, Alium has manufacturing centers for batteries and PACK in Asia and USA.With a highly automated

Lithium-Ion Battery Assembly Process & Key

May 17, 2025 · Discover the key stages in the lithium-ion battery assembly process, from raw materials to pack assembly. Learn how battery-making

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · Lithium-ion batteries are usually produced using two lithium-ion battery assembly process methods: manual assembly and automated assembly. Manual assembly is the most

Lithium battery for energy storage system in Douala Cameroon

Are energy storage systems suitable for new generation lithium-ion batteries? Finally, the applicability of these suitable energy storage systems is evaluated in the light of their most

Battery Pack Assembly: From Cells to Power Packs

Discover how individual battery cells become high-performance battery packs. Learn about cell connection, modularization, and the critical role of battery

The Manufacturing Process of Lithium Batteries

The production of lithium-ion battery cells involves three main stages: electrode manufacturing, cell assembly, and cell finishing.

Battery Pack Manufacturing Process

Mar 15, 2025 · The battery cell manufacturing process is a complex, multi-step procedure that ensures the efficiency, safety, and longevity of battery packs. It

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · A lithium battery pack is a collection of individual lithium-ion or lithium-polymer cells grouped together to store and deliver electrical energy. These packs are widely used in

Felicity SOLAR Cameroon LTD

Jul 26, 2025 · LPBF series lithium batteries all in one: A type of lithium iron phosphate (LiFePO4) battery, specifically designed for solar energy storage systems in homes.#Known

Lithium Battery Pack Process: Assembly, Management and

The pack process of lithium battery involves many links such as the assembly, management and protection of battery cells, which has an important impact on the performance and safety of

Battery Pack Assembly: Techniques and

Nov 27, 2024 · Battery pack assembly is a critical component of the electric vehicle (EV) ecosystem. The efficiency, safety, and longevity of EVs depend

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · This final stage in the lithium-ion battery manufacturing process integrates individual cells into fully functional battery modules, complete with

CAMEROON

Huijue Energy Storage Cameroon Plant Operation: Powering Africa''s Sustainable Future a football field-sized facility in Douala humming with lithium-ion battery racks, quietly solving

The Ultimate Guide For Lithium-Ion Battery

This in-depth guide explores lithium-ion battery packs from the inside out. Learn about the key components like cells, BMS, thermal management, and enclosure.

Customised assembly of battery & rechargeable

Fast delivery times We keep standard packs in stock. We manufacture customised battery and rechargeable battery packs in a short time - thanks to

Lithium-Ion Battery Assembly Line Process

Feb 25, 2025 · Explore the Lithium-Ion Battery Assembly Line —how precision, automation, and testing ensure high performance, safety, and reliability in

MAERSK OPENS TECHNOLOGY DRIVEN WAREHOUSE IN DOUALA CAMEROON

HuaXin New Energy Storage Technology Huaxing Energy specializes in integration of all technologies including Cathode Material, Lithium Cell, Lithium Battery Packs, BMS and

Batterie +panneau solaire au lithium 500W

Achetez votre Batterie +panneau solaire au lithium 500W sur light Cameroun et faites vous livrer au Cameroun en toute sécurité Caractéristiques Type de produit: Batterie solaire Longue

6 FAQs about [Assembly of lithium battery packs in Douala Cameroon]

What is a lithium ion battery pack?

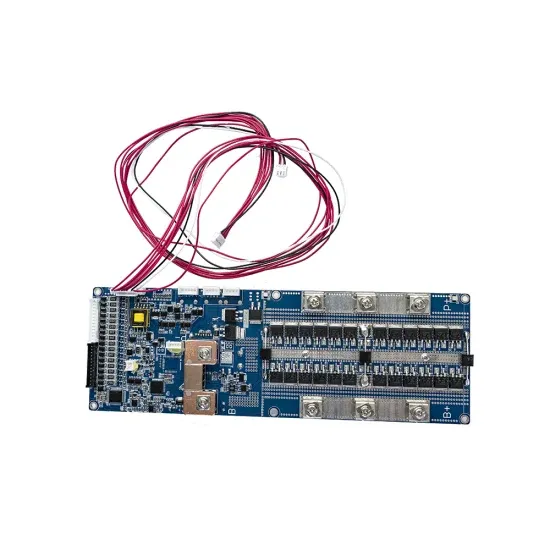

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

Which battery cells are used in a CMB battery pack?

CMB’s battery pack designer gives priority to the following three most common battery cells for the battery pack design: INR (Ternary Lithium), LFP (Lithium Iron Phosphate Chemistry) and LiPo (Lithium Polymer).

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

What is battery pack assembly?

The battery pack assembly is the process of assembling the positive electrode, negative electrode, and diaphragm into a complete battery. This involves placing the electrodes in a cell casing, adding the electrolyte, and sealing the cell.

How a lithium ion battery is made?

The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries. The lithium-ion battery manufacturer should have a strict gap standard of less 5mv voltage gap, less 15mΩ internal resistance, and less 5mAh capacity gap.

What is battery pack production?

In conclusion, Battery pack production is a complex and multifaceted process that requires meticulous attention to detail, strict quality control, and a commitment to safety.

Industry Information

- Democratic Republic of Congo professional custom cylindrical lithium battery

- Automation Technology Capacity of a container energy storage cabinet

- Luxembourg BMS lithium battery

- 13kw photovoltaic inverter price

- China bryant circuit breakers in Jamaica

- Industrial and Commercial Energy Storage Management System

- 48v500f supercapacitor price

- Vanuatu UPS battery cabinet quotation

- 60N06 as inverter

- Hot sale high quality lfp powerstation Price

- Wholesale solar power supply in Saudi-Arabia

- Communication base station lithium battery communication

- Cheap quad circuit breaker factory Factory

- What is the battery cabinet used for communication high voltage cabinet

- Uninterrupted power supply for West Asia heavy rain communication base station

- Botswana Energy Storage Power Station

- Foreign communication base station lead-acid battery centralized procurement

- Albania high frequency inverter cabinet accessories

- Energy storage battery for charging piles

- Uninterruptible power supply prices for enterprises in Vietnam

- Mogadishu lithium battery energy storage cabinet system

- Royu circuit breaker for sale in Senegal

- Inverter and energy storage products

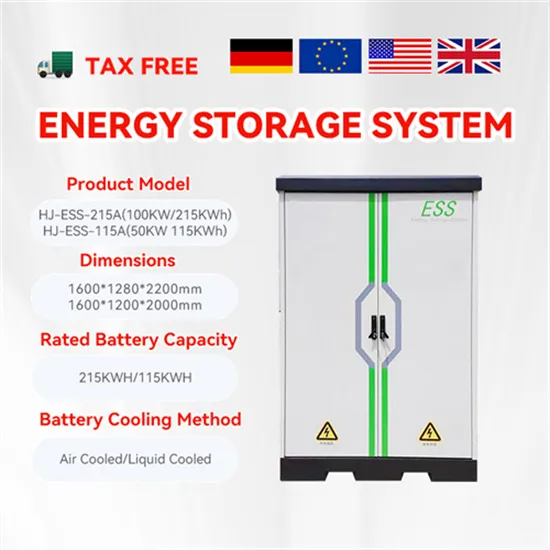

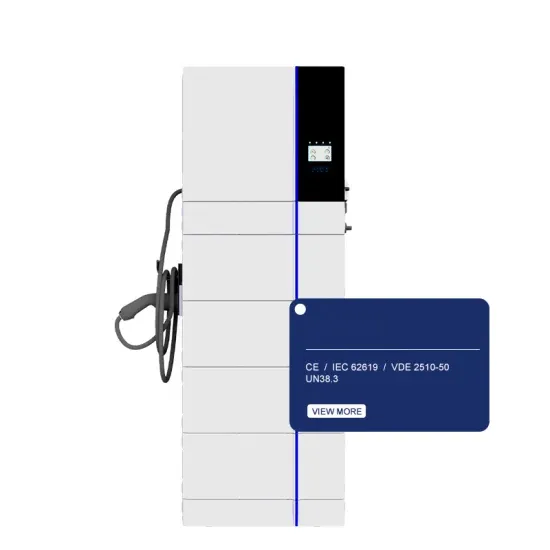

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.