Step-by-Step Inverter Troubleshooting Guide

May 25, 2025 · Voltage levels must also be within the inverter''s specified range; otherwise, the inverter may shut down or fail to start. Proper wiring and

10 most common fault codes and how to solve

Aug 25, 2024 · Trouble shooting is the same as for the overvoltage fault, the overvoltage controller will increase the reference in an attempt to bleed off excess voltage Not all series of

Classification of phase loss detection algorithms.

Download scientific diagram | Classification of phase loss detection algorithms. from publication: Phase Loss Detection Using Current Signals: A Review |

undefined

Jul 29, 2025 · Issue: Troubleshooting an Altivar Process Drive with an Output Phase Fault. Product Line: ATV600 and ATV900 series Resolution: [Single Output Phase Loss] OPF1

SMA Tripower connects with lost phase

Feb 19, 2015 · SMAs response was that the inverters have met UL1741 and we should just turn up the reconnect voltage to prevent this from happening. Turning up the reconnect voltage did

Causes and detection methods of inverter output phase loss

The reason why the inverter output is missing phase The working principle of the inverter is to convert AC into DC, and then invert it into AC. Therefore, some small inverters can also be

Troubleshooting a Frequency Inverter That Won''t Start

Jun 26, 2025 · To troubleshoot a frequency inverter (variable frequency drive, VFD) that won''t start, proceed as follows: 1. Power Supply Verification. Input Voltage: Measure input voltage at

What are Enphase Micro Inverter Problems?

Mar 2, 2024 · What are Enphase Micro Inverter Problems: These inverters have communication problems, overheating issues, grounding issues, and the like

Three-Phase Inverters

Likewise, other voltage patterns can easily be extrapolated and understood as shown for Van in Figure 22. Figure 22: Typical Phase to Neutral Voltages in Three-Phase Inverter Figure 23:

In three phase inverter during unbalance condition,control

What am I missing? I''m modeling three phase Inverter using three-single phase full bridge inverters. My aim is to provide constant voltage at both unbalanced and non linear load

Voltage Control Methods of Inverter – PWM

Feb 12, 2022 · In practice, the waveform of the output voltage obtained from a single-phase inverter is rectangular in nature with an amplitude approximately

A Literature Review of Fault Detection and

Sep 9, 2024 · This review paper offers a comprehensive examination of the various types of faults that occur in inverters and the methods used for their

All ABB Inverter Error Codes & How to Fix Them

Oct 11, 2021 · Here you''ll find a complete list of common error code faults found on ABB inverters, along with troubleshooting tips and solutions.

How exactly does grid-tied hybrid inverter detect loss of grid?

Aug 17, 2022 · Toughest thing for inverter to do is detecting when AC input goes open circuit, like when you open AC input breaker. Zero AC input current is a legit condition and voltage on AC

New original OMr K8DS-PA2 inverter phase missing relay voltage

New original OMr K8DS-PA2 inverter phase missing relay voltage monitoring, You can get more details about New original OMr K8DS-PA2 inverter phase missing relay voltage monitoring

Phase Voltage Determination for Three-Phase Inverters

Mar 17, 2025 · Calculation Expression Output Phase Voltage: The output phase voltage (Vm) of a three-phase inverter is calculated based on the DC bus voltage and firing angle.

The AC Terminal of the Inverter Has no Output Voltage (The

Mar 27, 2025 · Use a multimeter to measure the phase-to-phase impedance of the AC terminals of the inverter. If the impedance is greater than 1 megohm, it is normal. If the impedance is

Why there is no output voltage after the inverter

Apr 9, 2024 · The inverter has no U, V, W phase voltage output, but there is normal voltage between P and N of the main circuit (both ends of the energy

ABB ACS880

Mar 5, 2021 · , ABB ACS880 - INPUT PHASE LOSS (FAULT 3130), UK Electrical Forum, ElectriciansForums Est.2006 | Free Electrical Advice Forum and page_number.

What Is the Fault When the Frequency Inverter

Aug 19, 2025 · Start the variable frequency inverter in a no-load condition and observe the U, V, and W three-phase output voltage: Check for missing

Loosing a phase of a 3-phase system | Eng-Tips

Mar 26, 2009 · The voltage on two secondary phases will be 50% of nominal and will be in phase, not 120° out of phase. They will be 180° out of phase with the third phase. If you draw out the

US5548207A

A missing phase detector circuit which monitors the ac three-phase output voltages of power equipment or sources and produces an output signal in the event a missing ac phase is

PID Repairing Guide : Solis North America

If the board was loose, reconnect it and check if the inverter exits "PID Repairing" before proceeding. Check AC Voltage: Confirm AC voltage is present at the site. Inspect RSD Fuses:

User Manual Guide for the Fuji High Voltage

Feb 10, 2025 · Power Input: The inverter requires a three-phase high voltage input, commonly 3φAC 3.0kV, 3.3kV, 6kV, etc. When connecting the power

Summary of common causes and countermeasures of inverter

Cause: When the inverter power supply phase is lost, the three-phase rectification becomes two-phase rectification. After the load is applied, the DC voltage after rectification is low, causing

Residential Loss of Phase | Eng-Tips

Aug 24, 2010 · The inverter is a grid tied inverter, it has all the requied under/over voltage, under/over frequency, and anti-islanding protections required by UL1741. The problem is it''s a

Voltage Troubles? A Guide to Diagnosing Inverter Low Voltage

Dec 17, 2023 · One prevalent cause could be a faulty battery. An old or damaged battery may not be able to provide sufficient power, leading to low voltage from the inverter. Another possible

How to judge and repair the inverter phase failure?-EEWORLD

Phase loss fault of the inverter is one of the common faults. It should be noted that there are mainly single-phase 220V and three-phase 380V inverter products. Of course, input phase

10 Common Inverter Errors and Effective

Inverters play a crucial role in industrial automation and energy systems, converting DC power into AC for various applications. However, inverter errors

VFD''s Capacitor Reforming & Alarm/Warning

If we suddenly supply it with full voltage, there will be a high inrush charging current which leads to the breakdown of the capacitor In a normal scenario and for all the new drives, there is no

Inverter Phases Explained

Split-phase inverters are pivotal in ensuring efficient power distribution within homes and other settings requiring such voltage options. Pros: precise

A Literature Review of Fault Detection and

Sep 9, 2024 · To identify the open-circuit fault of a power semiconductor in the three-phase, a two-level, voltage-source inverter-fed permanent magnet

Phase-Voltage Calculation for Three-Phase Inverters

Dec 11, 2024 · Explanation Three-Phase Inverter Voltage Calculation: This calculator uses standard formulas to compute the output phase and line-to-line voltages of a three-phase

Output Phase Loss: Typical Variable Speed Drive

Oct 28, 2019 · One critical function monitored is the health of each phase of the VSD''s output; when a fault occurs there, it is termed an Output Phase Loss.

The 3 Most Common Faults on Inverters and how to Fix Them

Dec 16, 2019 · This can be caused by a missing supply voltage phase from a blown fuse or faulty isolator or contactor or internal rectifier bridge fault or simply low mains voltage.

Warnings, Trips, Faults and Failures

If the inverter continues to supply voltage to the motor, then the motor will generate and feed energy back to the drive. This will increase the DC link

How to judge and repair inverter phase fault?

Feb 11, 2025 · If the lack of phase in operation is very dangerous, the motor current increases 1.2 times, the heat is serious, the vibration is aggravated, and the motor is easily burned. By

6 FAQs about [Inverter phase voltage missing]

What are the most common faults on inverters?

In this article we look at the 3 most common faults on inverters and how to fix them: 1. Overvoltage and Undervoltage Overvoltage This is caused by a high intermediate circuit DC voltage. This can arise from high inertia loads decelerating too quickly, the motor turns into a generator and increases the inverter’s DC voltage.

What causes undervoltage failure in an inverter?

1. Power supply phase loss Cause: When the inverter power supply phase is lost, the three-phase rectification becomes two-phase rectification. After the load is applied, the DC voltage after rectification is low, causing undervoltage failure.

What causes a power inverter to fail?

There are numerous factors that contribute to these faults; among them are the overheating of the power switches caused by overloading and control failure, as well as external causes such as mechanical accidents and the impacts on the overall structure of the inverter.

Why is my inverter NOT working?

By understanding the causes behind such issues and following the appropriate diagnostics, you can get your inverter back to working optimally. Remember to check the battery health, power source, and electrical connections regularly to avoid potential voltage troubles in the future. Are you experiencing voltage troubles with your inverter?

What is inverter low voltage?

Now that we know what inverter low voltage is, let's explore some common causes behind it. One prevalent cause could be a faulty battery. An old or damaged battery may not be able to provide sufficient power, leading to low voltage from the inverter. Another possible cause could be an inadequate power source or improper electrical connections.

Why is my inverter low voltage?

Another possible cause could be an inadequate power source or improper electrical connections. Faulty wiring can also result in voltage fluctuations. If you are experiencing inverter low voltage problems, it's essential to diagnose the issue accurately. Start by checking the battery health.

Industry Information

- S power supply system be used as an outdoor power supply

- LiFePO4 Inverter Outdoor Power Supply

- Best China circuit breaker outdoor Factory

- Cost structure of gravity energy storage

- Energy storage cabinet non-module design

- Dhaka outdoor power supply store

- How to install the air duct of the battery compartment of the energy storage container

- How much does lead-carbon energy storage battery cost

- Base station power supply national standard

- South America Outdoor Mobile Energy Storage Power Plant

- Photovoltaic communication battery cabinet manufacturer in Bahrain

- Design of power system of energy storage power station

- Safety requirements for liquid flow energy storage batteries

- Croatia single glass photovoltaic module prices

- Substation energy storage system lithium battery pack

- Cabinet battery pack factory

- Base station battery pack connection

- Cross-border sellers of energy storage products

- Marshall Islands Home Energy Storage System EK

- Factory price single breaker in Mumbai

- Solar PV Degradation Panel

- RV equipped with lithium iron phosphate battery pack

- Wholesale reset gfci breaker in Monaco

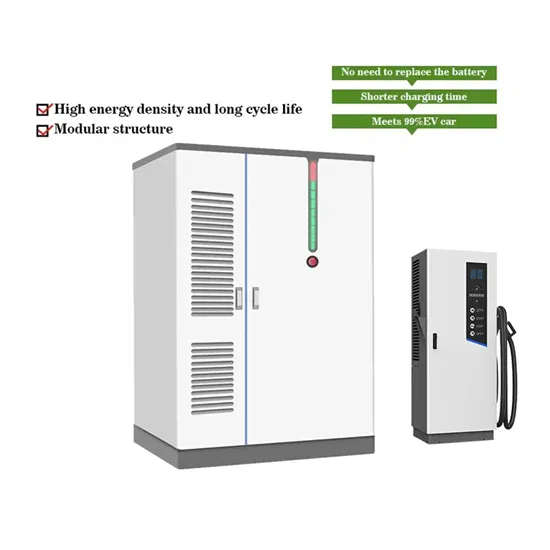

Commercial & Industrial Solar Storage Market Growth

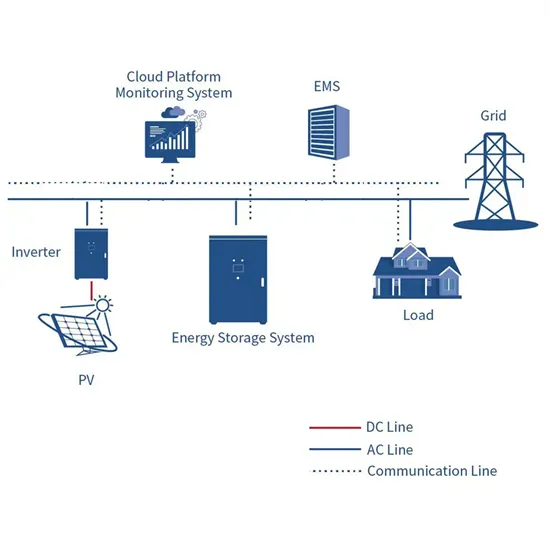

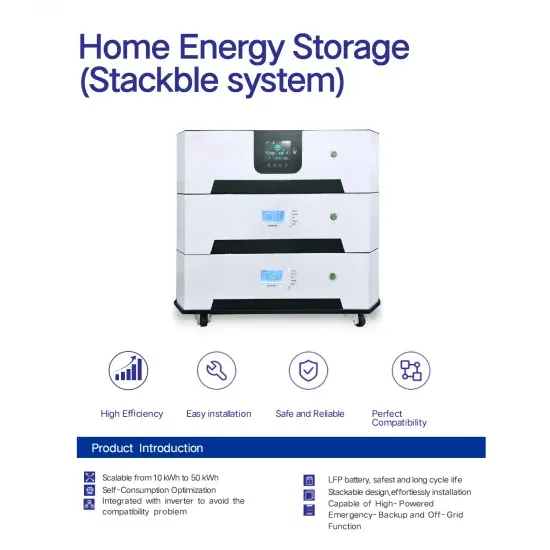

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

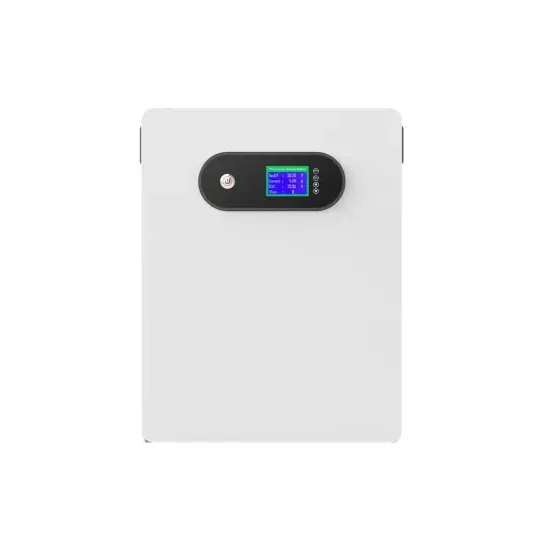

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.