Battery Room Ventilation Code Requirements

Dec 13, 2022 · Battery Room Ventilation Code Requirements Battery room ventilation codes and standards protect workers by limiting the accumulation of hydrogen in the battery room.

2012

Apr 17, 2021 · 2012 - 2016 Camry Hybrid Battery Installation Step-by-Step Hybrid Battery Removal and Installation Instructions Video demonstration is available at our website:

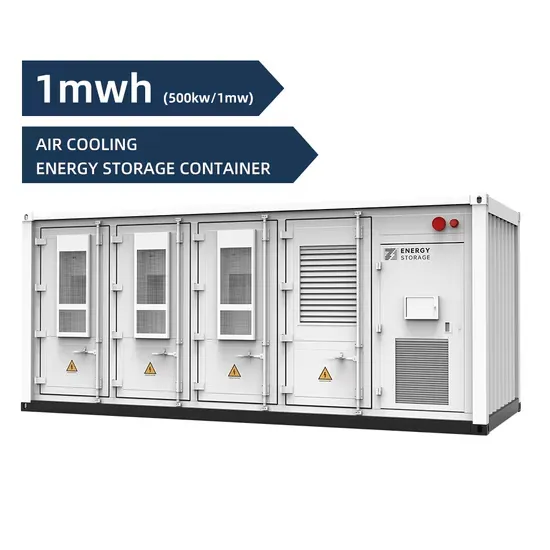

Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · Discover the essential steps in designing a containerized Battery Energy Storage System (BESS), from selecting the right battery technology and system architecture to

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · Adjusting the position of the return air vent further improves temperature uniformity and air flow distribution within the battery compartment. When the air supply angle is 90° and

Ductwork Assembly: A Step-by-Step Guide to

A well-executed ductwork assembly minimizes energy losses, enhances indoor air quality, and contributes to the overall effectiveness of the HVAC system. In

An optimization study on the performance of air-cooling

Jul 1, 2025 · An optimization study on the performance of air-cooling system for energy storage battery packs using a novel thermoelectric coupling model

Coupling simulation of the cooling air duct and the battery

Abstract The air-cooled battery thermal management system (BTMS) is a safe and cost-effective system to control the operating temperature of the battery energy storage system (BESS)

Maximizing efficiency: exploring the crucial role of ducts in air

Jan 29, 2025 · The present work reviews the critical role of duct design in enhancing the efficiency of air-cooled LIBs, by comparing symmetrical and asymmetrical duct configurations.

Portable Diesel Heater RV Storage Compartment

Oct 1, 2023 · Install Overview I installed my Vevor 8KW portable diesel heater (click to view current model Amazon) in a large storage compartment in my 24

Nissan Rogue Service Manual: Ducts and grilles

Other materials: Engine compartment check locations Engine compartment check locations QR25DE engine Engine coolant reservoir Engine oil filler cap Brake

How to install container battery energy storage

In order to facilitate transportation and installation and reduce the floor space, the energy storage system design of the project is based on lithium iron phosphate battery energy storage

Battery Room HVAC Technical Requirements | Specification

Dec 9, 2024 · This article is about Battery Room HVAC Technical Requirements and Specification as per International Codes and standards. Battery Room HVAC Technical Requirements Air

Understanding the Air Duct Design in Air-Cooled Energy Storage

Jun 11, 2025 · Air duct design in air-cooled energy storage systems (ESS) refers to the engineering layout of internal ventilation pathways that guide airflow for optimal thermal

How to install the air duct of the battery compartment of the energy

The air-cooled battery thermal management system (BTMS) is a safe and cost-effective system to control the operating temperature of the battery energy storage system

HOW TO: Lithium Battery Powered Vent System

Mar 12, 2021 · Conditioned air intake: A 4" duct vent under the street side bed and another 4" duct vent in the battery box right above the street side wheel well. There''s plenty of room for 3.75"

Durkduct Integrated Flexible Air Ducting

May 30, 2024 · After more than a decade of application and promotion in the global and domestic markets, Durkduct hvac duct manufacturer Flexible Air

Installing an Air Duct

Align the positioning pins on the air duct with the fixing holes on the mainboard by following the instructions on the chassis. Vertically place the air duct downwards. See Figure 6-14. Install

How to install batteries in the lead-acid battery

How should a car battery compartment be installed? INSTALLATION OF BATTERIES The battery compartment in the vehicle should be ventilatedand designed in a manner to keep out

VINTAGE AIR 561163 MANUAL Pdf Download | ManualsLib

View and Download Vintage Air 561163 manual online. 1963-66 CORVETTE WITHOUT FACTORY A/C. 561163 automobile accessories pdf manual download.

EngineeredSystems May 2018: Designing Ventilation For Battery

May 3, 2018 · The room ventilation method can be either forced or natural and either air-conditioned or unconditioned. Battery manufacturers require that batteries be maintained at

Numerical investigation of the effect of inlet dimensions air

Jan 7, 2022 · Numerical investigation of the effect of inlet dimensions air duct and distance of battery packs for thermal management of three lithium-ion battery packs,Journal of Energy

Energy storage battery cabinet air duct

An energy-storage system (ESS) is a facility connected to a grid that serves as a buffer of that grid to store the surplus energy temporarily and to balance a mismatch between demand and

How to Put Batteries In An Airsoft Gun:

To put batteries in an airsoft gun, follow these steps: Locate the battery compartment of your rifle. Some are found on the buttstock while others are in

Coupling simulation of the cooling air duct and the battery

Jun 5, 2023 · The air-cooled battery thermal management system (BTMS) is a safe and cost-effective system to control the operating temperature of the battery energy storage system

HOW BIG IS THE AIR DUCT DESIGN OF THE ENERGY

Here''s how to install air ducts Energy Storage Container integrated design for easy delivery; Control the cooling and heating system of the air conditioner through thermal management

Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

Section 7 Batteries

Feb 5, 2024 · Goal Safe energy storage and dependable supply of power to consumers. Functional requirements Reasonably foreseeable hazards external to the battery shall be

How to install batteries in the lead-acid battery

A lead acid battery is a number of cells filled with a mixture of sulfuric acid and water called electrolyte. The electrolyte covers vertical plates made of two types of lead. Chemical action

A thermal management system for an energy storage battery container

May 1, 2023 · The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes

Design and optimization of the cooling duct system for the battery

Abstract: This study takes a certain type of container energy storage system as the research object. A personalized uniform air supply scheme in the form of "main duct + riser" is proposed

How to Install a Lantern Battery

Aug 15, 2025 · Align the positive and negative terminals of the new battery to match the alignment of the removed battery (or the lantern''s battery compartment). These terminals, which look like

1969-74 Chevrolet Nova

Apr 20, 2022 · From the engine side, install the firewall cover onto the firewall from the passenger compartment, secure the firewall cover using (5) 1/4" flat washers and (5) 1/4-20 nuts with star

HOW TO: Lithium Battery Powered Vent System

Mar 12, 2021 · Conditioned air intake: A 4" duct vent under the street side bed and another 4" duct vent in the battery box right above the street side wheel

6 FAQs about [How to install the air duct of the battery compartment of the energy storage container]

What is the best airflow distribution in a battery compartment?

Combined with the temperature distribution on the surface of the battery table and the final ranking results of each evaluation index, the airflow distribution in the battery compartment is most ideal when the air supply angle is 90° and the return air vent is at Z = 0.85 m on the side of the fire door. Table 7.

Where is the air supply duct located?

The air supply ducts are positioned directly above the battery racks, with six identically sized air conditioning vents along the duct sidewalls, opposite the partition. The control cabinet is situated on the left side of the battery compartments, while the air conditioning units are installed on the right side of the container. Fig. 1.

What is a containerized energy storage battery system?

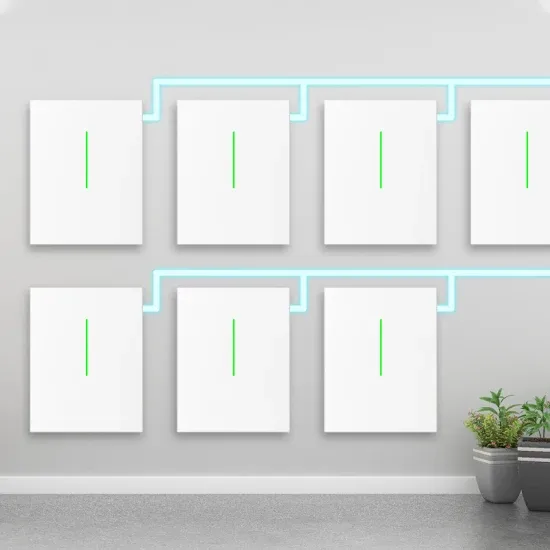

The containerized energy storage battery system comprises a container and air conditioning units. Within the container, there are two battery compartments and one control cabinet. Each battery compartment contains 2 clusters of battery racks, with each cluster consisting of 3 rows of battery racks.

What is a containerized storage battery compartment?

The containerized storage battery compartment is separated by a bulkhead to form two small battery compartments with a completely symmetrical arrangement. The air-cooling principle inside the two battery compartments is exactly the same.

Does air supply angle affect heat transfer characteristics in energy storage battery system?

energy storage battery system CFD simulation. The effects of different air supply angles on the heat transfer characteristics inside the container were studied. The return air vent was optimized, and a new air supply and return air vent arrangement method was proposed.

What is the spacing between battery racks?

The spacing between the battery racks is 10 mm (d 1), the spacing between the two clusters is 130 mm (d 2), the left-side battery rack is 40 mm (d 3) from the wall and the right-side battery rack is 70 mm (d 4) from the wall. Three views of the thermal management system are shown in Fig. 3.

Industry Information

- How much electricity can a set of photovoltaic panels generate

- Energy Storage RV Battery Sales

- Nouakchott solar home power generation system

- Glass energy storage power generation

- How much does a 1000 degree battery container cost

- Actual power consumption of 5g base stations

- How much does an uninterruptible power supply cost in Baku

- Papua New Guinea imports a large number of photovoltaic panel manufacturers

- Honduras Mobile Base Station Site

- High-performance flow batteries

- Venezuela energy storage battery export company

- Solar power storage batteries in Albania

- How much does 2400 watts of solar energy cost

- Solar power with grid backup in Durban

- Niger building photovoltaic curtain wall supplier

- Masai outdoor lithium battery station cabinet integrated system

- Which battery should be used for 12V60A inverter

- Mobile Indoor Power Box Specifications

- Vaduz lithium energy storage power supply customization company

- Solar roof translucent tiles

- What is the use of 21700 battery cells

- Huawei s Italian energy storage project

- Sukhumi Photovoltaic Energy Storage

Commercial & Industrial Solar Storage Market Growth

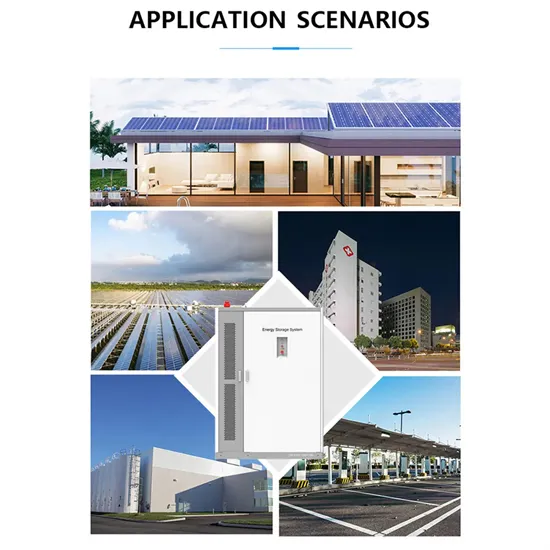

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.