Solar Panel Recycling Machine & Equipment Manufacturer

We provide complete solutions for PV panel dismantling, material separation, and eco-friendly waste management. PV Solar panels typically consist of glass, polymer, aluminum, copper,

Photovoltaic panel solar panel glass removal machine

6 days ago · The solar de glassing machine is an efficient and environmentally friendly device mainly used to separate photovoltaic cells from photovoltaic glass. It is driven by solar or

Solar Panel Recycling Machine & Equipment Manufacturer

Professional manufacturer of solar panel recycling machines and equipment. We provide complete solutions for PV panel dismantling, material separation, and eco-friendly waste

Photovoltaic Panel Recycling Plant Machine | SUNY GROUP

Oct 17, 2024 · Main technical equipment Different equipment undertakes key tasks at different stages of the PV panel recycling process, from pre-processing, and material separation to final

Factory Direct Smart Temperature Control Photovoltaic Glass Separation

Waste solar panel glass removal machine is a device specifically designed for processing waste photovoltaic panels, specifically for single crystal silicon and polycrystalline silicon single glass

Solar PV Glass Removing Machine-Solar Panel Recycling

Low energy consumption: The Solar PV Glass Removing Machine focuses on energy-efficient design and adopts energy-saving heating, vibration and separation technology to minimize

Solar Panel Recycling Plant

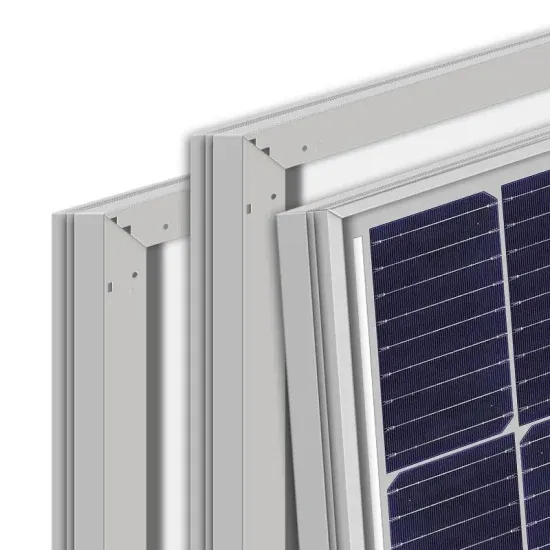

With solar PV panel recycling machines, valuable materials such as copper, silver, silicon, plastics, and glass can be recovered from their components such as aluminum frames,

Photovoltaic Panels Recycling Machines | SUNY GROUP

Jun 28, 2025 · The main process of PV panel recycling Currently, the recycling of photovoltaic panels consists of three main steps: dismantling → crushing and sorting → material reuse.

Photovoltaic Panel Glass Frame Junction Box Separation and

Key attributes type Recycling Plant Power 160 Kw core components motor, Engine, Other machinery test report Provided video outgoing-inspection Provided warranty 1.5 years material

Solar Panel Glass Removal Machine Photovoltaic Panel Glass Separation

Photovoltaic panel glass separation machine is a device specifically designed for processing waste photovoltaic panels, specifically for single crystal silicon and polycrystalline silicon single

Glass recycling: Efficient Glass Interlayer

Our crushing equipment FDS1250 or FDS1250PV can efficiently separate laminated glass into glass and interlayer, or separate photovoltaic panel into

Photovoltaic solar panel glass removal machine

3 days ago · The photovoltaic panel glass removal machine is a key equipment for the recycling and treatment of waste photovoltaic panels. It removes the glass layer on the photovoltaic

Recycling Technology Using Hot Knife Separation Method

Jul 5, 2024 · NPC Inc. provides a variety of custom-made manufacturing equipment to various industries, including vacuum laminators, which is one of its core technologies. We have been

Solar Panel Recycling Machine | NPC incorporated

2 days ago · Make solar panel recycling more efficient and high-quality. Our equipment realizes no metal residue and breakage on the glass after

Photovoltaic Panel Recycling | WANROOETECH

4 days ago · Photovoltaic panel recycling machine Photovoltaic panel recycling machine, also known as photovoltaic panel recycling equipment or

Full Automatic Solar Glass Separation Equipment Photovoltaic

The photovoltaic panels are transported in the center. The width of photovoltaic panels of different sizes can be adjusted (when used with 3D scanning)., the broken glass is collected by a

Solar photovoltaic panel glass removal machine

The solar photovoltaic panel glass removal machine is a key equipment for the recycling and treatment of waste photovoltaic panels. It separates the glass layer on the photovoltaic panel

Waste photovoltaic panel glass separation equipment

Waste photovoltaic panel glass separation equipment As the photovoltaic (PV) industry continues to evolve, advancements in Waste photovoltaic panel glass separation equipment have

Photovoltaic Pv Grass Removing Machine-Henan Recycle Equipment

Jan 24, 2025 · Working principle of photovoltaic panel deglazing machine The core components of photovoltaic panels are glass, silicon wafers, backplanes and other materials. The surface of

Detailed Explanation of the Operating Steps of

Mar 18, 2025 · Among the key challenges in PV recycling is the separation of glass, a major component that accounts for up to 70% of a panel''s weight.

Solar panel disassembly equipment | Machines

Solar panel disassembly equipment including what machines? How to make money from diamantling PV panels? We can help you.

Photovoltaic Solar Panel Recycling Machine Solar Panel Glass Separation

The rest of the components in a solar panel consist of good quality glass,aluminum frames,polymers, sinlicon,copper and silver paste (used for the printed conductors on each

Photovoltaic Panel Glass Separation Machine Professional

Product descriptions from the supplier The photovoltaic panel glass removal machine is a device specially used to separate the glass layer of photovoltaic panels from other components (such

Solar Photovoltaic Panel Glass Remove Equipment Solar Cell Separation

Solar panel recycling equipment Solar panel recycling equipment can process discarded solar panels and separate and recycle materials such as glass, silicon materials, aluminum frames,

Solar Panel Glass Remove Machine

Solar Panel Glass Remove Machine This device is designed for removing glass from photovoltaic modules. It can remove glass from photovoltaic modules

Photovoltaic Panel Glass Removal Equipment Glass Separation

Photovoltaic panel glass separation machine is a device specifically designed for processing waste photovoltaic panels, specifically for single crystal silicon and polycrystalline silicon single

Photovoltaic solar panel glass removal machine

3 days ago · The photovoltaic panel glass removal machine is mainly used in the recycling and processing of waste photovoltaic panels in the photovoltaic industry. Its core function is to

High-Yield PV Glass Separation Machine Rapidly Produces Recycled Glass

High-Yield PV Glass Separation Machine Rapidly Produces Recycled Glass Granules in Recycling Plants No reviews yet Gongyi Shield Machinery Manufacturing Co., Ltd 4 yrs CN

Single/Double Crystal Silicon Photovoltaic Panel

Jun 29, 2025 · Single/double crystal silicon photovoltaic panel de glassing machine is a specialized equipment used to separate glass and solar cells in

Manufacturer''s Photovoltaic Panel Glass Recycling Machine

Photovoltaic panel glass separation machine is a device specifically designed for processing waste photovoltaic panels,specifically for single crystal silicon and polycrystalline silicon single

Photovoltaic Panel Glass Separation Machine Professional

The photovoltaic panel glass removal machine is a device specially used to separate the glass layer of photovoltaic panels from other components (such as silicon circuit chips, packaging

CN110369043A

The invention discloses a kind of glass for cullet photovoltaic module to separate and recover equipment, which is characterized in that including housing, housing is tightly connected with

Solar Panel Glass Recycling Scrap Photovoltaic Panels Glass

The photovoltaic panel recycling equipment supports dynamic adjustment of production capacity (50% -120% rated capacity), and optimizes the speed of each link in real time through the PLC

Photovoltaic Solar Panel Recycling Machine Solar Panel Glass Separation

2. Remove the glass This equipment is specially designed for glass removal equipment of photovoltaic modules, which can efficiently, quickly and safely remove glass from photovoltaic

Solar Panel Glass Separation Equipment for Photovoltaic

This equipment adopts automation technology to achieve automatic feeding, discharging, and separation of finished glass and panels, improving production efficiency and reducing labor costs.

Industry Information

- Fiji communication base station flywheel energy storage power generation requirements

- On grid inverter 5kw for sale in Calcutta

- Slovenian lithium power storage company

- 240v circuit breaker for sale in Tanzania

- Guinea s latest lithium battery energy storage solution

- Thimphu Energy Storage Solution

- Photovoltaic container battery calibration

- Photovoltaic glass factory in Cyprus in 2025

- Solar Photovoltaic Panel Source Factory

- Photovoltaic inverter overheating

- Monaco Energy Storage Cabinet Lithium Battery Agent

- China home circuit breaker in China producer

- Photovoltaic energy storage and independent energy storage

- Botswana communication base station supporting equipment

- Sucre s power storage container equipment is mainly solar energy

- Quad circuit breaker in China in Slovakia

- Beirut Housing Photovoltaic Folding Container Wholesale

- Full set of energy storage solutions

- Where is the location of Kyrgyzstan s green communication base station

- Huawei Taiwan Energy Storage Project

- 800W solar energy footprint

- Ecuador PV combiner box wholesale price

- China Communications Signal Base Station Settings

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

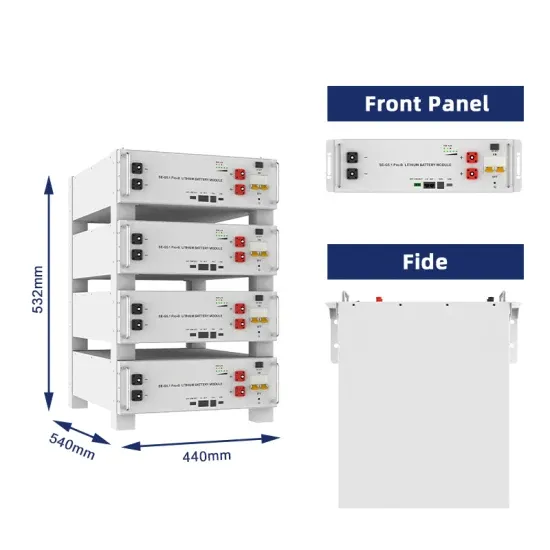

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.