Flywheel Energy Storage for Grid and Industrial

Nova Spin, our flywheel battery, stores energy kinetically. In doing so, it avoids many of the limitations of chemical batteries. It can charge and discharge 10x

Regenerative drives and motors unlock the

Jul 14, 2022 · The ABB motor and drive takes excess electrical energy from the grid and uses it to speed up the rotation of the flywheel, so it is stored as

Design and Research of a New Type of Flywheel Energy Storage

Feb 18, 2025 · This article proposes a novel flywheel energy storage system incorporating permanent magnets, an electric motor, and a zero-flux coil. The permanent magnet is utilized

Overview of Control System Topology of

Nov 25, 2024 · Due to its low environmental impact and great efficiency, flywheel energy storage is a nearly mature technology that is being implemented in a

Outer-rotor ac homopolar motors for flywheel energy storage

Apr 10, 2014 · Flywheel energy storage technology has been successfully commercialized for applications requiring high power, high cycle-life, and short storage intervals. High idling

Energy Storage Flywheels and Battery Systems

Piller is a market leader of kinetic energy storage ranging up to 60MJ+ per unit. The Piller POWERBRIDGE™ storage systems have unique design

Design and analysis of bearingless flywheel

Jan 1, 2016 · Flywheel energy storage system is an energy storage device considered to be the most competitive and promising energy storage

Artificial intelligence computational techniques of flywheel energy

Dec 1, 2024 · However, the intermittent nature of these RESs necessitates the use of energy storage devices (ESDs) as a backup for electricity generation such as batteries,

Flywheel Energy Storage | Energy Engineering

Sep 29, 2021 · The flywheel energy storage system is useful in converting mechanical energy to electric energy and back again with the help of fast

The controls of motors in flywheel energy storage system

Jun 11, 2014 · During startup stage of short-term acceleration system such as continuous shock test, high power induction motor draws dramatically high current in a short time, which would

An Overview of the R&D of Flywheel Energy

Nov 5, 2024 · Flywheel energy storage (FES) is a kind of physics energy storage method exploiting a rotational block with kinetic energy that changes with the

Introduction to motors and controllers of flywheel energy storage

Abstract: This paper introduces flywheel energy storage system (FESS) with particular focus on motors and controllers. The paper covers the principle and characteristics of permanent

Design of Flywheel Energy Storage System – A Review

Aug 24, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extensively

Regenerative drives and motors unlock the

Jul 14, 2022 · S4 Energy, a Netherlands-based energy storage specialist, is using ABB regenerative drives and process performance motors to power its

Magnetic Levitation Flywheel Energy Storage System With Motor-Flywheel

Feb 13, 2025 · This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate the idling loss

An Overview of the R&D of Flywheel Energy

Nov 5, 2024 · The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

Loss and Vibration Analysis of Flywheel Energy Storage Motor

Nov 8, 2024 · When the flywheel energy storage motor for UPS system is running at high speed through standby, its motor loss and electromagnetic vibration will increase. In order to improve

Flywheel energy storage system with magnetic hts

Sep 28, 2016 · The paper presents the results of studies on the development of a fully integrated design of the flywheel energy storage system (FESS) with combined high-temperature

eriyabv

How Flywheel Energy Storage Systems Work. Flywheel energy storage systems (FESS) employ kinetic energy stored in a rotating mass with very low frictional losses. Electric energy input

Influence of Hybrid Excitation Ratio on Standby Loss and

Jan 30, 2025 · Standby loss has always been a troubling problem for the flywheel energy storage system (FESS), which would lead to a high self-discharge rate. In this article, hybrid excitation

Magnetic Levitation Flywheel Energy Storage System With Motor-Flywheel

Feb 13, 2025 · This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate th

Flywheel energy storage systems: A critical

Jul 19, 2021 · Energy storage systems (ESSs) are the technologies that have driven our society to an extent where the management of the electrical

Control strategy of MW flywheel energy storage system

Nov 1, 2022 · This study analyzes the basic requirements of wind power frequency modulation, establishes the basic model of the flywheel energy storage system, adopts a six-phase

Flywheel Energy Storage System Basics

Sep 23, 2021 · Today, flywheel energy storage systems are used for ride-through energy for a variety of demanding applications surpassing chemical batteries.

The controls of motors in flywheel energy storage system

Jun 11, 2014 · During startup stage of short-term acceleration system such as continuous shock test, high power induction motor draws dramatically high current in a short time

Design and Analysis of a Unique Energy Storage Flywheel

Apr 1, 2015 · This paper presents a unique concept design for a 1 kW-h inside-out integrated flywheel energy storage system. The flywheel operates at a nominal speed of 40,000 rpm.

What is Flywheel Energy Storage? (with picture)

May 23, 2024 · The largest problem with flywheel energy storage is the potential for damage and injury if a charged flywheel is broken. These systems store energy as kinetic, rotational

A review of control strategies for flywheel energy storage

Nov 1, 2022 · The flywheel energy storage system (FESS) offers a fast dynamic response, high power and energy densities, high efficiency, good reliability, long lifetime and low maintenance

A review of flywheel energy storage rotor materials and

Oct 19, 2023 · The flywheel is the main energy storage component in the flywheel energy storage system, and it can only achieve high energy storage density when rotating at high speeds.

Multi-Objective Optimal Design of High-Speed Surface

Apr 25, 2019 · This paper presents a multi-objective optimized design for a 75 kW, 24 000 r/min high-speed surface-mounted permanent magnet synchronous motor (SMPSM) for a

Control of a High Speed Flywheel System for Energy

Aug 6, 2020 · However, several advanced technologies must be demonstrated for the flywheel energy storage system to be a viable option for future space missions. These include high

A new approach to analysis and simulation of flywheel energy storage

Aug 10, 2022 · To power electronic gadgets, hybrid energy storage systems have emerged as a worldwide option during the last several years. Many of the benefits of energy storage systems

Could Flywheels Be the Future of Energy

Jul 7, 2023 · Flywheels are one of the world''s oldest forms of energy storage, but they could also be the future. This article examines flywheel technology, its

Coordinated Control of Flywheel and Battery Energy Storage

Apr 10, 2025 · Due to the inherent slow response time of diesel generators within an islanded microgrid (MG), their frequency and voltage control systems often struggle to effectively

A novel flywheel energy storage system: Based on the barrel

Mar 1, 2022 · Flywheel energy storage system (FESS), as one of the mechanical energy storage systems (MESSs), its essence is that the M/G drives the flywheel with a large inertia to

Motors for energy storage

Design Challenges: Electrical insulation performance in a vacuum Thermal issues in vacuum environments Expertise: Motor operation in a vacuum, typically with

A Comprehensive Analysis of the Loss

May 28, 2025 · This paper presents a comprehensive analytical framework for investigating loss mechanisms and thermal behavior in high-speed magnetic

Modeling and Control of Flywheel Energy Storage System

May 15, 2023 · Flywheel energy storage has the advantages of fast response speed and high energy storage density, and long service life, etc, therefore it has broad application prospects

6 FAQs about [Flywheel energy storage dedicated motor]

How to design a flywheel energy storage motor?

The design of the motor for flywheel energy storage mainly adopts the stator core, winding, magnet, and a matching optimization to improve the power and efficiency. The challenge in motor design is to reduce the loss of the permanent magnet motor rotor and prevent the failure of the motor caused by high-temperature rise. 3.3.

What is the main technology of Flywheel energy storage system?

The main power circuit technology is mature, and the main research is the conversion control algorithm. China has successfully developed MW-class motor converters for flywheel energy storage systems. 4. FES System

How does a high-speed flywheel energy storage system work?

Zhang employed a high-speed flywheel energy storage system (FESS) charge–discharge control method based on the DC traction network voltage to achieve effective operation of the FESS in the subway traction power supply system .

What is a compact and highly efficient flywheel energy storage system?

Abstract: This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate the idling loss caused by the flux of permanent magnetic machines. A novel compact magnetic bearing is proposed to eliminate the friction loss during high-speed operation.

What is the energy storage capacity of a flywheel?

A steel alloy flywheel with an energy storage capacity of 125 kWh and a composite flywheel with an energy storage capacity of 10 kWh have been successfully developed. Permanent magnet (PM) motors with power of 250–1000 kW were designed, manufactured, and tested in many FES assemblies.

Can axial-type same pole motor be used as a flywheel energy storage system?

Ekaterina Kurbatova proposed a magnetic system for an axial-type same pole motor suitable as both motor/generator in combination with the integrated design of the motor/generator, which can be utilized in conjunction with the flywheel energy storage system.

Industry Information

- The largest photovoltaic glass company in western Guinea

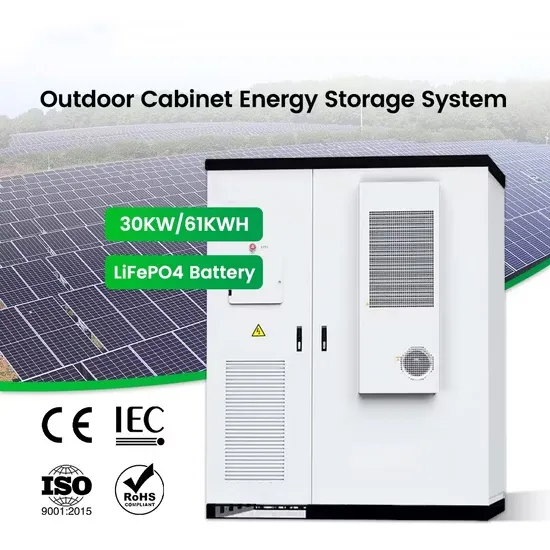

- Brand of energy storage cabinets on the grid side in Aarhus Denmark

- Wholesale 220 circuit breaker in Mozambique

- Manchester Power Station Generator UK

- Luanda Energy Storage Systems Company

- Is the quality of large battery cabinet good

- Huawei Brasilia Energy Storage Vehicle Price

- Solar energy system planning and design

- Is the inverter output voltage 240v normal

- Mauritius Sun Energy Small Container Station

- Energy storage battery manufacturing company in Dubai UAE

- Korea lithium iron phosphate battery pack

- Sierra Leone Industrial Energy Storage Cabinet Brand

- 5kva inverter system for sale in Brunei

- Mexican power station energy storage system manufacturer

- Congolese energy storage high power supply manufacturer

- Huawei Portable Energy Storage in Tampere Finland

- Lome solar photovoltaic tile power generation

- Battery group for wind power generation system in Lagos Nigeria

- Introduction to Electrochemical Energy Storage Power Station

- Battery specifications for energy storage power stations

- Does radio communication have a base station

- Which companies have wind and solar complementary technology for communication base stations in Papua New Guinea

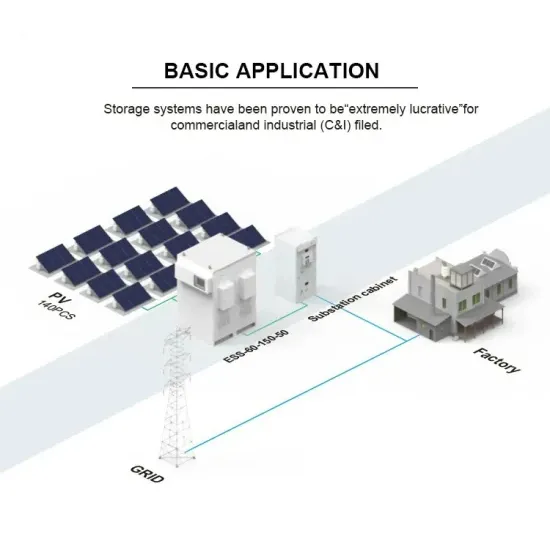

Commercial & Industrial Solar Storage Market Growth

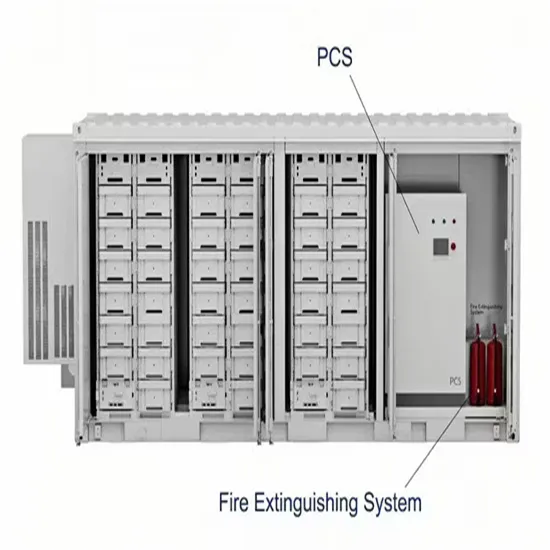

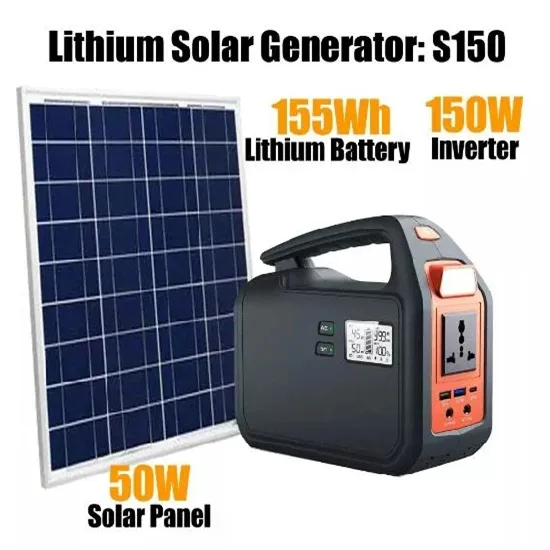

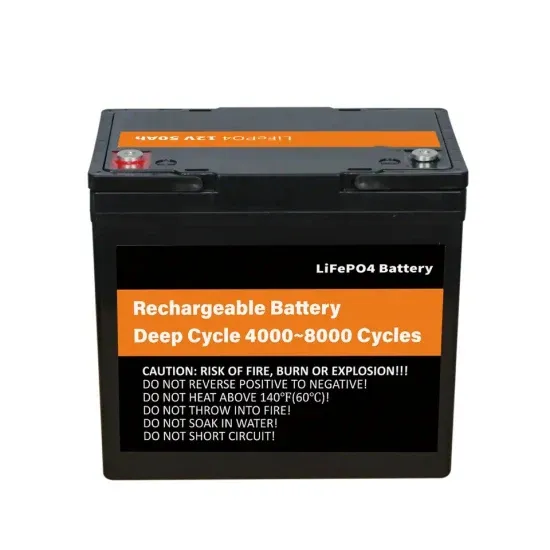

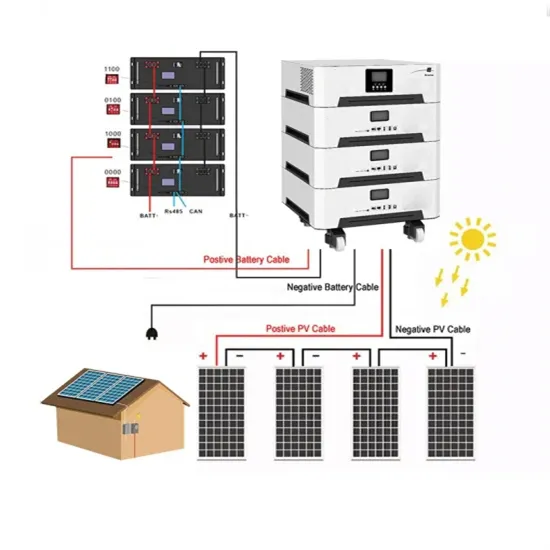

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

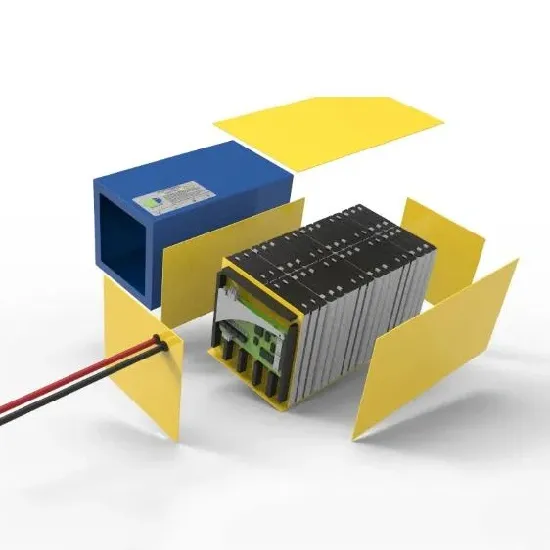

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.