DESIGN GUIDE HEAT SINKS FOR HIGH-POWER

Mar 3, 2025 · Forced Convection Forced convection is aided by fans, pumps, or other external sources of airflow. Forced convection is often necessary when working with higher heat

How to dissipate heat in 5G base stations

Nov 29, 2021 · 5G technology is constantly developing and popularizing. The 5G communication base station equipment is developing in the direction of

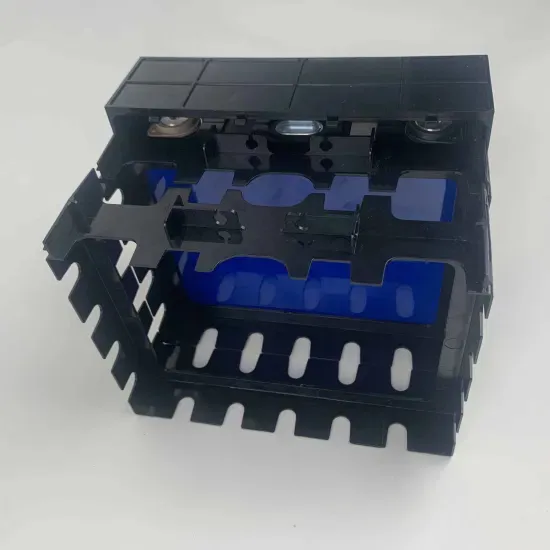

How to Install a CPU and Heatsink

Oct 21, 2024 · A do-it-yourself article explaining how to properly install a CPU with a cooling solution onto a motherboard.

How to Select a Heat Sink

Jan 11, 2022 · Heat sinks are used with high-power semiconductor devices such as power transistors and optoelectronics such as lasers and light-emitting

How to Select a Heatsink

Dec 16, 2024 · Discover how to select the right heatsink, from types and mounting options to thermal interface materials and airflow considerations.

Thermal Design for the Passive Cooling System of Radio Base Station

Jun 2, 2021 · This paper investigates different improvement methods for a radio base station by numerical simulation, including installation method, metal conduction rod, geometric

Ultimate Guide to Transistor Heat Sinks:

Feb 15, 2025 · Learn everything about transistor heat sinks: how they work, how to choose the right one, installation tips, and DIY solutions for optimal thermal

Design Guide: Heat Sinks for High-Power Applications

Apr 6, 2023 · a bonding agent. Soldered fin heat sinks are among the most eficient, making them an excellent choice for high-power, high-heat applications—especially where space

Install The CPU Heat Sink

Jan 21, 2025 · Installing a CPU heat sink is one of the fundamental tasks in computer assembly and maintenance. The heat sink plays a crucial role in dissipating heat generated by the CPU,

What is a Heat Sink in a Computer and How Does it Work?

Apr 6, 2024 · Introduction: A heat sink is an essential component in a computer that helps dissipate heat generated by the central processing unit (CPU) and other components. In this

5G Base Station Heat Sink Struggling to Keep Up with 5G''s Power

Jun 30, 2025 · If your 5G base station heat sink isn''t designed for high power density, compact size, and extreme durability, it''s time to rethink your supply chain. Here''s why:

AND9859

describes heat-sink mounting methods, considerations, contact thermal resistance, and mounting torque for various packages. Figure 1. Thermal Resistance Model of an Package Assembly

High Heat-Flux Heat Sink Design | Celsia

May 10, 2025 · This article compares heat sink design for moderately high-power density applications (100 W/cm²), evaluating five designs in terms of

Installing CPU Heatsink & Fan

Mar 31, 2023 · The TR4 processor socket has four threaded holes for mounting a processor fan heat sink. The illustrations shows installation of a typical

How to calculate heatsink

1 day ago · Thermal management of electronic devices is important for best performance. How to calculate heatsink is demonstrated by 7805 examples.

USING HEAT SINKS WITH A SWITCH MODE POWER

Jun 15, 2023 · In recent years, with high power density requirements and increased heat generated by devices in electronic equipment, the problem of how to cool these electronic

What is a heatsink and how to install it and CPU

Sep 10, 2021 · Hybrid Heat sinks: As the name itself speaks, Hybrid heat sinks are a combination of both active and passive heat sinks. These types of heat sinks require control systems to

Optimized heat sink assembly method for effective heat

Mar 20, 2021 · This application note shows the optimized assembly of power modules to heatsinks and presents the effect of optimized mounting on effective dissipation of heat from

How to use MOSFET heat sink correctly in

Oct 8, 2024 · In electronic circuit design, the heat sink treatment of MOS tube is a crucial link because it directly affects the electromagnetic compatibility (EMC)

Heat Sink Design for A Power Amplifier

Jul 3, 2019 · Figure 1 shows a typical thermal model for power amplifier (PA) heat dissipation paths. Ra is the junction to case thermal resistance of the hottest component of the amplifier

How To Basics: Intro to Heatsink Selection and

5 days ago · A heatsink is a mass of metal that conducts heat generated by power semiconductor devices to a location with a cooler temperature —

A comprehensive review of air-cooled heat sinks for thermal

Dec 1, 2024 · A detailed discussion on various heat sink geometries available in the open literature, heat transfer mechanism (active, passive, and radiation heat transfer) and effect of

How to dissipate heat in 5G base stations

Nov 29, 2021 · Thermally conductive silicone sheet and copper heat sink can well solve the reliability and electromagnetic compatibility problems of equipment

5G base stations and the challenge of thermal

Dec 1, 2021 · Phase change 5G materials enhance the transfer of heat to heat sinks, which allows the component to run at a lower temperature, minimizing

Thermal Design for the Passive Cooling System of Radio Base Station

Jun 2, 2021 · As communication systems are gradually transferred to 5G, communication base station (CBS) is developing toward large capacity, high power density, and high integration.

Power Transistor Heat Sink: Your Comprehensive Guide

Sep 6, 2024 · A power transistor heat sink is an essential component in any high-power electronic system. By dissipating excess heat from power transistors, heat sinks help to prevent

DESIGN GUIDE HEAT SINKS FOR HIGH-POWER

Mar 3, 2025 · Modes of Heat Transfer Heat sinks leverage conduction and convection, the two simple properties of heat transfer in which thermal energy naturally moves from hotter areas to

Heat Sink Guide: Types, Uses & Tips | Kenfatech

Jun 12, 2025 · Explore the Heat Sink Guide by Kenfatech! Learn types, uses, and tips to keep devices cool with expert solutions. Read now!

Heat Sinks: A Step-by-Step Guide | DigiKey

Jan 10, 2019 · A heat sink''s role is in creating a larger surface area on a heat-producing device, allowing for more efficient transfer of heat out and into its

Heat Sinks in Computers | SpringerLink

Jan 1, 2014 · Finned heat sinks are used in computers to promote heat transfer from the Integrated Circuit (IC) chips to cooling air. This chapter provides the

High Thermal Conductivity Aluminum Heat Sinks

Feb 6, 2025 · Discover how advanced die casting, precision CNC machining, and optimized surface treatments enhanced thermal efficiency and durability for

A Cooler Solution: Optimizing Heat Sink Installation for

Oct 31, 2024 · When it comes to electronics, heat sinks play a crucial role in maintaining optimal operating temperatures and preventing overheating. However, the effectiveness of a heat sink

Experimental investigation on the heat transfer performance

Apr 1, 2024 · The power consumption of a 5G station is 4 kW, which is three times that of a 4G station [3]. The power consumption of telecommunication base stations operating at full load

USING HEAT SINKS WITH A SWITCH MODE POWER

May 31, 2023 · In recent years, with high power density requirements and increased heat generated by devices in electronic equipment, the problem of how to cool these electronic

Heat sinks, Part 1: Thermal principles

Dec 18, 2018 · Heat sinks, Part 1: Thermal principles December 18, 2018 By Bill Schweber Leave a Comment A heat sink is a non-electronic, passive

Design Guide: Heat Sinks for High-Power Applications

Apr 6, 2023 · Modes of Heat Transfer Heat sinks leverage conduction and convection, the two simple properties of heat transfer in which thermal energy naturally moves from hotter areas to

6 FAQs about [How to install the heat sink of a high-power communication base station]

What is a heat sink?

low, especially when used in conjunction with fans.Heat sinks provide a base level of heat dissipation that forms the backbone of any efective thermal management system. Regardless of the specific layout, thermal management components should be selected early in the electronics

Why is a heat sink important?

Since air is a good thermal insulator, it is important that a heat sink is used to increase the overall heat transfer area to the ambient, i.e., the overall thermal performance, R θ heat sink-ambient, as shown in Figure 1. This is especially true for power device packages.

How does a heat sink work?

electronics at a sustainable operating temperature. A passive component made from metals with high thermal conductivity, heat sinks disper e heat by drawing it away from sensitive circuitry. Heat sinks may be cooled by liquids or simple air low to remove heat more efectively from the system. They may also incorporate fins to direct air

How do I choose a heat sink insulator?

washer slightly increases the thermal resistance. Choose an insulating material between the package and heat sink for optimal thermal performance. PowerSite is a trademark of Parker Hannifin Corporation. Sil Pad is a trademark of the Bergquist Company. Clip mounting is a more stable and safer method than screw mounting.

How do you fill a gap between a base plate and heat sink?

A thermal sheet or thermal grease is used commonly to fill the gap between the base plate and heat sink surface. This would be necessary, even if there were no gap at room temperature, as the baseplate shape changes with the temperature.

What causes a gap between base plate and heat sink?

The height differences reach around 40μm. This induces gaps at the interface of module base plate and heat sink, deteriorating the heat dissipation, and as a result, the chip temperatures may exceed maximal allowed chip temperature. A thermal sheet or thermal grease is used commonly to fill the gap between the base plate and heat sink surface.

Industry Information

- Wholesale al hamad switchgear in Botswana

- Energy storage cabinet outdoor power supply 600w solar charging

- Western Europe Notice on Liquid Flow Batteries for Communication Base Stations

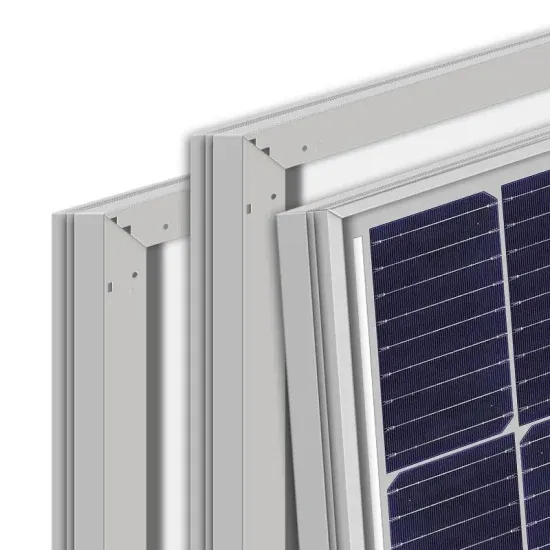

- Sarajevo Communication Green Base Station Photovoltaic Power Generation Outdoor Unit

- Solar photovoltaic panel power generation set

- Which is safer Tonga outdoor power supply or lithium iron phosphate

- Syria rechargeable energy storage battery manufacturers price

- How many kilowatt-hours of electricity does solar energy produce in one hour at 1500 watts

- EK Super Double Layer Capacitor

- Antananarivo large-scale energy storage investment project

- RV Energy Storage Solution

- Standard length of mobile power box

- Praia Energy Storage Production Project

- Which is better photovoltaic or energy storage in Denmark

- How to set up outdoor base station AP

- Moroni New Energy Storage Company

- Outdoor solar light dual-purpose

- How much does one watt of solar photovoltaic power generation cost in Brussels

- The most expensive equipment in the battery energy storage system of communication base stations

- Small energy storage inverter for home use

- Wholesale 5kw hybrid inverter in Iran

- Solar energy storage 500 degrees

- High quality on grid inverter in Lisbon

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.