Complete Explanation of Parameter Names for

Jan 16, 2025 · Dive into the intricate world of energy storage batteries! Explore key parameters such as capacity, voltage, energy density, and cycle life that

BESS version 3 magazine dd

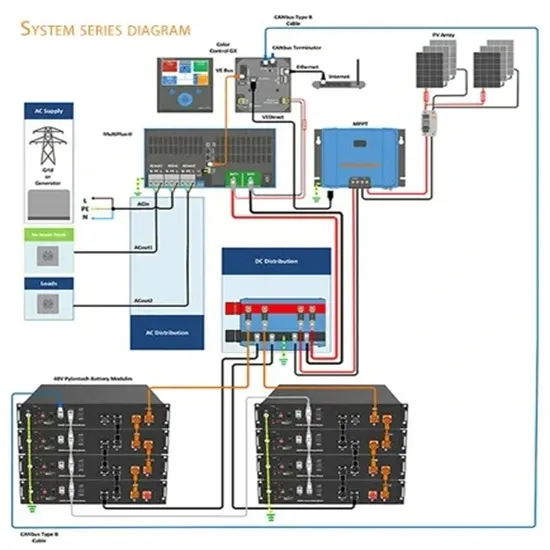

Mar 5, 2024 · Power conversion system or bi-directional inverter converting direct current (dc) produced by the batteries into alternating current (ac) supplied to the application: on-grid (e.g.

A Guide to Understanding Battery Storage

Aug 19, 2025 · Understanding Battery Storage Specifications In today''s fast-changing energy world, battery storage systems have emerged as a

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Utility-scale BESS system description — Figure 2. Main circuit of a BESS Battery storage systems are emerging as one of the potential solutions to increase power system

How to design an energy storage cabinet: integration and

Jan 3, 2025 · How to design an energy storage cabinet: integration and optimization of PCS, EMS, lithium batteries, BMS, STS, PCC, and MPPT With the transformation of the global

New National Standards for Electric Vehicle Battery Safety Set

May 30, 2025 · The recently released "Strictest Electric Vehicle Safety Standards" is set to have a significant impact on the new energy vehicle industry. As of July 1, 2025, the new national

NFPA | The National Fire Protection Association

NFPA is the world''s leading resource on fire, electrical, and related hazards. NFPA is a self-funded nonprofit dedicated to eliminating loss through knowledge.

USER MANUAL BATTERY CABINET

Jul 28, 2025 · 3.1 SAFETY INSTRUCTIONS Before beginning any work, carefully read all safety instructions, and always observe them when working on or with the cabinet and/or batteries.

Interpreting Battery Parameters and

In this section, we will discuss basic parameters of batteries and main factors that affect the performance of the battery. The first important parameters are the

Battery Standards Overview

May 13, 2019 · An overview of UPS battery standards. Refer to IEEE standards table for recommendations and resources for UPS batteries.

Battery cabinet power parameters

Battery cabinets for all KEBOS UPS from 1KVA up to 1200KVA Power Range.The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 17AH to 250AH.The

Detailed explanation of photovoltaic energy storage

Does a battery storage system provide firmness to photovoltaic power generation? This paper proposes an adequate sizing and operation of a system formed by a photovoltaic plant and a

Analysis of the Quality Parameter Requirements of National Standard

By distributing questionnaires to 190 respondents, the Framework for Analysis, Comparison, and Testing of Standards (FACTS) approach was used to analyze stakeholder needs, compare

Battery storage cabinet parameter settings

When using the latest firmware on all compatible connected devices, and once the battery module has been detected by the GX device, battery charging parameters (e.g. Maximum Charge

Electrical installation handbook Protection, control and

Mar 14, 2024 · The IEC publishes international standards, technical guides and reports which are the bases or, in any case, a reference of utmost importance for any national and European

Battery Sizing Considerations IEEE 2020

Mar 11, 2020 · Batteries provide DC power to the switchgear equipment during an outage. Best practice is to have individual batteries for each load/application. *Lead-Acid has a minimum

Replacing GB 38031-2020

May 26, 2025 · 8.2.1.4 For battery packs or systems installed on categories M1 and N1 vehicles, the vibration test parameters shall be set according to Table 3 and Figure 3, where the RMS of

DESIGN FOR SAFE AND RELIABLE ELECTRICAL

Jan 23, 2019 · DESIGN FOR SAFE AND RELIABLE ELECTRICAL PROTECTION OF BATTERY SYSTEM These guidelines are specifically designed for electrical systems in EMEA, Asia and

Analysis of the Quality Parameter Requirements of

Analysis of the Quality Parameter Requirements of National Standard Development for Battery Swap in Electric Vehicles Widia Citra Anggundari1,a, Auraga Dewantoro2,a, Bendjamin

What are the standard requirements for battery energy storage cabinets

Jun 2, 2024 · Battery energy storage cabinets must comply with several critical criteria: 1. Material durability, ensuring resilience against environmental factors, 2. Adequate thermal

Simple installation manual of DC cabinet

Jun 4, 2024 · Simple installation manual of DC cabinet 1. Basic components The DC cabinet mainly collects and distributes current to each battery cluster to realize charge and discharge

Battery Cabinet

Feb 28, 2025 · To check for inadvertent grounding of the battery, use a digital multi-meter set to the DC Volts scale to measure the voltage between any battery terminal and either the cabinet

Standard Specifications for Lithium Battery Energy

AZE''''s 27U indoor battery rack cabinets painted with polyester powder, suitable for different brands lithium-ion batteries, it is the perfect solution for housing your Low Voltage Energy

Battery Cabinet Working Space Front Aisle Floor Loading

Recommended practices for the design of dc power systems for stationary applications are provided in this document. The components of the dc power system addressed by this

NFPA 70 and NFPA 70E Battery-Related Codes Update

Jan 10, 2023 · Abstract Two code documents have a dramatic impact on the acceptance or rejection of a battery installation by an inspector. These are the National Electrical Code (NEC

UPS power system design parameters | PDF

This application note serves as a guide for the design, configuration, selection, sizing, and installation of uninterruptable power supply (UPS) systems, aimed

Battery Cabinets

The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 24Ah to 105Ah (C10). The battery cabinets are available in 5

946-2020

Sep 23, 2020 · The components of the stationary dc power system addressed by this recommended practice include the following: - Storage batteries - Static

Analysis of the Quality Parameter Requirements of

The battery requires a long energy charge when the energy in the battery runs out. The solution to this energy charging time is a battery swap system. The purpose of this study was to analyze

IEEE DC Power System Design Recommended

IEEE Recommended Practice for DC power system design in stationary applications. Covers batteries, chargers, distribution, and protection. Technical

New National Standards for Electric Vehicle

May 29, 2025 · The new standards are a significant step forward, providing a framework to enhance battery safety across the industry. Overall, the new

480.7 (B) and 480.7 (C) Battery System

2020 Code Language: 480.7 DC Disconnect Methods. (A) Disconnecting Means. A disconnecting means shall be provided for all ungrounded conductors

8 Key Lithium Batteries Parameters You Should

Mar 27, 2024 · Discover the 8 key lithium batteries parameters that impact performance. Learn how each factor influences your device''s efficiency. Read

2018 Title Contents

Dec 20, 2022 · In layman''s terms, a standard provides minimum requirements and/or instructions in agreement within the industry for common reference. Common standards in the battery

BATTERY BANKS

The substation battery banks are sized and purchased by the substation engineering activity. Battery banks are purchased direct from pre-approved battery bank manufacturers. Battery

BESS version 3 magazine dd

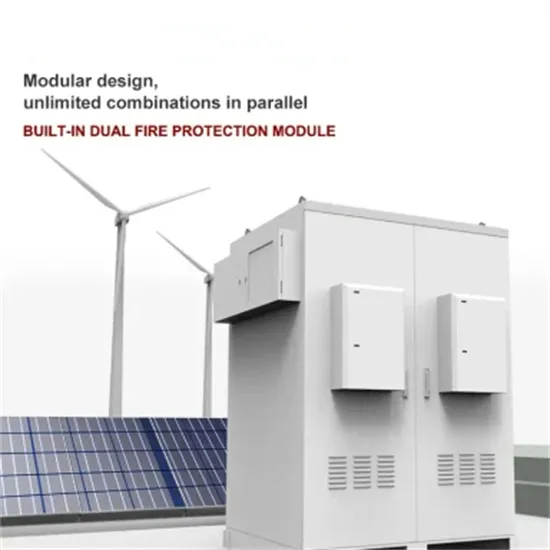

Mar 5, 2024 · Standard solutions BESS cabinet of 187 kW-200 kWh for both indoor and outdoor use with battery racks built of LFP cells. BESS 10 ft container of 500 kW-600 kWh built by LFP

IEEE Recommended Practice for the Design of DC Power

Approved 30 January 2020 IEEE-SA Standards Board Abstract:Recommended practices for the design of dc power systems for stationary applications are provided in this document. The

6 FAQs about [National standard parameter setting for DC battery cabinet]

What is a Recommended Practice for a stationary DC power system?

Guidance in selecting the quantity and types of equipment, the equipment ratings, interconnections, instrumentation and protection is also provided. This recommendation is applicable for power generation, substation, and telecommunication applications. Scope: This recommended practice provides guidance for the design of stationary dc power systems.

What is IEEE Recommended Practice for DC power system design?

IEEE Recommended Practice for DC power system design in stationary applications. Covers batteries, chargers, distribution, and protection. Technical standard.

How many rectifiers are required for a DC power system?

W = 12 . 07 rectifiers 10 500 (B.19) 54 IEEE Std 946-2020 IEEE Recommended Practice for the Design of DC Power Systems for Stationary Applications Due to then+ I rectifier redundancy/reliability requirement, this means that 14 rectifiers are required.

What should be included in a DC power system?

9. DC power system instrumentation, controls, and alarms 9.1 General Control devices, instrumentation, and alarms should be provided in order to both enable monitoring and control of the de po"ver system (e.g., voltages, currents, OCPD operation, temperatures), and to annunciate during abnormal conditions.

What should be included in a battery design process?

A recommended practice is to create a diagram at the start of the design process sho"ving the battery or batteries, charger (s), de panel (s), and all connected loads. Consideration should also be given for future growth. Redundant de po"ver systems may also be considered.

What is a D C power system?

Description and operation D C power systems provide reliable po\ver to critical loads.

Industry Information

- Mainstream photovoltaic energy storage products

- China Hybrid Energy Communication Base Station

- Production cost of photovoltaic glass

- Dubai Liquid Flow Battery Wholesale

- Uruguay solar rooftop power generation system

- Havana joins the solar air conditioning is a bureau

- 1200W portable power station in Canberra

- How many batteries does a 60w inverter usually use

- China high voltage switchgear in Ireland

- Lilongwe Outdoor Power Supply N15

- E3ks uninterruptible power supply ups

- San Salvador Flywheel Energy Storage

- What is the role of container energy storage cells

- 10000w power inverter factory in Kazakhstan

- Yaounde Industrial Power Storage Project

- Does the solar wind heating system use electricity

- Can the inverter high voltage output be increased

- Hot sale koten safety breaker factory for sale

- Battery equalization charging cycle for communication base stations

- Capacity of Swedish containerized energy storage system

- How many watts should I buy for a two-for-one solar panel

- 155w photovoltaic panel specifications

- Industrial Park Energy Storage Container

Commercial & Industrial Solar Storage Market Growth

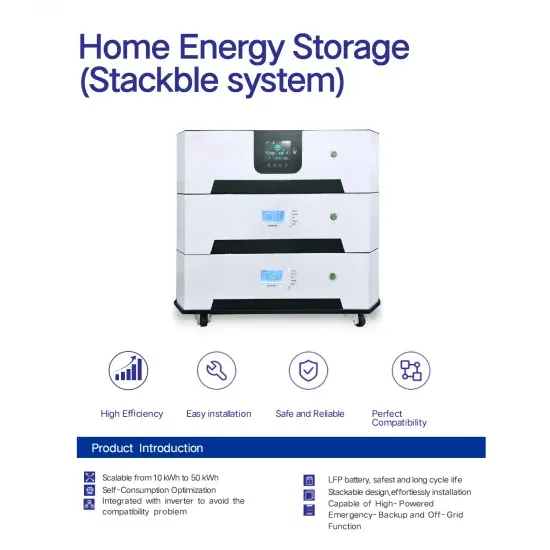

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.