Layered energy equalization structure for series battery pack

Apr 1, 2025 · This two-layer equalization structure enables energy equalization between any batteries within the series-connected battery pack, ensuring the diversity of the equalization

Research on Equalization Strategy of Lithium

May 12, 2022 · It can equalize multiple batteries simultaneously and ensure the normal operation of the batteries. A layered control strategy was then found to

An intelligent thermal management system for optimized lithium

May 5, 2021 · Battery thermal management system is one of the most essential parts for the battery pack in electric vehicles. In this paper, a new battery thermal management system is

Engineering a passivating electric double layer for high

Apr 19, 2022 · Here, the authors created a new strategy by engineering a passivating electric double layer to achieve a fast-charging and lowtemperature high voltage lithium metal batteries.

Thermal management system of lithium-ion battery packs

Aug 1, 2022 · Abstract Lithium-ion batteries (LIBs) are becoming gradually common in our everyday lives, associated with the rapid growth of electric vehicles (EVs) as well as hybrid

The critical role of interfaces in advanced Li-ion battery

Dec 15, 2024 · Ideally, this layer serves as a barrier that inhibits further electrolyte decomposition by obstructing electron transport while permitting the passage of lithium ions during charging

Battery pack passive insulation strategies of electric vehicles

Aug 15, 2024 · Further application of electric vehicles (EVs) in frigid regions is hindered by the diminished performance of lithium-ion batteries (LIBs) at sub-zero temperatures. Developing

An End-To-End Methodology for Battery Pack Design

Oct 6, 2021 · With the expected high penetration of electric vehicles and electrochemical energy storage, there is a need to better understand and predict battery pack performance and

Thermal management of lithium-ion battery pack under

Oct 1, 2023 · The effects of two-layer CPCM combination, inlet temperature and inlet velocity of cooling water, ambient temperature, forward flow and different counter flow schemes of cooling

Direct recycling of Li-ion batteries from cell to

Direct recycling is a novel approach to overcoming the drawbacks of conventional lithium-ion battery (LIB) recycling processes and has gained considerable

Achieve Superior Lithium-Ion Performance with Double-Layer

Jan 20, 2025 · The innovative double-layer coating technology is reshaping the design of electrode pieces for lithium-ion batteries. This multi-layer architectural approach boosts

Multi-objective optimization of lithium-ion battery pack

Jan 1, 2025 · This study employs a multi-objective optimization approach integrating the fast non-dominated sorting genetic algorithm (NSGA-II) and response surface methodology (RSM) to

Recent Development of Thermal Insulating

Sep 3, 2024 · As one of the core components of electric vehicles, Li-ion batteries (LIBs) have attracted intensive attention due to their high energy density and

Module-Based Active Equalization for Battery Packs: A Two-Layer

Jul 8, 2021 · High-performance and safe operation of a serially connected lithium-ion battery pack in the electric vehicle necessitates effective cell equalization to maintain the state-of-charge of

Anion-Modulated Solvation Sheath and Electric

Jan 27, 2025 · As a proof of concept, we utilized lithium nitrate (LiNO 3) to establish an anion-controlled solvation structure and electric double layer. The

Module-Based Active Equalization for Battery Packs: A Two-Layer

Jul 8, 2021 · Then, a two-layer model predictive control (MPC) strategy is proposed, in which the ML equalizers are controlled by the top-layer MPC and the controlled CMC equalizing currents

Battle for the EV Battery Box

Mar 17, 2023 · Whether you call them packs, boxes, or trays, the structures that envelop and protect EV battery cells and their supporting electrical and

PCM-based passive cooling solution for Li-ion battery pack,

Dec 1, 2024 · We propose in this study a novel cooling solution for Li-ion battery packs based on Phase Change Materials (PCM) and metallic fins placed around each

Inhibition of Thermal Runaway Propagation in

Sep 25, 2023 · The main concern hindering the large-scale application of lithium-ion batteries (LIBs) in electric vehicles (EV) is thermal runaway (TR). In this

Modeling of local electrode stresses and pressures in lithium

Oct 30, 2023 · While the development of coupled mechanical-electrochemical models is an essential tool to predict the performance of lithium-ion battery cells inside the modules/packs,

Lithium-ion Battery: Structure, Working Principle

Mar 21, 2022 · Hello everyone, I am Rose. Welcome to the new post today. Lithium battery is a kind of battery with lithium metal or lithium alloy as

Optimization of liquid cooling and heat dissipation system of lithium

Aug 1, 2021 · A stable and efficient cooling and heat dissipation system of lithium battery pack is very important for electric vehicles. The temperature uniformity design of the battery packs has

The battery pack consisting of two layers placed

The battery pack consisting of two layers placed inside the test container. The burner used to initiate thermal runaway is also shown.

Use of a multiphysics model to investigate the performance

Jan 1, 2023 · An inconsistency within lithium-ion batteries (LIBs) in a battery pack can lead to reduced power as well as short cycle life. The cell-to-cell connection structure and thermal

Lithium-ion battery packs | VARTA AG

Aug 18, 2025 · In the Power Pack Solutions division, VARTA develops rechargeable standard and customized lithium-ion battery packs. Regardless of the technology or the complexity of the

Mixed Two-Layer Balancing of Battery Packs for

Jan 2, 2024 · One opportunity to improve traditional balancing in sub-medium size battery packs is to combine two balancing methods: passive and active.

The Ultimate Guide For Lithium-Ion Battery

This in-depth guide explores lithium-ion battery packs from the inside out. Learn about the key components like cells, BMS, thermal management, and enclosure.

Safer Lithium-Ion Batteries from the Separator

The separator is a crucial component that prevents the direct contact of anodes and cathodes and facilitates lithium ions to shuttle between the two

Energy Storage System,LiFePO4 Battery,Lithium

Superpack solar lithium battery delivers reliable energy storage for homes & businesses. It pairs with solar panels to bank excess daytime power, ensuring

Smart Lithium-Ion Battery Pack – All You Need

Nov 6, 2024 · This added layer of safety minimizes risks and ensures the battery packs deliver a reliable, long-lasting energy storage solution. Scalability:

Multi-layered electrolytes for solid-state lithium batteries

Sep 1, 2023 · Solid-state lithium batteries are promising candidates for improving battery safety and boosting energy density. However, the application of both typical solid-state electrolytes,

Electrolyte additives for Li-ion batteries

Jan 1, 2025 · Electrolyte composition strongly affects the performance of Li-ion batteries in terms of their general electrochemical properties, electrode stability, cycle life, long-term stability

Compressible battery foams to prevent cascading thermal

Sep 1, 2022 · Lithium-ion battery packs require thermal management to achieve optimum life and safety. This is becoming crucial for battery packs composed of high-e

Bosch 18V CORE18V® Lithium-Ion 4 Ah Advanced Power Battery, 2-Pack

This 2 Pack features two Bosch CORE18V® 4 Ah Advanced Power Batteries, each of which is a compact battery delivering power in a lightweight solution. It allows you to get the power and

Comprehensive review of multi-scale Lithium-ion batteries

Feb 1, 2025 · This review integrates the state-of-the-art in lithium-ion battery modeling, covering various scales, from particle-level simulations to pack-level thermal management systems,

Electric Double Layer and Structure of the Li-ion

Oct 16, 2024 · We have used Atomic Force Microscopy (AFM) as a powerful tool to study the structure of the separator in Li-ion batteries. The measurements

Effects of thermal insulation layer material on thermal

Jan 15, 2024 · An experimental system for thermal spreading inhibition of lithium-ion battery modules was set up, in order to achieve the goal of zero spreading of thermal runaway

Equalization strategy of lithium-ion battery packs under two

Jun 15, 2025 · Energy transfer between two adjacent battery packs is facilitated by a double-layer switch located between each pair of adjacent battery packs. The inter-group equalization

6 FAQs about [Lithium battery pack two-layer solution]

Which balancing method is best for lithium batteries?

Passive and active balancing, often known as dissipative and non-dissipative balancing, are the two basic approaches for balancing lithium batteries [16, 17].

Why should a lithium battery pack be balanced?

As a result, a balanced system must be built to balance and control the lithium battery, improve consistency between the single batteries in the lithium battery pack, extend the battery pack’s cycle life, and increase safety during battery pack operation.

What is the efficient equalizing method for lithium-ion batteries?

An Efficient Equalizing Method for Lithium-Ion Batteries Based on Coupled Inductor Balancing. Electronics 2019, 8, 136. [Google Scholar] [CrossRef] [Green Version] Chen, F.; Yuan, J.; Zheng, C.; Wang, C.; Li, Z.; Zhou, X. A State-of-Charge Based Active EV Battery Balancing Method.

What is layered battery equalization method?

A layered battery equalization method is proposed, which reduces the calculation difficulty of the equalization current by layered equalization of the batteries in the group and calculates the equalization current in real-time according to the state of the batteries in the group.

Does a multi-layer equalization strategy improve battery balancing performance?

According to the equalization results, the proposed multi-layer equalization strategy’s equilibrium efficiency is raised by 23.55% compared with the adjacent battery equalization approach, demonstrating the proposed multi-layer equalization strategy’s good performance. Figure 12. The adjacent cell balancing circuit.

What is a battery pack?

A battery pack is fabricated of multiple batteries connected in series, each with the same charge and discharge current . When a cell in the battery pack is fully charged/discharged, the connection to the external power source/load must be discontinued to prevent overcharge/over-discharge of the Li-ion battery.

Industry Information

- Liberia 300 solar photovoltaic panels

- Wholesale battery and storage in Lithuania

- Power inverter voltage low

- Wholesale c20 circuit breaker in Ecuador

- Macedonia Emergency Portable Power Supply Manufacturer

- Battery cabinet management system structure

- Bahrain off-grid photovoltaic power generation system

- Timor-Leste energy storage fire protection system price

- 5g base station electromagnetic battery equivalent

- Armenia large ups uninterruptible power supply

- Xinfa Industrial Energy Storage Inverter Plant

- Base station power supply and supporting equipment

- Abkhazia communication base station inverter grid-connected new basic EPC project

- China circuit breaker outdoor in Estonia

- 4 Hundred Watt Solar Light

- High quality branded inverter in Pakistan

- Several suppliers of battery energy storage systems for communication base stations in China

- Singapore 96v to 220v inverter manufacturer

- Wireless Small Solar On-site Energy

- Burundi 11kw high quality inverter company

- Photovoltaic power generation and inverters

- Power peak storage

- Kathmandu Secondary Photovoltaic Power Station Generator

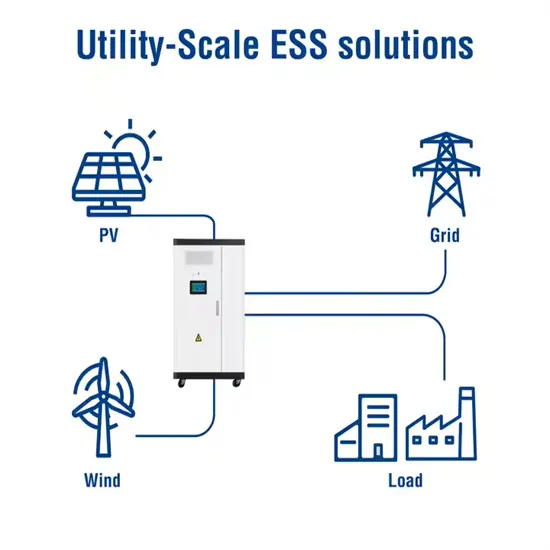

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.