Silicon Solar Cell: Types, Uses, Advantages

Jul 14, 2022 · A silicon solar cell is a photovoltaic cell made of silicon semiconductor material. It is the most common type of solar cell available in

Monocrystalline silicon solar energy specifications

alline solar panels deliver a higher efficiency Monocrystalline solar panels are one of the most popular choices for h. meowners looking to take advantage of solar energy. Monocrystalline

Monocrystalline solar panels – Uses, Benefits and Drawbacks

Apr 17, 2024 · Key Takeaway: Monocrystalline solar panels offer superior efficiency and longevity compared to other types of solar panels, making them a prime choice for those seeking to

Comprehensive Guide to Monocrystalline Solar

Aug 13, 2025 · Monocrystalline solar panels are photovoltaic cells composed of a single piece of silicon. These cells contain a junction box and electrical cables,

Monocrystalline silicon solar cells applied in

Jul 1, 2012 · Purpose: The aim of the paper is to fabricate the monocrystalline silicon solar cells using the conventional technology by means of screen

Monocrystalline Silicon Solar Panels: Efficient

Feb 3, 2025 · What is the Meaning of Monocrystalline Silicon Solar Panels? When discussing solar panel meaning, monocrystalline silicon solar panels refer to

How Crystalline Silicon Becomes a PV Cell

Apr 25, 2024 · Discover the making of solar cells: from silicon purification to panel assembly for efficient PV modules.

Review of silicon recovery in the photovoltaic industry

Dec 1, 2023 · Figure 1 illustrates the value chain of the silicon photovoltaic industry, ranging from industrial silicon through polysilicon, monocrystalline silicon, silicon wafer cutting, solar cell

Types of Solar Panels: Monocrystalline vs

Jan 30, 2024 · Introduction: Solar panels are a popular choice for renewable energy generation. It is important to understand the different types of solar

Comparing Monocrystalline vs Polycrystalline

May 1, 2025 · Compare monocrystalline vs polycrystalline solar panels in terms of efficiency, cost, appearance, and performance. Find the best option for your

Monocrystalline Solar Panels

Monocrystalline is also commonly known as crystalline silicon and is by face the most widely used solar photovoltaic technology. If you see a solar panel, chances are it is made of

Solar panel types and differences:

The main types of solar panels on the market today are monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. Differences between

sunhero

Discover the differences between monocrystalline and polycrystalline solar panels, including their efficiency, appearance, and suitability for various applications.

Environmental impact assessment of monocrystalline silicon solar

Jan 20, 2016 · Life cycle assessment on monocrystalline silicon (mono-Si) solar photovoltaic (PV) cell production in China is performed in the present study, aiming to evaluate the

Why Silicon is Used in Solar Panels | Efficient PV

Jun 4, 2024 · Silicon''s semiconductor properties, abundance, and mature production make it ideal for solar panels - extracting energy from sunlight

Why Silicon is the Most Widely Used Material in

May 15, 2024 · Discover why silicon is used in solar panels as the key material for harvesting clean energy efficiently. Explore its vital role in solar technology.

Life Cycle Assessment of Monocrystalline Silicon Solar Cells

Feb 28, 2025 · Crystalline silicon solar cells used crystalline silicon as the photovoltaic conversion material to convert solar energy into direct current electricity. At that time, there were two main

What Is a Monocrystalline Solar Panel?

Aug 4, 2024 · Monocrystalline solar panels, known as mono panels, are a highly popular choice for capturing solar energy, particularly for residential

Types of solar panels: monocrystalline,

There are three main types of solar panels used in solar projects: monocrystalline, polycrystalline, and thin-film. Each kind of solar panel has different

Environmental impact of monocrystalline silicon photovoltaic

Jun 30, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

What Are Monocrystalline Solar Panels?

Aug 29, 2022 · Monocrystalline solar panels can be used for residential and commercial purposes and are a highly efficient type of PV panel.

Monocrystalline vs. Polycrystalline vs. Thin-Film

Mar 7, 2025 · When it comes to Monocrystalline vs. Polycrystalline vs. Thin-Film Solar Panels, understanding their distinct characteristics and benefits is

Monocrystalline vs. Polycrystalline Solar Panels: Key Differences

5 days ago · Compare monocrystalline and polycrystalline solar panels. Learn their pros, cons, efficiency, and costs to choose the best option for your energy needs.

What Is a Silicon Wafer for Solar Cells?

Solar cells are an essential part of systems that convert sunlight into electricity using the photovoltaic effect. Wafer-based solar cells are the most commonly

Unleashing the Power of Monocrystalline Solar

Sep 27, 2024 · Discover the unparalleled power of monocrystalline solar panels, the cutting-edge technology revolutionizing solar energy efficiency. With their

Monocrystalline Solar PV Panels

How Monocrystalline Panels Work: Monocrystalline solar panels are made from single-crystal silicon ingots, which are produced by melting high-purity silicon

Monocrystalline Solar Panels vs Polycrystalline

Jan 24, 2023 · Over six decades ago, NJ scientists invented a practical silicon solar panel. This article compares the 2 main types of silicon used in solar

What kind of silicon is used in solar photovoltaic

Jun 19, 2024 · Silicon is primarily categorized into three types utilized in solar photovoltaic panels: monocrystalline silicon, polycrystalline silicon, and

How Monocrystalline Solar Cells Work

May 10, 2012 · The difference between monocrystalline and polycrystalline solar panels is that monocrystalline cells are cut into thin wafers from a singular

Thin Film vs. Silicon Solar Panels: What''s the

May 10, 2023 · Learn the difference between thin film vs. silicon for solar panels, including their advantages and environmental considerations.

Monocrystalline vs. Polycrystalline Solar Panels

Mar 21, 2024 · A photovoltaic effect is achieved when light is converted into electricity caused by absorbing photons and discharging electrons. These

Holistic Assessment of Monocrystalline Silicon (mono-Si) Solar Panels

Jun 16, 2023 · With the rising demand for lower carbon energy technologies to combat global warming, the market for solar photovoltaics (PVs) has grown significantly. Inevitab

Monocrystalline silicon solar energy specifications

What is a Monocrystalline Solar Module? Monocrystalline solar modules are panels assembled using ''''mono'''' cells - solar cells composed of single-crystal silicon. The single-crystal

Monocrystalline solar panels: a comprehensive guide

Aug 30, 2024 · How is a monocrystalline solar panel made Monocrystalline panels are thin slabs typically composed of 30-70 photovoltaic cells assembled, soldered together, and covered by

Monocrystalline Silicon Solar Panels: Efficient

Feb 3, 2025 · Monocrystalline silicon solar panels have an efficiency range of 18% to 22%, making them one of the most efficient photovoltaic panels available.

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

6 FAQs about [Monocrystalline silicon for solar photovoltaic panels]

What are monocrystalline solar panels?

Monocrystalline solar panels offer superior efficiency and longevity compared to other types of solar panels, making them a prime choice for those seeking to invest in renewable energy. These panels utilize a single silicon crystal structure, enhancing their ability to convert sunlight into energy effectively and with fewer panels.

Why is monocrystalline silicon used in photovoltaic cells?

In the field of solar energy, monocrystalline silicon is also used to make photovoltaic cells due to its ability to absorb radiation. Monocrystalline silicon consists of silicon in which the crystal lattice of the entire solid is continuous. This crystalline structure does not break at its edges and is free of any grain boundaries.

What is a monocrystalline photovoltaic (PV) cell?

Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si). Monocrystalline cells were first developed in the 1950s as first-generation solar cells. The process for making monocrystalline is called the Czochralski process and dates back to 1916.

What is the efficiency of a monocrystalline photovoltaic (PV) panel?

With an efficiency rate of up to 25%, monocrystalline panels reach higher efficiency levels than both polycrystalline (13-16%) and thin-film (7-18%) panels. Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si).

What is a polycrystalline solar panel?

Polycrystalline solar panels are made of numerous silicon crystals, whereas thin-film solar panels are made of photovoltaic material layers. Monocrystalline solar panels are created by developing a single crystal of silicon in a cylindrical form. This material is then cut into narrow wafers, from which solar cells are made.

What is monocrystalline silicon used for?

Monocrystalline silicon is the base material for silicon chips used in virtually all electronic equipment today. In the field of solar energy, monocrystalline silicon is also used to make photovoltaic cells due to its ability to absorb radiation.

Industry Information

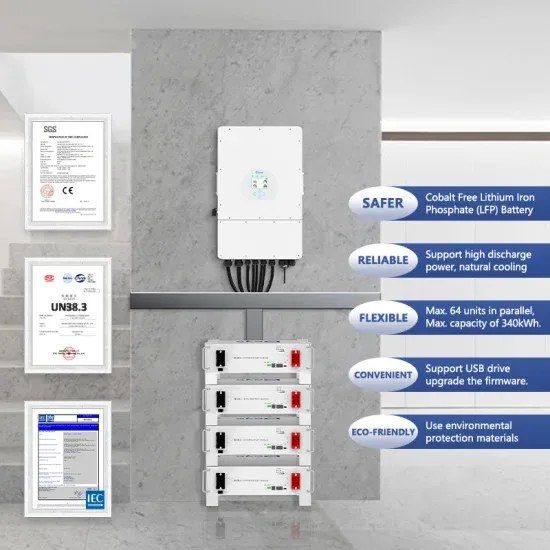

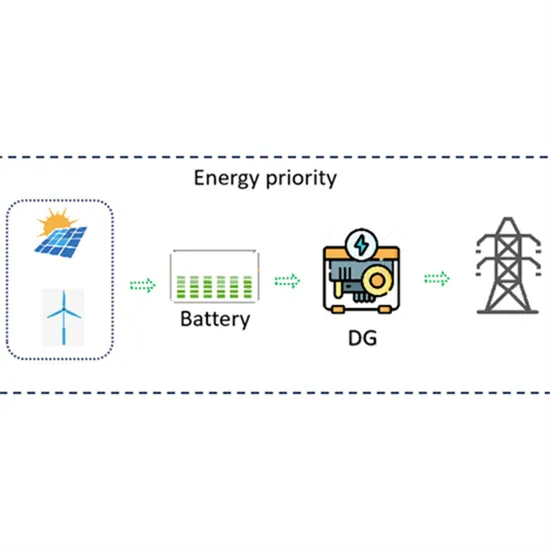

- Grid-connected inverter with battery

- New container energy storage cabinet

- Portable photovoltaic panel manufacturers in Western Europe

- Can an inverter be used for battery-powered appliances

- Energy storage cabinet 200w solar power generation

- Photovoltaic energy storage companies around Cairo

- Construction of power supply system for base stations in Iran

- The difference between inverter grid connection and hybrid grid connection

- Cheap wholesale 10000 watt inverter producer

- Large-capacity energy storage battery in Manchester UK

- Install photovoltaic energy storage in self-built houses

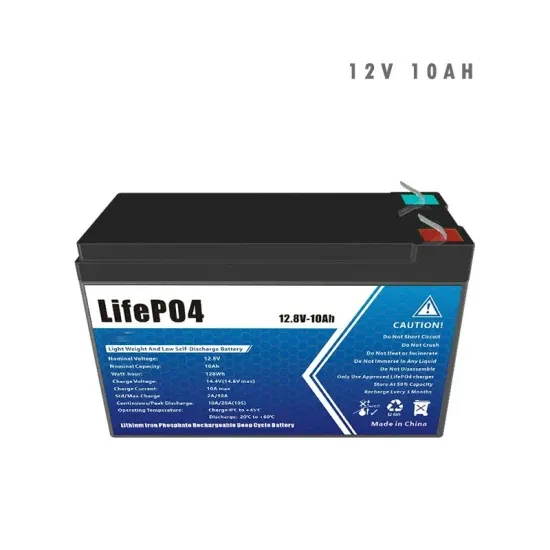

- Can lithium battery be used with 220v inverter

- Wind power communication base station

- Atess 100kw inverter in China in Australia

- There is a sound of current in the energy storage battery cabinet

- Price of dual-purpose inverter for reverse charging

- Power Distribution Uninterruptible Power Supply Processing

- 10W solar charging

- 30kw hybrid inverter for sale in Bandung

- Apia Solar Control System

- 100ah power station in China in indonesia

- Juba cylindrical lithium battery winter charging

- Swiss photovoltaic panels wholesale factory direct sales

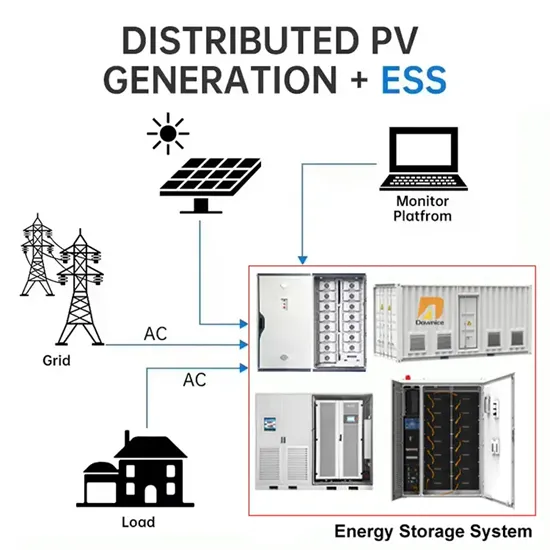

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

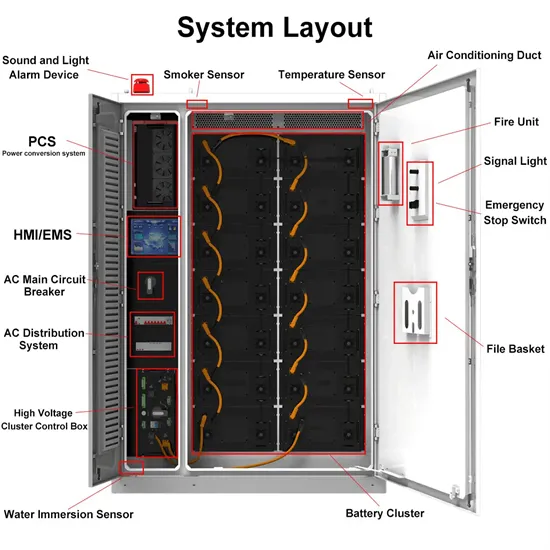

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.