Experimental studies of reciprocating liquid immersion

Mar 30, 2023 · In this study, the reciprocating liquid immersion cooling has been proposed and tested for cooling the cylindrical lithium-ion battery (LIB) under fast charging conditions. First,

18650 Cylindrical Lithium-Ion Batteries: Powering Innovation

The 18650 cylindrical lithium-ion battery, named for its 18mm diameter and 65mm length, has become a ubiquitous power source in numerous electronic devices. Renowned for its high

Research on charging strategy of lithium-ion battery system

Research and experiments show that this strategy has a good charging effect, and specific charging schemes can be formulated according to actual needs, which can effectively solve

Optimized fast charging protocol for cylindrical lithium‐ion

Sep 14, 2020 · Therefore, the investigation of fast charging protocol becomes increasingly important. In this work, a novel self-adaptive fast charging protocol for cylindrical lithium-ion

Optimized fast charging protocol for cylindrical lithium‐ion battery

Sep 1, 2020 · A new fast charging method for cylindrical Li‐ion battery is proposed based on constant incremental capacity algorithm. The method improves battery life by inhibition of

Study on Li-ion battery fast charging strategies: Review,

Nov 15, 2022 · The long charging time of Li-ion batteries in comparison to ICEV (Internal Combustion Engine Vehicle) refuelling time is a barrier to the adoption of

Identifying Efficient Cooling Approach of Cylindrical Lithium‐Ion Batteries

Nov 19, 2021 · The present research work discusses a numerical modeling approach to simulate the temperature distribution inside a cylindrical LIB using "finite difference analysis" (FDA)

(PDF) Degradation of Commercial Lithium-Ion

Sep 2, 2020 · Abstract and Figures Energy storage systems with Li-ion batteries are increasingly deployed to maintain a robust and resilient grid and facilitate

Principles and trends in extreme fast charging

The aim of this review is to discuss current trends and provide principles for fast charging battery research and development. We begin by comparing the

Optimal Fast-Charging Strategy for Cylindrical Li-Ion

Oct 23, 2024 · Abstract: Ensuring eficiency and safety is critical when developing charging strategies for lithium-ion batteries. This paper introduces a novel method to optimize fast

Thermal modelling of cylindrical Lithium-Ion batteries to

With inputs and average characteristics such as open-circuit voltage (OCV), state of charge (SOC), thermal conductivities, specific heat capacities, and density of the materials employed,

A systematic investigation of thermal and electrochemical

He et al. [29] developed an electrochemical-thermal coupled model for thermal runaway of 18650 cylindrical lithium-ion batteries during charging and discharging, and the results showed that

How to Charge a Lithium Battery Correctly in Winter

Jul 8, 2025 · In winter, lithium batteries face unique challenges due to low temperatures. The most common lithium batteries for vehicles come in 12V and 24V configurations. The 24V systems

Juba new lithium battery material

What are lithium ion batteries? Lithium-ion batteries (LIBs) with layered oxide cathodes have seen widespread success in electric vehicles (EVs) and large-scale energy storage systems (ESSs)

Investigation on thermal management of cylindrical lithium

Aiming to tackle the issues of excessive module temperature and inadequate thermal balance of vehicle power batteries under high discharge rates, a novel interwound cooling belt structure

Experimental study of liquid immersion cooling for different

Nov 29, 2022 · In this study, the liquid immersion cooling scheme based on SF33 has been proposed and tested for cooling the six different types of cylindrical lithium-ion batteries (LIBs)

Capacity estimation of retired lithium-ion batteries using

Feb 19, 2025 · The repurposing of retired lithium-ion batteries from electric vehicles is a critical strategy for reducing carbon emissions. Capacity estimation play

Thermal management of cylindrical lithium-ion batteries

Jul 15, 2025 · Effective BTMS is essential to keep LIBs in their optimal operating temperature range. Efficient thermal management methods are required because research has shown that

Enhanced cycling performance of cylindrical lithium-ion battery

Oct 26, 2019 · Increasing the areal capacity of electrodes in lithium-ion batteries (LIBs) is one of the effective ways to increase energy density due to increased volume fraction of active

Thermal Performance of a Cylindrical Lithium-Ion Battery

Jan 6, 2024 · In this paper, a battery thermal management system with a two-phase refrigerant circulated by a pump was developed. A battery module consisting of 240 18650-type Li-ion

Best Practices for Charging, Maintaining, and

Welcome to our comprehensive guide on lithium battery maintenance. Whether you''re a consumer electronics enthusiast, a power tool user, or an electric

Thermal behavior study of discharging/charging cylindrical lithium-ion

May 1, 2018 · We study, by the developed model, the battery module''s thermal behavior, and investigate the effects of discharge/charge C-rate, the liquid flow rate, the heat exchange area

How to Store Lithium Batteries for the Winter

Aug 12, 2024 · How do you store lithium batteries for the winter? Find the answer to this question and much more by reading below.

Thermal runaway behaviour of a cylindrical lithium-ion battery

Mar 1, 2025 · Lithium-ion batteries (LIBs) may experience thermal runaway (TR) accidents during charge and discharge processes. To ensure the safe operation of batt

The next generation of fast charging methods for Lithium-ion batteries

Jul 1, 2022 · The fast charging of Lithium-Ion Batteries (LIBs) is an active ongoing area of research over three decades in industry and academics. The objective is

2025 Guide to Lithium Ion Battery Winter Care

Jan 11, 2022 · Discover Essential Tips for 2025 on How to Maintain and Protect Your Lithium Ion Battery During Winter. Learn the Secrets to Optimal

Rapidly-Charging Freezing Lithium Batteries

Apr 6, 2025 · Scientists at University of Michigan develop a method of rapidly-charging freezing lithium batteries in cold weather. See their findings here.

The Ultimate Guide to Cylindrical Batteries

Mar 29, 2024 · Here we summarize the cylindrical battery types, capacity, voltage, etc., so you can have a more comprehensive understanding of

BU-410: Charging at High and Low

Mar 1, 2022 · Older battery technologies, such as lead acid and NiCd, have higher charging tolerances than newer systems, such as Li-ion. This allows

Low temperature heating methods for lithium-ion batteries:

May 1, 2025 · Solid-state lithium batteries operate by using a solid electrolyte to facilitate the movement of lithium ions between the electrodes, offering enhanced safety and stability

6 FAQs about [Juba cylindrical lithium battery winter charging]

What is interwound cooling belt structure for cylindrical lithium-ion batteries?

Aiming to tackle the issues of excessive module temperature and inadequate thermal balance of vehicle power batteries under high discharge rates, a novel interwound cooling belt structure for cylindrical lithium-ion batteries based on the temperature distribution characteristics of battery modules is proposed.

Do cylindrical lithium-ion batteries have a thermal stability problem?

This work is motivated by the critical need to improve the thermal stability of cylindrical lithium-ion batteries, especially in electric vehicles and high-performance electronics, where overheating during rapid charging and high discharge rates can lead to thermal runaway and decreased lifespan.

Can lithium-ion batteries be used for pure electric vehicles?

A critical review of thermal management models and solutions of lithium-ion batteries for the development of pure electric vehicles Renew. Sustain. Energy Rev., 64 ( 2016), pp. 106 - 128 Design of direct and indirect liquid cooling systems for high- capacity, high-power lithium-ion battery packs

Why are cylindrical lithium-ion batteries used in electric vehicles?

This study is particularly significant because cylindrical lithium-ion batteries are widely used in electric vehicles due to their high energy density and mechanical robustness. Various fin configurations are analyzed to optimize heat dissipation, effectively reducing peak temperatures during high discharge operations.

Does heat pipe thermal management work for lithium ion batteries?

An experimental study of heat pipe thermal management system with wet cooling method for lithium ion batteries A theoretical and computational study of lithium-ion battery thermal management for electric vehicles using heat pipes Experimental investigation of battery thermal management system for electric vehicle based on paraffin/copper foam

What are lithium ion batteries?

Lithium-ion batteries (LIBs), due to the high capacity, long lifespan and low self-discharge rate , , are widely adopted for applications in electric vehicles (EVs) .

Industry Information

- Yaounde Off-Grid Energy Storage Battery

- Which UPS is the best in Greece

- Niger Solar Energy Storage

- Jinshasa Tower Communication Base Station Wind Power

- Cheap factory price 5 5 kw inverter manufacturer

- Wholesale solar power supply in Botswana

- Rcb circuit breaker for sale in France

- Taipei energy storage product prices

- Kigali Heavy Industry Energy Storage Cabinet Supplier

- Colombian energy storage fire equipment manufacturer

- Solar power system for cabin in Switzerland

- What is the inverter 12v240hz

- Cambodia photovoltaic carport with energy storage wholesale

- Wholesale 63a circuit breaker in indonesia

- Professional inspection of new energy battery cabinets

- High quality factory price main switchgear for sale

- Pretoria solar photovoltaic customization

- A container can hold solar panels

- How much does a large energy storage cabinet cost in Luxembourg

- Cylindrical lithium battery all

- Huawei Senegal foldable photovoltaic panels

- Distribution of the energy storage industry chain in the Democratic Republic of the Congo

- Cameroon Energy Storage Power Source Factory

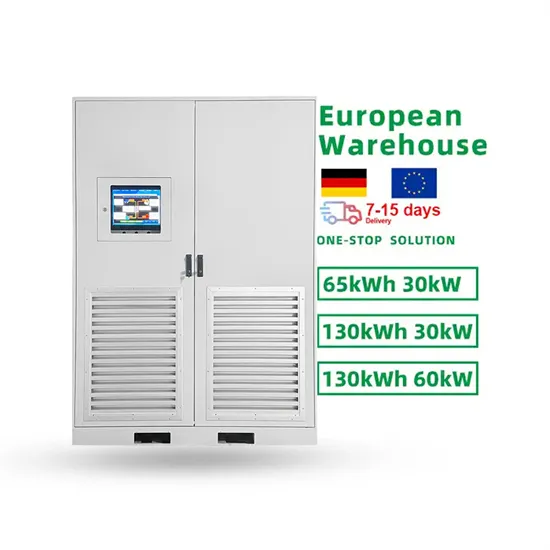

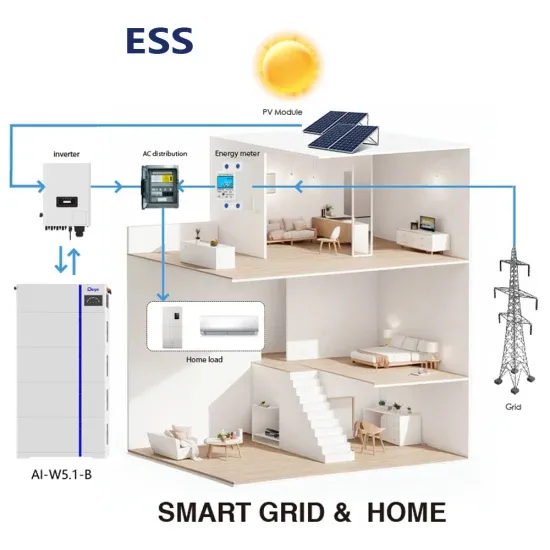

Commercial & Industrial Solar Storage Market Growth

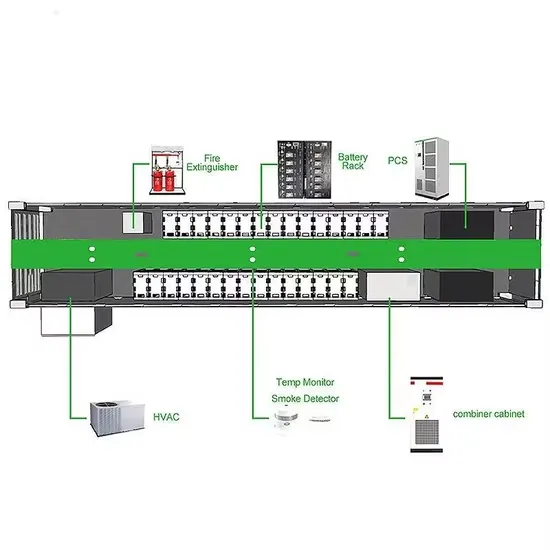

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

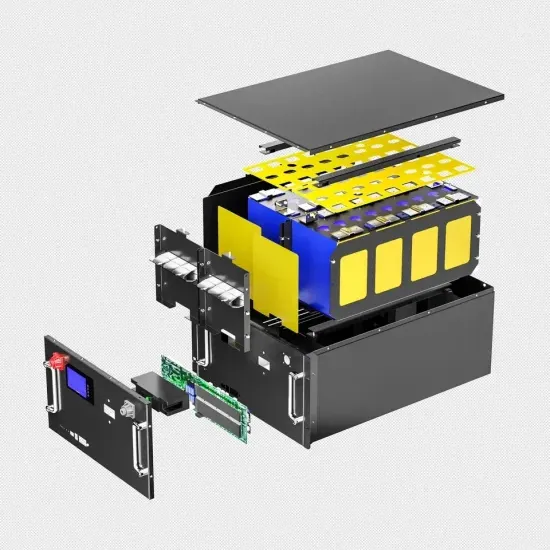

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.