How much silicon is in a photovoltaic panel

How many photovoltaic cells are in a solar panel? There are many photovoltaic cells within a single solar module,and the current created by all of the cells together adds up to enough

How much voltage does a silicon photovoltaic cell

A single solar cell, also known as a photovoltaic (PV) cell, is an electrical device that converts sunlight directly into electricity through the photovoltaic a single solar cell produces a

How Many Watts of Silicon Wafers Power Your Photovoltaic Panels?

Let''s start with a tasty metaphor: silicon wafers in solar panels are like pizza slices – their size, thickness, and quality determine how much energy you get. But instead of calories, we''re

How many V does a photovoltaic solar panel

Oct 24, 2024 · Photovoltaic solar panels have typically 36, 60, or 72 cells, with a direct implication for their voltage output. The voltage of a single solar cell is

What Is a Silicon Wafer for Solar Cells?

Most PV modules — like solar panels and shingles — contain at least several and up to hundreds of wafer-based crystalline silicon solar cells. How Does a

Solar Photovoltaic Cell Basics

3 days ago · There are a variety of different semiconductor materials used in solar photovoltaic cells. Learn more about the most commonly-used materials.

PV Cell Working Principle – How Solar

Mar 1, 2025 · A PV Cell or Solar Cell or Photovoltaic Cell is the smallest and basic building block of a Photovoltaic System (Solar Module and a Solar Panel).

What Voltage Does a Solar Panel Produce? The

Sep 27, 2024 · Monocrystalline panels, made from a single silicon crystal, tend to have the highest voltage and efficiency ratings among the three solar panel

Understanding Solar Panel Voltage: A

Jul 14, 2023 · On average, a solar panel can produce between 170 and 350 watts per hour, corresponding to a voltage range of approximately 228.67 volts to

How much silicon does a photovoltaic panel contain

Most panels on the market are made of monocrystalline, polycrystalline, or thin film ("amorphous") silicon. In this article, we''''ll explain how solar cells are made and what

Photovoltaic panel silicon wafer content requirements

How much silicon is used in photovoltaic power? The amount of silicon in metric tons is converted to MW based on an average consumption of about 3''910 kg of polysilicon per MWof

solar power

Apr 24, 2016 · I''d have to add a caveat to the very informed answer above. There is a difference between the solar silicon and the silica in the glass that is attached to the silicon. The answer

Components of a Solar Panel: Complete Technical Guide

1 day ago · As photovoltaic technology continues to advance, understanding the intricate components of a solar panel becomes crucial for making informed purchasing decisions and

Solar Silicon Wafers as-cut wafers high-quality

Mar 15, 2025 · Amorphous silicon panels are the second most widely used thin-film PV technologies, and they are used for small load requirements. They are

What is the voltage produced by a silicon solar cell

Jan 19, 2024 · Solar panels don''t all spit out the same voltage—it varies based on cell type, sunlight conditions, and system design. A single silicon solar cell typically produces 0.5V to

How many silicon wafers are needed for 1 photovoltaic

There are three parts of a solar panel that need to be manufactured: the silicon wafer, the solar cell, and the photovoltaic module. Very little of this is manufactured

What Is a Silicon Wafer for Solar Cells?

Much of the cost of manufacturing solar panels comes from the silicon wafer production process. By increasing the size of the silicon wafers, manufacturers

How Do Solar Cells Work? Photovoltaic Cells

Jul 25, 2024 · You''ve probably seen solar panels on rooftops all around your neighborhood, but do you know how they work to generate electricity? In this

How Crystalline Silicon Becomes a PV Cell

Apr 25, 2024 · Discover the making of solar cells: from silicon purification to panel assembly for efficient PV modules.

How Many Volts Does a Photovoltaic Panel Generate? Let''s

Ever stared at a solar panel and wondered, "How much juice does this thing actually pack?" You''re not alone. While the average homeowner might focus on wattage, voltage is the

How Many Silicon Cells Are in a Solar Panel?

Apr 2, 2024 · The best parameters defining an individual cell''s electrical propriety are open-circuit voltage and short-circuit current. Therefore, open-circuit voltage represents the voltage

How Solar Silicon Wafers Are Made into Cells

Jan 9, 2024 · How Solar Silicon Wafers Are Made into Cells The process of transforming solar silicon wafers into cells involves several meticulous steps,

Solar Panel Voltage: What Is It & Does It Matter?

In solar photovoltaic (PV) setups, the voltage yield of the PV panels usually ranges between 12 to 24 volts. Yet, the collective voltage output from the solar

Silicon-Based Technologies for Flexible

Nov 1, 2024 · Conventional PV cells are made from a silicon wafer that transforms sunlight directly into electricity. These silicon-based solar cells use 150 to 200

How many watts does a solar panel wafer have?

Sep 21, 2024 · Solar panel wafers serve as the foundation of photovoltaic cells. They are usually made from silicon, which plays a crucial role in converting

How a Photovoltaic Cell Works

Oct 19, 2021 · Step 1 A slab (or wafer) of pure silicon is used to make a PV cell. The top of the slab is very thinly difused with an "n" dopant such as phosphorous. On the base of the slab a

Everything You Need To Know About The

Sep 30, 2022 · Each solar cell voltage determines how much power the panels can provide for everyday electricity needs. Want to get more insights on solar

How many V does a solar wafer have?

Jun 5, 2024 · Generally, the standard output voltage for a single solar cell, such as those using crystalline silicon wafers, is approximately 0.5 to 0.6 volts. This voltage reflects the electrical

Prospects for reusing silicon from end-of-life

Dec 27, 2024 · Scientists in the Netherlands proposed a new testing scheme for recycling silicon from end-of-life photovoltaic panels. Their methodology

How many watts does a solar wafer produce? | NenPower

May 4, 2024 · 1. UNDERSTANDING SOLAR WAFERS Solar wafers form a fundamental part of modern photovoltaic (PV) technology, serving as the substrate upon which solar cells are

Solar Wafers: The Building Blocks of Photovoltaic

Apr 5, 2024 · Solar panels mainly use monocrystalline or polycrystalline silicon for today''s photovoltaic technology. Monocrystalline silicon wafers show excellent

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Advance of Sustainable Energy Materials:

Sep 12, 2024 · Modules based on c-Si cells account for more than 90% of the photovoltaic capacity installed worldwide, which is why the analysis in this

A Detailed Guide about Solar Wafers:

Aug 16, 2022 · FAQs Q. What is a wafer-based solar cell? As the name suggests, slices of either one or multi-crystalline silicon are used to create wafer-based

Solar Photovoltaic Manufacturing Basics

4 days ago · Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background

What is the voltage produced by a silicon solar cell

Jan 19, 2024 · A CdTe panel might need 120 thin-film cellsto match the 36V outputof a 60-cell silicon panel. This makes them bulkier and less space-efficient, but they perform 5–10% better

How many volts does a single silicon wafer in a

Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology. EcoFlow''s rigid,flexible,and portable solar panels use the highest quality

How much energy does a solar panel produce in a day

Nov 10, 2023 · The daily energy output of a solar panel depends on its wattage, sunlight hours, and efficiency. For example, a 400W panel receiving 5 peak sun hours at 20% efficiency

What Is a Silicon Wafer for Solar Cells?

Aug 27, 2024 · Much of the cost of manufacturing solar panels comes from the silicon wafer production process. By increasing the size of the silicon wafers,

6 FAQs about [How much silicon wafer voltage does a photovoltaic panel have ]

What are silicon wafer-based photovoltaic cells?

Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology. EcoFlow’s rigid, flexible, and portable solar panels use the highest quality monocrystalline silicon solar cells, offering industry-leading efficiency for residential on-grid and off-grid applications.

Which solar panels use wafer based solar cells?

Both polycrystalline and monocrystalline solar panels use wafer-based silicon solar cells. The only alternatives to wafer-based solar cells that are commercially available are low-efficiency thin-film cells. Silicon wafer-based solar cells produce far more electricity from available sunlight than thin-film solar cells.

Do silicon wafer-based solar cells produce more electricity than thin-film solar cells?

Silicon wafer-based solar cells produce far more electricity from available sunlight than thin-film solar cells. It’s helpful to note that efficiency has a specific meaning when applied to solar cells and panels. It’s a spec that measures the wattage produced per square meter (m²) of photovoltaic material exposed to peak sunlight.

Do thin film solar panels use wafers?

Thin-film solar panels do not use wafers but are highly inefficient and only used in rare circumstances. Over 90% of solar panels use silicon wafers. What Is the Difference Between a Solar Cell and a Solar Wafer?

What is a solar wafer?

Solar wafers are crucial for this clean energy option. They are made of monocrystalline or polycrystalline silicon. This makes up 95% of today’s solar panel market. Monocrystalline silicon is top-notch, with efficiencies between 18% and 22%. This is remarkable since the highest efficiency for silicon solar cells is around 32%.

What are photovoltaic wafers?

Photovoltaic wafers are a key part of the solar energy world. They merge semiconductor making with solar cell technology. These parts are essential for renewable energy systems, turning sunlight into electricity. Getting to know about photovoltaic wafers helps us see how we can have a sustainable future with renewable energy.

Industry Information

- Paraguay electric stand-alone solar air conditioning

- Can I apply for lithium-ion batteries for communication base stations

- Bishkek solar photovoltaic panels in the countryside

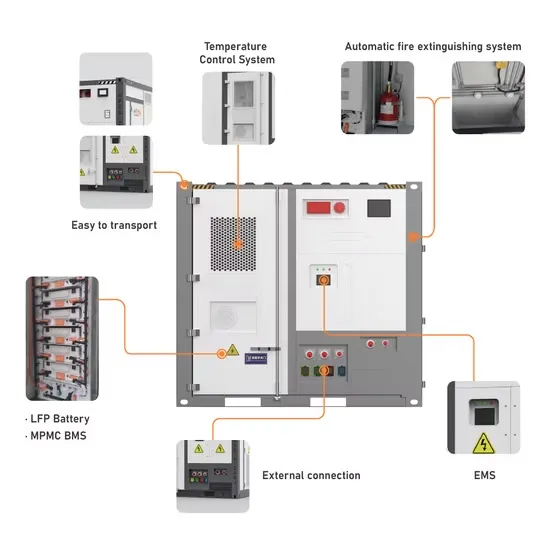

- Energy Storage Container System Installation Specifications

- Ranking of wind power signal quality of communication base stations

- Composition of solar power supply system

- Hot sale 3000w solar inverter for sale producer

- 5v step-up inverter 12v

- A brief introduction to photovoltaic solar panels

- Site energy field marketing plan design

- Asuncion energy storage capacitor price

- Niger Photovoltaic Energy Storage System Sales

- Russia St Petersburg high power UPS uninterruptible power supply

- Gaborone Portable Power Kit Wholesale Manufacturer

- High wattage garden solar lights

- Single-phase photovoltaic inverter control

- Lesotho solar panels photovoltaic power generation

- Cheap smart solar inverter for sale for sale

- Brasilia Uninterruptible Power Supply Customization Company

- Inverter manufacturers in Asia

- How much does the energy storage battery cost in Izmir Türkiye

- Fuel Cell System Pack

- Household three-phase energy storage inverter

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

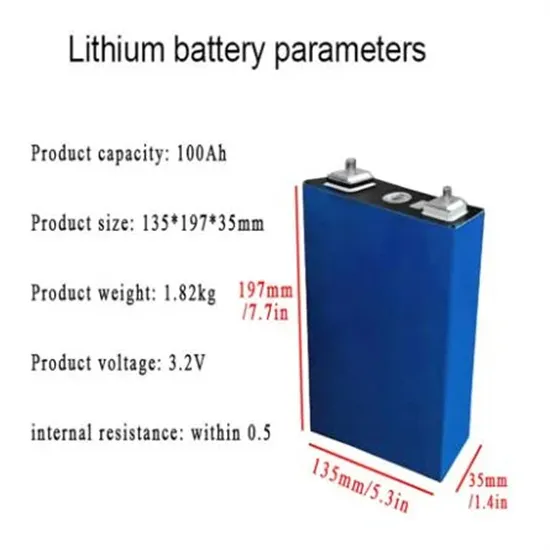

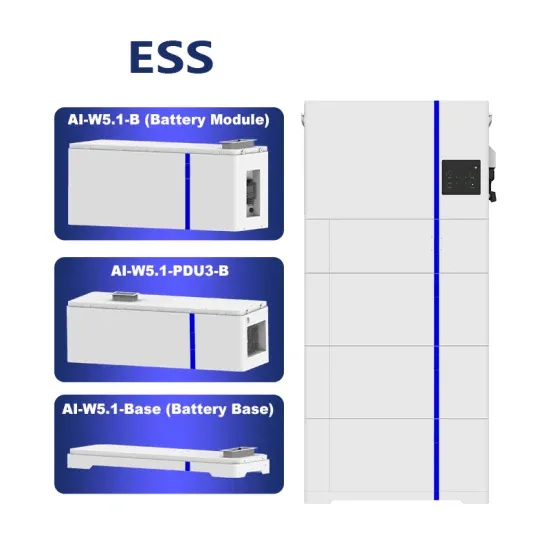

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.