The FCH2RAIL Project: A Demonstration of a Modular Fuel Cell

Jan 1, 2023 · In this paper, the Horizon 2020 project FCH2RAIL is outlined. The project aims to develop a bi-modal propulsion system, which combines an overhead catenary powertrain and

Fuel Cell Stacks

Below you will find many stacks that can easily be integrated into a system to provide an operational power system tailored for most specific applications.

Fuel cell power pack

Aug 19, 2025 · A fuel cell power pack consists of a fuel and gas processing system (the balance of plant), and a stack of fuel cells that convert the

Test of hybrid power system for electrical vehicles using a lithium

Jan 22, 2014 · This work presents the proof-of-concept of an electric traction power system with a high temperature polymer electrolyte membrane fuel cell range extender, usable for

Fuel cell technology review: Types, economy, applications,

Mar 1, 2025 · This study conducts a thorough review of fuel cell technology, including types, economy, applications, and V2G scheme. Fuel cells have been considered

Adaptive Control of Fuel Cell-Battery Hybrid Systems

Mar 31, 2025 · This article proposes an adaptive control for the power distribution of fuel cell (FC) hybrid electric vehicles. port-Hamiltonian framework is utilized to describe the fuel cell hybrid

Fuel cell electrified propulsion systems for long-haul heavy

Sep 1, 2022 · Fuel cell electrified propulsion may currently represent a promising option for long-haul heavy-duty trucks. However, appropriately sizing fuel cell electrified propulsion systems to

Investigation of the integrated fuel cell, battery, and heat

Jan 15, 2023 · In contrast, the proposed fuel cell backup heat pump assisted BEV thermal management system recovered the heat from the fuel cell coolant and battery pack and did

Hydrogen Fuel Cell System

Powerzone H2 develops small and lightweight air-cooled fuel cell stacks to offer an alternative power source with advantages over traditional batteries. PZH2

Fuel Cell Power Pack with Integrated Metal Hydride

Jul 27, 2022 · Here, we present fuel cell power pack with integrated metal hydride hydrogen storage for powering 3-ton electric forklift. Liquid-cooled 9SSL PEM fuel cell stack with 75 cells

How to Optimise Fuel Cell Balance of Plant with

Jan 11, 2024 · Multi-stack fuel cell systems are developed through the integration of multiple fuel cell stacks with a single, optimised, Balance of Plant (BoP).

Review and analysis of thermal management for proton

May 1, 2025 · With the advancement of low-carbon process, fuel cell vehicle has emerged as a promising solution for heavy-duty trucks. Thermal management is a crucial factor affecting the

Analysis of Hybrid Ship Machinery System with

Feb 7, 2024 · As marine traffic is contributing to pollution, and most vessels have predictable routes with repetitive load profiles, to reduce their impact on

Fuel cells

Some fuel cell designs that are sized for peak power demand can be prohibitively expensive to construct – the stack varies from $500 to $5000/kW, depending

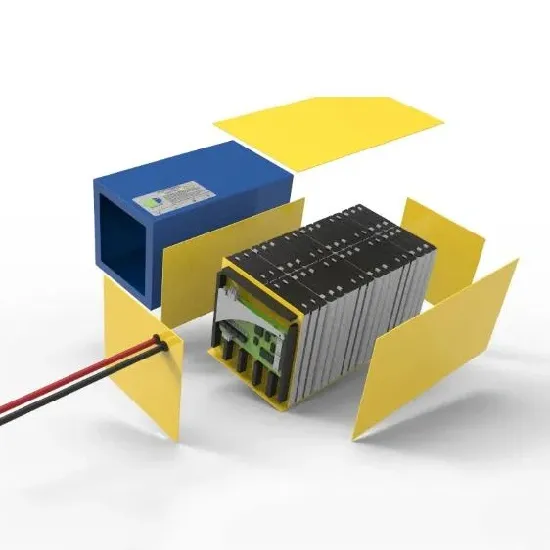

新能源车电池包(PACK)系统介绍

Apr 14, 2023 · PACK作为新能源锂电动力电池系统生产、设计和应用的关键步骤,是连接上游 电芯 生产与下游整车运用的核心环节。 电池包的设计需要考虑

StackPack™ 75 | Hydrogen fuel cell system for

Aug 14, 2025 · StackPack™ 75 is a compact, high-performance, zero emission 75 kW hydrogen fuel cell system for medium-duty truck and city bus applications.

Tata Advanced Systems

Portable Fuel Cell Systemss First rugged all terrain indigenous system developed by TASL. The Portable Fuel Cell System (FCS) is an indigenously developed

StackPack™ 40 | Hydrogen fuel cell system for

Aug 18, 2025 · A compact and efficient zero emission hydrogen fuel cell system for all passenger cars segments and light commercial vehicle applications.

The battery for the fuel cell

Nov 30, 2021 · This also permits to size the fuel cell on average power and not on maximum power, thus reducing the overall system cost. Working at low

Power pack – S-FUELCELL

4 days ago · Fuel cell power pack It is suitable for electric power sources that require a lot of energy, and the capacity change is freely available with the

Fuel cell power module

The scalable fuel cell power module is a fuel cell system that generates electricity from hydrogen in vehicles. It is primarily used in commercial vehicles,

XRANGETM | Emission-Neutral Heavy-Duty

Sep 27, 2023 · Freudenberg e-Power Systems is one of the world''s leading suppliers of emission-neutral energy systems for heavy-duty applications. With

Characteristic study on fuel cell/battery hybrid power system

Jun 1, 2012 · First, major components of the hybrid power system such as a fuel cell stack, a membrane humidifier, a lithium-ion battery pack, a microcontroller, a DC/DC converter, and

We''re hiring an Intern/Project Staff as Vehicle

What You''ll Do: Coordinate integration of the fuel cell system, hydrogen storage, battery pack, and auxiliary systems into the vehicle platform.

Fuel Cell Applications

Toyota fuel cell applications beyond cars include buses, trucks, forklifts, boats, trains and stationary generators, all of which are operational today.

Fuel Cell and Hybrid Power Pack (FCHPP)

The Fuel-Cell Hybrid Powerpack is a holistic and integrated approach to realising climate-friendly, resource-efficient and sustainable rail transport. The Fuel Cell and Hybrid Power Pack

DP30M2S

With proper customization of the airframe, Doosan''s fuel cell Powerpacks can be integrated to different types of drones for long endurance. Upgrade your

Symbio unveils the ready-for-industrialization

Dec 16, 2024 · Symbio unveils its industrializable StackPack™ 75 hydrogen fuel cell system at Tokyo''s H2 & FC Expo from February 19 to 22.The new

Fuel Cell Power Pack with Integrated Metal Hydride

Jul 26, 2022 · Here, we present a developed power fuel cell pack with MH hydrogen storage which was developed by Hydrogen South Africa Systems [13] and integrated by Hot Platinum

Applications : Doosan Mobility Innovation

The green hydrogen-based fuel cell provides 100% eco-friendly energy with zero carbon emissions. Real-time monitoring service allows for pre-detection of potential failures and offers

Fuel Cells vs. Batteries: What''s the Difference?

Dec 22, 2022 · The fuel cell market is growing rapidly, too, estimated to grow by 36% annually and reach $29 billion by 2028. The differences between fuel

Air-cooled fuel cells: Keys to design and build the oxidant/cooling system

Sep 1, 2018 · In these fuel cells, the Oxidant/Cooling subsystem is of crucial importance and along with three others (Fuel, Electrical and Control subsystems) make up the Balance of Plant

Fuel cell and lithium iron phosphate battery hybrid powertrain with

Apr 1, 2015 · To validate the Fuel cell-Li-ion battery-Ultracapacitor (FC-LIB-UC) hybrid powertrain and energy management strategies developed in this study, a test station powered by a 1 kW

Metal hydride systems for hydrogen storage and supply for

Sep 21, 2015 · Metal hydride systems for hydrogen storage and supply for stationary and automotive low temperature PEM fuel cell power modules

E-Mobility for Heavy-Duty | Freudenberg e

4 days ago · Discover sustainable e-mobility solutions for the heavy-duty sector. Freudenberg e-Power Systems innovates in battery and fuel cell technologies.

Portable Power Fuel Cells | Bramble Energy

For off grid, temporary or hybrid power – Bramble''s portable power fuel cell solutions are perfect for low-output power.

6 FAQs about [Fuel Cell System Pack]

What is a scalable fuel cell power module?

The scalable fuel cell power module is a fuel cell system that generates electricity from hydrogen in vehicles. It is primarily used in commercial vehicles, especially in long-distance applications. The system comprises a fuel cell stack and the fuel cell submodules, such as those for hydrogen and air, which are required for the stack to operate.

What is a fuel cell system?

The system comprises a fuel cell stack and the fuel cell submodules, such as those for hydrogen and air, which are required for the stack to operate. Highly integrated system solution for fuel cell-electric commercial vehicles providing fuel cell systems from a single source for higher power density and improved efficiency

What is a fuel cell stack?

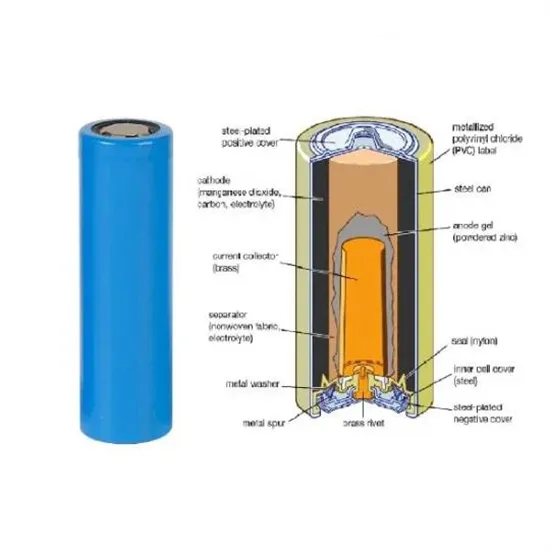

This assembly of cells is called a fuel cell stack, or just a stack. The power output of a given fuel cell stack will depend on its size. Increasing the number of cells in a stack increases the voltage, while increasing the surface area of the cells increases the current. A stack is finished with end plates and connections for ease of further use.

Why do fuel cell PowerPacks have a stack structure?

A key material used in the stack is MEA (Membrane Electrode Assembly). This enables high energy output and durability for our fuel cell Powerpack. And thanks to the design of the stack structure, which maintains even energy output among cells, high energy output of the fuel cell Powerpack remains stable during flight.

How does a fuel cell work?

A single fuel cell consists of a membrane electrode assembly (MEA) and two flow-field plates delivering about 0.5 and 1V voltage (too low for most applications). Just like batteries, individual cells are stacked to achieve a higher voltage and power. This assembly of cells is called a fuel cell stack, or just a stack.

What are the different types of fuel cells?

Different fuel cell types are available and can be characterized by the materials used in the membrane. Molten Carbonate Fuel Cell (MCFC) and Solid Oxide Fuel Cell (SOFC) technologies are high-temperature fuel cells that are flexible as regard to choice of fuel: methanol, ethanol, natural gas, biogas, and hydrogen are most commonly used.

Industry Information

- Large-scale energy storage project in Rome

- Photovoltaic solar panel manufacturer in Barcelona Spain

- Uruguayan rooftop photovoltaic panels

- Base station power supply stable power supply

- Multi-function uninterruptible power supply ups

- Lithium power station factory in Nigeria

- Are there any battery cabinet companies in Bamako

- Huawei Iran photovoltaic panels

- Use of building solar energy system

- Industrial solar panel energy storage

- Lifepo4 power station factory in Iraq

- Outdoor power supply phosphorus power supply lithium iron phosphate

- South Sudan household energy storage battery manufacturer

- Croatia industrial energy storage cabinet brand ranking

- Kiribati 45kw high quality inverter manufacturer

- 12v 10 watt solar panel water pump installation

- Korea Uninterruptible Power Supply Solution

- Congo Outdoor Energy Storage Power Supply

- Inverter DC side voltage to ground

- Podgorica tariff photovoltaic inverter

- Constant power control of photovoltaic inverter

- Hot sale metal clad switchgear factory Wholesaler

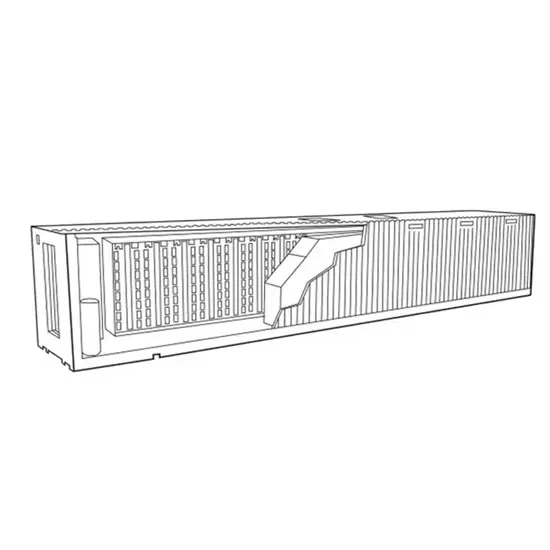

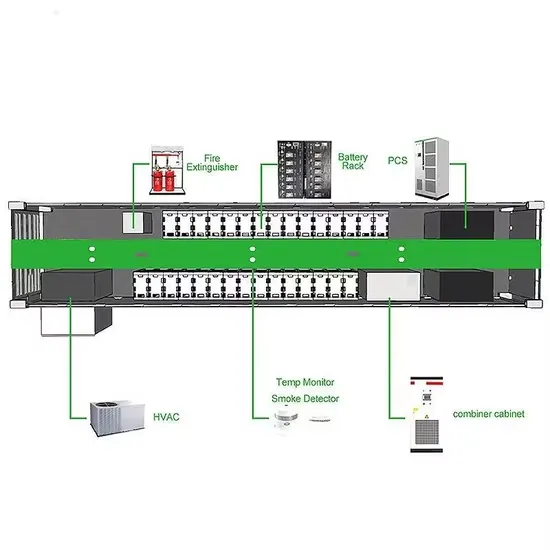

- Prefabricated power generation and energy storage cabin

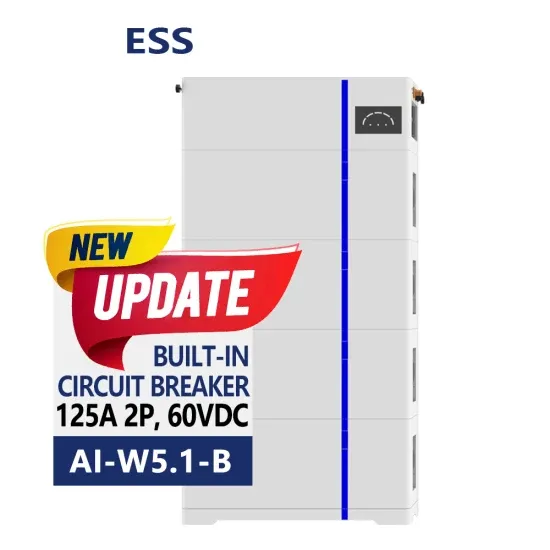

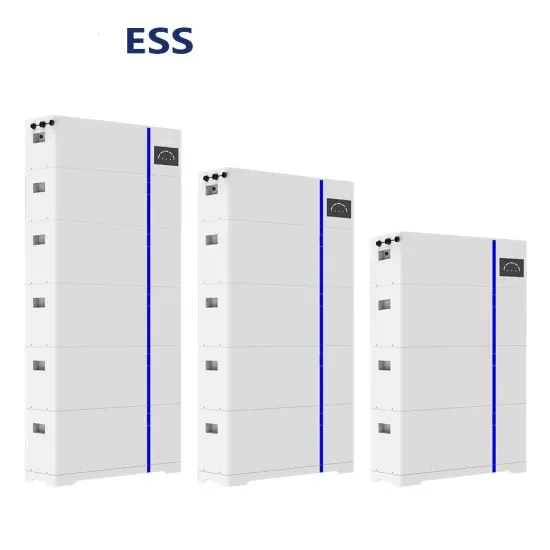

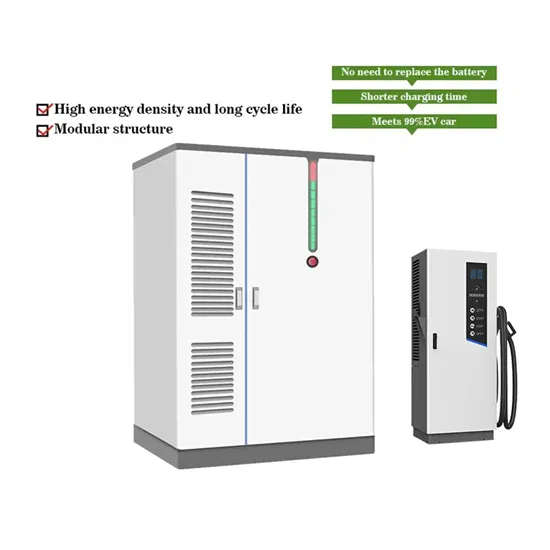

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.