Inquiry about battery protection circuit

Jun 19, 2023 · Other Parts Discussed in Thread: BQ2980, BQ27Z746 Hi, TI support team I have received inquiries about the battery pack protection circuit

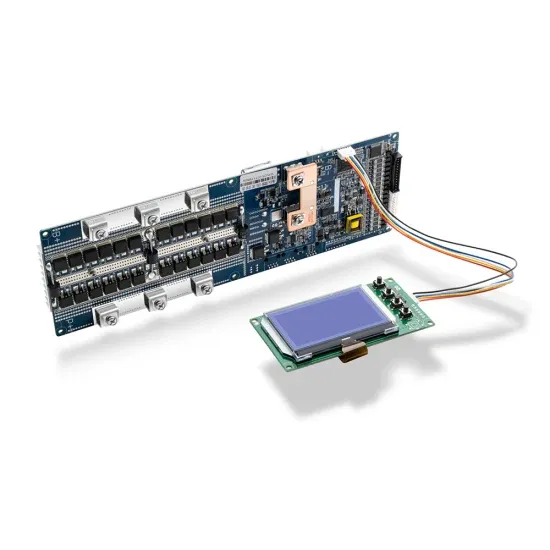

Battery Cell Balancing: What to Balance and How

Jun 26, 2007 · I. INTRODUCTION Different algorithms of cell balancing are often discussed when multiple serial cells are used in a battery pack for particular device. Means used to perform cell

Battery monitors & balancers | TI

Aug 19, 2025 · Accurate monitoring enables more efficient battery use, resulting in longer run time and a reduction in battery size and cost. Our monitors and balancers provide accurate, real

BQ76952: BMS system solution recommendation

The battery pack is 63V 90AH with 21700 cells. There are 2 types for it, one is 15 cells in series and 18 cells in parallel for one battery pack unit. Another one is a big box and insert 6 battery

HEV/EV 电池管理系统 (BMS) 设计资源 | TI .cn

借助业内出色的无线 BMS 网络可用性变革电动汽车 (EV) 电池管理,通过采用经独立评估的功能安全概念,使汽车制造商能够降低其设计的复杂性,提高可靠性并减轻车辆重量,从而延长续航

Presentation Title Here

Aug 15, 2025 · In 2008: 2 parallel tracks: charger and gauge with lab session, 50-60 engineers from BMS customers, distributors, and TI FAEs Since 2011: An educational conference for

BQ76952: Paralleling of battery packs

May 12, 2022 · Part Number: BQ76952 I am using BQ76952 IC for BMS which is used in a scenario where multiple battery packs are connected in parallel. I have seen a strange

Ti parallel two battery pack bms solution

you can use just one of the BMSs that is installed on one of the packs. tie the B- and B+ terminals of the two packs together, connect the two packs through the sense wires

BQ76940: Question about parallel stacks

More commonly the voltages of the cells are matched at manufacturing of the battery pack and cells connected in parallel to form effective cells with larger capacity, then that 15s4p assembly

BQ25792: Using BQ25792 as a fast charging IC in

Dec 23, 2024 · Part Number: BQ25792 Other Parts Discussed in Thread: BQ25798 Tool/software: Hello, I was finding fast charging supported IC for my battery pack of 3S3P configuration, and I

How to Balance Lithium Batteries with Parallel

Sep 1, 2023 · By connecting two or more lithium batteries with the same voltage in parallel, the resulting battery pack retains the same nominal voltage but

Battery Packs BMS in Parallel Wiring

Oct 15, 2024 · Parallel BMS (Battery Management System) is a management solution used when multiple battery cells are connected in parallel. Its main functions are to monitor parameters

BQ79616: Establishing Daisy Chain Links for

Nov 26, 2024 · Part Number: BQ79616 Tool/software: Hello Experts, Our team is developing a battery management system for a 10 kWh battery pack using the

BQ76952: Paralleling of battery packs

May 12, 2022 · I am using BQ76952 IC for BMS which is used in a scenario where multiple battery packs are connected in parallel. I have seen a strange phenomena while testing the battery

BQ2947: Combining two battery packs both with BMS

I would like to combine two 3s2p Li-ion packs to make one 3s4p pack. Each of the 3s2p packs utilize the BQ2947 for over-voltage protection and both use the BQ40Z50 to balance cells. If I

BQ77915: How to implement two sense resistor

Jan 9, 2025 · I work in a startup making medical exoskeleton for people with disabilities and hence it is of upmost importance to ensure the battery is safe

Stackable Multicell balancer for series/parallel

My thought is to use a two stackable battery balancers and make two battery packs with a 4S1P configuration. I would than either cascade the battery

Presentation Title Here

Dec 3, 2011 · TI''s patented PowerPumpTM/ACB technology uses inductive strategy for high efficiency and wide balancing current range TI can provide solutions for balancing currents

BQ24610: How to charge 2 battery packs in parallel

Hi, We currently use the Texas BQ24610 chip to charge a 6.5Ah li-ion battery (robotics application). In the new version of the robot, 2 packs of 6.5Ah Li-ion battery can be connected

BQ79616-Q1: BMS system solution

Hi team, The battery pack is 63V 90AH with ''21700'' cells. There are 2 types for it, one is 15 cells in series and 18 cells in parallel for one battery pack unit.

Solution for 2 Li-ion Battery Packs in Parallel

One of the specifications when buying a battery charger IC is the number of cells in SERIES. What if you have 2 battery packs in parallel and they each have 2 cells in series.

Run two (almost) same battery packs in parallel

Feb 21, 2025 · Hello everyone, I have two battery packs built with LG MH1 18650 cells which each have a 50A BMS (60V/30AH). One is a 2-3 years older than the other though. I''d really like to

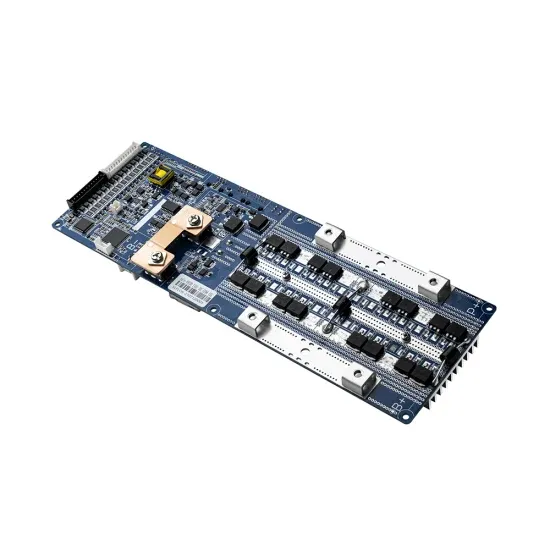

TI Battery Management Solutions for New Energy

Jun 5, 2012 · EM1401 BMS Pack Architecture Pack <750V Number of Packs is Pack Voltage Limited Stack Current Sense

E-Two-Wheeler Battery Management System

2 days ago · A Battery Management System (BMS) is an intelligent embedded system. It ensures that the battery pack is safely charged, monitors the health

BQ77915: Beginning new on-shore sourced BMS

Jan 21, 2025 · I''m pretty new to battery pack BMS design as well, so I''d love to be shown some good design resources on the topic. I will be designing a BMS capable of protecting and

Battery protectors | TI

2 days ago · We understand performance and safety are major care-abouts for battery packs with lithium-based (li-ion and li-polymer) chemistries. That is why we design our battery protection

How to Balance Lithium Batteries with Parallel

Sep 1, 2023 · A parallel BMS regulates the current flow between 2 or multiple batteries connected in parallel, learn how it works and how to connect it.

Hybrid, electric & powertrain systems design resources | TI

2 days ago · Our advanced battery management system (BMS) solutions can help you overcome monitoring, sensing, protection and communication challenges that affect driving range,

TI BATTERY MANAGEMENT SYSTEMS SEMINAR

Sep 29, 2023 · Using an optimized, unique daisy chain communication protocol, the battery monitors can be stacked up to support various battery pack sizes. Cheapest solution, but

A BMS

Jul 12, 2024 · When it comes to implementing a BMS in parallel battery configurations, choosing the right technology partner is crucial. Himax

BQ76952: Series and Parallel connection of BMS

We have designed a BMS with BQ76952 for a 10s battery pack. The design is perfectly working. But, we are in need of connecting 2 or more of these BMS in parallel and series combinations.

6 FAQs about [Ti parallel two battery pack bms solution]

What is a parallel battery management system (BMS)?

A Parallel BMS plays an important role in achieving safe and efficient parallel battery configurations. It continuously monitors the voltage, temperature and charging status of each battery, ensuring that the battery is balanced and protected during the charge and discharge cycle. A BMS for parallel cells performs several essential functions:

What happens if you connect two lithium batteries in parallel?

By connecting two or more lithium batteries with the same voltage in parallel, the resulting battery pack retains the same nominal voltage but boasts a higher Ah capacity. For example, connecting two 12V 10Ah batteries in parallel method creates a 12V 20Ah battery.

What is a parallel BMS?

MOKOEnergy ‘s Parallel BMS offers an innovative solution to efficiently manage parallel battery configurations. Understanding the complexities involved will enable the industry to fully harness the potential of parallel battery systems.

Should battery management systems be integrated in parallel battery configurations?

The integration of Battery Management Systems (BMS) in parallel battery configurations is a critical consideration for anyone looking to enhance the efficiency, safety, and longevity of their battery systems.

What is a parallel lithium battery pack?

According to the parallel principle, the current of the main circuit is equal to the sum of the currents of the parallel branches. Therefore, a parallel lithium battery pack with “n” parallel batteries achieves the same charging efficiency as a single battery, with the charging current being the sum of the individual battery currents.

Can a BMS be connected to a 14500 Li-ion battery?

Thought of connecting BMS (mostly for the balancing feature, since they already have protection) so the protected 14500 Li-ion batteries will be balanced.

Industry Information

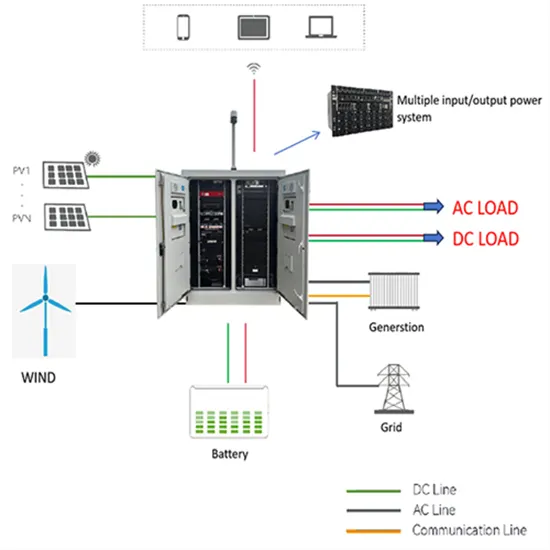

- Inverter grid-connected box combiner box

- Circulation wind power generation system

- Hybrid power inverter factory in France

- Photovoltaic panel production and manufacturing companies

- St Johns 72v60a battery cabinet

- Prospects for home energy storage battery maintenance

- How much is the subsidy for energy storage batteries in Cordoba Argentina

- Zimbabwe Grid Energy Storage

- Container outdoor power supply light charging

- Hollow photovoltaic panel price

- Base station uses power chip or power supply

- Kyrgyzstan communication base station wind tower manufacturer customization

- 5g base station 1 electricity fee introduction

- Which battery plus inverter is better

- Are there any flywheel energy storage companies in Dhaka

- Shushi New Energy Battery Cabinet

- 220v circuit breaker for sale in Argentina

- Huawei liquid flow battery usage scenarios

- Communication base station solar energy price trend China

- Doesn t the Paris energy storage power station use lithium batteries

- Villa outdoor roof solar lights

- France Energy Storage Cabinet Container

- Energy storage power in solar-storage-charging projects

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

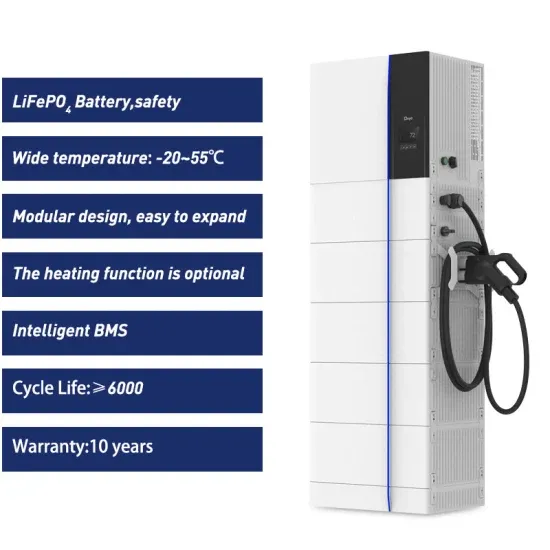

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.