A review on thermal management of lithium-ion batteries

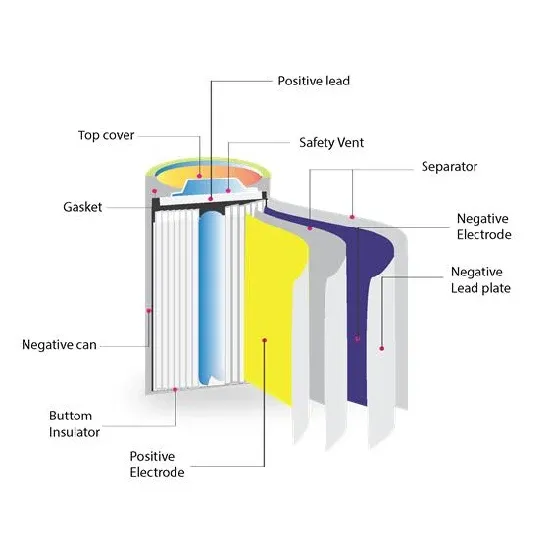

Jan 1, 2022 · From the perspective of global new energy vehicle development, its power sources mainly include lithium-ion batteries (LIBs), nickel metal hydride batteries, fuel cells, lead-acid

Future smart battery and management: Advanced sensing from external

Mar 31, 2021 · Amongst others, the lithium-ion battery (LIB) technology continues to rise up rapidly and has witnessed the most widespread applications, attributed to its unique

Modeling and control strategy optimization of battery pack

Nov 1, 2024 · This paper establishes the liquid cooling thermal management system model for an electric vehicle''s battery pack, which accurately characterizes the temperature distribution and

A Power Management IC Used for Monitoring

Apr 9, 2021 · In this paper, a fully integrated, high-reliability, and high-precision power management system IC for the electric system with Li-ion battery packs

DelftX: Battery Management Systems (BMS) and Pack Design

Aug 14, 2025 · Learn how to effectively manage battery safety and lifecycle in battery pack design. Learn about applications of Battery Management Systems (BMS) in electric vehicles,

Battery Management Systems in Electric Vehicles

A battery management system (BMS) is one of the core components in electric vehicles (EVs). It is used to monitor and manage a battery system (or pack) in EVs. This chapter focuses on the

Battery management systems (BMS) | Infineon Technologies

Infineon''s battery management solutions and reference designs for automotive or industrial and consumer applications help you lay out your battery management system to perfectly fit your

Review of battery thermal management systems in electric

Mar 1, 2024 · Lithium-ion batteries are the most commonly used battery type in commercial electric vehicles due to their high energy densities and ability to be repeatedly charged and

Optimization Analysis of Power Battery Pack Box Structure

Mar 10, 2023 · The power battery is the only source of power for battery electric vehicles, and the safety of the battery pack box structure provides an important guarantee for the safe driving of

Battery Management Systems

Default DescriptionRole of Power Electronics in BMS Battery management systems (BMS) are critical to the effective functioning and long-term viability for many different battery storage

Application of Power Electronics and Control for

Dec 12, 2022 · An overview of different applications of power electrons, voltage balance methods, SOC estimation in energy storage, and battery storage

Thermal management system of lithium-ion battery packs

Aug 1, 2022 · Hence the thermal management system (TMS) of battery packs for EVs is one of the prominent research areas in recent years. In this study, bibliometric analysis has been

Crush simulation and optimisation study of power battery pack

In order to ensure thermal safety and extended cycle life of Lithium-ion batteries (LIBs) used in electric vehicles (EVs), a typical thermal management scheme was proposed as a reference

The Ultimate Guide For Lithium-Ion Battery

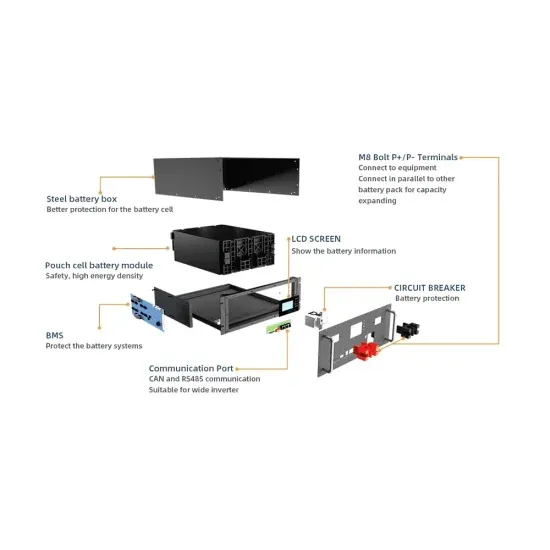

Key Takeaway: Lithium-ion battery packs are complex assemblies that include cells, a battery management system (BMS), passive components, an

Energy Storage Systems: How to Easily and Safely Manage Your Battery Pack

May 3, 2024 · How do we account for the various burdens placed upon the energy grid over 24 hours? This can be done by using battery-based grid-supporting energy storage systems

Battery Management System Hardware

This paper focuses on the hardware aspects of battery management systems (BMS) for electric vehicle and stationary applications. The purpose is giving an

Battery Management Systems (BMS): A

Mar 22, 2024 · Increased safety: By continuously monitoring and protecting the battery pack, a BMS significantly reduces the risk of thermal runaway, fires, or

Battery Management Systems

Battery charging, discharging, and cell balancing procedures must be properly orchestrated for effective battery management. These functions are crucial for ensuring peak performance,

A review of power battery cooling technologies

May 1, 2025 · Driven by the rapid development of EVs, research on battery thermal management has increased significantly in recent years, with annual keywords constantly evolving. Recent

Working principle and application prospects of battery packs

Jan 3, 2025 · Explore the importance and advancements in battery packs, from powering electronics to energy sustainability. Discover key components, future prospects, and

Battery Power Management for Portable Devices

Jul 19, 2024 · Along with describing each chemistry''s peculiarities, answers to many practical common questions important information about rechargeable batteries is pro-vided, including

A Review on Safety Management Strategies: Theory and

Jun 28, 2024 · To facilitate the understanding of lithium-ion power battery safety design methods, this includes battery selection, module assembly design, battery pack safety protection, and

A comprehensive review of battery modeling and state

Oct 1, 2020 · As one of the key components of electric vehicles, the lithium-ion battery management system (BMS) is crucial to the industrialization and marketization of electric

A Power Management IC Used for Protection System of Li-Ion Battery Packs

Dec 12, 2019 · Power management system is a critical component of the system which needs Li-Ion battery packs for power supply. This paper proposes a fully-integrated, high- p

Simulation and Application of Thermal Management

Feb 28, 2019 · In order to improve the utilization rate and safety of power battery, the thermal management system of pow-er battery pack is simulated and applied. In this paper, the

Modeling and Simulation of Lithium-ion Power Battery

and one important issue is the thermal management of lithium-ion power batteries. Research on thermal management of power batteries for electric vehicles mainly involves the following three

A comprehensive review on thermal management systems for power

Apr 1, 2021 · Electric vehicles must adapt to hot and cold environments, which requires the battery pack to keep good performance at both low and high temperatures. A lot of

Overview of batteries and battery management for electric

Nov 1, 2022 · Advances in EV batteries and battery management interrelate with government policies and user experiences closely. This article reviews the evolutions and challenges of (i)

Key features of a Battery Management System

Mar 6, 2025 · What is a Battery Management System (BMS)? A Battery Management System (BMS) is integral to the performance, safety, and

Battery Management Systems (BMS) and Pack Design

Learn how to effectively manage battery safety and lifecycle in battery pack design. Learn about applications of Battery Management Systems (BMS) in electric vehicles, energy storage and

Shaping the Future of Power Tool Battery Pack

Mar 20, 2025 · Owen McNally, Principal Design Engineer at Alexander Battery Technologies, explores the key factors shaping next-generation battery packs

Application of phase change material (PCM) in battery

Aug 31, 2023 · The battery thermal management system (BTMS)''s goals are to maintain the batteries'' ideal operating temperature range and to offer safety precautions. The need for more

Design and validation of a battery management system for

Nov 30, 2021 · Abstract Expanding the travel mileage of power batteries is of great significance for electric vehicles (EVs). The solar battery pack is considered as a promising supplement to the

Application of Power Electronics and Control for Dual

An overview of different applications of power electrons, voltage balance me- thods, SOC estimation in energy storage, and battery storage management has been presented as

6 FAQs about [Management and application of power battery pack]

What is a battery management system?

It regulates and tracks factors such as voltage, current, and temperature in each cell of a battery pack to guarantee safe operation within set limits while maximizing battery life and ensuring the highest level of performance. In numerous ways, power electronics play an important role in battery management systems:

What is a battery pack management system (BMS) course?

This course is designed for engineers, researchers, and technical professionals seeking in-depth knowledge of battery technology and pack management systems. Comprehensive coverage: Delve into the key functions of BMS for battery packs, including protection, optimization, and monitoring of the state of battery.

What role do power electronics play in battery management systems?

In numerous ways, power electronics play an important role in battery management systems: Energy Conversion And Conditioning: Power electronics interfaces are the foundation of the charging and discharging operations for batteries.

What is battery management systems (BMS)?

Explore the vital role of Battery Management Systems (BMS) in ensuring the performance, safety, and longevity of lithium-ion battery packs. This course is designed for engineers, researchers, and technical professionals seeking in-depth knowledge of battery technology and pack management systems.

What is battery safety management?

The management of battery safety primarily encompasses charge and discharge safety, high-voltage safety, and thermal safety. Among these, charge and discharge safety management aims to prevent battery damage or safety incidents caused by overcharge or over discharge.

Why are power electronics used in balancing a battery system?

Power electronics, which are frequently used in active balancing circuits using buck-boost converters, assist in redistributing charge among cells to sustain a balanced SoC. Protection: The battery system is also protected by power electronics devices.

Industry Information

- Where to put the inverter on the roof of photovoltaic BESS

- Hydraulic transmission system of wind turbine

- Communication base station solar power plant photothermal equipment information

- Energy storage power station electricity price settlement

- Is there any pollution around the photovoltaic glass factory

- Which is the best uninterruptible power supply in Marseille

- Wholesale 300wh power station in Honduras

- Main breaker switch in China in Bangladesh

- How many watts does solar energy have per square meter

- Wholesale gfci breaker wiring in Japan

- Chilean lithium energy storage power supply customization company

- West Africa Solar System Wholesale

- Wholesale 4000 amp switchgear in Azerbaijan

- Huawei Communication Base Station Supercapacitor Research Institute

- Stockholm large corrugated container wholesale

- Unit cost of photovoltaic glass production

- Valletta Home Yard Solar Lights

- Communication base station power supply configuration

- What is the size of the photovoltaic panels of 660

- Stockholm photovoltaic inverter installation company

- Are all 60V inverters universal

- Energy storage cabinet battery 9v photovoltaic

- Kuala Lumpur container villa wholesale

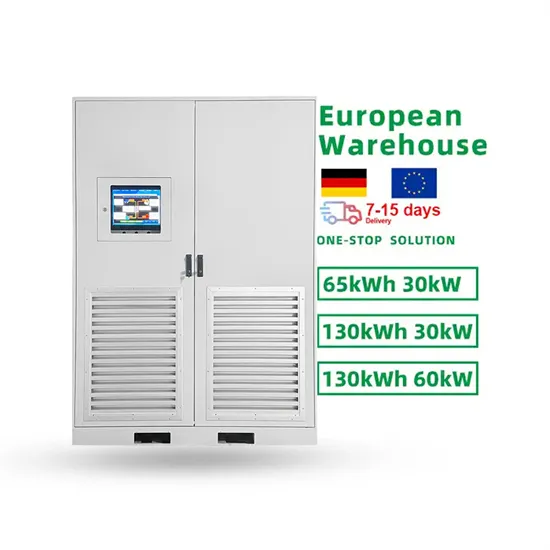

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.