BATTERY CABINETS VS. BATTERY RACKS

How to wire multiple batteries in parallel? To wire multiple batteries in parallel, connect the negative terminal (-) of one battery to the negative terminal (-) of another, and do the same to

Computer room design (revised) | PDF | IT and

This document provides guidance on planning and designing a data center computer room. It discusses key considerations such as room dimensions,

UPS5000-E

Jul 2, 2019 · Lower the four leveling feet at the bottom of the battery cabinet by using a wrench until all the four castors at the bottom hang in the air and the leveling feet bear all of the

4400 SERIES BATTERY CABINET

The battery cabinet is equipped with narrow pallet jack or forklift access openings in the front and rear of the cabinet. Move the equipment into the desired location and set in place.

How to install the 4-pole battery pack in the computer room

This document provides guidelines for how to check the external battery cabinet delivery and how to install and operate the cabinet. The reader is expected to know the fundamentals of

UPS Battery Cabinets | Information by Electrical Professionals

Feb 7, 2024 · The batteries are factory installed in the cabinets and connected by jumpers between the cabinets. Depending on the battery size the cabinets can weigh up to 5000

BATTERY CABINETS AND THEIR BENEFITS

How to connect parallel battery cabinets The basic concept is that when connecting in parallel, you add the amp hour ratings of the batteries together, but the voltage remains the same. For

Battery configurations in data centers

Nov 13, 2017 · Battery cabinets - Only VRLA can be installed in cabinets. Because cabinets can have locked doors, the cabinets do not have to be in

Connecting Batteries in Series and Parallel

Aug 22, 2022 · Doing so with batteries increments their total voltage, provided we connect negative and positive terminals. So, if for example we connect four

Stationary UPS Sizing Calculations – Part Six

2 days ago · in Article " Stationary UPS Sizing Calculations -Part Four ", we explained Selection and sizing of UPS protective devices (CBs or Fuses).

What are the factors that must be considered

Dec 16, 2020 · The computer room often uses a dedicated power distribution cabinet for the computer room to standardize the power supply and

Battery Room Safety Guide

Jan 3, 2025 · Battery room safety involves implementing strict protocols to prevent electrical hazards, chemical exposure, and fire risks. Behind the silent

Computer Room UPS FAQs | Server Room Evironments

Can a raised access floor support a large UPS system? Raised access floors are designed to support server racks whose weights can run up to 300Kg. In terms of a larger single or three

What Are the Critical Components of a Data Center Battery Room

Feb 17, 2025 · A data center battery room houses backup power systems, primarily uninterruptible power supply (UPS) batteries, to ensure continuous operations during grid

Powerware 9390 Integrated Battery Cabinet (Models IBC

May 2, 2022 · During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load. The

Battery Cabinet

Feb 28, 2025 · Use tools with insulated handles. Wear rubber gloves and boots. Do not lay tools or metal parts on top of batteries. Confirm that the charging source prior to connecting or

Complete Guide for Battery Enclosure

May 29, 2024 · Everyone wants a safe, durable, high quality and secure battery enclosure. However, finding the right information about these battery boxes or

Data center batteries

Oct 12, 2023 · Calculate the charging voltage based on the battery parameters, and measure the data center batteries output charging voltage, which meets

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the

Battery Room Design Requirements –

It does not cover maintenance free or computer room type batteries and battery cabinets. Main keywords for this article are Battery Room Design

Considerations For Battery Room Design, Battery Stands and

This article looks at the preferred designs for battery rooms and discusses how batteries should be laid out to give a safe environment. Alternative battery stand types are discussed to

RESIDENTIAL BATTERY CABINETS

How to connect parallel battery cabinets The basic concept is that when connecting in parallel, you add the amp hour ratings of the batteries together, but the voltage remains the same. For

Maintaining Compliance in the VRLA Battery Room

Dec 20, 2022 · Introduction Battery room compliance can be interpreted differently depending on your battery type, amount of cells or multi-cell units in a common area, volume of electrolyte

Computer Science Keypoints: Computer Room Management

In conclusion, effective computer room management involves a combination of ergonomic considerations, environmental controls, and adherence to established rules. By following these

Battery Room Ventilation and Safety

Mar 15, 2023 · BATTERY ROOM VENTILATION AND SAFETY It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms

Powerware 9395 Integrated Battery Cabinet (Model IBC

Jun 17, 2016 · 1 Introduction During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load.

How to Connect 4 Batteries in Series

Dec 13, 2023 · Learn how to connect 4 batteries in series for optimal power output and efficiency with our easy-to-follow step-by-step guide.

A Design Guide and Checklist For Server Room

Mar 19, 2019 · A design guide and checklist for server rooms including server racks, cooling, critical power, cabling and fire suppression systems.

General requirements for the installation of UPS

Oct 21, 2023 · Safety Measures: Use flame retardant doors for added safety. Limit electrical installations to lighting, ventilation, and safety equipment. Safety

Battery Cabinet technical specifications | 1 to 4 Story Cabinets

Jun 8, 2025 · Extremely strong battery cabinet is available to hold heavy batteries in various dimensions. The possibility of access to the cabinet inside from all four sides is a prominent

Eaton 93PM Integrated Battery Cabinet-Small Welded

Mar 29, 2025 · The battery detect signal wiring from the battery cabinet must be connected to a programmed UPS building alarm in the 93PM (480V) UPS and to CN8 in the 93PM-L (208V)

6 FAQs about [How to connect four battery cabinets in the computer room]

Do battery cabinets need to be in a battery room?

Because cabinets can have locked doors, the cabinets do not have to be in battery rooms; they can be installed directly adjacent to the UPS system and/or the information technology equipment. This eliminates the need for long dc cabling. Battery cabinets can be made to be indistinguishable from IT equipment cabinets.

How do I connect a ups to a battery cabinet?

Locate the UPS-to-battery cabinet breaker sensing cable inside the first battery cabinet. Mate the connector on this cable with the matching connector in the cabinet (see Drawing 164201536-8 on page A-17). Route the other end of this cable through conduit (top or bottom entry) to UPS cabinet and connect to terminal strip TB2.

How do you secure a battery cabinet?

Secure the battery cabinet position by lowering the leveling feet until cabinet is not resting on the casters. Ensure the cabinet is level and matches the height of the installed UPS cabinet. NOTE Two cabinet joining brackets are provided in the field kit for securing each cabinet at the top and bottom.

How do I connect a battery to a ups?

Connect and route cables from positive (+) and negative (–) terminals in the bottom of the first battery cabinet into the UPS cabinet. Connect the (+) lead to terminal E4 (+) and the (–) to terminal E5 (–) in the UPS cabinet.

How do I install a battery cabinet breaker?

Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the matching connector in that cabinet (see Drawing 164201536-8 on page A-17). If installing multiple battery cabinets, proceed to Step 3; otherwise, proceed to Step 5.

How do I install a battery cabinet?

Create an installation plan for the battery cabinet (Chapter 2). Prepare your site for the battery cabinet (Chapter 2). Inspect and unpack the battery cabinet (Chapter 2). Unload and install the battery cabinet, and wire the system (Chapter 3). Complete the Installation Checklist (Chapter 3).

Industry Information

- Inverter grid-connected box combiner box

- Circulation wind power generation system

- Hybrid power inverter factory in France

- Photovoltaic panel production and manufacturing companies

- St Johns 72v60a battery cabinet

- Prospects for home energy storage battery maintenance

- How much is the subsidy for energy storage batteries in Cordoba Argentina

- Zimbabwe Grid Energy Storage

- Container outdoor power supply light charging

- Hollow photovoltaic panel price

- Base station uses power chip or power supply

- Kyrgyzstan communication base station wind tower manufacturer customization

- 5g base station 1 electricity fee introduction

- Which battery plus inverter is better

- Are there any flywheel energy storage companies in Dhaka

- Shushi New Energy Battery Cabinet

- 220v circuit breaker for sale in Argentina

- Huawei liquid flow battery usage scenarios

- Communication base station solar energy price trend China

- Doesn t the Paris energy storage power station use lithium batteries

- Villa outdoor roof solar lights

- France Energy Storage Cabinet Container

- Energy storage power in solar-storage-charging projects

Commercial & Industrial Solar Storage Market Growth

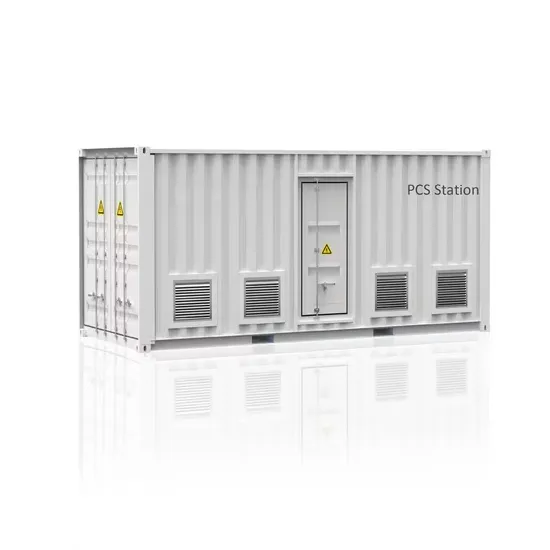

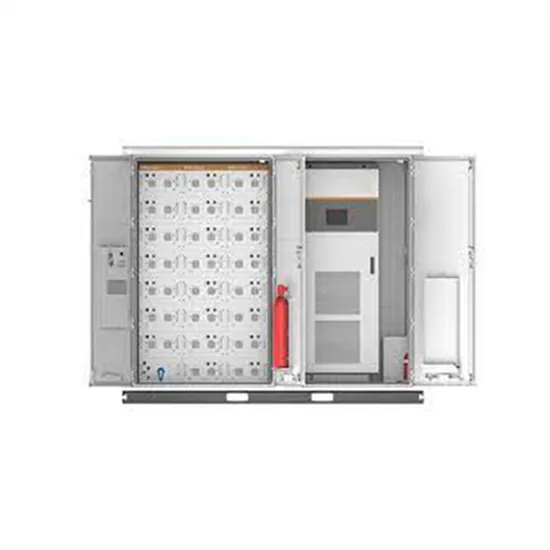

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

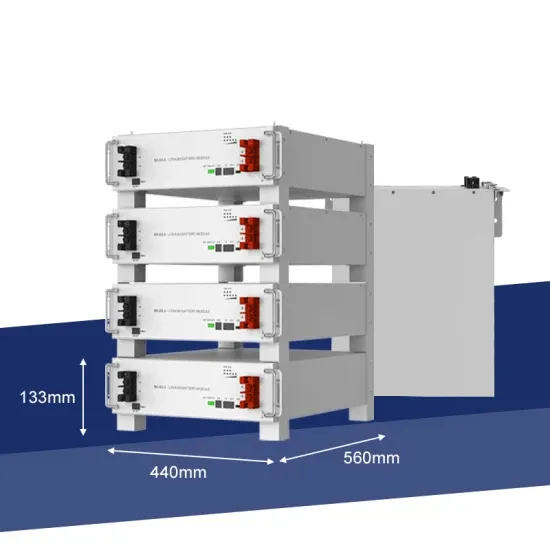

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.