Custom Lithium-Ion Battery Packs

Our team, headed by a dedicated project manager, develops your custom battery pack design from concept through to manufacturing. Working collaboratively

Wholesale Custom Lithium-Ion Battery Packs

Nov 14, 2024 · The advantages of custom lithium-ion battery packs are significant: Improved Device Performance: Custom packs are optimized for specific devices, ensuring better

Riga lithium battery equipment production

Lithium battery manufacturing equipment encompasses a wide range of specialized machinery designed to process and assemble various components, including electrode materials,

Custom Lithium Battery Packs in Latvia Tailored Solutions for

Why Latvian Lithium Battery Customization Matters Latvia''s growing focus on sustainable energy and technological innovation has positioned lithium battery pack customization as a critical

Battery Giant Online Store

Custom Battery Pack Builder Welcome to Battery Giant''s Custom Battery Pack Builder. Although we carry an incredible inventory of battery packs for nearly every application, we know that

Custom Battery Pack Manufacturer: Tailored

The process encompasses basic and advanced lithium battery pack design features, each tailored to meet specific requirements. This includes

Custom Lithium Battery Pack Manufacturer

Gushine is a custom lithium-ion battery manufacturer based in China. We integrate high-precision fuel gauges from trusted brands such as TI, MAXIM,

Custom Lithium-Ion Battery Packs

Your specialist custom lithium-ion battery pack manufacturer. We design and manufacture custom lithium battery packs for diverse industries.

Anodox Energy Systems to build EV batteries in

Anodox Energy Systems to build EV batteries in Latvia, create 300+ jobs. Riga is a great destination for everyone. Business opportunities, art galleries,

Custom Battery Packs | Batteries INC

Understanding Custom Battery Packs At Batteries Inc., we''ve been in the business of powering up your devices with our custom battery packs for over

Riga lithium battery box manufacturer

The LithiumSafe(TM) Battery Box is designed for safely storing, charging and transporting lithium ion batteries. The most intensively tested battery fire containment solution on the market,

Custom Battery Solutions & Custom Lithium

With 14 years of experience and over 3,500 successful custom battery deliveries, we design and manufacture lithium battery packs to meet diverse industry

How to Build a Custom Lithium Battery Pack:

Mar 20, 2025 · 🔋 Why Build a Custom Lithium Battery? Custom lithium batteries power everything from EV conversions to solar storage systems and DIY

The repair of a lithium battery pack is an important task that requires technical knowledge and skill, but luckily, with some basic knowledge and tools, you can learn how to revive your dead

Custom Lithium Battery Pack Manufacturing: A

Mar 1, 2025 · Our methodology ensures every custom lithium-ion battery pack – from ultra-low-temperature 18650 configurations to high-voltage LiFePO4

CellPac PLUS

5 days ago · With CellPac PLUS, VARTA supports and accompanies the development process of your project from the initial consultation, through planning and production to the end-of-life of

Custom Lithium-ion battery | With 10 Years

Saphiion specialize in design 18650 21700 custom lithium-ion battery pack with smart UART, SMBus BMS. From design to manufacturing, expert guidance

Custom Battery Packs

With a team of over 300 professionals across our production and development facilities in Europe and Asia, we deliver safe and reliable battery packs,

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · In this article, we will explore the world of battery packs, including how engineers evaluate and design custom solutions, the step-by-step manufacturing process, critical quality

Custom Lithium Battery

Lithium Battery Customized & Charged by MEAN WELL MEAN WELL now delivers high-performance custom lithium battery packs for industries like

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering

Custom Lithium Battery Pack

Jul 19, 2025 · If you are looking for a custom lithium battery pack tailored to your specific needs, RahaBattery, as a company specializing in custom battery manufacturing, offers design and

Riga energy storage lithium battery manufacturer

Long-cycle energy storage battery, which reduces the system OPEX. High Safety From materials, cells, components to systems, focus on the safety during the whole design process, and the

Battery logistics: Shipping batteries

Team of battery logistics and DG experts ready to design a solution that meets the complex transport and handling requirements for lithium batteries. Compliant with local, state, federal

Custom Lithium Battery Pack Manufacturing

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves

Saphiion

Saphiion specializes in custom lithium-ion battery packs (18650, 21700, LiFePO4) for e-bikes, robotics, golf carts, energy storage, trolling motors, and more.

Riga lithium battery polymer processing plant

Anodox Energy to build two battery plants in Latvia The Swedish company Anodox Energy Systems wants to build two factories in Latvia to produce batteries for electric vehicles.

Argentina lithium battery custom processing factory

Your Custom Lithium-Ion Battery Pack Manufacturer. Designing, developing and manufacturing customised lithium-ion battery packs using a full range of battery chemistries, Alexander

EV Lithium Battery PACK Design Process from

Mar 18, 2025 · EV Lithium Battery PACK Design Process: A Comprehensive Guide The design of Electric Vehicle (EV) lithium battery packs ⇱ is a complex

Custom Lithium Battery Pack Solutions for Your

Aug 4, 2025 · Experience precision-engineered custom lithium battery pack solutions designed to meet your unique power requirements. Discover solution

Riga New Energy Lithium Battery Assembly Plant

LATVIA: Latvenergo launches tender for battery energy storage at Riga Latvenergo, Latvia''''s state-controlled electricity provider, has initiated a procurement process for constructing a

Riga lithium battery equipment production

The first rechargeable lithium battery was designed by Whittingham (Exxon) and consisted of a lithium-metal anode, a titanium disulphide (TiS 2) cathode (used to store Li-ions), and an

6 FAQs about [Riga lithium battery pack custom processing]

How do you make custom lithium-ion battery packs?

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support.

How can lithium-ion cell technology improve a custom pack design?

Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities. Concurrent electrical and mechanical engineering is needed to optimize the custom pack design within constraints.

How are prismatic or pouch lithium-ion cells manufactured?

Producing prismatic or pouch lithium-ion cells with the consistency required for pack assembly mandates tightly controlled environments and processes. Cell fabrication steps include: Maintaining process capability delivers the cell consistency vital for pack assembly. Small cell variations compound when multiplied by thousands in a pack.

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

What makes a custom lithium-ion battery pack unique?

The foundation of any custom lithium-ion battery pack lies in the selection of the integrated cells. Our cell selection for custom packs involves: Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities.

Industry Information

- Khartoum Grid Energy Storage Power Station

- Heavy Industrial Energy Storage Vehicle Classification

- Application of energy storage projects in chemical enterprises

- Supplier of photovoltaic energy storage system in Sao Paulo Brazil

- Thailand power inverter price

- Kinshasa Outdoor Power

- Does Brazil have outdoor power supply BESS

- Bucharest New Energy Storage Industry

- Cambodia new energy storage price

- Riyadh Communication Base Station Lithium Battery Pack

- Brasilia energy storage photovoltaic enterprise latest

- Can a 60v inverter use a 12v power supply

- Amman 5g base station manufacturer

- Energy storage battery 4MW price

- Djibouti Enterprise Energy Storage Project

- Battery pack in low temperature environment

- Vienna large UPS uninterruptible power supply price

- Venezuela monitors solar power supply systems

- Monaco Energy Storage Battery Assembly

- Solar power with grid backup in Chile

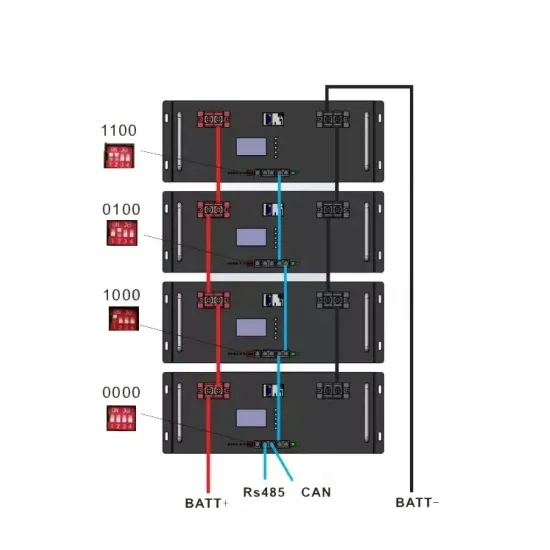

- How to match the battery cabinet

- What are the containerized energy storage power stations in Pristina

- Huawei Slovenia photovoltaic panels

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.