ESS (ENERGY STORAGE SYSTEM) BATTERY

Aug 20, 2025 · Comprehensive analysis of ESS (Energy Storage System) battery enclosures: design, materials, thermal management, safety features, and

PCM-Based Passive Cooling Development for EV Batteries

Jul 30, 2025 · Protecting batteries in electric vehicles (EVs) and other applications to enhance safety and reliability using multifunctional battery modules with tubular energy absorbers filled

Phase Change Material (PCM) as the Smart Heat-Storing

Jan 9, 2023 · The attractive identities of PCM materials are high capacity of thermal energy storage, great heat conductivity, little dilatation, shrinkage amid phase change, and minimum

Investigation on Cooling Performance of

Sep 5, 2024 · ABSTRACT Modern electric vehicle (EV) batteries need phase change materials (PCM) that are capable of efficient battery cooling. In this

PCM配置及PCM比例优化对PCM与风冷组合结构方形电池热

Jan 11, 2024 · 相变材料(PCM)的不同配置和比例对电池热管理系统(BTMS)的热性能具有至关重要的影响。在这项工作中,通过相结合的 PCM 和空气冷却技术研究电池组的热性能。首

A review of battery thermal management systems using liquid cooling and PCM

Jan 15, 2024 · Moreover, the research status and advantages of the combination of PCM and liquid cooling BTMS are introduced. In addition to PCM and liquid cooling, the BTMS operation

THERMAL ENERGY STORAGE

Sep 9, 2021 · Thermal Energy Storage TES is the temporary storage of high or low temperature energy for later use, bridging the gap between requirement and energy use. The storage cycle

Phase change materials for thermal energy

Aug 19, 2025 · Advantages and disadvantages of PCM use compared to stratified water storage The two main advantages of employing phase change materials

Influence of PCM configuration and optimization of PCM

Mar 1, 2024 · The influences of filling amount of PCM on the temperature difference, the maximum temperature and energy consumption were discussed in a BTMS combining closed air-cooling

PCM products and their fields of application

Jul 1, 2022 · Phase Change Materials, or briefly PCM, are a promising option for thermal energy storage, depending on the application also called heat and cold stor

CNT@MXene porous composite PCM based thermal

Mar 1, 2025 · Phase change materials (PCM) battery thermal management system has been studied widely because of its higher heat storage capacity, low cost, and perfect chemical

BYD Battery-Box – BYD Battery-Box

Easy Installation Flexible Configuration Awards The Battery-Box meets the highest safety standards like VDE 2510-50 (HVS/HVM/LVS) and receives

Performance improvement of phase change material (PCM)

Nov 7, 2024 · This work aims to improve the efficacy of phase change material (PCM)-based shell-and-tube-type latent heat thermal energy storage (LHTES) systems utilizing differently

Phase Change Materials in Battery Systems

Nov 11, 2024 · Overheating can cause lithium-ion battery cells to degrade faster and in some cases lead to catastrophic failure through thermal runaway. This

Pcm energy storage battery box

PCM in thermal energy storage. Solid-liquid phase change materials (PCMs) have been studied for decades,with application to thermal management and energy storage due to the large

PCM Energy storage design-Shanghai Cloud chemical

Our PCM energy storage solutions have a wide range of applications, including solar energy, greenhouses, cold chain transportation, and building energy efficiency. According to the

Enhanced thermal performance of a hybrid battery thermal

Jun 1, 2025 · To ensure the working temperature environment of batteries at an ultra-high discharge rate of 5 C, this work proposes a hybrid battery thermal managem

Thermal Management in Battery Systems

Learn how thermal management systems improve battery safety, extend lifespan, and boost performance in energy storage applications like rack-mounted BESS.

Influence of PCM configuration and optimization of PCM

Jan 11, 2024 · In this work, the thermal performance of the battery pack is investigated by a combined PCM and air cooling technique. Firstly, four cases of PCM configuration are

BYD Energy

Aug 6, 2025 · As a global pathfinder, leader and expert in battery energy storage system, BYD Energy Storage specializes in the R&D, manufacturing, marketing, service and recycling of the

Experimental investigation of pressure effect on the PCM

Feb 15, 2024 · The purpose of this study is to experimentally investigate the effectiveness of using pressure as a tool to increase the energy storage capability in Polyethylene-glycol-1000

4 Things You Should Know Before Buying

Apr 25, 2024 · A protection circuit module(PCM) is an electronic circuit that protects and extends the battery''s life by safeguarding potential threats.

Phase change materials for battery thermal management of

Sep 1, 2022 · Higher enthalpy of phase change is desirable for PCM to enable storage of a bundle of energy into a small volume for achieving greater energy density storage. It is better that the

Battery Thermal Management System Using

Abstract This research paper explores the integration of Phase Change Materials (PCMs) into Electric Vehicle (EV) battery packs for enhanced thermal

BMS vs. PCM: What''s the Difference in Battery

Jan 16, 2025 · Table of Contents Introduction When it comes to managing the safety and efficiency of batteries, especially in devices like electric vehicles or

PCM Constemp logistic box | New Material Technology

Based on PCM energy storage technology with world-class composite insulation materials. THERO developed a long-lasting, constant-temperature cold-chaincase with customizable

PCM Microencapsulation: An Engineering

Aug 3, 2024 · Thermal energy storage technologies capture heat in a medium and release it later, like how batteries store and dispense electrical power.

Energy storage system

Aug 6, 2025 · As a global pathfinder, leader and expert in battery energy storage system, BYD Energy Storage specializes in the R&D, manufacturing, marketing, service and recycling of the

Revolutionizing battery thermal management: hybrid nanofluids and PCM

Jul 7, 2025 · Hybrid nanofluids, offering enhanced heat transfer properties, and PCMs, capable of storing and dissipating latent heat, represent a promising synergy for improving thermal

Application of phase change material (PCM) in battery

Aug 31, 2023 · The PCM material is a substance that releases a sufficient amount of heating or cooling while transitioning in phase. There are different types of phase-changing materials that

Experimental investigation to enhancing the energy

May 26, 2025 · The experimental findings demonstrate that incorporating PCM significantly enhances energy efficiency by reducing average power consumption from 48 to 40 W.

Research on the optimization control strategy of a battery

Feb 28, 2025 · The widespread use of lithium-ion batteries in electric vehicles and energy storage systems necessitates effective Battery Thermal Management Systems (BTMS) to mitigate

Facile Ester-based Phase Change Materials

Jan 13, 2025 · And, it introduces an innovative battery thermal management method using PCM immersion. This approach greatly improves temperature

Phase Change Materials for Thermal Energy

Phase Change Materials (PCM) by PLUSS offers innovative solutions for sustainable thermal energy storage, enabling efficient heating, cooling, and

High-Temperature Phase Change Materials (PCM)

Oct 1, 2013 · To store thermal energy, sensible and latent heat storage materials are widely used. Latent heat TES systems using phase change material (PCM) are useful because of their

Thermal management of Li-ion batteries with passive

Jun 1, 2024 · In this paper, we proposed a novel thermal regulator that intelligently utilizes the volume changes to modulate heat transfer. The thermal regulator establishes a passive and

6 FAQs about [Pcm energy storage battery box]

Why should a battery pack have a PCM?

In industries that consume large amounts of energy, the combination of cost reductions and lessened environmental impact is a key motivator for adopting hybrid cooling systems. Incorporating PCMs into battery packs enables the removal of extensive cooling channels, simplifying the overall design.

Does PCM affect the thermal performance of battery thermal management system (BTMS)?

Different configurations and proportion of phase change material (PCM) have a vital impact on the thermal performance of the battery thermal management system (BTMS). In this work, the thermal performance of the battery pack is investigated by a combined PCM and air cooling technique.

How can a PCM module improve the performance of solar energy systems?

For instance, in electric vehicle (EV) batteries, PCM modules reduce thermal gradients by 15–20%, enhancing cell performance and safety. Solar Energy Storage Systems: The integration of phase change materials (PCMs) and nanofluids significantly enhances the performance of solar thermal energy systems.

What is the thermal performance of a battery pack with PCM?

Governing equations To comprehensively explore the thermal performance of the battery pack with a combined PCM and air-cooling structure, the air is supposed to be incompressible owing to smaller velocity in the coolant passage and the airflow is deemed as turbulent owing to Re = 6366.58.

How does CPCM improve battery thermal management?

At 45 °C, the thermal regulator with cPCM successfully reduces the battery temperature to 35.02 °C. Integrating AlN in pure PCM lowers the battery module's peak temperature by 7.94 %. The thermal regulator also diminishes cyclic temperature variances, underlining its potential for enhancing battery thermal management. 1. Introduction

How do multifunctional battery modules protect EV batteries?

Protecting batteries in electric vehicles (EVs) and other applications to enhance safety and reliability using multifunctional battery modules with tubular energy absorbers filled with phase change materials (PCMs). The tubes surround the batteries and absorb impact forces during crashes.

Industry Information

- Serbia Communication Base Station Lithium Ion Battery Equipment Company

- Industrial Park Energy Storage Planning

- Kampala Micro UPS Uninterruptible Power Supply Manufacturer

- High quality circuit breaker fuse in China Factory

- Telecom Italia site installs battery cabinets

- Liquid flow energy storage battery effect

- Price of lightweight crystalline silicon photovoltaic modules

- Mainland solar photovoltaic panel installation

- Total capacity of lithium battery pack

- Uninterruptible Power Supply Franchise

- Huawei Freetown Photovoltaic Panels

- Asia 5g base station outdoor photovoltaic integrated system cabinet

- Battery cabinet repair price

- Operation model of energy storage wind power company

- Single crystal 390perc module

- Fast charging inverter 12v to 220v

- Outdoor energy storage power rendering

- Is the solar booster pump reliable

- Lithium battery 36v battery pack

- Tl494c inverter undervoltage protection

- How many watts is a 300w solar street light equivalent to an ordinary lamp

- Portable power supply DC adjustable

- High quality factory price 1000kw inverter producer

Commercial & Industrial Solar Storage Market Growth

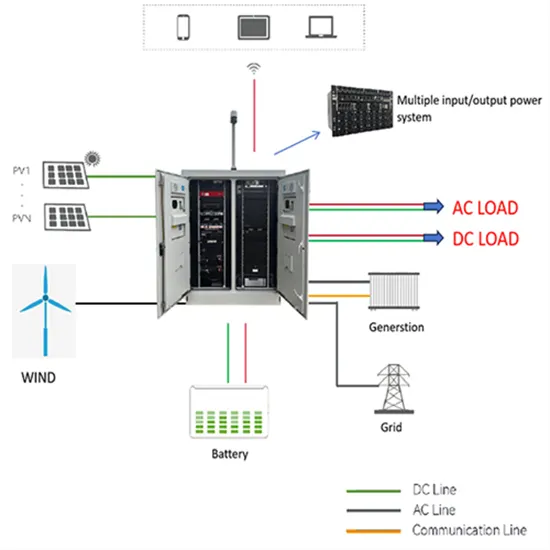

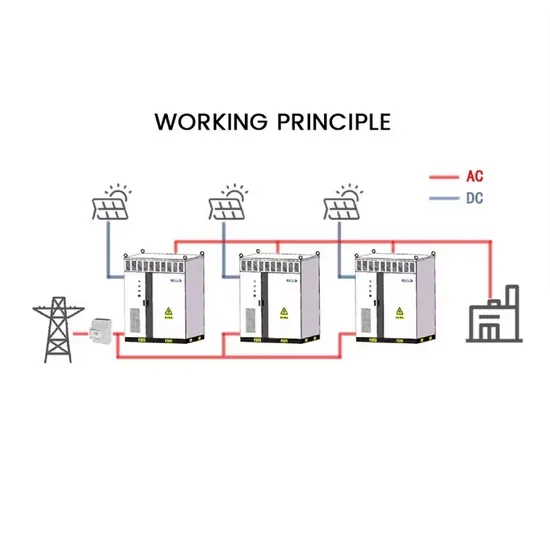

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.