EU Launches Anti-Dumping Investigation into Solar Panel

Sep 5, 2012 · The European Commission launched an investigation on Thursday into suspected dumping of solar panels concerning imports into the European Union (EU) of crystalline silicon

SolarPower Europe: High potential of European

May 23, 2025 · SolarPower Europe has published a new report mapping Europe''s solar PV module production equipment capacity. The new report „Solar

11 Best Solar Panel Manufacturers

Aug 25, 2024 · While less efficient than crystalline silicon panels, thin-film panels are lightweight, flexible, and can be integrated into building materials (Source).

Analogical environmental cost assessment of silicon flows

Apr 25, 2024 · In an effort to provide more understanding of this crucial topic, this research focuses on silicon flows—a key element for manufacturing crystalline silicon PVs.

Overview of life cycle assessment of recycling end-of-life photovoltaic

Jan 1, 2024 · Crystalline silicon (C–Si) photovoltaic (PV) modules are currently reaching the End-of-life (EOL) stage, and the environmental impact of recycling PV is of great concern. The life

What Is a Silicon Wafer for Solar Cells? | EcoFlow

Solar cells are an essential part of systems that convert sunlight into electricity using the photovoltaic effect. Wafer-based solar cells are the most commonly

DIGITAL DETRITUS

Overview of global status and challenges for end-of-life crystalline silicon photovoltaic panels: A focus on environmental impacts. Waste Management, 128, 45–54.

Solar Energy Suppliers In Europe

Viridian Solar is a UK-based manufacturer of roof integrated solar panels. Our Clearline Fusion range of photovoltaic (electric) solar panels fit in the roof and take building integration of solar

Solar Production Equipment

Mar 5, 2025 · Manufacturers of solar module production equipment are an enduring link in the European solar PV industrial ecosystem. This report shines a light on these key actors of the

Embodied energy and carbon from the manufacture of

Jul 20, 2022 · Looking beyond the traditional cost and efficiency metrics of photovoltaics (PV), this work evaluates the impact of embodied energy, embodied carbon,

Analysis of Material Recovery from Silicon Photovoltaic

Sep 15, 2023 · An Italian company is currently developing the project FRELP (Full Recovery End-of-Life Photovoltaic) as part of the European ''LIFE'' programme. The FRELP project focuses

Mass-produced European solar panels on the

5 days ago · The most efficient crystalline silicon solar-cell technology concepts on the market – interdigitated back-contacted (IBC) type solar cells – are

An overview of solar photovoltaic panels'' end-of-life material

Jan 1, 2020 · The EU has pioneered PV electronic waste regulations including PV-specific collection, recovery and recycling targets. The EU Waste of Electrical and Electronic

Top 10 solar panel Manufacturers in Europe

Jun 7, 2024 · Here in Lovsun, we will look at the top 10 solar panel manufacturers in Europe, their strengths, new technologies, safety considerations, uses and

Technoeconomic analysis of high-value, crystalline silicon photovoltaic

May 1, 2022 · The vast majority of PV modules sold globally are crystalline-silicon (c-Si); most of the rest of the market are cadmium telluride thin film modules whose primary manufacturer

Global status of recycling waste solar panels: A review

May 1, 2018 · The crystalline silicon in crystalline silicon PV panels, and the rare metals such as indium, gallium, germanium, tellurium, in thin film PV panels, concentrator PV panels, and

A Review of End‐of‐Life Silicon Solar Photovoltaic

Feb 6, 2025 · The mass deployment of solar energy technology has been inspired by sustainable energy objectives. However, end-of-life solar photovoltaic modules present the growing

Sinovoltaics Updates Map of Solar Module

Aug 19, 2024 · The report highlights that Croatia-based Vallis Solaris, Spain''s Silicon Valen, and Turkey-based Kalyon PV are planning to establish 20 GW

The 9 largest solar panel manufacturers in the

Jun 6, 2025 · Discover which companies are producing the highest number of solar panels around the world, ranked from ninth to first.

Crystalline silicon photovoltaic panel component

What are the efficiencies of crystalline silicon solar cells? The efficiencies of typical commercial crystalline silicon solar cells with standard cell structures are in the range of 16-18%for

Monocrystalline -

List of Monocrystalline solar panel manufacturers. Directory of companies that make Monocrystalline solar panels, including factory production and power ranges produced.

Microsoft Word

Apr 15, 2020 · To maintain compliance with the prevailing laws in Europe (e.g., European WEEE directive 2012/19/EU; Directive 2008/98/EC on waste), current commercial-scale crystalline

The research progress on recycling and resource utilization

Jun 15, 2024 · Proposes PV subsidy policies and dynamic standard adjustments. The exponential growth in global photovoltaic installations has led to a continuous increase in photovoltaic (PV)

A review of crystalline silicon bifacial

The International Technology Roadmap for Photovoltaic (ITRPV) predicts an upward trend for the shares of crystalline silicon (c-Si) bifacial PV cells and

Making solar a source of EU energy security

Aug 29, 2022 · Europe''s solar dependency on China By 2008, China emerged as the dominant producer of solar PV panels. By 2012, it accounted for 64 % of worldwide production and, as of

Reshoring silicon photovoltaics manufacturing contributes to

Mar 8, 2023 · The globalized supply chain for crystalline silicon (c-Si) photovoltaic (PV) panels is increasingly fragile, as the now-mundane freight crisis and other geopolitical risks threaten to

Sinovoltaics updates map of European solar

Aug 9, 2024 · It maps plants that produce PV modules, cells, wafers, ingots, polysilicon, and metallurgical-grade silicon. European manufacturing is the

Photovoltaic silicon panel manufacturing process

The creation of photovoltaic panels centers around turning crystalline silicon into solar cells. These cells are part of large solar projects worldwide. Learning about the solar cell

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · Life Cycle Assessments (LCA) of single-crystalline silicon (sc-Si) photovoltaic (PV) systems often disregard novel module designs (e.g. glass-glass modules) and the fast pace of

Sustainable Strategies for Crystalline Solar Cell

Jul 7, 2024 · The classification of PV recycling companies based on various components, including solar panels, PV glass, aluminum frames, silicon solar

Comprehensive Review of Crystalline Silicon

Dec 20, 2023 · This review addresses the growing need for the efficient recycling of crystalline silicon photovoltaic modules (PVMs), in the context of global

Solar photovoltaic recycling strategies

Mar 1, 2024 · This paper overviews the commitment level of different countries to solar PV recycling. It summarizes the various solar PV recycling strategies for different types of solar

Latest Solar Supply Chain Map Europe PV

Sinovoltaics Europe Solar Energy Supply Chain Map. Latest PV solar panel manufacturers & BESS supply chain traceability and manufacturing insights.

6 FAQs about [European crystalline silicon photovoltaic panel manufacturers]

How many companies in Europe manufacture solar PV modules?

Today, at least 38 companies are active in Europe manufacturing the equipment and machinery that produces vital steps of the solar PV module supply chain, including cells, ingots, wafers, and polysilicon. EU Clean Industrial Deal: Opportunity for renewables and European manufacturing

What does the new EU report 'solar production equipment' mean for solar PV?

The new report „Solar Production Equipment – Key players in the EU’s industrial ecosystem for solar PV’“ explores the European capacity to manufacture the equipment and machinery that produces at each stage of the solar module manufacturing process.

Can European solar production underpin resilience?

A new market analysis from SolarPower Europe highlights the potential of European solar production to underpin the resilience of the European sector. SolarPower Europe has published a new report mapping Europe’s solar PV module production equipment capacity.

Are European solar panels a good alternative?

In fact, Europe for some years now has been a front-runner in solar power as an alternative form of energy. With the world growing more aggressive of climate change, and we needing to reduce carbon emissions. EU-based solar panel manufacturers have reacted at the challenge

How many solar plants are there in Europe?

The latest report on the supply chain for European PV module production provides the status of 121 solar manufacturing sites, including closures and capacity on hold. It maps plants that produce PV modules, cells, wafers, ingots, polysilicon, and metallurgical-grade silicon.

What is the role of European companies in the solar industry?

In the solar sector, European companies originally played a key role in developing the production equipment needed for the mass production of solar wafers, cells, and modules. While the rise of China’s solar manufacturing sector initially provided a significant export market, a highly competitive local industry has since emerged.

Industry Information

- Off-grid inverter and electrical connection

- Iceland EK supercapacitor price

- Moscow promotes energy storage products outside eBay

- Vilnius 48v lithium battery pack

- China molded circuit breaker in Croatia

- How far is the mobile base station from the outdoors

- 100W DC water pump for solar panel

- Photovoltaic energy storage forms

- Bamako Advantage Battery Cabinet Price

- Grenada energy storage battery customization company

- Monocrystalline silicon double-glass cell components

- How many milliamps does the outdoor power supply have

- Photovoltaic energy storage system for communication

- Inverter 220v manufacturers

- 36V300W solar photovoltaic panel power generation

- Moroni photovoltaic energy storage power supply price

- Czech EK Industrial and Commercial Energy Storage Cabinet

- How many watts can a 12v inverter convert at most

- Portable energy storage inventory tail goods

- Türkiye Communication BESS Power Station Manufacturer

- What is a double-glass module

- Will photovoltaic panels on the roof provide enough electricity

- Dodoma photovoltaic panel greenhouse manufacturer

Commercial & Industrial Solar Storage Market Growth

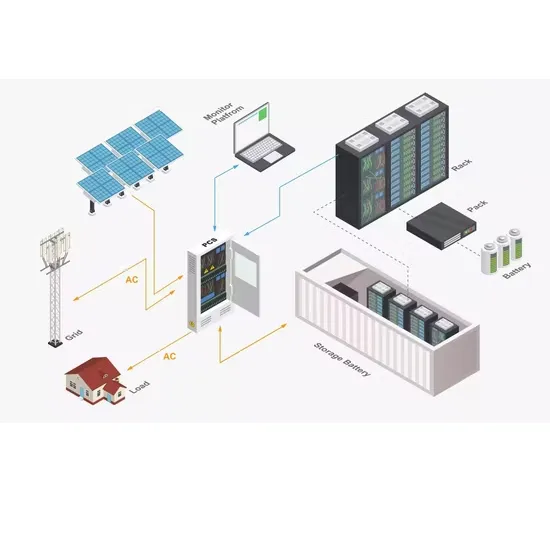

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.