A critical review of battery cell balancing techniques, optimal

Jun 1, 2024 · A BMS (act as the interface between the battery and EV) plays an important role in improving battery performance and ensuring safe and reliable vehicle operation by adding an

What is cell balancing in a BMS and why is it

May 20, 2025 · Cell balancing refers to the process of equalizing the charge across all cells in an electric vehicle (EV) battery pack, ensuring each cell

Novel active and passive balancing method-based battery management

Oct 20, 2021 · In the present study, a novel BMS circuit topology that is able to charge four battery cells with active and passive balancing methods was designed and implemented. The most

Battery Balancing Techniques

By enabling the battery pack to work within safe and efficient factors, battery balancing strategies are used to equalize the voltages and the SOC among the cells. Numerous parameters such

What is cell balancing in a BMS and why is it

May 20, 2025 · Cell balancing is not limited to EV battery packs; it applies to any electrical system, such as renewable energy, where a battery pack with

Battery Balancing Techniques

A deep knowledge of both the chosen balancing approach and the overall system structure of the BMS is needed for combining battery balancing techniques into a BMS. It consists of accurate

Battery Balancing Techniques

A deep knowledge of both the chosen balancing approach and the overall system structure of the BMS is needed for combining battery balancing techniques into a BMS. It consists of accurate

Battery Management System, Li Ion Bms, Bms

Aug 5, 2021 · To become a leading global provider of new energy solutions, DALY BMS specializes in the manufacturing, distribution, design, research,

How Much Cell Balancing Current Do You Need

Sep 5, 2023 · By continuously balancing whenever the pack is plugged in, BMS systems increase the available balancing time, enhancing their balancing

How Cell Balancing Works

Apr 24, 2015 · How Cell Balancing Works Balancing on the Orion BMS only occurs when the BMS is powered in CHARGE mode (powered by pin 3 on the Main I/O connector). When any one

Applications of artificial intelligence and cell balancing

Nov 1, 2024 · BMS optimizes battery via SOC monitoring, cell balancing, and safety control. FLC, SVM, PSO, ANN, and GA algorithms improve SOC estimation accuracy. Cell balancing

Design and Performance Analysis of Active and Passive

Nov 5, 2023 · ce. These balancing circuits are integrated with non-ideal RC models of a lithium-ion battery. The bleed resistor based passive cell balancing took more than 16000 seconds to

BMS Board Balance Management: How to

Mar 26, 2025 · Battery Balancing, Why Is It Important? In various electronic devices and new energy applications, batteries are indispensable energy

Battery Balancing: A Crucial Function of Battery

Mar 14, 2025 · Passive balancing and active balancing are the two basic approaches to battery balancing. Burning off the extra energy in the higher charged cells as heat is the process of

Best Battery Bms [Updated On: August 2025]

4 days ago · When consulting with DIY enthusiasts and engineers about their battery management needs, one requirement consistently topped their list: reliable, precise protection

Analysis Of Cell Balancing Techniques In BMS For Electric

Jul 23, 2022 · This paper explains how the Battery Management System (BMS) in an Electric Vehicle uses cell balancing techniques to balance the li-ion cells in lithium-ion bat

Active Cell Balancing in Battery Packs

Nov 23, 2016 · 2 Balancing methods There are two main methods for battery cell charge balancing: passive and active balancing. The natural method of passive balancing a string of

TOP 10 Battery Management System Suppliers

Jan 11, 2022 · About the battery management system Battery management system (BMS) is commonly known as battery nanny or battery steward. The

Understanding Battery Management Systems (BMS):

Jan 18, 2025 · A Battery Management System (BMS) plays a crucial role in modern energy storage and electrification applications. It oversees a battery pack''s operational health,

How Does A BMS Balance A Lithium Battery?

May 10, 2023 · BMSs balance lithium batteries by two main process which vary from bms to bms, read more on this here!

Industrial Battery Management System (BMS) devices

Oct 13, 2023 · L9963E 14-channel battery monitoring/balancing IC Accurate, real-time measurement of battery cell voltage, current, and temperature balancing, and protection

Active balancing vs. Passive balancing in Battery

Nov 18, 2024 · Active balancing and passive balancing are two methods used in battery management systems (BMS) to ensure that all cells within a battery

汽车电池监控和平衡 | Infineon英飞凌官网

通过电池平衡来优化电池系统性能,并使用高精度ADC监控电压和温度等关键参数。TLE9012DQU 是一款多功能电池监控和平衡 IC,适用于汽车、工业和消费应用。它支持电动汽车(MHEV

A complete analysis of lithium battery balancing

May 25, 2025 · The balancing technology of battery management system (BMS) has evolved from simple passive balancing to intelligent adaptive balancing

Global and China Power Battery

Aug 18, 2016 · Three core functions of BMS are cell monitoring, state of charge (SOC) estimation, and single-cell battery balancing. BMS monitors the operating temperature and electric

Battery Balancing: Techniques, Benefits, and How It Works

Learn how battery balancing improves performance, safety, and lifespan. Explore key techniques, benefits, and the science behind balancing battery cells effectively.

Why battery cell balancing is important for BMS?

Mar 19, 2025 · Discover why battery cell balancing is crucial for BMS. Learn how it optimizes performance, extends battery lifespan, and ensures safety in

Battery Cell Balancing: What to Balance and How

Jun 26, 2007 · Different algorithms of cell balancing are often discussed when multiple serial cells are used in a battery pack for particular device. The means used to perform cell balancing

Recent Advancements in Cell Balancing Techniques of BMS

Jan 20, 2025 · Recently, a severe danger has evolved regarding the explosion of Electric Vehicle (EV) batteries due to their thermal issues. A proficient system is employed for managing the

浅谈电动汽车BMS的电池均衡 (Cell Balance)

Mar 24, 2024 · Kris Xie 读完需要 3 分钟 速读仅需 1 分钟 通过被动和主动电池均衡,以使电池单元保持健康的电池荷电状态 (SOC)。这不仅延长了电池的循环

What is a Battery Management System? Complete Guide to BMS

Aug 3, 2025 · A Battery Management System (BMS) is an electronic control unit that monitors and manages rechargeable battery packs to ensure safe operation, optimal performance, and

Active Balancing vs Passive Balancing

Jan 24, 2023 · Learn the differences between active and passive battery balancing so you can make an informed decision on which is best for your build.

Optimal Cell Balancing in BMS: Reviewing Key Techniques for Battery

Mar 30, 2024 · Examine the best strategies for cell balancing in BMS using redox shuttle, lossless, active, and passive methodologies.

Effective Cell Balancing in BMS: Maximizing

Feb 20, 2024 · Explore the importance of cell balancing in BMS for lithium batteries, covering active and passive methods to enhance battery efficiency

What Is a BMS Battery? A Complete Guide for Beginners and

Apr 23, 2025 · In the world of lithium-ion batteries, the term "BMS battery" has become increasingly common — especially among manufacturers, engineers, and consumers of

6 FAQs about [BAIC BMS battery balancing]

How battery management system (BMS) in an electric vehicle uses cell balancing?

Conferences > 2022 International Conference... This paper explains how the Battery Management System (BMS) in an Electric Vehicle uses cell balancing techniques to balance the li-ion cells in lithium-ion battery pack. Cell balancing is done to ensure that all li-ion cells in a battery pack are charged and drained together.

What is a battery balancing system (BMS)?

A BMS (act as the interface between the battery and EV) plays an important role in improving battery performance and ensuring safe and reliable vehicle operation by adding an external balancing circuit to fully utilize the capacity of each cell in the battery pack. The overview of BMS is shown in Fig. 2. Fig. 2. Overview of BMS.

What is cell balancing in a BMS?

What is cell balancing in a BMS and why is it important? Cell balancing refers to the process of equalizing the charge across all cells in an electric vehicle (EV) battery pack, ensuring each cell charges and discharges at the same rate.

How are battery cells charged simultaneously using a BMS?

The battery cells were charged simultaneously using the BMS. It can be seen that the voltage values of the battery cells were around 3.52 V before the charging process. After the charging process, the voltage of the battery cells increased to 3.66 V. All of the cells were charged with a passive balancing technique in this period.

Can a BMS control the voltage adjustment of a charger?

The BMS has been tested for manually controlling the voltage adjustment of a charger. First, the charge voltage values of two battery cells were adjusted to have a lower voltage value than the other two cells. In this case, two battery cells were bypassed, and the system only charged the two lower voltage cells.

Can a simple battery balancing scheme reduce individual cell voltage stress?

Individual cell voltage stress has been reduced. This study presented a simple battery balancing scheme in which each cell requires only one switch and one inductor winding. Increase the overall reliability and safety of the individual cells. 6.1.

Industry Information

- Does a 5G base station need a UPS power supply

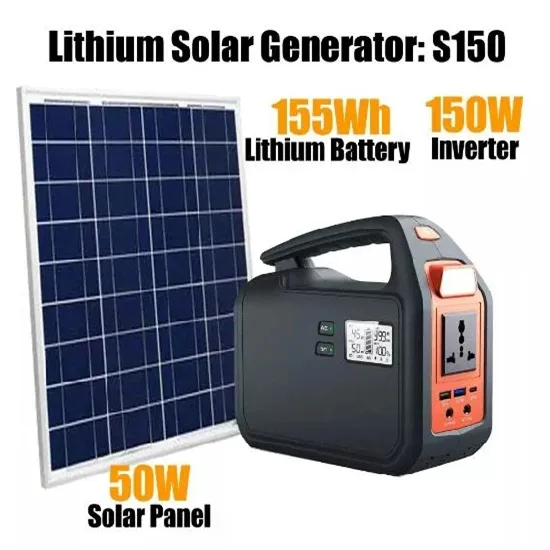

- Solar Panel On-site Energy Assembly

- High quality wholesale c32 circuit breaker Buyer

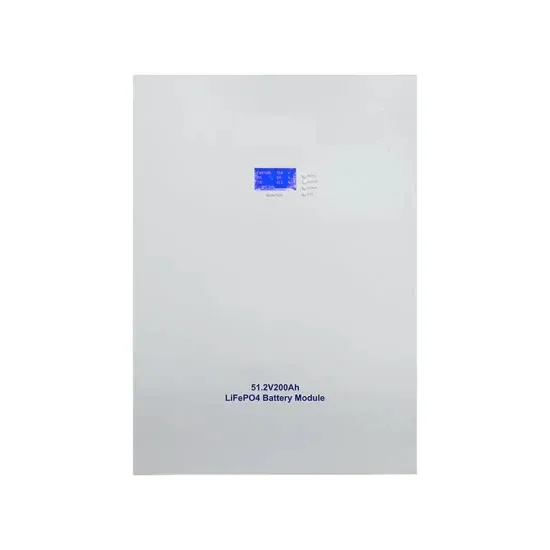

- Battery energy storage system manufacturers in the United Arab Emirates

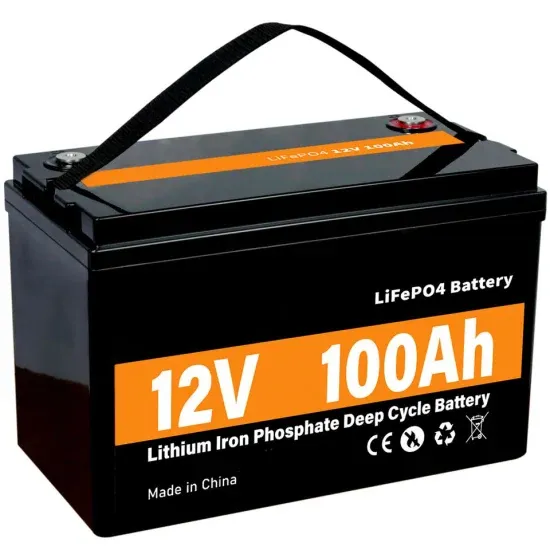

- How much is the price of lithium battery for energy storage in Aarhus Denmark

- New photovoltaic panels for sale in Greece

- Circuit breaker fuse for sale in Johannesburg

- UPS uninterruptible power supply output becomes 280V DC

- Solar energy application system integration in New York USA

- Ecuador power battery bms wholesale

- High quality wholesale 1500 watt inverters for sale

- Palau photovoltaic energy storage manufacturer

- Tallinn 5G base station battery is not yet home appliance news

- Indonesia photovoltaic tile direct sales

- Mobile power supply or outdoor power supply

- Does the photovoltaic glass factory cause pollution

- Substation Direct-mounted Energy Storage

- Inverter 48W

- Type level of flywheel energy storage in communication base stations

- Wind and solar energy storage projects

- Seoul communication base station battery manufacturer

- High voltage breaker for sale in Canberra

- Ghana Large Mobile Energy Storage Vehicle

Commercial & Industrial Solar Storage Market Growth

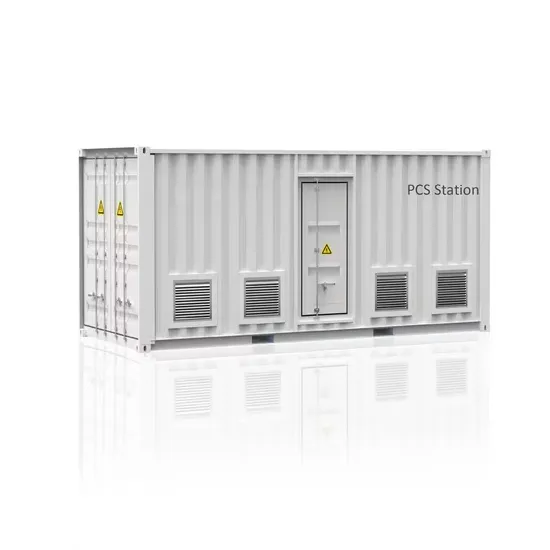

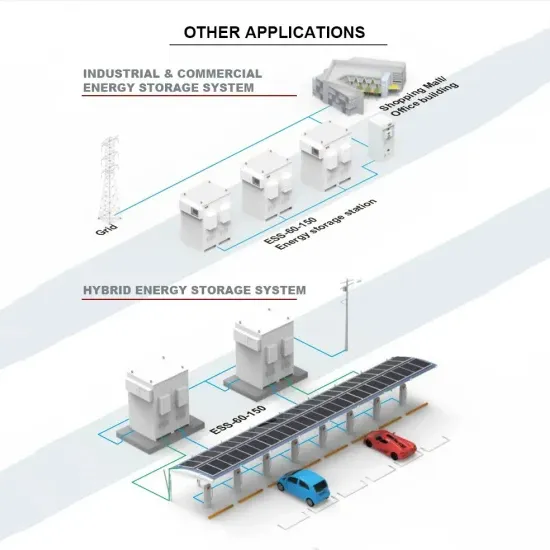

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.