Analysis and design of the capacity and efficiency of a flywheel energy

Current flywheel energy storage systems could store approximately 0.5-100 kW·h energy and discharge at a rate of 2-3000 kW. Here a design of a 100kW·h flywheel is proposed. By using

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Flywheel Energy Storage System

Flywheel Energy Storage Systems (FESS) are defined as systems that store energy by spinning a rotor at high speeds, converting the rotor''s rotational energy into electricity. They utilize a high

Design and prototyping of a new flywheel

Sep 5, 2017 · This study presents a new ''cascaded flywheel energy storage system'' topology. The principles of the proposed structure are presented.

How much does a flywheel energy storage

Mar 2, 2024 · 1. The cost of a flywheel energy storage system varies based on several factors, including size, design, and installation requirements. 2. On

Design of Flywheel Energy Storage System – A Review

Aug 22, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extensively

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

Energy Storage Flywheel Rotors—Mechanical

Energy storage flywheel systems are mechanical devices that typically utilize an electrical machine (motor/generator unit) to convert electrical energy in

Overview of Flywheel Systems for Renewable Energy

Jul 12, 2024 · Energy can be stored through various forms, such as ultra-capacitors, electrochemical batteries, kinetic flywheels, hydro-electric power or compressed air. Their

Energy and environmental footprints of flywheels for utility

Jan 1, 2021 · The net energy ratio is a ratio of total energy output to the total non-renewable energy input over the life cycle of a system. Steel rotor and composite rotor flywheel energy

Peer Review Oct 2005

May 15, 2012 · Design, Fabrication, and Test of a 5 kWh Flywheel Energy Storage System Utilizing a High Temperature Superconducting Magnetic Bearing – Phase III

Design, modeling, and validation of a 0.5 kWh flywheel energy storage

Nov 1, 2024 · The flywheel energy storage system (FESS) has excellent power capacity and high conversion efficiency. It could be used as a mechanical battery in the

Advancing renewable energy: Strategic modeling and

Nov 1, 2024 · This study introduces a hybrid energy storage system that combines advanced flywheel technology with hydrogen fuel cells and electrolyzers to address the variability

Design Optimization of a Rotor for Flywheel

May 26, 2023 · The aim of this study is to design and shape optimization of flywheel rotor with different combinations of diameter and height with constant

Critical Review of Flywheel Energy Storage

Apr 13, 2021 · This review presents a detailed summary of the latest technologies used in flywheel energy storage systems (FESS). This paper covers the types

(PDF) Flywheel Energy Storage System

Mar 28, 2019 · PDF | An overview of flywheel energy storage system. | Find, read and cite all the research you need on ResearchGate

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power

Applications of flywheel energy storage system on load

Mar 1, 2024 · Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Abstract−While energy storage technologies cannot be considered sources of energy; they provide valuable contributions to enhance the stability, power quality and

A Review of Flywheel Energy Storage System

Sep 7, 2023 · The operation of the electricity network has grown more complex due to the increased adoption of renewable energy resources, such as wind

Design of Flywheel Energy Storage System – A Review

Aug 22, 2024 · Flywheel energy storage systems (FESS) are devices that are used in short duration grid-scale energy storage applications such as frequency regulation and fault

Design and prototyping of a new flywheel energy

Dec 21, 2020 · Fundamental operation of the flywheels is based on the well-known equation of stored energy in a rotating mass. If angular speed changes, amount of energy absorbed or

Flywheel energy storage

Jan 1, 2022 · This chapter takes the reader from the fundamentals of flywheel energy storage through to discussion of the components which make up a flywheel energy storage system.

A Review of Flywheel Energy Storage System

Energy storage systems (ESS) provide a means for improving the efficiency of electrical systems when there are imbalances between supply and demand.

Design and Research of a New Type of Flywheel Energy Storage System

Feb 18, 2025 · This article proposes a novel flywheel energy storage system incorporating permanent magnets, an electric motor, and a zero-flux coil. The permanent magnet is utilized

Overview of Flywheel Systems for Renewable Energy

Jul 12, 2024 · storage systems (FESS) are summarized, showing the potential of axial-flux permanent-magnet (AFPM) machines in such applications. Design examples of high-speed

Kainat Riaz1, Syeda Fatima Imam1, Nida Ilyas1, Zia ul

Oct 19, 2022 · ABSTRACT Flywheel Energy Storage System (FESS) is an emerging technology with notable applications. To conduct analysis of flywheel''s rotors, cylindrical shape

A comprehensive review of Flywheel Energy Storage System

Jan 1, 2017 · Energy storage systems (ESSs) play a very important role in recent years. Flywheel is one of the oldest storage energy devices and it has several benefits. Flywheel Energy

Design of flywheel energy storage device with high specific energy

Jun 27, 2025 · The flywheel energy storage system is a way to meet the high-power energy storage and energy/power conversion needs. Moreover, the flywheel can effectively assist the

Flywheel Design: Calculation & Considerations | Vaia

Aug 30, 2024 · Flywheel design is an engineering practice that focuses on creating a rotating mechanical device to efficiently store rotational energy. Optimized parameters in flywheel

Design of a flywheel energy storage system for

Sep 18, 2015 · Flywheel energy storage system (FESS) will be needed at different locations in the wind farm, which can suppress the wind power fluctuation and

Design of Flywheel Energy Storage System – A Review

Aug 24, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extens

The most complete analysis of flywheel energy

Aug 23, 2023 · This article introduces the new technology of flywheel energy storage, and expounds its definition, technology, characteristics and other

Overview of Control System Topology of

Nov 25, 2024 · In [15], the authors analysed a hybrid energy performance using solar (PV) and diesel systems as energy sources, with a flywheel to store

Flywheel energy storage systems: Review and simulation for

Dec 1, 2012 · Flywheel energy storage systems (FESSs) store mechanical energy in a rotating flywheel that convert into electrical energy by means of an electrical machine and vice versa

A review of flywheel energy storage systems: state of the art

Mar 16, 2024 · The existing energy storage systems use various technologies, including hydroelectricity, batteries, supercapacitors, thermal storage, energy storage flywheels, [2] and

Flywheel Energy Storage System Dimensions: Balancing

Jun 10, 2021 · Designing optimal flywheel energy storage system dimensions isn''t just about math - it''s like solving a Rubik''s Cube blindfolded while riding a unicycle. Consider: 1. The Safety

Design and analysis of a flywheel energy storage system fed

Jan 1, 2022 · This paper presents design, optimization, and analysis of a flywheel energy storage system (FESS) used as a Dynamic Voltage Restorer (DVR). The first

Technology: Flywheel Energy Storage

Oct 30, 2024 · Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical

6 FAQs about [Energy storage system design flywheel size]

How does a flywheel energy storage system work?

Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical energy is thus converted to kinetic energy for storage. For discharging, the motor acts as a generator, braking the rotor to produce electricity.

What is flywheel energy storage system (fess)?

but lower energy density, longer life cycles and comparable efficiency, which is mostly attractive for short-term energy storage.Flywheel energy storage systems (FESS) have been used in uninterrupted power supply (UPS) –, brake energy recovery for ra

Are flywheel energy storages commercially available?

Flywheel energy storages are commercially available (TRL 9) but have not yet experienced large-scale commercialisation due to their cost disadvantages in comparison with battery storages (higher investment, lower energy density). Another challenge is the comparably high standby loss in FESS caused by the magnetic drag of the motor-generator.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Are flywheel-based hybrid energy storage systems based on compressed air energy storage?

While many papers compare different ESS technologies, only a few research [152,153] studies design and control flywheel-based hybrid energy storage systems. Recently, Zhang et al. present a hybrid energy storage system based on compressed air energy storage and FESS.

Why are high-strength steel flywheels a good choice?

High-strength steel flywheels have a high energy density (volume-based energy) due to their high mass density. Furthermore, they are superior to composite ones regarding thermal conductivity and design data availability, such as SN curves and fracture toughness.

Industry Information

- Cheap wholesale old circuit breaker Factory

- Outdoor Base Station Power Solution

- How to match batteries with 1500w photovoltaic panels

- There are several battery cabinet factories in St George

- How much does the energy battery cabinet cost at the Libya site

- Huawei Energy Storage System Optical Fiber Module

- What is the general capacity of a new energy battery cabinet

- Kosovo photovoltaic energy storage manufacturer

- How many volts does the 5g base station DC power supply

- Inverter three-phase overvoltage

- China 220v circuit breaker in China producer

- Athens Power Storage Equipment Manufacturer

- Feasibility of constructing a battery energy storage system for communication base stations

- Ireland Portable Energy Storage Power Supply Customized Manufacturer

- Ottawa Communications 5g base station 5MWH liquid cooling is good

- Home courtyard solar energy on site

- High quality on grid inverter in Estonia

- Energy storage product power

- Port Vila Volt Energy Storage Battery

- 5mm tempered photovoltaic glass price

- Small Base Stations and Optical Communications

- Photovoltaic battery energy storage discharge at night

- Porto Novo flywheel energy storage power generation

Commercial & Industrial Solar Storage Market Growth

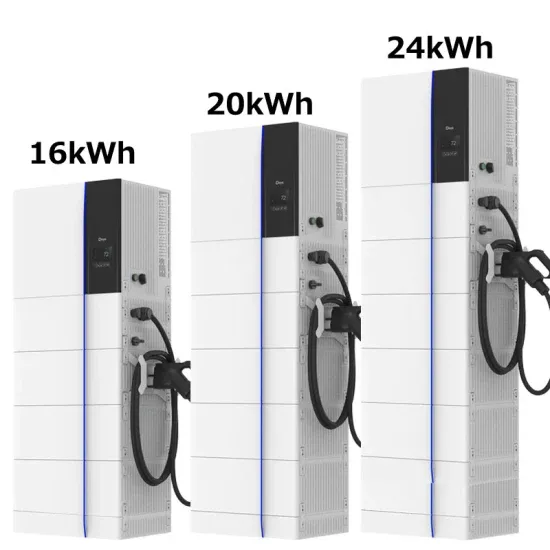

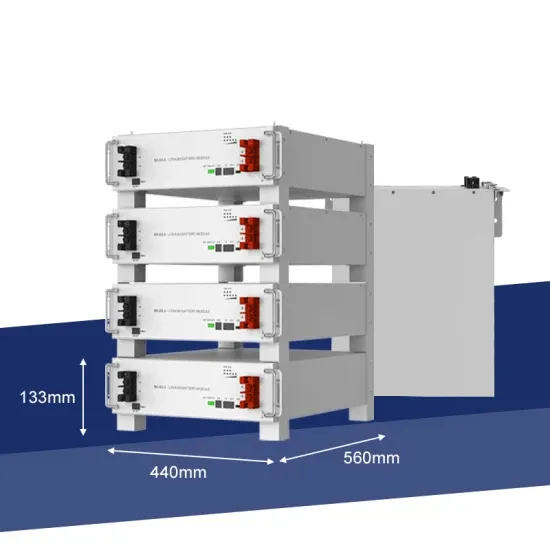

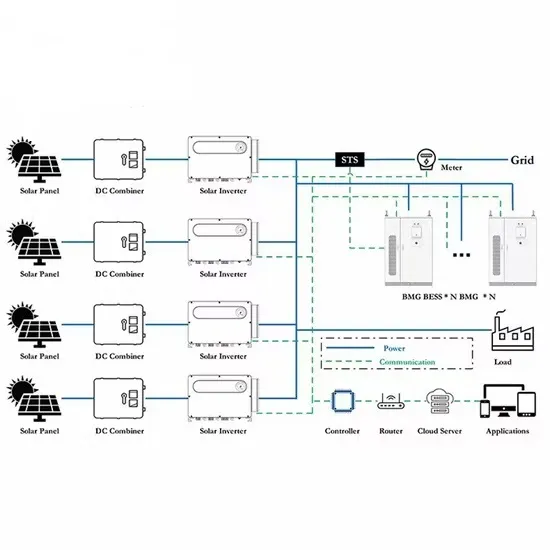

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.