The Rise of 5MW Flywheel Energy Storage: Powering the

Why Your Grid Needs a Giant Spinning Metal Donut Imagine a 10-ton metal wheel spinning at 25,000 RPM in a vacuum chamber – that''s essentially your modern 5MW flywheel energy

Energy Storage Flywheel Rotors—Mechanical

Energy storage flywheel systems are mechanical devices that typically utilize an electrical machine (motor/generator unit) to convert electrical energy in

DESIGN AND ANALYSIS OF FLYWHEEL ENERGY

Aug 4, 2016 · A. Flywheel Rotor Design Flywheel design is essential in establishing both the energy storage capacity and maximum power delivery of the flywheel system. There are four

DOE ESHB Chapter 7 Flywheels

Mar 17, 2022 · broad range of applications today. In their modern form, flywheel energy storage systems are standalone machines that absorb or provide electricity to an application.

Energy Storage Flywheels

Energy storage flywheels feature a mass rotating around an axis. The main purpose of flywheels is to store energy in the form of kinetic energy, which can then be used to generate power. By

Flywheel Energy Storage Study

May 4, 2020 · The core of this particular FES System technology involves the development of a lower-cost steel flywheel, which will reduce the first cost of the energy storage device, while

Flywheel Energy Storage Systems and Their

Apr 1, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel

Analysis of a flywheel energy storage system for light rail

Jul 15, 2016 · These models are used to study the energy consumption and the operating cost of a light rail transit train with and without flywheel energy storage. Results suggest that

Applications of flywheel energy storage system on load

Mar 1, 2024 · Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

Flywheel energy and power storage systems

Feb 1, 2007 · During that time several shapes and designs where implemented, but it took until the early 20th century before flywheel rotor shapes and rotational stress were thoroughly

How much power does the flywheel energy

Apr 26, 2024 · FLYWHEEL ENERGY STORAGE MOTORS PROVIDE HIGH-EFFICIENCY POWER SOLUTIONS, 2. POWER OUTPUT VARIES BASED

Learn how flywheel energy storage works

Jun 7, 2019 · Flywheel energy storage consists in storing kinetic energy via the rotation of a heavy object. Find out how it works.

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

Comprehensive review of energy storage systems

Jul 1, 2024 · Battery, flywheel energy storage, super capacitor, and superconducting magnetic energy storage are technically feasible for use in distribution networks. With an energy density

General Design Method of Flywheel Rotor for Energy Storage

Jan 1, 2012 · Flywheel rotor design is the key of researching and developing flywheel energy storage system.The geometric parameters of flywheel rotor was affected by much restricted

Flywheel Energy Storage System

Flywheel energy storage system is an energy storage device that converts mechanical energy into electrical energy, breaking through the limitations of chemical batteries and achieving energy

Could Flywheels Be the Future of Energy

Jul 7, 2023 · Flywheels are one of the world''s oldest forms of energy storage, but they could also be the future. This article examines flywheel technology, its

Design of flywheel energy storage device with high specific energy

Jan 1, 2025 · Flywheel energy storage systems (FESSs) may reduce future power grid charges by providing peak shaving services, though, are characterized by significant standby energy losses.

An Overview of the R&D of Flywheel Energy

Nov 5, 2024 · The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

World''s Largest Flywheel Energy Storage System

May 17, 2020 · Beacon Power is building the world''s largest flywheel energy storage system in Stephentown, New York. The 20-megawatt system marks a

Flywheel energy storage systems: A critical

Jul 19, 2021 · From Table 2, it can be inferred that the FESS technology proves to be the best with maximum efficiency, low impact on the environment, high

Design of flywheel energy storage device with high

Jun 28, 2025 · Flywheel energy storage has many advantages, such as high efficiency (up to 90%), large instantaneous power (single megawatt level), fast response speed (several

Kainat Riaz1, Syeda Fatima Imam1, Nida Ilyas1, Zia ul

Oct 19, 2022 · Renewable energy storage devices are instantaneous power, reduced carbon emissions, longer lifetime, larger efficiency, and high charging and discharging rates which are

Rotor Design for High-Speed Flywheel Energy Storage

Sep 25, 2018 · More recently, flywheel systems were developed as true energy storage devices, which are also known as mechanical or electromechanical batteries. A remarkable example of

The role of flywheel energy storage in

Aug 17, 2025 · The minimum speed of the flywheel is typically half its full speed, the storage energy is be given by ½ (12-0.52) Ifwf2 where If is the rotor

Design of flywheel energy storage device with high specific energy

Jun 27, 2025 · The flywheel energy storage system is a way to meet the high-power energy storage and energy/power conversion needs. Moreover, the flywheel can effectively assist the

FESS Fkywheel Energy Storage Systems

Jun 26, 2025 · In Australia do flywheels have a role as energy storage devices? All flywheel energy systems use the same basic concepts to store energy.

What is Flywheel Energy Storage – How Does it

Jul 5, 2019 · Flywheel energy storage is a promising technology for replacing conventional lead acid batteries as energy storage systems. Most modern

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems have gained increased popularity as a method of environmentally friendly energy storage. Fly wheels store energy in mechanical rotational

Flywheel energy storage

Jan 1, 2023 · Comparison of supercapacitor and flywheel energy storage devices based on power converters and simulink real-time. In 2018 IEEE international conference on environment and

Research on the application of flywheel energy storage device

The application case of the flywheel energy storage device in engineering has verified that the flywheel energy storage device has a good voltage stabilization effect, with an average energy

Kinetic Energy Storage (Flywheels)

Kinetic Energy Storage (Flywheels) Principle kinetic energy storage system is composed simply by a flywheel driven by an electrical machine (different types of technologies are considered,

Energy management of flywheel-based energy storage device

Oct 1, 2013 · This paper proposes an energy management strategy for a flywheel-based energy storage device. The aim of the flywheel is to smooth the net power flow injected to the grid by

Technology: Flywheel Energy Storage

Oct 30, 2024 · Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical

Technology: Flywheel Energy Storage

Oct 30, 2024 · Summary of the storage process Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to

A Review of Flywheel Energy Storage System

Mar 16, 2017 · Energy, Exergy and Economic (3E) analysis and multi-objective optimization of a combined cycle power system integrating compressed air

6 FAQs about [Maximum power of flywheel energy storage device]

How does a flywheel energy storage system work?

Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical energy is thus converted to kinetic energy for storage. For discharging, the motor acts as a generator, braking the rotor to produce electricity.

Are flywheel energy storage systems environmentally friendly?

Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage and release, high power density, and long-term lifespan. These attributes make FESS suitable for integration into power systems in a wide range of applications.

Can flywheel energy storage system array improve power system performance?

Moreover, flywheel energy storage system array (FESA) is a potential and promising alternative to other forms of ESS in power system applications for improving power system efficiency, stability and security . However, control systems of PV-FESS, WT-FESS and FESA are crucial to guarantee the FESS performance.

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Are flywheel batteries a good option for solar energy storage?

However, the high cost of purchase and maintenance of solar batteries has been a major hindrance. Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power density and a low environmental footprint.

Industry Information

- Which company is good at photovoltaic glass

- Energy storage cabinet research and development

- What are the wind power projects for Riyadh communication base station

- What are the energy storage power sources in Belize

- Base station battery base station power module

- Lithium battery container energy storage fire protection

- Battery replacement for communication base stations

- Marshall Islands rooftop photovoltaic panel installation

- The wind-solar complementary structure of future communication base stations

- Portable power station 6000w in Italy

- Uninterruptible power supply equipment of Krakow Power Plant Poland

- 2KW inverter battery

- 1000w solar inverter in China in Honduras

- Electrochemical energy storage is expected to be installed

- Battery module with bms

- How to choose a solar inverter

- Inverter Intelligent Sine Wave

- Power tool lithium battery step-down module

- Power inverter high voltage

- Energy storage industry replacement project model

- 3k uninterruptible power supply

- Battery cabinet direct cooling and heating technical indicators

- Huawei inverter has low power at noon

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

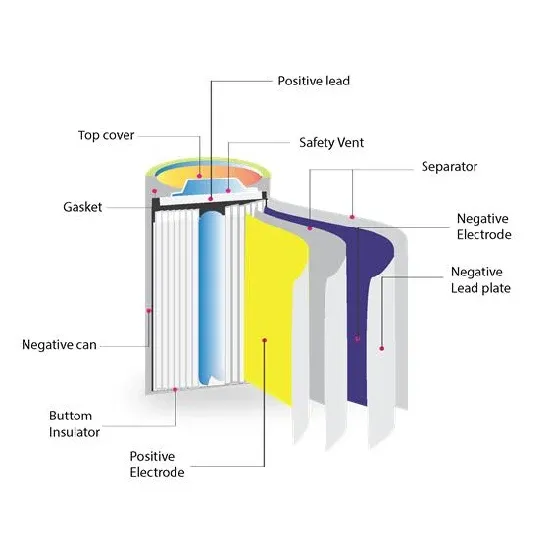

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.