Liquid Cooling Battery Cabinet: Modern BESS Technology

The evolution of Battery Cabinet Cooling Technology has been driven by the need to handle greater thermal loads in more compact spaces. As battery modules are packed tighter to

A Comparative Life Cycle Analysis of an Active

Feb 12, 2025 · This study extends beyond conventional Battery Thermal Management System (BTMS) research by conducting a Life Cycle Analysis

Direct cooling thermal management of cylindrical batteries

Apr 9, 2025 · For lithium-ion batteries, excessive temperature and nonuniform thermal distribution reduce stability, shorten service life, and may even lead to thermal runaway. To mitigate these

Thermal runaway behaviour and heat generation

Mar 1, 2024 · The results indicated that the temperature change in the battery in the first layer was more significant than that in the third layer. Furthermore, the proposed double-layer cooling

Battery Cabinet Cooling Requirements | HuiJue Group E-Site

As battery chemistries evolve toward solid-state architectures, our cooling paradigms must adapt – perhaps even leveraging quantum tunneling composites for direction-controlled heat transfer.

A review on the liquid cooling thermal management system

Dec 1, 2024 · Currently, the maximum surface temperature (T max), the pressure drop loss of the LCP, and the maximum temperature variance (T max-v) of the battery are often applied to

ESS-GRID Cabinet Brochure EN-241028

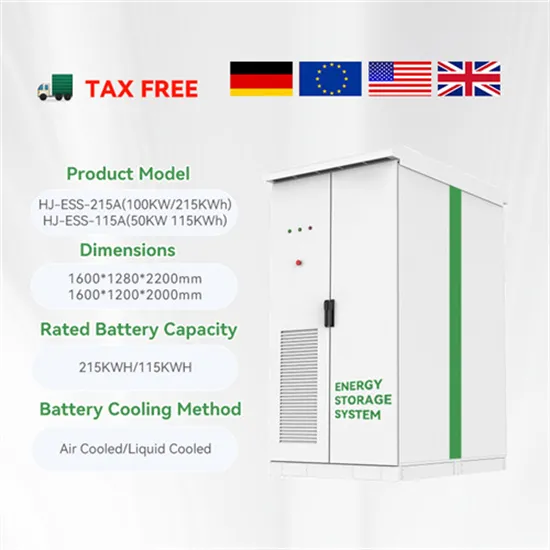

Oct 28, 2024 · The ESS-GRID Cabinet series are outdoor battery cabinets for small-scale commercial and industrial energy storage, with four diferent capacity options based on diferent

Paper Title (use style: paper title)

Nov 8, 2018 · Abstract—Fast charging electric vehicles will pose new challenges for battery thermal management systems. The waste heat produced by the battery cell exceeds the

Next-Gen Battery Cooling: Using AI, New Tech, and

Mar 21, 2025 · Battery Thermal Management Systems (BTMS) play a pivotal role in maintaining safe and optimal operating temperatures within lithium-ion batteries. Without effective thermal

Investigation on High-Temperature-Uniformity Direct

Jun 21, 2025 · Two specifically designed direct cooling plate schemes are proposed and tested under the condition of charging at 38 °C. The results demonstrate that a significant

Analysis of the Battery Direct Cooling Thermal Management

Jan 31, 2025 · To investigate the characteristics of a battery direct-cooling thermal management system integrated with the passenger compartment air-conditioning in a range-extended

(PDF) A Review of Advanced Cooling Strategies

Jun 28, 2023 · Research studies on phase change material cooling and direct liquid cooling for battery thermal management are comprehensively reviewed

Experimental and numerical investigation on thermal

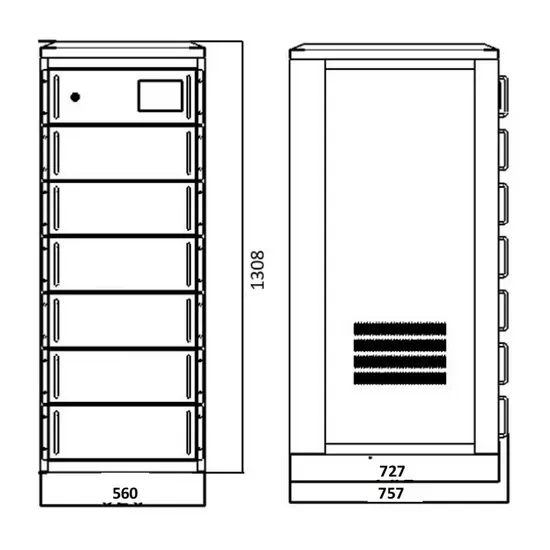

Dec 5, 2015 · Battery placement has significant effect on temperature field in battery cabinet. The six-layer configuration achieves better temperature uniformity. Internal air circulation depends

Battery Cabinet Warning Signs: Critical Indicators for Modern

As we stand at the crossroads of energy transition, one truth emerges clear: Understanding battery cabinet warning signs isn''t just about reading indicators – it''s about interpreting the

A rapid lithium-ion battery heating method based on bidirectional

Dec 15, 2020 · Cooling technology aims to restrain temperature rise [5] and reduce the risk of thermal runaway [6], [7] On the other side, low temperatures also have a complicated effect on

Application of Refrigerant Cooling in a Battery

Jun 5, 2024 · Battery thermal management (BTM) is crucial for the lifespan and safety of batteries. Refrigerant cooling is a novel cooling technique that is

Thermal performance of direct two-phase refrigerant cooling for lithium

Jun 5, 2020 · An efficient battery thermal management system is essential for lithium-ion batteries with high cooling performance and long lifetime. The objective of this study is to investigate the

Simulation analysis and optimization of containerized energy

Sep 10, 2024 · The air-cooling system is of great significance in the battery thermal management system because of its simple structure and low cost. This study analyses the thermal

Battery Thermal Characterization

Oct 10, 2019 · Measurements pack under realistic conditions • Assessing vapor compression, • Heat capacity air, and liquid cooling systems • Heat generation NREL provides critical thermal

A review of power battery cooling technologies

May 1, 2025 · Theoretical methods for enhancing the cooling effect are analyzed based on governing equations. The main cooling technologies are reviewed, including air cooling, liquid

Design and analysis of electric vehicle thermal

Jul 1, 2022 · A thermal management system (TMS) based on R134a refrigerant is proposed, which not only meet the thermal requirements of cabin, but also refrigerant-directly cool and

A thermal management system for an energy storage battery

May 1, 2023 · The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper

Cabinet Cooling: A Key Aspect in Energy Storage Systems

Apr 29, 2025 · Significance of Cabinet Cooling Energy storage systems, whether they are used in renewable energy integration, grid stabilization, or backup power applications, generate a

Comparison of the different types of

Why is it important to choose the right thermal management system? Choosing the right thermal management system for

Thermal Simulation and Analysis of Outdoor Energy Storage Battery

Jan 8, 2024 · We studied the fluid dynamics and heat transfer phenomena of a single cell, 16-cell modules, battery packs, and cabinet through computer simulations and experimental

2025-01-7065: Analysis of the Battery Direct Cooling

The results indicated that within a certain range, a lower outlet pressure of the cooling plate led to a greater average temperature reduction of the battery pack. (3)Under high-speed cruising

Study on performance effects for battery energy storage

Feb 1, 2025 · By increasing air supply volume, cooling effect of cooling system can be improved. Design A has lower temperature standard deviation than other three designs. Effect of

What is liquid-cooled battery cooling? – TYCORUN

Apr 1, 2022 · The principle of liquid-cooled battery heat dissipation is shown in Figure 1. In a passive liquid cooling system, the liquid medium flows through

Data centers waste heat recovery technologies: Review and

Apr 15, 2025 · A new relative exergy efficiency indicator of waste heat recovery in term of the amount of equivalent electrical energy recovered from waste heat εre is then suggested and

Comparative analysis of battery electric vehicle thermal

Dec 11, 2021 · Abstract Due to increasing regulation on emissions and shifting consumer preferences, the wide adoption of battery electric vehicles (BEV) hinges on research and

Comparison of different cooling methods for lithium ion battery

Feb 5, 2016 · When choosing a cooling method and developing strategies, trade-offs need to be made among many facets such as costs, complexity, weight, cooling effects, temperature

Liquid Cooling System

The liquid cooling system consists of the primary side and secondary side. The primary side includes the cooling tower and (optional) chiller. The secondary side includes a coolant

Advances in direct cooling battery thermal management

Aug 8, 2024 · Direct cooling systems are distinguished by their more compact design and faster response times, contributing to more effective thermal management and improved

Experimental and numerical investigation on thermal

Dec 5, 2015 · In this paper, the flow field and temperature distribution inside an outdoor cabinet are studied experimentally and numerically. The battery cabinets house 24 batteries in two

Performance Study of the Direct Cooling Thermal

Sep 23, 2024 · Using numerical simulation, we evaluated the thermal management system''s performance. Under 1.5 C charging and equal refrigerant mass flow rate, the shunt-controlled

Energy Storage System Cooling

May 5, 2025 · Battery back-up systems must be efficiently and effectively cooled to ensure proper operation. Heat can degrade the performance, safety and operating life of battery back-up

Passive Cooling Techniques for EV Battery Protection

Mar 11, 2025 · Power battery thermal management system that integrates cooling and power generation using phase change materials and heat pipes. The system sandwiches the battery

Electric Vehicle Battery Cooling Methods Are

Mar 15, 2023 · A liquid coolant such as water, a refrigerant, or ethylene glycol—a type of liquid coolant also found in antifreeze—is used for the purpose of

3 FAQs about [Battery cabinet direct cooling and heating technical indicators]

How do additives and cell architecture improve battery thermal performance?

We identified additives and cell architecture that improved the high and low temperature performance of the cell. Thermal properties are used for the thermal analysis and design of improved battery thermal management systems to support and achieve life and performance targets.

How has data been shared with the battery developers?

The data has been shared with the battery developers to improve their designs. We developed innovative thermal management strategies in partnership with the battery manufacturers. We identified additives and cell architecture that improved the high and low temperature performance of the cell.

How did NREL work with US drive and USABC battery developers?

NREL collaborated with U.S. DRIVE and USABC battery developers to obtain thermal properties of their batteries. We obtained heat capacity and heat generation of cells under various power profiles. We obtained thermal images of the cells under various drive cycles. We used the measured results to validate our thermal models.

Industry Information

- Indonesia PV combiner box price

- 6v lithium battery pack 4500

- Huawei inverter and energy storage

- Hybrid solar inverter factory in Guinea

- Non-silicon flexible photovoltaic panels

- Pulse inverter 12v24v to 220v

- Cuba Industrial Energy Storage Project

- What is the uninterruptible power supply UPS function

- Smart hybrid inverter factory in Honduras

- Economical and durable life of uninterruptible power supply

- East Africa Energy Storage Photovoltaic Project Installation

- Lisbon 5g base station outdoor cabinet

- Nauru Energy Storage Power Direct Sales

- What photovoltaic panels are used on sloping roofs

- Rooftop solar rainproof photovoltaic panels

- Sucre photovoltaic panel installation manufacturer

- The role of combiner box in photovoltaic power generation

- Retractable solar power generation system

- San Diego Solar Power Generation System

- High quality power switchgear in Guinea

- St Lucia Off-Grid Inverter Installation

- Outdoor 24v solar powered water pump

- How about solar energy storage inverter for communication base station Communication power supply

Commercial & Industrial Solar Storage Market Growth

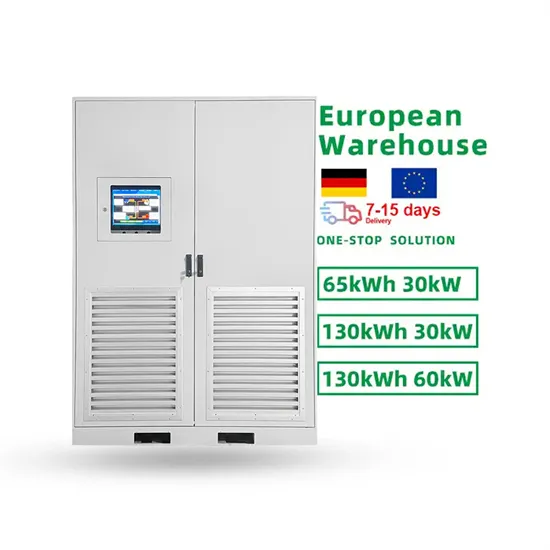

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.