Photovoltaic Pv Grass Removing Machine-Henan Recycle Equipment

Jan 24, 2025 · As the core equipment in the recycling and reuse process, the photovoltaic panel deglazing machine has a unique working principle and technical characteristics. The core

Design and test of pneumatic dedusting equipment for photovoltaic panels

Feb 1, 2024 · In recent years, energy consumption has increased and environmental pollution has become more and more serious. Therefore, distributed photovoltaic power generation

Photovoltaic Module Manufacturing Equipment

Oct 28, 2016 · From assembling the photovoltaic cells to finishing the complete module, each phase is scrupulously carried out by a specific machine. Our engineers design and develop

What is hermetic glass sealing photovoltaic cells equipment?

Photovoltaic panel glass removal machine-Solar Panel Photovoltaic panel deglazing machine is mainly used to remove the glass on the surface of photovoltaic panels.The main components

Structure of waste photovoltaic panel deglazing machine

Klugmann-Radziemska (2011) discussed the reuse of the solar panels and the impact on the economy in PV recycling industry. However, the recycling procedures are different based on

Solar Panel Glass Treatment Production Equipment for Photovoltaic Panel

Jul 1, 2025 · Solar Panel Glass Removing Machine is the core equipment for the recycling and processing of PV modules, which realizes the efficient stripping and resource utilization of the

The machine that can remove glass from solar panels | PV Panel

Jan 23, 2025 · E-waste Recycling Solutions January 23 · Follow The machine that can remove glass from solar panels | PV Panel Deglazing Machine

Photovoltaic Panel Recycling | WANROOETECH

4 days ago · Photovoltaic panel recycling machine Photovoltaic panel recycling machine, also known as photovoltaic panel recycling equipment or

Solar panel production equipment and machinery

Oct 28, 2016 · Nowadays the solar panels'' production equipment is divided into the following required machinery and accessories. The first run automated processes are the stringing and

Equipment for the Recycling of Solar and

Apr 24, 2025 · First of all, the first step of PV panel recycling is dismantling. To effectively recover reusable materials such as metal and glass, an automatic

Scrapped Solar Panel Glass Removal Machine for

2 ame Removal: The recycled waste photovoltaic panels are first used to remove the aluminum frame of the solar panel using a frame removal machine to obtain metallic aluminum. 3.Glass

Working principle of photovoltaic panel deglazing machine

The photovoltaic panel glass removal machine is a key equipment for the recycling and treatment of waste photovoltaic panels. It removes the glass layer on the photovoltaic panel through high

List of solar PV panel cleaning equipment and its efficiency

Sep 20, 2024 · Explore efficient solar PV panel cleaning equipment to boost energy output and extend the lifespan of your solar systems. Clean smarter, save energy!

Solar Module Equipment & Solar Testing

Contact Us for PV Production! Ready to take your solar module equipment business to the next level? Reach out to our team today to discuss your

What equipment is included in the photovoltaic panel

Jan 26, 2024 · The above introduction is a comprehensive production of photovoltaic panels. The entire equipment of the photovoltaic panel production line covers the entire process from raw

Manufacturer''s Photovoltaic Panel Glass Recycling Machine Solar Panel

Compared to traditional manual processing methods, photovoltaic panel glass separation machines have significant advantages. Firstly, it can quickly and accurately separate glass

Fully Automatic Solar Panel Recycling and Processing Equipment

5 days ago · Fully Automatic Solar Panel Recycling And Processing Equipment Solar Energy Panel Recycling Waste solar panels have high recovery value, which not only helps reduce

Solar Panel/PV Glass Separator

Solar Panel Deglazing Machine is a key step in processing waste pv panels. It removes 90% of the pv panel glass after removing the aluminum frame.

Scrapped Photovoltaic Panel Recycling Equipment

Jan 4, 2025 · Photovoltaic modules contain high-value silver, aluminum, silicon wafers and glass materials. Photovoltaic panel recycling equipment can achieve efficient classification and

Fully Automated Photovoltaic Panel Cleaning Equipment

May 4, 2025 · The global market for fully automated photovoltaic (PV) panel cleaning equipment is experiencing robust growth, driven by the increasing adoption of solar energy worldwide and

Photovoltaic Panel Recycling Equipment | SUNY

With the rapid development of renewable energy, photovoltaic panels play an important role in solar power generation. However, when photovoltaic panels

Equipment for the Recycling of Solar and

Apr 24, 2025 · To reduce resource waste and environmental pollution, the recycling of PV panels is particularly important. First of all, the first step of PV

Solar photovoltaic panel glass removal machine

The solar photovoltaic panel glass removal machine is a key equipment for the recycling and treatment of waste photovoltaic panels. It separates the glass layer on the photovoltaic panel

Solar/PV Panel Recycling Plant

Jiangxi Mingxin Metallurgy Equipment Co., Ltd. As a famous manufacturer in recycling equipment of China Found in 1988, with more than 30 years experience in design, production &

Photovoltaic panels: operation and electrical

Sep 2, 2015 · A photovoltaic solar panel is an element designed to convert solar energy into electricity. Types and characteristics of photovoltaic panels.

Solar Panel Glass Remove Machine With Dust Extractor

The solar panel glass remove machine with dust extractor serves as a dedicated piece of equipment for the recycling of photovoltaic panels. Its primary function is to disassemble and

Fully Automatic Production Line for Aluminum Frame

The main components of solar panels are aluminum frames, glass, cells, EVA film, back sheets, etc., which have high recycling value. The waste solar panel recycling equipment production

Specialist In Solar Panel Production Line

A Chinese High-Tech Company For Solar Panel Production Equipment&Turnkey Solution. Radiant PV Solar focus on manufacturing solar panel production line

Specialist in Solar Panel Manufacturing Equipment | Horad

Jan 16, 2025 · Since foundation, Horad has been committed to becoming a leading manufacturer of intelligent PV panel production lines by focusing on the solar panel line R&D, designing,

Photovoltaic panel solar panel glass removal machine

6 days ago · Photovoltaic panel de glassing machine is a device specifically designed for efficient and non-destructive separation of solar cells from glass backboards in photovoltaic modules.

Single/Double Crystal Silicon Photovoltaic Panel

Jun 29, 2025 · Single/double crystal silicon photovoltaic panel de glassing machine is a specialized equipment used to separate glass and solar cells in

What are the solar panel production equipment?

Sep 23, 2024 · 1. Solar panel production equipment comprises various machines and tools necessary for manufacturing solar photovoltaic cells, modules, and

Solar Panel Cleaning Equipment For

Streamline® offers a comprehensive range of pure water supply equipment to aid solar panel cleaning, from simple plug and play mobile units to complete

Automated Solar Panel Disassembly Equipment

Jun 26, 2023 · However, the widespread adoption of solar panels has brought new challenges - the proper handling and recycling of end-of-life photovoltaic (PV) modules. To solve this

Industry Information

- Guinea-Bissau best-selling photovoltaic panel manufacturers

- Huawei Micro Inverter Assembly

- Iraq container generator manufacturers

- Do you have a 100kw inverter

- Energy storage power cabinet manufacturers

- Guinea Solar Power System Manufacturer

- Home Base Station Power Supply

- What does outdoor power storage capacity mean

- Are silicon wafers used for power generation or energy storage

- Accra Single Energy Storage Project

- Tokyo Energy Storage Vehicle Price

- French Photovoltaic Glass Project

- Which lithium iron phosphate battery energy storage container is better

- New energy vehicles require outdoor power supply

- Recommended brand of portable power bank in El Salvador

- Cambodia explodes communication base station battery

- Does a photovoltaic inverter not require a battery

- What is the hybrid energy power supply for communication base stations called

- Portable energy storage product production in Romania

- Micro inverter support

- Canberra communication base station inverter grid-connected manufacturer

- Photovoltaic inverter belongs to photovoltaic module

- North Macedonia photovoltaic off-grid power generation system

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

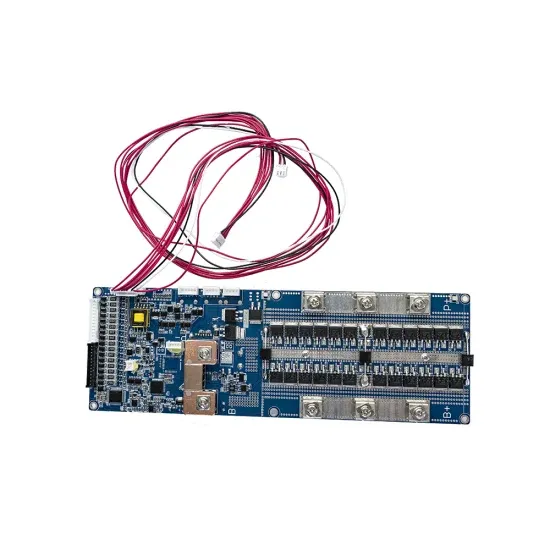

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.