Temperature effect on efficiency of

Download scientific diagram | Temperature effect on efficiency of monocrystalline and amorphous silicon PV panels. from publication: Study of the Effects of

Types of solar panels: monocrystalline,

There are three main types of solar panels used in solar projects: monocrystalline, polycrystalline, and thin-film. Each kind of solar panel has different

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

Comparative Analysis of Solar Cell Efficiency between Monocrystalline

Dec 4, 2020 · Many Malaysians do not know in depth about silicon-based solar panels, but the current generation uses solar panels photovoltaic either at home or elsewhere to save costs

What Are Amorphous Solar Panels, and Should

Mar 11, 2022 · Windows with transparency gradients Comparing Amorphous Solar Panels to Conventional Solar Panels Solar panels come in all shapes

What is the difference between monocrystalline silicon for

Feb 14, 2025 · This article introduces the differences between monocrystalline silicon, polycrystalline silicon, and amorphous silicon, focusing on their applications in semiconductors

Amorphous silicon solar cells: Solar Facts and Advice

Some amorphous solar panels also come with shade-resistant technology or multiple circuits within the cells, so that if an entire row of cells is subject to complete shading, the circuit won''t

What kind of silicon is used in solar photovoltaic

Jun 19, 2024 · Silicon is primarily categorized into three types utilized in solar photovoltaic panels: monocrystalline silicon, polycrystalline silicon, and

Solar Cells Comparison

Nov 6, 2017 · Photovoltaic solar panels are devices specifically designed for the generation of clean energy from sunlight. In general, photovoltaic panels are

Thin Film vs. Silicon Solar Panels: What''s the

May 10, 2023 · Learn the difference between thin film vs. silicon for solar panels, including their advantages and environmental considerations.

Amorphous Solar Panels: Everything You Need

Amorphous silicon solar panels generally have lower efficiency compared to crystalline solar panels. Crystalline solar panels, which include

Amorphous Vs Monocrystalline Vs

3 days ago · What Is the Difference Between Amorphous, Monocrystalline and Polycrystalline Solar Panels. Here''s Everything You Need to Know.

Amorphous PV Panels: A Comprehensive Guide to Their

May 8, 2025 · How do amorphous solar panels compare to monocrystalline and polycrystalline panels? Amorphous panels have lower efficiency (6-10%) than monocrystalline (15-23%) and

Monocrystalline vs Amorphous Solar Panels: A

Aug 16, 2023 · Monocrystalline solar panels are built from a single, pure silicon crystal, while amorphous panels are made by layering thin silicon on a

Amorphous solar panel: features and advantages

Jul 12, 2024 · There are various types of solar panels: monocrystalline, polycrystalline, and amorphous silicon. The choice between these involves

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Monocrystalline, Polycrystalline, and Thin-Film

3 days ago · Thin-film panels are constructed from ultra-thin layers of photovoltaic materials, such as cadmium telluride or amorphous silicon, deposited onto a

Monocrystalline vs Polycrystalline vs Amorphous

When it comes to solar cell technology for solar panels, there are basically three types you can find in the market: amorphous vs monocrystalline vs

What are monocrystalline, polycrystalline and

Aug 25, 2014 · Basic introduction into solar panel and cell technology. Monocrystalline, polycrystalline and thin film solar panels and how to indentify

The schematic diagram of the two types of solar cells: Amorphous

The temperature of the monocrystalline silicon panels is lower than that of the amorphous silicon panel in the majority of measurements.

Types of PV Panels – Solar Photovoltaic

Compared to monocrystalline silicon, multicrystalline silicon PV cell is moderately efficient with a market efficiency ranging from 11-14%, as a result, the cost of

Monocrystalline photovoltaic panels: what they are and their

Dec 11, 2024 · Monocrystalline photovoltaic panels are advanced devices designed to convert sunlight into electrical energy through a process called the photovoltaic effect. Their

Amorphous vs Monocrystalline Solar Panels | A Detailed

Dec 3, 2023 · When it comes to solar panels, two types of silicon dominate the market: amorphous and monocrystalline. These materials, while both derived from silicon, exhibit

Solar panel types and differences:

The main types of solar panels on the market today are monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. Differences between

Crystalline and Thin Film Solar Panels | The

Crystalline Silicon Solar Panels c-Si solar panels can be grouped into two categories — monocrystalline solar cells and polycrystalline cells — which rely

Amorphous solar photovoltaic panels

Amorphous solar cells are typically less than half as efficient as conventional silicon solar cells. Most amorphous solar panels hover around 7%conversion efficiency,while monocrystalline or

Properties of polycrystalline silicon cell

Oct 26, 2018 · Polycrystalline silicon is a material composed of multiple misaligned silicon crystals. It serves as an intermediate between amorphous

Comprehensive investigation of rooftop photovoltaic power

May 3, 2025 · Photovoltaic (PV) panels are devices that transform sunlight into electrical energy through the displacement of electrons in a semiconductor material after being excited by

Amorphous Vs Monocrystalline Vs

Aug 10, 2025 · There are three main types of solar panels: amorphous, monocrystalline, and polycrystalline. Each of them has its pros and cons.

Crystalline Silicon vs. Amorphous Silicon: the Significance of

Nov 21, 2020 · In short, the outstanding conversion efficiency and user-friendly cost of crystalline silicon solar cells prove successful, while the disturbing nature of amorphous silicon solar cells

Types of photovoltaic solar panels and their

Nov 6, 2017 · Instead of using silicon in crystalline form, they use a thin layer of photovoltaic material deposited on a substrate such as glass, plastic or metal.

Monocrystalline silicon: efficiency and

Sep 3, 2018 · Manufacture of monocrystalline silicon photovoltaic panels In addition to the low production rate, there are also concerns about wasted

Monocrystalline vs Amorphous Solar Panels

2 days ago · The main difference between Amorphous and Monocrystalline Solar Panels is that one is flexible and the other isn''t. Amorphous panels can be bent to match the lines of a

3 Amorphous Solar Panels Advantages and

Mar 2, 2024 · Amorphous solar panels are created by depositing thin layers of photovoltaic silicon on a suitable substrate. Well, talking about them why not

6 FAQs about [Photovoltaic panels monocrystalline and amorphous silicon]

What is a monocrystalline solar panel?

A monocrystalline solar panel is one that is composed of a single silicon solar cell. The Czochralski process is used to make these types of cells, which are also known as 'mono solar panels'.

Are amorphous solar panels better than monocrystalline solar panels?

Monocrystalline solar panels hold a clear advantage when it comes to efficiency, boasting a higher conversion rate of solar energy to electricity. However, amorphous panels perform better in less-than-ideal light conditions. The lifespan of amorphous solar panels is shorter when compared to monocrystalline panels.

What are amorphous solar panels?

Amorphous solar panels are not split into solar cells. Instead, photovoltaic layers cover the whole surface, making them also known as “thin-film solar panels.” Unlike polycrystalline and monocrystalline panels, amorphous panels do not consist of individual solar cells.

How are monocrystalline solar cells made?

A monocrystalline solar panel is one that is composed of a single silicon solar cell. The Czochralski process is used to make these types of cells. They are also called “mono solar panels.” Each PV cell in a polycrystalline panel is constructed from several silicon crystal pieces that are fused together in the course of the production process.

Are amorphous solar cells better than crystalline silicon solar cells?

In short, the outstanding conversion efficiency and user-friendly cost of crystalline silicon solar cells prove successful, while the disturbing nature of amorphous silicon solar cells demonstrates several optical and electrical properties, like high absorption coefficient and Staebler-Wronski Effect, never before anticipated.

What is a polycrystalline solar cell?

Polycrystalline is blended with multiple pieces of silicon (less wasteful) to create the solar cells. It's efficiency is less than monocrystalline due to imperfections in the solar cells surface, but it's much cheaper to make.

Industry Information

- Portable photovoltaic energy storage

- High-end large-capacity outdoor power supply

- Omega solar inverter in China in Belarus

- Power battery pack front and back

- Irish Home Energy Storage

- China transfer switch breaker in Vietnam

- Myanmar 24-hour energy storage system

- EK s first zero-carbon energy storage battery factory in Kuala Lumpur

- Independent photovoltaic power generation system off-grid

- Factory price 3000w inverters in Chile

- New energy battery cabinet assembly method

- Pakistan Karachi Power Photovoltaic Module Prices

- Dakar single glass photovoltaic curtain wall advantages

- The latest energy storage power station project in Montenegro

- Do communication base stations have electromagnetic batteries

- Household energy storage power supply price

- Does the BESS battery have a BMS

- 72v inverter 2000 watts

- What are the container battery factories in Valletta

- Senegal 5G communication base station wind power construction

- Base station power cabinet replacement

- Best new circuit breaker in China distributor

- Energy storage cells in new energy

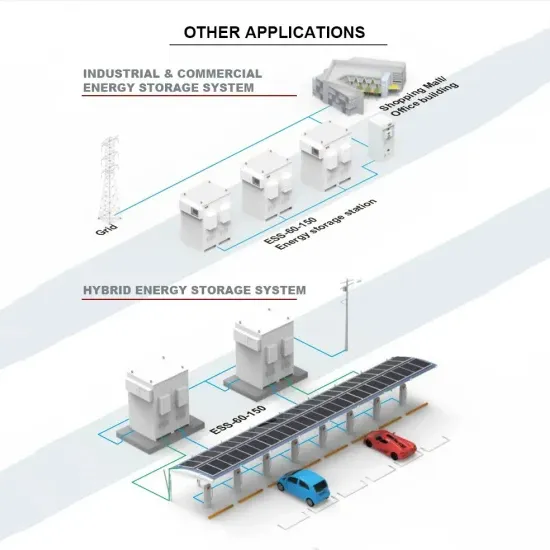

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

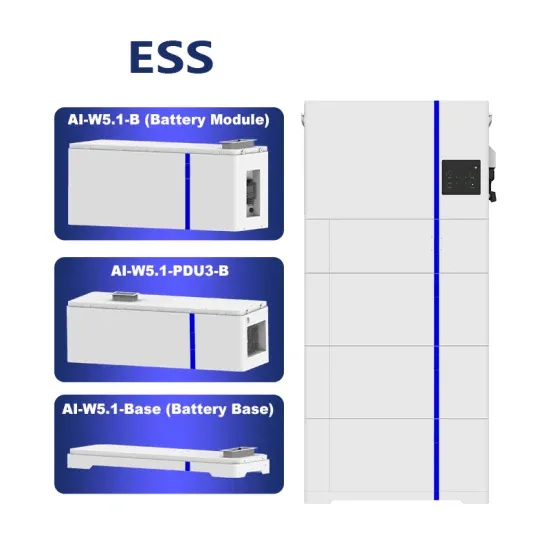

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.