Facilities of a lithium-ion battery production plant

May 3, 2018 · This Chapter describes the set-up of a battery production plant. The required manufacturing environment (clean/dry rooms), media supply,

A comprehensive review and analysis of technology

Jun 1, 2025 · Thus, we aim at developing comprehensive process overview specifications for state-of-the-art lithium-ion battery cell production by applying a systematic, methodical

Battery Production | Lithium-ion & EV Battery Manufacturing Equipment

Nordson is globally renowned for providing high-quality and innovative battery manufacturing equipment, including 2K dispensing systems, bulk unloaders, slot dies, die lip adjustment

Battery manufacturing solutions

Battery manufacturing solutions: Specialty equipment for electrode production for lithium-ion batteries. Your partner for comprehensive battery production

Full Sets Battery Making Equipment for Lithium

Jul 9, 2025 · Full Sets Battery Making Machine for Lithium Ion Battery Production Line EV Battery Machine Lithium ion battery production line Introductions:

The Manufacturing Process of Lithium Batteries

The lithium battery manufacturing industry is dominated by countries like China, Japan, and South Korea, which are major manufacturers and suppliers of

Advanced lithium-ion battery process manufacturing equipment

Jul 18, 2025 · Summary Lithium-ion battery cell manufacturing depends on a few key raw materials and equipment manufacturers. Battery manufacturing faces global challenges and

Advanced lithium-ion battery process manufacturing equipment

Summary Lithium-ion battery cell manufacturing depends on a few key raw materials and equipment manufacturers. Battery manufacturing faces global challenges and opportunities as

Digatron Systems

Digatron Systems specialises in the engineering and manufacturing of lithium battery equipment, providing advanced machinery and complete lines and plants.

The battery industry has entered a new phase –

Mar 5, 2025 · The Chinese battery ecosystem covers all steps of the supply chain, from mineral mining and refining to the production of battery

Lithium ion Battery Manufacturing Plant Cost Report

Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an lithium ion battery manufacturing plant. The report

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · Developments in different battery chemistries and cell formats play a vital role in the final performance of the batteries found in the market.

Empowering lithium-ion battery manufacturing with big

Dec 15, 2024 · However, the complexity of the lithium-ion battery manufacturing process, coupled with numerous process parameters, poses challenges for quality management and control. In

Key Processes and Equipment for Lithium

Nov 29, 2023 · Currently, the manufacturing processes for power lithium battery cells mainly include winding and stacking, corresponding to three battery

Top 10 lithium battery production equipment

Jul 29, 2023 · Lithium battery equipment is the necessary equipment for the production and manufacture of lithium batteries. The production of lithium batteries is complex and involves

A Look at the Manufacturing Process of Lithium

Sep 20, 2024 · The lithium-ion battery manufacturing process continues to evolve, thanks to advanced production techniques and the integration of renewable

Lithium Battery Production Line,Supercapacitor

Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision

Battery production equipment and services

Jun 14, 2024 · BATTERY PACK ASSEMBLY and fitting of entire battery factories. Our aim is to offer the manufacturers of lithium-ion batteries a single source of supply for fitting their acilities

Key Processes and Equipment for Lithium

Nov 29, 2023 · The equipment cannot be shared for production, and the cost of simply retrofitting or switching production capacity is high (ternary materials

Lithium-ion Battery Production

DJK specializes in providing comprehensive solutions for lithium-ion battery (LiB) manufacturing. We offer a wide range of equipment and technologies for

8 Basic Guides to Lithium-Ion Battery Recycling

Sep 6, 2022 · When looking to purchase a lithium-ion battery recycling machine or system, a thorough understanding will allow you to make the best choice

From Raw Materials to Finished Product: The

Nov 10, 2024 · In the lithium-ion battery pack production plant, there is a vast amount of lithium battery science to know, combined with the huge

Automatic Equipment Lithium Ion Battery

Mar 28, 2017 · Gelon as a leading manufacturer of lithium cell industry,We have accumulated 15+ years experiences on lithium ion battery raw material

Batterymaking : Lithium Ion Battery

Tmax is a battery manufacturing equipment and Li ion battery materials supplier with over 20 years of Lithium Ion battery industry experience and professional

Battery Manufacturing Basics from CATL''s Cell

Jun 13, 2021 · A summary of CATL''s battery production process collected from publicly available sources is presented. The 3 main production stages and 14

Lithium Battery Machines | High-Precision Production Solutions

Explore TERTRON''s advanced lithium battery machines, including spot welding, sticker, and capacity grading equipment. Boost efficiency and quality in lithium battery production with

Battery Equipment Solutions for Cell

5 days ago · The Targray Battery Division is focused on providing advanced materials and supply chain solutions for lithium-ion battery manufacturers

A Deep Dive into Lithium-Ion Battery

Nov 22, 2023 · Discover India''s role in shaping energy storage''s future through innovative Lithium-Ion Battery (LIB) manufacturing. Unveil breakthroughs and

Battery production equipment and services

Jun 14, 2024 · Dürr offers equipment for every stage of the value chain – not only paving the way for the production of efficient, high-quality batteries and electric vehicles, but also supporting

How to Start a Successful Lithium Ion Battery

Mar 29, 2025 · Launch your lithium ion battery manufacturing business with our step-by-step guide. Get tips on market analysis, financing, and more to succeed.

Battery Lab Equipment for Lithium-ion Manufacturing | Targray

Aug 18, 2025 · Targray Battery Lab Equipment is supplied to lithium-ion battery developers for the production of various energy storage technologies. Our catalog offers customized high efficient

Battery Manufacturing Process: Materials,

Jul 3, 2024 · The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Battery Production | Lithium-ion & EV Battery Manufacturing Equipment

Technology for Battery Manufacturers Nordson is globally renowned for providing high-quality and innovative battery manufacturing equipment, including 2K dispensing systems, bulk unloaders,

Lithium Battery Module Pack Assembly Line

In the rapidly evolving electric vehicle (EV) and energy storage markets, the Lithium Battery Module Pack Assembly Line plays a pivotal role in ensuring high-efficiency, safety, and

Essential Equipment for Lithium Battery Module Production

Aug 13, 2025 · The production of lithium battery modules requires a range of specialized equipment to ensure efficiency and quality. Understanding the essential equipment for a

What Are the 9 Operating Costs of Lithium Ion

Jul 24, 2025 · Discover the nine key operating costs in lithium-ion battery production. Get actionable insights to optimize expenses and boost efficiency.

Lithium Cell Manufacturing Line

Dec 12, 2024 · Lithium Cell Manufacturing Line: Key to Efficient and Scalable Battery Production A lithium cell manufacturing line is a specialized production facility designed to manufacture

6 FAQs about [Full set of equipment for lithium battery production]

What is the most professional lithium-ion battery production equipment?

TOB offers the most professional automatic lithium-ion battery production equipment for battery manufacturing. TOB offers the most professional semi-auto lithium-ion battery production equipment for battery manufacturing. TOB offers the most professional pouch cell and supercapacitor assembly line equipment for battery research and manufacturing.

What is Tob's semi-auto lithium-ion battery production equipment?

TOB offers the most professional semi-auto lithium-ion battery production equipment for battery manufacturing. TOB offers the most professional pouch cell and supercapacitor assembly line equipment for battery research and manufacturing. TOB offers a full set of semi-auto pouch cell production line solution.

What equipment does Tob offer for lithium-ion battery laboratory R&D?

TOB offers a full set of coin cell assemble line for lithium-ion battery laboratory R&D. TOB offers the most professional battery and supercapacitor laboratory equipment for battery research and manufacturing. Including glove box, ball mill, viscosity meter and muffle furnace, etc.

How can a local battery manufacturing system help a battery plant?

Local manufacturers will scale up and cover the entire machinery for a battery plant through collaborations, from producing electrodes to the final cell formation. Localizing innovation and equipment manufacturing will build a sustainable and competitive battery manufacturing system.

What is the future of battery manufacturing?

More compact, multifunctional machines can transform battery production, making it more efficient in terms of space, cost, and scalability. The future of battery manufacturing will see increased integration of space-saving equipment and advanced formation processes that reduce production time and costs.

How can a battery production line be sustainable?

Innovations such as simultaneous cell formation processes, seen in companies like Tesla and Panasonic, exemplify how global manufacturers are optimizing battery production lines to meet the demands of electrification and sustainable energy storage worldwide. - Equipment manufacturing can rely on green production.

Industry Information

- Output voltage 220v inverter

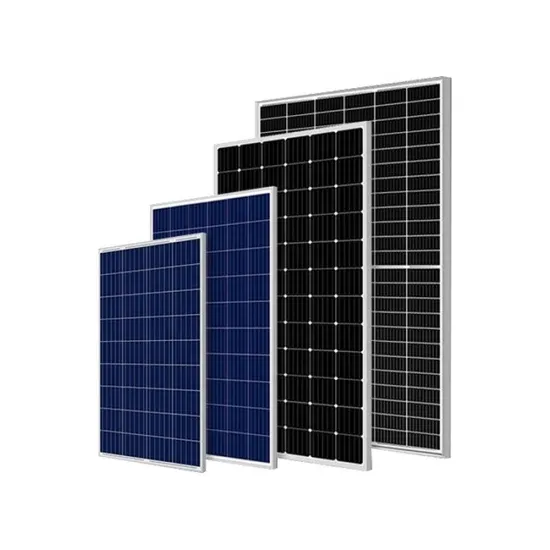

- Is photovoltaic power generation equipped with energy storage in Venezuela

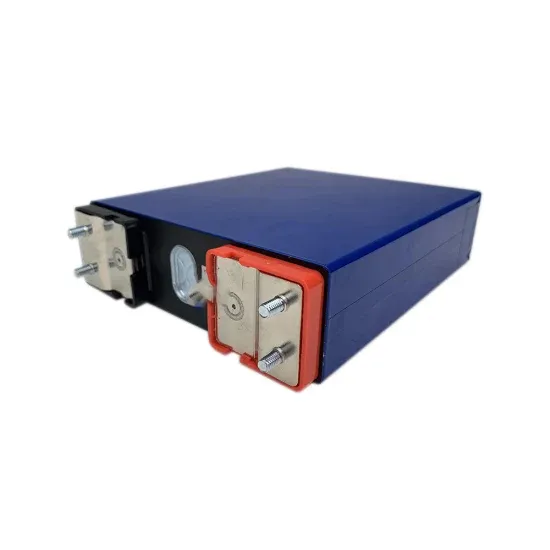

- Industrial and commercial battery pack

- Cost reduction solutions for portable power supplies

- China Solar Energy Storage Cabinet Communication Power Supply

- Tuvalu 100MW photovoltaic energy storage project

- Inverter 12v24v household universal 3000w

- Iranian container energy storage cabin manufacturer

- International brand of solar cell energy storage cabinet for communication base station

- Energy Storage Battery Sales in East Africa

- Glass Tower Photovoltaic

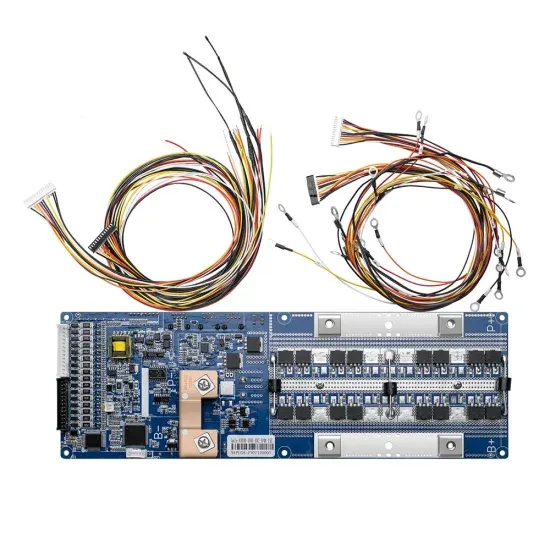

- BMS battery maximum allowable temperature

- What are the mobile energy storage site inverter grid-connected operators

- How much does it cost to change the power supply of Belgrade 5G base station

- Andorra City Monomer Supercapacitor Manufacturer

- 5g base station power distribution cabinet factory

- Portable UPS uninterruptible power supply price in Tunisia

- Huawei Vatican Energy Storage Container

- Photovoltaic glass sales tax rate concession

- Panama Communication Base Station Uninterruptible Power Supply Installation Process

- Recommendation of small outdoor power supply of 100 to 200 RMB

- Wind power generation for communication base stations is exempted from environmental assessment

- Where can I find lithium battery power supply

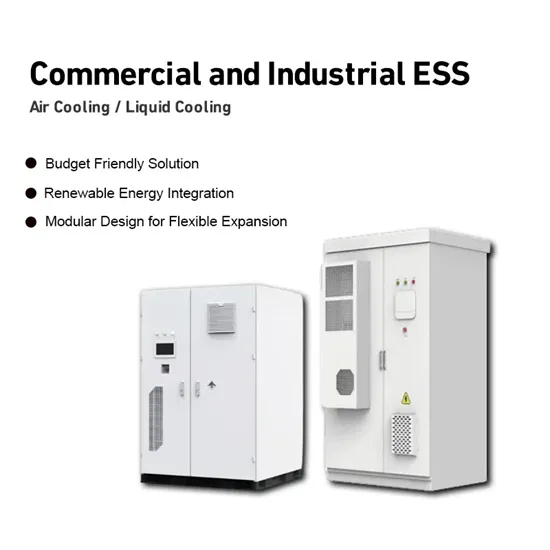

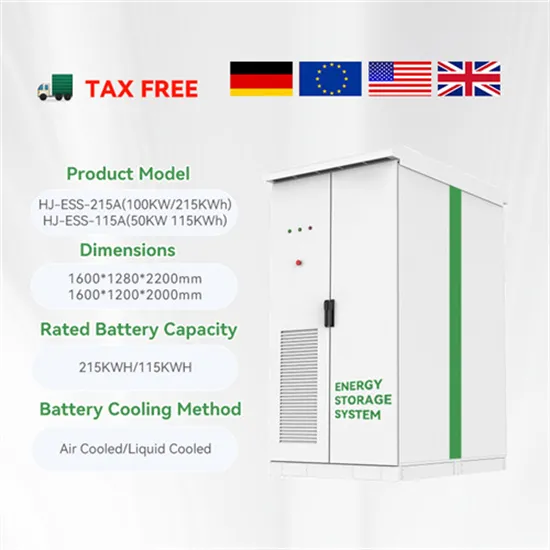

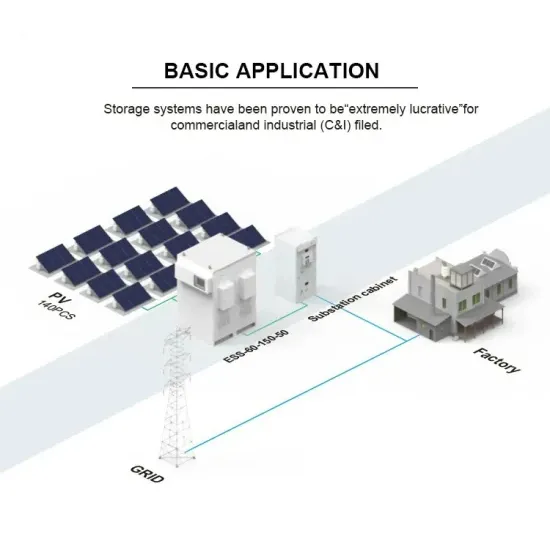

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.