Vanadium Redox Flow Batteries

Jul 30, 2023 · Introduction Vanadium redox flow battery (VRFB) technology is a leading energy storage option. Although lithium-ion (Li-ion) still leads the industry in deployed capacity,

Chile Vanadium Redox Flow Battery (VRB) Market (2024

Historical Data and Forecast of Chile Vanadium Redox Flow Battery (VRB) Market Revenues & Volume By Carbon Paper Electrode for the Period 2020- 2030 Historical Data and Forecast of

Flow battery production: Materials selection and

Oct 1, 2020 · In zinc-bromine flow batteries, the titanium-based bipolar plate contributes higher environmental impact compared to carbon-based materials, and the polymer resins used in all

Vanadium flow batteries at variable flow rates

Jan 1, 2022 · Vanadium flow batteries employ all-vanadium electrolytes that are stored in external tanks feeding stack cells through dedicated pumps. These batteries can possess near limitless

A novel carbon paper based flow field design strategy

Sep 30, 2024 · In summary, we develop a carbon paper based flow field design strategy for high performance vanadium flow batteries, which can simultaneously reduce pressure drop and

Evolution of Vanadium Redox Flow Battery in

May 5, 2023 · The vanadium redox flow battery (VRFB) is a highly regarded technology for large-scale energy storage due to its outstanding features, such

Research progress of flow battery technologies

Abstract: Energy storage technology is the key to constructing new power systems and achieving "carbon neutrality." Flow batteries are ideal for energy

Carbon and metal-based catalysts for vanadium

As one of the most promising electrochemical energy storage systems, vanadium redox flow batteries (VRFBs) have received increasing attention owing to their

Evolution of Vanadium Redox Flow Battery in

May 5, 2023 · It discusses potential applications, recent industrial involvement, and economic factors associated with VRFB technology. The study also

A Vanadium Redox Flow Process for Carbon

Jan 29, 2025 · This work, inspired by vanadium redox flow batteries (VRFB), introduces an integrated electrochemical process for carbon capture and

Vanadium Redox Flow Battery Applications

4 days ago · Learn about the diverse applications of our Vanadium Redox Flow Battery technology, from renewable energy integration and grid stabilization to

Bringing Flow to the Battery World (II)

Mar 21, 2024 · Market readiness The technology readiness level (TRL) and commercial readiness index (CRI) of redox flow battery technologies vary by

Boosting vanadium flow battery performance by Nitrogen

Aug 31, 2016 · Fabricating cost effective and high-performance electrodes is essential to the development of vanadium flow battery (VFB). Moreover, improving the stability of electrodes in

A comparative study of iron-vanadium and all-vanadium flow battery

Feb 1, 2022 · The flow battery employing soluble redox couples for instance the all-vanadium ions and iron-vanadium ions, is regarded as a promising technology for large scale energy storage,

Vanadium Flow Batteries: All You Need to Know

Oct 30, 2023 · Vanadium flow batteries (VFBs) are a promising new technology for stationary energy storage. This blog post provides everything you need to

Enhanced Electrochemical Performance of

Nov 21, 2024 · Enhanced Electrochemical Performance of Vanadium Redox Flow Batteries Using Li 4 Ti 5 O 12 /TiO 2 Nanocomposite-Modified Graphite Felt

Sustainable recycling and regeneration of redox flow battery

Feb 1, 2025 · Understanding the composition of RFB components, such as the vanadium electrolyte (USD$ ca. 20 — 50 per kg for vanadium metal), ion-exchange membranes (USD$

Assessing the role of vanadium technologies in

Nov 11, 2021 · Here, we explore the role of vanadium in decarbonizing construction by serving as a microalloying element and enabling the energy transition as the primary component of flow

Vanadium Redox Flow Batteries: Potentials and Challenges of

Dec 21, 2016 · Vanadium redox flow battery (VRFB) systems complemented with dedicated power electronic interfaces are a promising technology for storing energy in smart-grid a

Vanadium Redox Flow Battery: Review and

Jul 12, 2024 · Vanadium redox flow battery (VRFB) has garnered significant attention due to its potential for facilitating the cost-effective utilization of

A novel flow design to reduce pressure drop and enhance

Feb 1, 2025 · The Vanadium Redox Flow Battery (VRFB) is one of the promising stationary electrochemical storage systems in which flow field geometry is essential to ensure uniform

Flow Batteries Tour

Discover the Flow Batteries Tour to learn about different flow battery projects being undertaken from Flow Batteries Europe members in Europe and beyond.

Vanadium Flow Battery for Energy Storage:

Mar 28, 2013 · The vanadium flow battery (VFB) as one kind of energy storage technique that has enormous impact on the stabilization and smooth output of

H2 Inc. Secures Landmark 8.8MWh Vanadium Flow Battery

September 2, 2024 - H2 Inc. announced today that it has been awarded a project to deploy a 1.1MW/8.8MWh vanadium flow battery (VFB) system in Spain, marking the largest VFB

Vanadium Redox Flow Batteries

Jul 30, 2023 · Flow batteries are durable and have a long lifespan, low operating costs, safe operation, and a low environmental impact in manufacturing and recycling. Key advantages of

Performance enhancement of vanadium redox flow battery

Oct 10, 2024 · This study investigates a novel curvature streamlined design, drawing inspiration from natural forms, aiming to enhance the performance of vanadium redox flow battery cells

Vanadium Redox Flow Battery Using Activated Carbon

Waste low-density polyethylenes (LDPEs) are converted into useful carbon catalysts for vanadium redox flow battery (VRFB) through their stabilization, carbonization and activation. By

Review of material research and development for vanadium redox flow

Jul 1, 2013 · The main battery technologies that are attracting the most attention for medium- to large-scale grid-connect energy storage applications are the sodium–sulfur, lithium ion and

Vanadium redox flow batteries: A technology

Oct 1, 2014 · Flow batteries have unique characteristics that make them especially attractive when compared with conventional batteries, such as their

Vanadium redox flow batteries: a technology

Oct 29, 2014 · The vanadium redox flow batteries (VRFB) seem to have several advantages among the existing types of flow batteries as they use the same

Design and development of large-scale vanadium redox flow batteries

Jan 30, 2024 · Vanadium redox flow battery (VRFB) energy storage systems have the advantages of flexible location, ensured safety, long durability, independent power and capacity

Boosting vanadium flow battery performance by Nitrogen

Aug 10, 2016 · Fabricating cost effective and high-performance electrodes is essential to the development of vanadium flow battery (VFB). Moreover, improving the stability of electrodes in

Electrode materials for vanadium redox flow batteries:

Jan 1, 2022 · Electrospun carbon nanofiber inlaid with tungsten carbide nanoparticle by in-situ carbothermal reaction as bifunctional electrode for vanadium redox flow battery

全钒液流电池的电极结构研究进展

Jul 22, 2024 · 关键词: 全钒液流电池, 电极, 结构设计 Abstract: The vanadium redox flow battery (VRFB) holds significant promise for large-scale energy

Unlocking the potential of vanadium redox flow batteries:

Biomass and lignin-based carbons are low-cost, sustainable alternatives for redox flow battery electrodes. Activation boosts surface area, conductivity, and durability of carbon electrodes for

Principle, Advantages and Challenges of Vanadium Redox Flow Batteries

Nov 26, 2024 · Reproduction of the 2019 General Commissioner for Schematic diagram of a vanadium flow-through batteries storing the energy produced by photovoltaic panels.

Review of vanadium redox flow battery technology

Vanadium redox flow battery (VRFB) has a brilliant future in the field of large energy storage system (EES) due to its characteristics including fast response speed, large energy

6 FAQs about [Valparaiso Vanadium Flow Battery Carbon in Chile]

Are vanadium redox flow batteries a viable energy storage system?

As one of the most promising electrochemical energy storage systems, vanadium redox flow batteries (VRFBs) have received increasing attention owing to their attractive features for large-scale storage applications. However, their high production cost and relatively low energy efficiency still limit their feasibility.

What is a vanadium redox flow battery (VRFB)?

Use the link below to share a full-text version of this article with your friends and colleagues. Learn more. The vanadium redox flow battery (VRFB) is a highly regarded technology for large-scale energy storage due to its outstanding features, such as scalability, efficiency, long lifespan, and site independence.

Will flow battery suppliers compete with metal alloy production to secure vanadium supply?

Traditionally, much of the global vanadium supply has been used to strengthen metal alloys such as steel. Because this vanadium application is still the leading driver for its production, it’s possible that flow battery suppliers will also have to compete with metal alloy production to secure vanadium supply.

How recyclable is Vanadium ion-exchange membrane?

From an economic standpoint, the recyclability of vanadium electrolytes, ion-exchange membranes and carbon felt electrodes substantially lowers the overall lifecycle costs for RFB systems. Vanadium can be reused for decades with minimal degradation, allowing VRFBs to maintain a low cost per cycle.

What is a decision flowchart for the vanadium electrolyte recycling process?

Decision flowchart for the vanadium electrolyte recycling process, illustrating the treatment pathways for addressing oxidation state imbalances, copper contamination, organic contamination and irreversible contamination.

Why are vanadium batteries so expensive?

Vanadium makes up a significantly higher percentage of the overall system cost compared with any single metal in other battery technologies and in addition to large fluctuations in price historically, its supply chain is less developed and can be more constrained than that of materials used in other battery technologies.

Industry Information

- Factory price 3 phase breaker in Chad

- The key to all-vanadium liquid flow batteries

- Light-transmitting photovoltaic glass

- Wholesale breaker with outlet in Poland

- Antimony battery energy storage

- Iraq portable outdoor energy storage power supply

- Does the battery cabinet need to be charged when opening it at a telecom site

- What is the acquisition price of energy storage cabinet batteries

- Samoa s new photovoltaic energy storage system

- Mozambique outdoor communication battery cabinet agent system

- Base station power supply construction process

- The cost of photovoltaic glass greenhouse in Ho Chi Minh Vietnam

- USA New York Energy Storage Power Plant

- Various small batteries for energy storage

- Single high power photovoltaic panel

- Battery costs for distributed energy storage power stations

- Can the Tallinn inverter form three-phase electricity

- Solar power collection and container area

- Household solar light round

- Kenya Mombasa customized lithium battery pack

- Bahrain Solar Photovoltaic Industrial Energy Storage Project

- Tanzania energy storage project brokerage fees

- Does a high-power inverter consume more electricity

Commercial & Industrial Solar Storage Market Growth

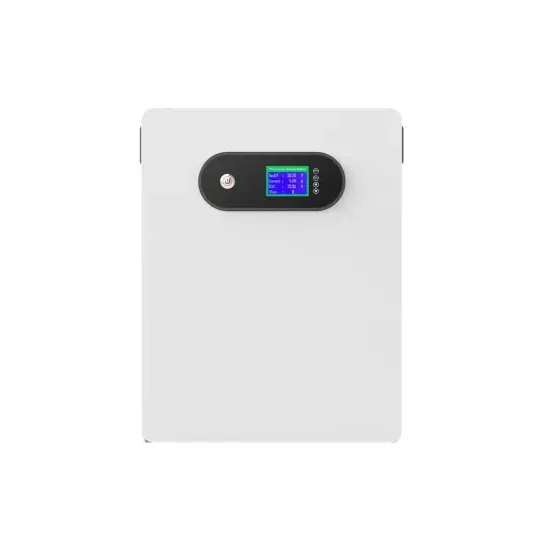

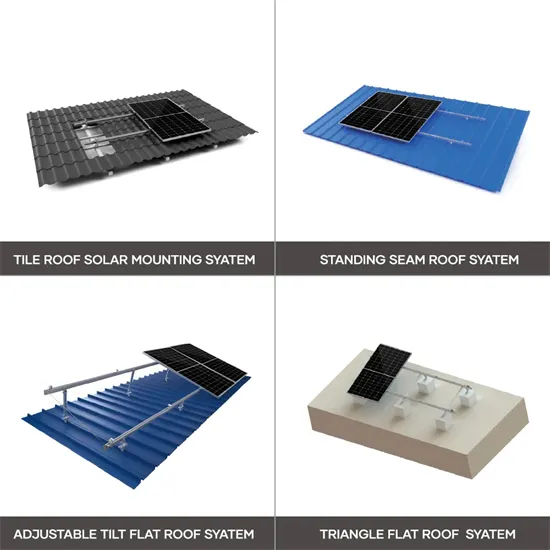

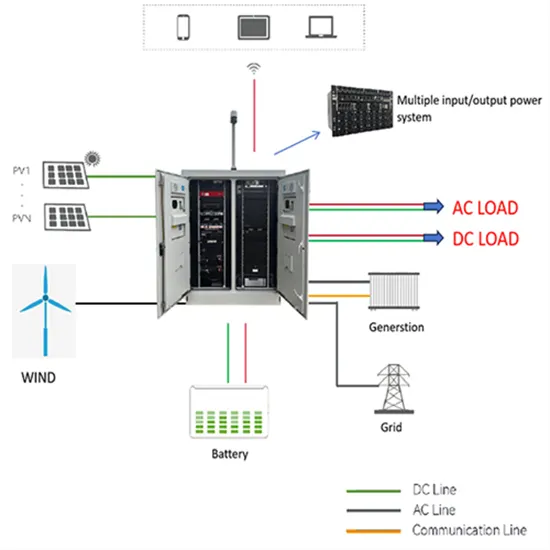

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.