Water cooling based strategy for lithium ion battery pack

Mar 5, 2018 · To investigate the thermal performance of water cooling based battery thermal management system in lithium ion batteries dynamic cycling, the experime

Liquid Immersion Cooling for Battery Packs

Jul 21, 2025 · Direct liquid cooling, also known as immersion cooling, is an advanced thermal management method where battery cells are submerged

Water cooling based strategy for lithium ion battery pack

Mar 5, 2018 · The water cooling system is still the best choice to improve the battery pack thermal performance at low cycling rate, and it may be a better choice to design a compound system

Numerical Study of Combined Heat Pipe and Water Cooling for Battery

Sep 28, 2023 · Battery thermal management is becoming more and more important with the rapid development of new energy vehicles. This paper presents a novel cooling structure for

EV/ESS Water Cooling Plates

Aug 15, 2025 · Trumonytechs water cooling plates, also known as liquid cold plates, are primarily made from high-thermal-conductivity aluminum. They are

Battery Liquid Cooling System Overview

1 day ago · Depending on the cooling needs, the valve directs the coolant back to the battery pack or an auxiliary cooling system. Coolant Circulation: The

Experimental study on 18650 lithium-ion battery-pack cooling

May 1, 2024 · Decreasing the flow rate of spray cooling water and increasing the inlet air speed promote the evaporation of water mist inside the system, thus further improving heat

Comparison of different cooling methods for lithium ion battery

Feb 5, 2016 · Choosing a proper cooling method for a lithium-ion (Li-ion) battery pack for electric drive vehicles (EDVs) and making an optimal cooling control stra

Numerical Simulations for Lithium-Ion Battery

Feb 10, 2023 · Qian et al. [25] proposed an indirect liquid cooling method based on minichannel liquid cooling plate for a prismatic lithium-ion battery pack and

Liquid Immersion Cooling for Battery Packs

Jul 21, 2025 · Liquid Immersion cooled battery Packs, direct cooling, dielectric cooling, Battery Thermal Management, advanced battery pack cooling methods.

Thermal Management of Battery Pack with Water Cooling

Mar 18, 2025 · Battery thermal management systems (BTMS) come in various forms, with air cooling being the conventional approach widely employed. However, our primary focus here is

What Is Battery Liquid Cooling and How Does It

5 days ago · Battery thermal management systems impact vehicle safety and performance. Electric vehicle owners want to be reassured about their cars''

Thermal management for a tube–shell Li-ion battery pack

A novel battery thermal management system (BTMS) based on water evaporation (WE) and air-cooling (AC) for a tube–shell Li-ion battery (LIB) pack is designed. A sodium alginate (SA) film

LIQUID COOLING SOLUTIONS For Battery Energy

Aug 3, 2022 · Active water cooling is the best thermal management method to improve the battery pack performances, allowing lithium-ion batteries to reach higher energy density and uniform

Thermal management for a tube–shell Li-ion

Abstract A novel battery thermal management system (BTMS) based on water evaporation (WE) and air-cooling (AC) for a tube–shell Li-ion battery (LIB)

Electric Vehicle Battery Cooling Methods Are

Mar 15, 2023 · Electric Vehicle Battery Cooling Methods Are Evolving Battery packs generate heat while they charge or discharge, therefore they need to be

Battery Cooling Techniques in Electric Vehicle

Air Cooling Types: Passive and active air cooling. Working: Uses ambient or forced air to dissipate heat. Fans may be employed for active air cooling.

Experimental and Simulative Investigations on a Water

Feb 1, 2022 · The cooling effect of the system on the battery pack was numerically studied. Even if the battery pack is discharged at 3 C rate, a small water flow rate (200 ml/min) can ensure

Power Battery Pack Aluminum Water Cooling Plate

The battery core is transferred to the power battery pack aluminum water cooling plate through the thermal conductive silica gel sheet. The heat is carried way

Experimental and Simulative Investigations on a

Feb 1, 2022 · This study presents an immersion cooling system that uses water as the cooling medium. In this system, a special seal structure was designed

Numerical Study of Combined Heat Pipe and Water Cooling for Battery

Sep 28, 2023 · Battery thermal management is becoming more and more important with the rapid development of new energy vehicles. This paper presents a novel cooling structure

Immersive EV Battery Cooling System

Sep 2, 2024 · What is an immersive battery cooling system? As EV range extension cannot rely solely on increasing the size of batteries, the only

Thermal management of lithium-ion battery pack under

Oct 1, 2023 · A fin-enhanced hybrid cooling system combining phase change material (PCM) and liquid cooling is designed and optimized in this work to ensure the stable operation of lithium

EV Battery Cooling: Key Applications and Impact

5 days ago · Liquid cooling is a more advanced method that circulates a coolant (typically a water-glycol mixture) through channels integrated into or around

Analyzing the Liquid Cooling of a Li-Ion Battery

Oct 17, 2019 · The battery pack geometry, shown below, consists of three stacked repetitive unit cells and two flow connector channels (one on the inlet and one

Thermal Management of Lithium-ion Battery

Mar 19, 2015 · Computational fluid dynamic analyses were carried out to investigate the performance of a liquid cooling system for a battery pack. The

Process cooling systems for EV battery factories:

Aug 19, 2025 · The increasing demand for reliable process cooling systems for battery manufacturing is d irectly linked to the rise of electric vehicles. As EV

A Review of Advanced Cooling Strategies for

Jun 28, 2023 · The present review summarizes numerous research studies that explore advanced cooling strategies for battery thermal management in EVs.

Battery Cooling Methods in Electric Cars_XNmotors

2 days ago · • How it works: A liquid coolant (like water-glycol) circulates through channels or pipes within the battery pack, absorbing heat and transferring it away via a radiator system.

A Battery Thermal Management System

Oct 17, 2024 · The battery thermal management system (BTMS) depending upon immersion fluid has received huge attention. However, rare reports have been

Simulation, Set-Up, and Thermal

Oct 12, 2022 · A constant and homogenous temperature control of Li-ion batteries is essential for a good performance, a safe operation, and a low aging rate.

Thermal Management of Battery Pack with Water Cooling

Mar 18, 2025 · Abstract : Based on the identified problem by our group of the unavailability of affordable commercial usable battery pack for electric vehicles and with the goal of

EV Battery Thermal Management System– Air

Mar 31, 2025 · EV Battery Thermal Management System – Liquid Cooling System for Lithium Ion Battery In our last blog post, we covered Battery Air Cooling

6 FAQs about [Battery pack water cooling]

Does a liquid cooling system work for a battery pack?

Computational fluid dynamic analyses were carried out to investigate the performance of a liquid cooling system for a battery pack. The numerical simulations showed promising results and the design of the battery pack thermal management system was sufficient to ensure that the cells operated within their temperature limits.

Which battery pack is best for a water cooling system?

It can be investigated that the battery pack with active water cooling system performance is the best due to the lowest temperature rise and temperature difference at low cycling rate.

How does a cooling system affect a battery pack?

The cooling effect of the system on the battery pack was numerically studied. Even if the battery pack is discharged at 3 C rate, a small water flow rate (200 ml/min) can ensure that the maximum temperature of the battery pack falls below 50°C. However, a good cooling capacity will increase the temperature difference of the battery pack.

What is a channeled liquid cooling thermal management system of lithium-ion battery pack?

A channeled liquid cooling thermal management system of Lithium-ion battery pack for electric vehicles to study the thermal behaviour, and hence to investigate the effects of discharge rates and the heat exchange area between neighbouring batteries is discussed in .

How to improve battery pack thermal performance at low cycling rate?

Therefore, it can be concluded the water cooling system is still the best choice to improve the battery pack thermal performance at low cycling rate, and it may be a better choice to design a compound system with PCM and water cooling, dealing with the situation of using battery pack in wide range at different rates.

How does a battery cooling system work?

As the battery is in direct contact with the cooling water, the heat transfer effect is greatly improved and the cooling performance of the system is enhanced. Even if the battery pack was discharged at 3 C rate, a small cooling flow rate of 200 ml/min can keep the battery temperature below 50°C.

Industry Information

- Energy Storage Power Portable Factory Ranking

- Solar cells directly connected to inverter

- 10-degree battery with inverter

- High quality solar power unit in Austria

- Large capacity off-grid photovoltaic inverter

- Rescue Communication Base Station Energy Management System

- Inverter full power and peak power

- Avaru new energy storage installation

- Can the 12v220a inverter be used

- Smart e-net 5g micro base station promotion

- New energy storage cabinet system transfer

- Retail home energy storage battery pack

- Manufacturing low voltage micro inverter companies

- Spanish BESS portable camping power supply

- Wholesale 2000 amp switchgear in Switzerland

- Portable mobile power bank battery replacement

- Estimating the capacity of lithium battery pack

- 5kw wind grid-connected inverter

- How to open the energy storage cabinet battery box ESS power base station

- Beirut PV combiner box price

- Royu circuit breaker for sale

- Seychelles battery energy storage equipment

- Latest factory price of photovoltaic glass

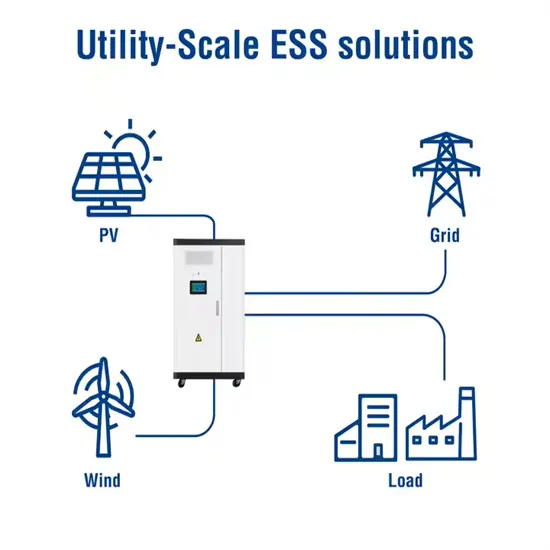

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.