A statistical distribution-based pack-integrated model

Jan 1, 2024 · The estimation of lithium battery pack is always an essential but troubling issue which has difficulty on considering the inconsistency during state estimation. Herein, an

A Review of Lithium-Ion Battery Capacity Estimation

Nov 9, 2022 · In this work, the mechanisms of Li-ion batteries capacity degradation are analyzed first, and then the recent processes for capacity estimation in BMSs are reviewed, including

LiFePO4 battery pack capacity estimation for electric vehicles based

Mar 15, 2013 · A small battery pack with four LiFePO 4 cells in series is employed to verify the method and the result shows that the estimation errors of both pack capacity and cell

State‐of‐health estimation of lithium‐ion batteries: A

Aug 14, 2024 · This paper provides a comprehensive literature review of lithium-ion battery SOH estimation methods at the cell, module, and pack levels. Analysis and summary of the SOH

Data-driven available capacity estimation of lithium-ion batteries

Feb 25, 2025 · Efficient and accurate available capacity estimation of lithium-ion batteries is crucial for ensuring the safe and effective operation of electric vehicles. However, incomplete

Battery pack capacity estimation for electric vehicles

5 days ago · Battery pack capacity estimation for electric vehicles based on enhanced machine learning and field data Qingguang Qi a, Wenxue Liu a,⇑, Zhongwei Deng b, Jinwen Li a, Ziyou

How to Calculate Lithium-Ion Battery Pack

Aug 8, 2024 · To calculate the capacity of a lithium-ion battery pack, follow these steps: Determine the Capacity of Individual Cells: Each 18650 cell has a

Capacity Estimation of Serial Lithium-ion Battery Pack Using

Nov 27, 2019 · A 16 serial LiFePO 4 battery pack is employed to verify the method. The result shows the estimation error of cell capacities is less than 3% rated capacity. With this method,

The process of cell capacity estimation in a

Download scientific diagram | The process of cell capacity estimation in a battery pack from publication: Capacity Estimation of Serial Lithium-ion Battery Pack

Capacity estimation of lithium-ion battery through

Feb 15, 2025 · Lithium-ion batteries inevitably undergo degradation over extended use, making precise capacity estimation essential for reliable state monitoring and

The capacity estimation of Li–Ion battery using ML-based

Jul 19, 2024 · Accurate estimation of State of Charge (SoC) and battery capacity estimation is critical for optimizing the performance and reliability of lithium–ion batteries in electric vehicles

EV design – battery calculation – x-engineer

Individual battery cells are grouped together into a single mechanical and electrical unit called a battery module. The modules are electrically connected

Capacity evaluation and degradation analysis of lithium-ion battery

Aug 15, 2023 · Accurately calculating the capacity of battery packs is of great significance to battery fault diagnosis, health evaluation, residual value assessment

Aging mechanism analysis and capacity estimation of lithium

Nov 15, 2023 · The method proposed in this paper is not only able to quantitatively analyze the dominant factors of battery capacity decay, but also achieves high accuracy capacity

How Load Current Affects a Lithium-Ion Battery''s

Jan 18, 2022 · How Load Current Affects a Lithium-Ion Battery''s Capacity and Runtime Capacity, the total amount of electricity generated through a battery''s

Method for estimating capacity and predicting remaining

Jun 25, 2014 · To ensure Li-ion batteries in these devices operate reliably, it is important to be able to assess the capacity of Li-ion battery and predict the remaining useful life (RUL)

A novel state of health estimation method for lithium-ion battery pack

Jan 1, 2025 · Feng et al. [16] designed a multi-time scale equalisation strategy based on SOC and capacity for lithium-ion battery pack with passive equalizer, which realized the battery pack

State‐of‐health estimation of lithium‐ion

Aug 14, 2024 · This paper provides a comprehensive literature review of lithium-ion battery SOH estimation methods at the cell, module, and pack levels.

Estimating the Power Limit of a Lithium Battery Pack by Considering

Apr 14, 2015 · Power limit estimation of a lithium-ion battery pack can be employed by a battery management system (BMS) to balance a variety of operational considerations, including

A Novel CNN-Transformer Capacity Estimation Model for

Dec 24, 2024 · Many studies have focused on estimating the capacity of single LIB cells or experimental datasets, but applying LIB packs in real-world situations requires customized

Battery pack capacity estimation for electric vehicles

5 days ago · To fill the gap, this study introduces a novel data-driven battery pack capac-ity estimation method grounded in field data. The proposed approach begins by determining

Capacity estimation of retired lithium-ion batteries using

Feb 19, 2025 · The repurposing of retired lithium-ion batteries from electric vehicles is a critical strategy for reducing carbon emissions. Capacity estimation play

Capacity estimation of lithium-ion battery through

Feb 15, 2025 · For instance, Zhang et al. combined temporal convolutional networks with Gaussian process regression (GPR) to establish a probabilistic capacity estimation method,

Lithium Battery SOC (State of Charge) Chart: A

Jul 18, 2025 · SOC (State of Charge) is a core parameter in lithium battery management, directly impacting battery performance and lifespan. This article

Fast Remaining Capacity Estimation for

Mar 26, 2022 · It remains challenging to effectively estimate the remaining capacity of the secondary lithium-ion batteries that have been widely adopted

Battery pack capacity estimation for electric vehicles based

May 1, 2024 · Accurate capacity estimation is of great importance for the reliable state monitoring, timely maintenance, and second-life utilization of lithium-ion batteries. Despite numerous

A LiFePO4 battery pack capacity estimation approach considering in

Mar 15, 2015 · A battery pack capacity estimation method is proposed according to the SOC and the capacity of the "normal battery module". Experimental results show that battery pack

Battery Pack Calculator | Good Calculators

Battery Pack Calculator Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and

A Novel CNN-Transformer Capacity Estimation Model for

Dec 24, 2024 · Finally, the proposed methods are validated using real-world EV dataset, demonstrating practical effectiveness in LIB pack capacity estimation. In conclusion, this

A capacity fade reliability model for lithium-ion battery

Oct 30, 2024 · Degradation characteristics of lithium-ion battery pack system (LIBPs) cannot be well described directly by the existing life model of cell, such as the interference imposed by

Estimation of lithium-ion battery health state using

Aug 8, 2024 · Accurately predicting the state of health (SOH) of lithium-ion batteries is fundamental in estimating their remaining lifespan. Various parameters such as voltage,

How to Measure and Calculate Lithium ion

Mar 13, 2025 · Here are two common formulas to help you calculate capacity quickly: 1. Based on Current and Time: Formula: `Capacity (Ah) = Current (A)

A Rapid Capacity-estimation Method of Lithium-ion Battery

Nov 26, 2021 · Aiming at the problems of low efficiency,high energy consumption,and offline application of traditional methods for determining the capacity of lithium-ion battery (LIB)

6 FAQs about [Estimating the capacity of lithium battery pack]

How do I calculate the capacity of a lithium-ion battery pack?

To calculate the capacity of a lithium-ion battery pack, follow these steps: Determine the Capacity of Individual Cells: Each 18650 cell has a specific capacity, usually between 2,500mAh (2.5Ah) and 3,500mAh (3.5Ah). Identify the Parallel Configuration: Count the number of cells connected in parallel.

How accurate is EV battery pack capacity estimation based on field data?

This work shows great potential for accurate large-sized EV battery pack capacity estimation based on field data, which provides significant insights into reliable labeled capacity calculation, effective features extraction, and machine learning-enabled health diagnosis.

How is battery capacity estimated?

Firstly, feature extraction is performed from raw data, typically including voltage, current, and temperature. Subsequently, various machine learning methods are employed to establish the relationship between HIs and capacity, thereby realizing battery capacity estimation.

What is a lithium-ion battery pack?

Lithium-ion batteries, particularly the 18650 battery pack design, have become the industry standard for many applications due to their high energy density and long lifespan. Understanding how to calculate a lithium-ion battery pack's capacity and runtime is essential for ensuring optimal performance and efficiency in devices and systems.

How do you calculate battery capacity?

Battery capacity is measured in ampere-hours (Ah) and indicates how much charge a battery can hold. To calculate the capacity of a lithium-ion battery pack, follow these steps: Determine the Capacity of Individual Cells: Each 18650 cell has a specific capacity, usually between 2,500mAh (2.5Ah) and 3,500mAh (3.5Ah).

Can fragmented charge data be used to estimate lithium-ion battery capacity?

This work highlights the promise of available capacity estimation using actual, readily accessible fragmented charge capacity data. Zhen Zhang and colleagues use machine learning to extract lithium-ion battery available capacity from fragmented charge data.

Industry Information

- Best 3000w solar inverter for sale producer

- Costa Rica 12W Solar Street Light

- Photovoltaic roofs in Sao Tome and Principe

- 72 volt solar panel 300 watts

- Democratic Congo greenhouse photovoltaic panel manufacturer

- Barbados outdoor power supply manufacturer

- Panama Colon energy storage low temperature lithium battery

- Equipment Capacitor Energy Storage

- Measurement of photovoltaic panel angle dimensions

- Build an energy storage pack battery factory

- Athens Compressed Air Energy Storage Power Generation

- 146 MW of solar energy

- Lead-acid battery box with inverter

- Who invested in the El Salvador energy storage project

- Burundi double glass photovoltaic curtain wall design unit

- Electricity work of Moldova communication base station

- Kathmandu outdoor power supply customization

- Assembly energy storage battery manufacturers

- Repair cylindrical lithium battery

- Somaliland Power Station Generator Manufacturer

- There are 5G base stations in the Middle East

- Solar 1 kW assembly machine price

- Solar Powered Off-Grid System

Commercial & Industrial Solar Storage Market Growth

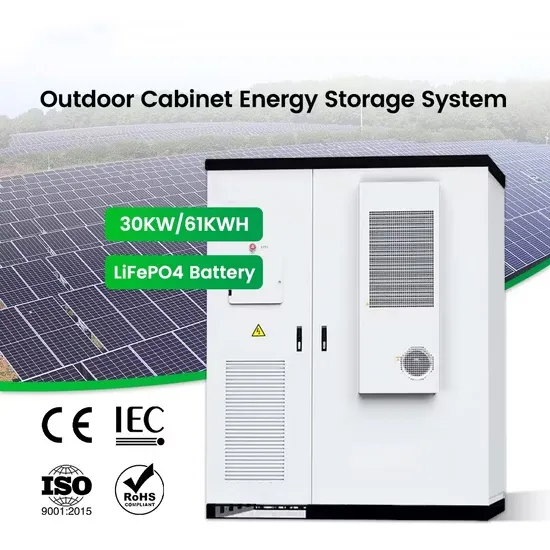

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.