Thermal and efficiency improvements of all vanadium redox flow battery

Apr 1, 2020 · To achieve a stronger energy density, a higher vanadium concentration of electrolyte for all-vanadium redox flow battery is needed. However, the risk of thermal

Dynamic electro-thermal modeling of all-vanadium

Jan 13, 2024 · Both the electrolyte temperature and terminal voltage can be accurately predicted. The flow rate of electrolyte and coolant significantly impact battery performance. article info.

Hybrid Cooling-Based Thermal Management of Containerised Vanadium Flow

May 8, 2023 · This paper explores and analyses the stack, tank, and container temperature dynamics of 6 h and 8 h containerised vanadium flow batteries (VFBs) during periods of higher

Vanadium Battery Electrolytic Liquid Cooling System

Vanadium Battery Electrolytic Liquid Cooling System As a new type of energy storage technology, the stability and efficiency of vanadium flow batteries largely depend on their cooling system.

Performance analysis of vanadium redox flow battery with

Jan 1, 2024 · It is very important to explore the thermal behavior and performance of batteries. This study establishes a three-dimensional model of a vanadium redox flow battery with an

Vanadium redox flow battery: Characteristics

Apr 30, 2024 · As a new type of green battery, Vanadium Redox Flow Battery (VRFB) has the advantages of flexible scale, good charge and discharge

Development of a Cooling System for Vanadium Redox Flow Batteries

Apr 10, 2025 · This study focuses on designing and optimizing a plate heat exchanger for a vanadium redox flow battery''s cooling and thermal stabilization system. Thermal and hydraulic

Vanadium Redox Flow Batteries: Electrochemical

Nov 26, 2019 · The vanadium redox flow battery is one of the most promising secondary batteries as a large-capacity energy storage device for storing renewable energy [1, 2, 4]. Recently, a

Hybrid Cooling-Based Thermal Management of Containerised Vanadium Flow

In this study, the effects of different battery operation time and load profiles on the temperature dynamics of a containerised vanadium flow battery system are modelled and simulated for a

Fact Sheet: Vanadium Redox Flow Batteries (October 2012)

Dec 6, 2012 · Unlike other RFBs, vanadium redox flow batteries (VRBs) use only one element (vanadium) in both tanks, exploiting vanadium''s ability to exist in several states. By using one

Structured Analysis of Thermo-Hydrodynamic Aspects in

Dec 31, 2024 · The paper presents a dynamic electro-thermal model for vanadium redox flow batteries that integrates forced cooling strategies. The authors develop a model combining a

VFlowTech

May 14, 2025 · VFlowTech is a Singapore based company that aims to produce the world''s best Vanadium Redox Flow Batteries to the power the sustainable

Hybrid Cooling-Based Thermal Mana... preview & related

In this study, the effects of different battery operation time and load profiles on the temperature dynamics of a containerised vanadium flow battery system are modelled and simulated for a

Prospects for industrial vanadium flow batteries

Jul 15, 2023 · Vanadium Flow Batteries (VFBs) are a stationary energy storage technology, that can play a pivotal role in the integration of renewable sources into t

FAQ | Vanadium Redox Flow Battery | Sumitomo Electric

Aug 13, 2025 · Frequently Asked Questions How is the Vanadium Redox Flow Battery system configured? The basic components include a cell stack (layered liquid redox cells), an

Technology Overview | Vanadium Redox Flow

4 days ago · Explore the fundamental principles and innovative technology behind our Vanadium Redox Flow Battery systems. Learn how our VRFB technology

Thermal dynamics assessment of vanadium redox flow batteries

Jun 30, 2023 · Abstract Understanding the thermal dynamics of vanadium redox flow batteries (VRFB) is critical in preventing the thermal precipitation of vanadium species that result in

Hybrid Cooling-Based Thermal Management of

May 8, 2023 · In this study, the effects of different battery operation time and load profiles on the temperature dynamics of a containerised vanadium flow battery system are modelled and

Battery and energy management system for vanadium redox flow battery

Feb 1, 2023 · As one of the most promising large-scale energy storage technologies, vanadium redox flow battery (VRFB) has been installed globally and integrated wi

VANADIUM REDOX FLOW BATTERY

Dec 16, 2014 · Vanadium redox flow batteries have come into the spotlight recently as a means of replacing rechargeable batteries in electric vehicles and has previously be used mainly to

Thermal modeling and temperature control of an all-vanadium redox flow

Jun 12, 2019 · Previous studies have demonstrated that the electrolyte temperature of an all-vanadium redox flow battery (VRB) has a significant influence on the safety and efficiency of

Vanadium Redox Flow Batteries

Jul 30, 2023 · Introduction Vanadium redox flow battery (VRFB) technology is a leading energy storage option. Although lithium-ion (Li-ion) still leads the industry in deployed capacity,

Vanadium redox flow battery: Characteristics and

Apr 30, 2024 · As a new type of green battery, Vanadium Redox Flow Battery (VRFB) has the advantages of flexible scale, good charge and discharge performance and long life.

Stereolithography 3D printing for vanadium redox flow battery

Jan 1, 2025 · Stereolithography (SLA) is a promising method for creating parts for vanadium redox flow batteries (VRFB), as SLA produces watertight and isotropic parts, unlike those made by

Advanced Electrolyte Formula for Robust

Jan 24, 2024 · Typically, cooling systems are employed to maintain the working temperature of the vanadium electrolyte in a safe range, preventing the V 2 O

Optimization of temperature in the Redox Flow Battery stack

Aug 1, 2025 · Excessive temperature causes vanadium salt precipitation, reducing battery performance and degrading the electrolyte. The authors introduced dedicated cooling

Thermal issues of vanadium redox flow batteries

Apr 1, 2023 · Vanadium redox flow batteries (VRFBs) are one of the most promising technologies for renewable energy storage. However, complex thermal issues caused by excessive heat

Sustainability and safety of flow batteries

A sustainable way to store energy: Flow batteries are mainly produced with low-cost materials and without ''conflict'' materials such as cobalt. Vanadium, the

Dynamic electro-thermal modeling of all-vanadium redox flow battery

Dec 15, 2014 · The present study focuses on the dynamic electro-thermal modeling for the all-vanadium redox flow battery (VRB) with forced cooling strategies. The Foster network is

Development of a Cooling System for Vanadium Redox Flow Batteries

Apr 10, 2025 · This study focuses on designing and optimizing a plate heat exchanger for a vanadium redox flow battery''s cooling and thermal stabilization system. Thermal and

100MW/600MWh Vanadium Flow Battery Energy Storage

Jan 16, 2025 · It includes the construction of a 100MW/600MWh vanadium flow battery energy storage system, a 200MW/400MWh lithium iron phosphate battery energy storage system, a

6 FAQs about [Vanadium flow battery cooling]

What are the thermal issues of vanadium redox flow batteries?

Schematic (a) and thermal issues (b) of vanadium redox flow batteries. The thermal issues of VRFBs include heat generation and heat transfer, temperature effects, thermal models, and thermal management (Fig. 1(b)).

Are vanadium redox flow battery electrolytes stable at high temperatures?

Insufficient thermal stability of vanadium redox flow battery (VRFB) electrolytes at elevated temperatures (>40 °C) remains a challenge in the development and commercialization of this technology, which otherwise presents a broad range of technological advantages for the long-term storage of intermittent renewable energy.

Can vanadium redox flow batteries eliminate cross-contamination?

Particularly, the vanadium redox flow batteries (VRFBs), as shown in Fig. 1(a), which use vanadium ions with different valence states as the anolyte and catholyte, can eliminate the cross-contamination , , , , , , .

What is a cooling system in a vanadium electrolyte?

Typically, cooling systems are employed to maintain the working temperature of the vanadium electrolyte in a safe range, preventing the V 2 O 5 precipitation.

What is vanadium redox flow battery (VRFB)?

Among the different mainstream ESSs, vanadium redox flow battery (VRFB) is one of the most reliable technologies among the flow battery family.

Why do vanadium electrolytes keep stable over a wider temperature range?

Temperature stability of vanadium electrolytes. Compared with static conditions, the flowing electrolyte in operation can keep stable over a wider temperature range, because the concentration of vanadium ions is dynamically changed.

Industry Information

- Best lifepo4 power station factory Factory

- Is the energy storage sector the same as the wind solar and energy storage sector

- AC Purification Uninterruptible Power Supply

- Micro photovoltaic power generation and energy storage

- How many kilowatts of power should be selected for outdoor power supply

- Suriname energy storage battery brand ranking

- China high tension switchgear in Vietnam

- 12v5w solar water pump

- China on grid hybrid inverter in Canada

- High frequency ultra-high voltage inverter square wave

- Banjul rooftop photovoltaic panel light room

- 320kw inverter maximum input current

- Portugal solar power generation and energy storage manufacturers

- 220v450w portable power bank

- Atess hybrid inverter factory in Laos

- Romanian outdoor power supply lithium iron phosphate

- 24v portable ups uninterruptible power supply

- How to calculate the current from the battery cabinet voltage

- Which inverter manufacturer is the best for sale

- Tajikistan grid-connected to off-grid inverter

- Managua Photovoltaic Curtain Wall Project

- Battery energy storage system share of Croatian communication base stations

- Omega solar inverter in China in Mongolia

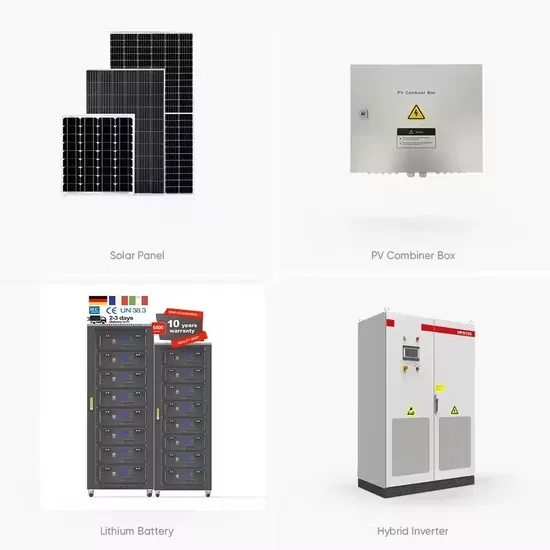

Commercial & Industrial Solar Storage Market Growth

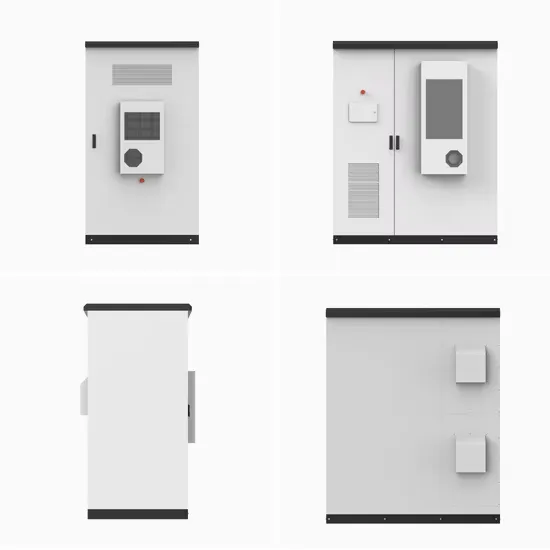

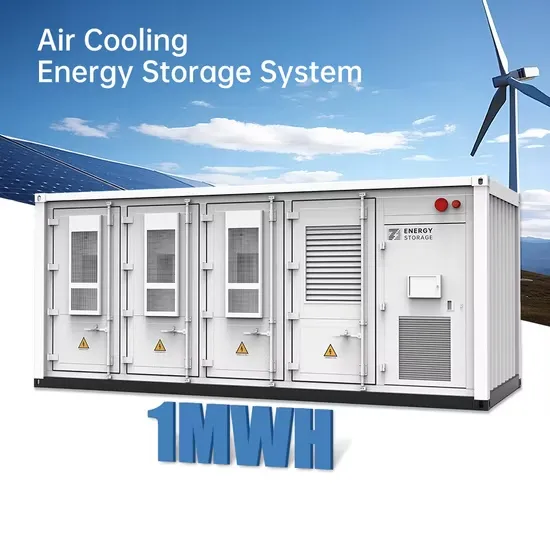

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

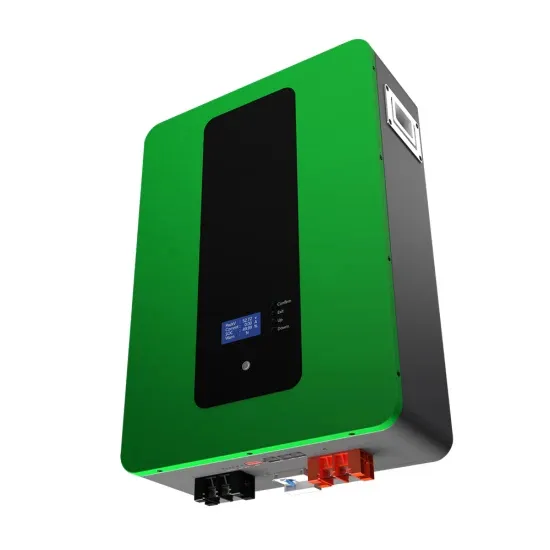

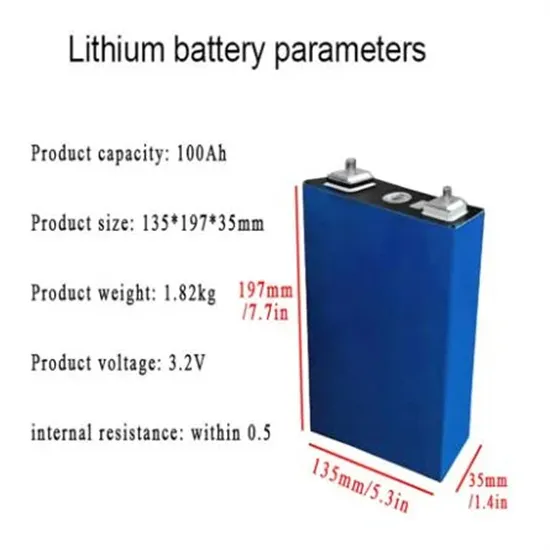

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.