Square lithium ion power battery structure

The utility model relates to a square lithium ion power battery structure, belonging to the technical field of power batteries. The square lithium ion power battery structure comprises a shell (1), a

Structural characteristics of 18650 cylindrical, square, and

Structural characteristics of 18650 cylindrical, square, and soft pack lithium batteries. With the further expansion of the electric vehicle market and the increasing demand for range, vehicle

How Do Lithium Ion Batteries Work?

How do lithium ion batteries work? This article will take you understand the internal structure of the battery, and working principle, etc.

Prediction of the internal structure of a lithium-ion battery

Nov 30, 2023 · This paper describes a means to predict the internal structure of a lithium-ion battery from the response of an ultrasonic pulse, using a genetic algorithm. Lithium-ion

Comparison of Structure and Technical

There are currently two main packaging methods for lithium-ion batteries: square packaging and soft packaging. Different packaging structures imply different

Cylindrical vs. Prismatic vs. Li-Po Battery: Key

Feb 29, 2024 · Curious about battery types? Learn how cylindrical, prismatic, and lithium polymer batteries stack up against each other. Make the best choice!

What''s Inside a Lithium-Ion Battery? A Detailed Overview

May 16, 2023 · Lithium-ion batteries are essential components in modern technology, powering everything from smartphones to electric vehicles. Understanding their internal structure is

Breaking Down the Components of a Lithium-Ion Battery

May 8, 2025 · Lithium-ion batteries power modern technologies by combining advanced components to ensure efficient energy storage and delivery. Inside a lithium battery, the

Square battery cell module structure and

The square battery module is generally composed of battery core, end plate, side plate, bottom plate, aluminum sheet (usually called Busbar), wiring harness

A review on structure model and energy system design of lithium

Sep 1, 2014 · Abstract Structure properties of lithium-ion battery determine the specific energy and specific power of renewable energy vehicle and have attracted extensive concerns.

Battery structure

3 days ago · Lithium battery structure consists of positive electrode, negative electrode, separator, electrolyte, etc. The positive electrode is usually made of lithium metal oxide, while the

A Visual Guide to Li-ion Battery Structure

Learn about the inner workings of a Li-ion battery with a detailed diagram. Understand how it stores and releases energy for various devices.

What''s Inside A Lithium-Ion Battery? | Lithium

May 21, 2021 · Inside a lithium-ion battery, you''ll find lithium-ion cells which have electrodes & electrolyte inside them. Learn more about what''s inside.

Square lithium ion power battery structure

The square lithium ion power battery structure comprises a shell (1), a battery cover (4) arranged at an opening part of the upper end of the shell, and an electric core (2) contained in an inner

Structure of Lithium-ion Batteries & How They

Jan 11, 2025 · Learn the working module, structure, and key components of lithium-ion batteries for efficient energy storage and performance insights.

What are the advantages and disadvantages of square lithium-ion batteries?

Aug 4, 2025 · Advantages: The packaging reliability of square lithium-ion batteries is high; High system energy efficiency; Relatively lightweight and high energy density; The structure is

Internal structure of a lithium-ion battery.

Aug 11, 2025 · Download scientific diagram | Internal structure of a lithium-ion battery. from publication: The lithium-ion battery modeling challenge: A

Analysis of manufacturing processes of lithium batteries with

May 12, 2025 · In the future, the development of lithium battery packaging shape technology will focus on improving energy density, enhancing safety, reducing costs, and adapting to diverse

Battery basic structure | Download Scientific

Download scientific diagram | Battery basic structure from publication: Simplified Heat Generation Model for Lithium ion battery used in Electric Vehicle | It is

What are the structure and advantages and disadvantages of square

What are the advantages and disadvantages of square lithium batteries Advantages: Reliability of square lithium battery packaging is high; system energy efficiency is high; relative light weight,

The Construction and Working of a Lithium Ion Battery: A

Jun 19, 2025 · The Construction and Working of a Lithium Ion Battery: A Detailed Guide Are you curious about the small but powerful device that powers your smartphones, laptops and

Prismatic Cells: structure, advantages and disadvantages

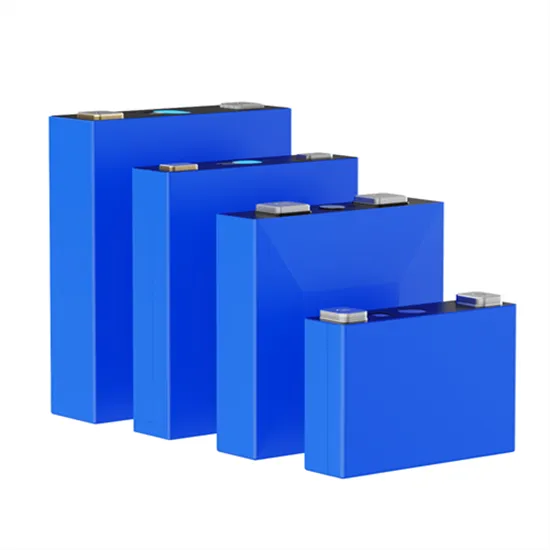

Apr 18, 2025 · There are three primary forms of mainstream lithium battery packages: cylindrical, prismatic, and pouch. Square lithium battery usually refers to aluminum or steel case square

THE ANATOMY & MECHANICS OF A LITHIUM

Dec 5, 2022 · A lithium-ion battery is comprised of six core battery components: anode, cathode, electrolyte, separator, current collectors, and the casing. In

A 3D distributed circuit-electrochemical model for the inner

Feb 1, 2023 · In this paper, starting from the simplest battery structure, the single-layer battery, we extend the form of coupling circuit network topology and electrochemical mechanism model to

3 Different Shapes Lithium Battery Structures

Nov 11, 2019 · Different lithium battery structure means different characteristics, and each has its own advantages and disadvantages.

Structural batteries: Advances, challenges and perspectives

Jan 1, 2023 · The development of light-weight batteries has a great potential value for mobile applications, including electric vehicles and electric aircraft. Along with increasing energy

Development of battery structure and recent structure of lithium

Jun 26, 2022 · This article has sorted out the development process of batteries with different structures, restored the history of battery development in chronological order, and mainly

What is inside a Lithium-Ion Battery?

Apr 30, 2025 · In this guide, we''ll break down the inner workings of a lithium-ion battery, exploring the key components, and how they function to power our

Prediction of the internal structure of a lithium-ion battery

Nov 30, 2023 · Abstract This paper describes a means to predict the internal structure of a lithium-ion battery from the response of an ultrasonic pulse, using a genetic algorithm. Lithium-ion

Electrochemical and thermal analysis of square lithium-ion battery

Feb 28, 2025 · However, there are still many challenges to be overcome. Lithium-ion batteries'' electrochemical and thermal properties significantly impact their safety, reliability, and energy

Lithium battery structure_yyw_articles_Shenzhen YYW Tech.

Lithium batteries usually have two shapes: cylindrical and square. The inner part of the battery adopts a spiral wound structure, which is made of a very fine and highly permeable

Inside a Lithium Battery: Components and

May 13, 2025 · To understand what''s inside a lithium ion battery, we need to explore its internal structure, from the cathode to the separator. A lithium-ion

Understanding the Structure of Square Lithium Batteries

Aug 24, 2024 · Square (or prismatic) lithium batteries are widely used in energy storage systems and electric vehicles due to their compact design and high energy density. Unlike cylindrical

Lithium-ion Battery: Structure, Working Principle

Mar 21, 2022 · Hello everyone, I am Rose. Welcome to the new post today. Lithium battery is a kind of battery with lithium metal or lithium alloy as

Structure, Pros and Cons of Square Lithium

Nov 14, 2024 · Square lithium batteries, also known as prismatic batteries, feature a rectangular shape that allows for efficient space utilization in various

THE ANATOMY & MECHANICS OF A LITHIUM

Dec 5, 2022 · Battery components play a pivotal role as lithium-ion batteries silently integrate into our daily routines, energizing devices ranging from

Simple battery structure

Aug 16, 2025 · Learn about battery structure at Panasonic Energy Co., Ltd.''s Battery Education Academy. Science fun for kids.

Understanding the Inner Workings of Battery: A

Any modifications or additions can be made with precision, minimizing the risk of damaging the battery or causing other electrical issues. Overall, battery

6 FAQs about [Structure of the inner part of a square lithium battery]

What is the structure of lithium battery?

Lithium battery structure consists of positive electrode, negative electrode, separator, electrolyte, etc. The positive electrode is usually made of lithium metal oxide, while the negative electrode is made of graphite. The electrolyte is usually a lithium salt dissolved in an organic solvent.

What is a battery structure?

The battery structure refers to the arrangement and installation of the internal components of the battery.Different needs and applications require corresponding adjustments to the battery structure to meet actual needs. For example, positive electrode materials differ between ternary lithium batteries and lithium iron phosphate batteries.

What is a lithium battery made of?

The container is made of hard rubber or plastic and contains an electrolyte, usually sulfuric acid. Lithium battery structure consists of positive electrode, negative electrode, separator, electrolyte, etc. The positive electrode is usually made of lithium metal oxide, while the negative electrode is made of graphite.

What are the components of a lithium ion battery?

A lithium-ion battery is comprised of six core battery components: anode, cathode, electrolyte, separator, current collectors, and the casing. In addition to these parts, there may be additional elements such as adhesives, insulation, and protective coatings, all depending on the design and application of the battery.

What are the components of a cylindrical battery?

A typical cylindrical battery structure mainly includes a casing, a cap, a positive electrode, a negative electrode, a separator, an electrolyte, a PTC element, a gasket, and a safety valve.

What is a lithium ion battery casing?

The lithium-ion battery casing, often referred to as the battery enclosure or housing, is the protective outer structure that holds the internal components of a lithium-ion battery. Its primary purpose is to ensure the safety of the battery and its surroundings by containing and insulating the potentially volatile materials within.

Industry Information

- South African power frequency inverter manufacturer

- Buenos Aires container energy storage company ranking

- Photovoltaic power station inverter selection

- Solar Panel Tile Hook

- Dakar photovoltaic glass panel prices

- Southeast Asia substation UPS uninterruptible power supply

- Price per kilowatt-hour of battery cabinet

- Niue home photovoltaic inverter

- Jamaica Base Station Energy Storage System Price

- Whole house solar greenhouse system

- Ee33 high frequency inverter production

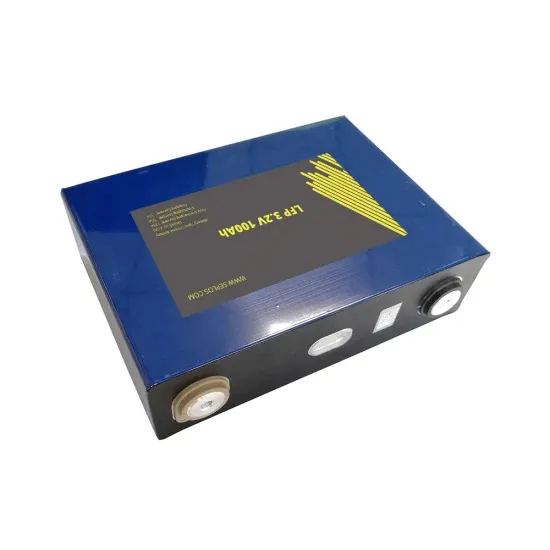

- Penang Malaysia one piece of energy storage battery

- On-site energy solar power supply solution design

- Bangji Energy Storage Equipment Box Customization Company

- Micro circuit breaker factory in Durban

- Ankara three-phase inverter

- Photovoltaic solar panels removed from Monterrey Mexico

- Cost of energy storage

- Is photovoltaic panel power generation practical

- Manufacturers of polycrystalline silicon photovoltaic cell modules

- Berne Power UPS Uninterruptible Power Supply System

- Low voltage energy storage device

- Avaru small UPS uninterruptible power supply manufacturer

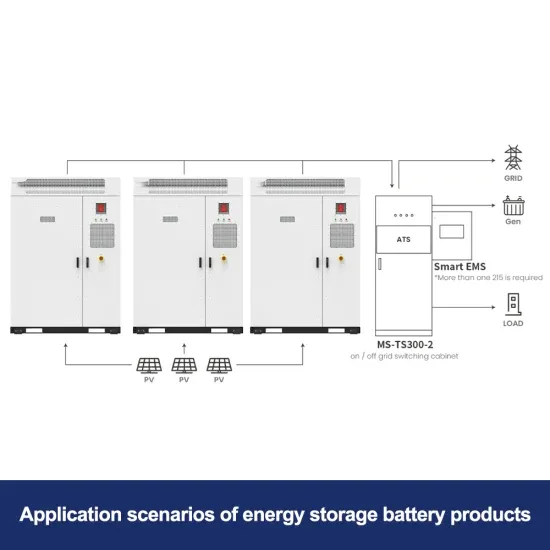

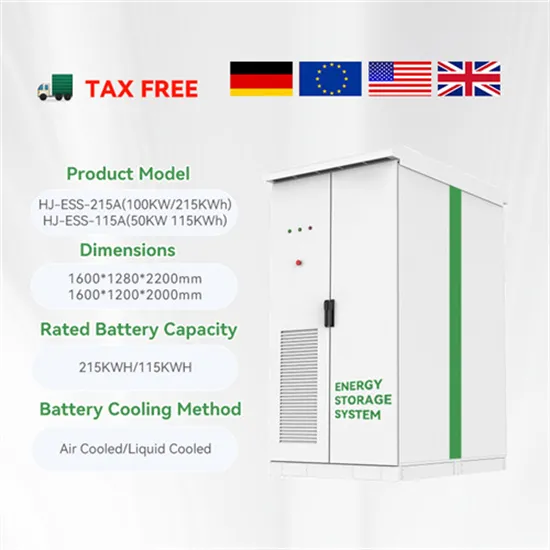

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.